Thermoformed Plastic Trays

Plastic trays | Workpiece carriers | Transport pallets | Load carriers | Reusable and disposable trays | Tray packaging | Blister packaging

What are plastic trays?

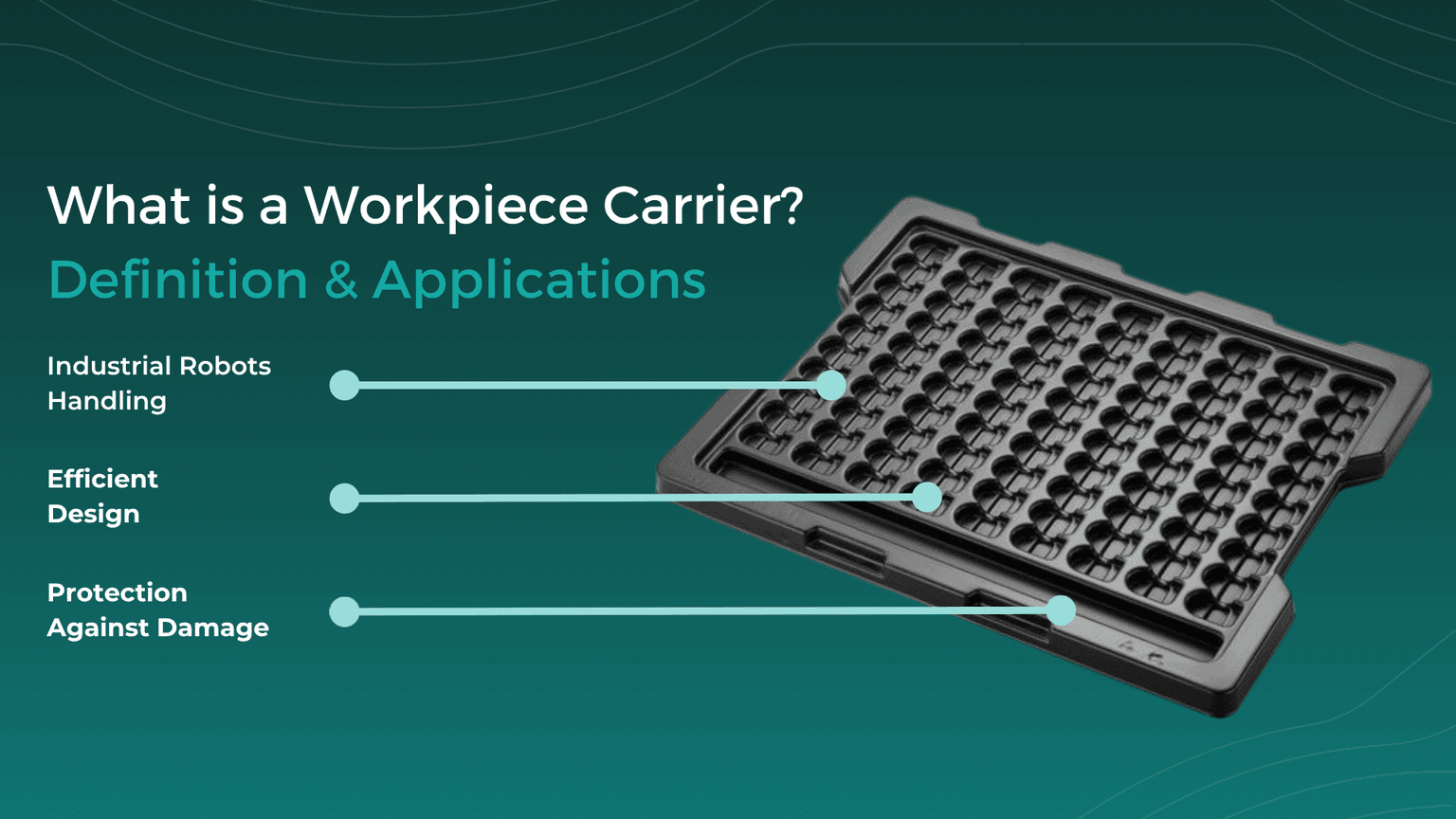

Plastic trays are thermoformed packaging solutions that secure products in molded cavities. They reliably protect components from contamination, damage, and electrostatic charge while enabling organized stacking and storage. In short, plastic trays are the ideal solution for safe transport and efficient storage of components in industrial and logistics applications.

Plastic Trays for Intralogistics

In intralogistics, plastic trays secure internal material flow. They reliably transport components, assemblies, or finished products from one station to the next, tailored to conveyor systems and processes.

- Transport of components between production steps

- Precisely fitting cavities for workpiece carrier transport systems

- Finger grip recesses for ergonomic loading and unloading

- Stackable for safe and space-saving storage

- Compatible with KLT containers and Euro containers

→ Learn more in our blog: Optimizing intralogistics with plastic trays

Advantages of Plastic Trays

Protection

from damage and scratches to your components during transportation and shipping with the help of plastic trays

Optimized Logistics

thanks to efficient packing, stacking, transporting, storing and shipping of plastic trays

Reusable Returnable Packaging

to establish an industrial cycle to your customers and suppliers with the plastic trays

Efficient Design

tailored to your processes and products, light weight of plastic

Customized or Small Load Carrier Standards

the outer dimensions of the individual plastic tray are adapted to your transport packaging

Reduce Transport and Storage Volumes

no empty spaces to store and transport thanks to stacking techniques with plastic trays

Different Component Variants

produce, store and transport with universal nests in a workpiece carrier

Plastics Characteristics

use plastic trays for your transport by selecting the material, ESD trays as well

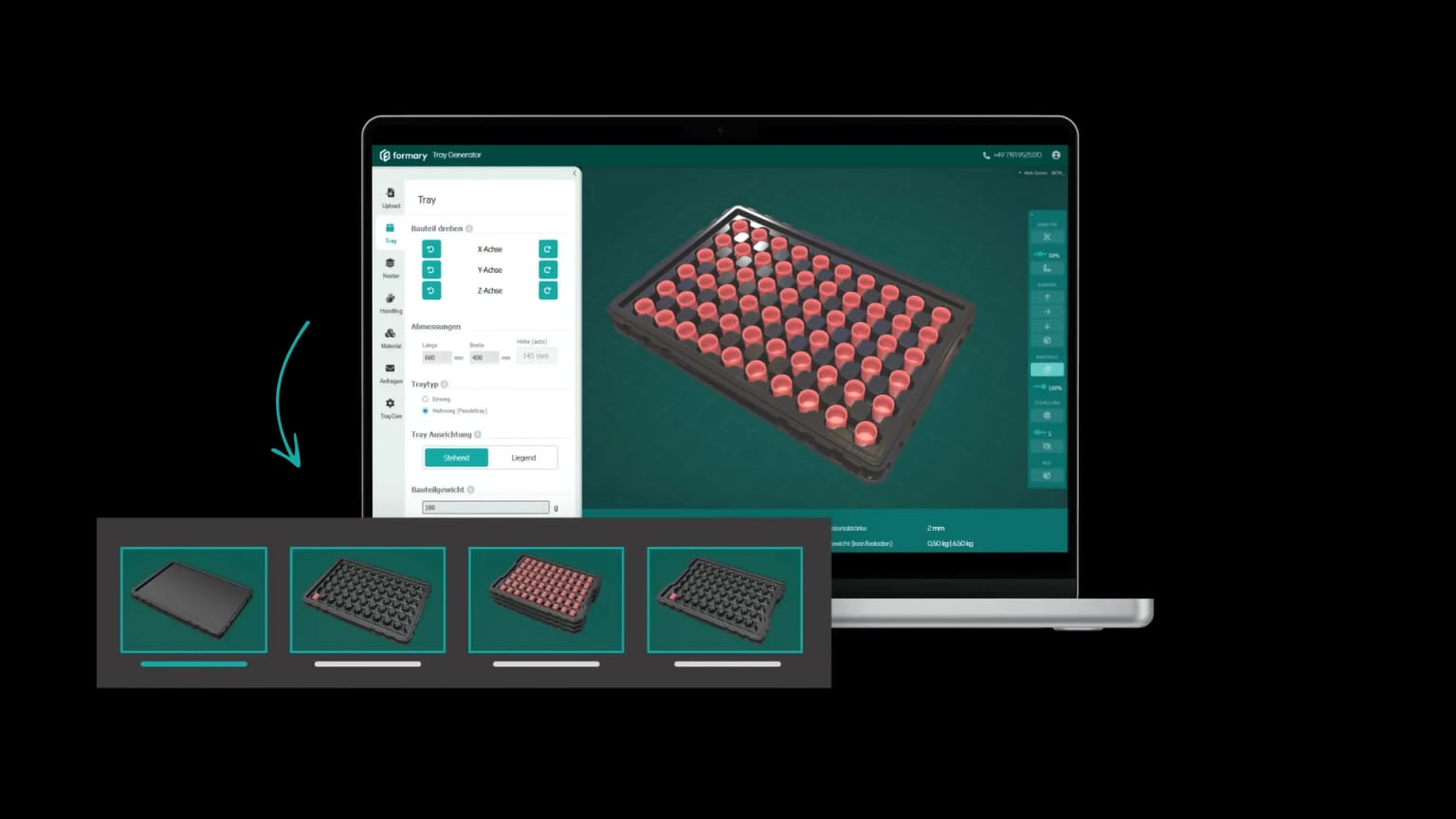

Smart plastic tray concept with the 3D Tray Generator

Do you have a CAD model of your component and want to know what a perfectly fitting plastic tray could look like?

Upload your component to our free 3D Tray Generator and receive a suitable tray concept within 30 seconds. Simply book a demo, and we will create your plastic tray together with you based on your component.

What design options are available for plastic trays?

Grip recesses

Integrated finger grip recesses make it easier to safely grip, lift, and place trays. Their size and positioning are individually designed, as they also influence cavity geometry and stackability.

Stacking techniques

Undercut and stud stacking ensure safe, space-saving storage—whether freestanding on pallets or inside transport containers. The design is based on the desired number of layers and the maximum height of the packaging unit.

Single-use & reusable trays

Single-use trays are cost-effective and suitable for one-time transport. Reusable trays, on the other hand, are durable, robust, and sustainable, making them ideal for returnable packaging systems and long-term circulation.

Compatibility with load carriers

Outer dimensions can be precisely matched to KLT containers, Euro containers, or cartons. This allows plastic trays to be easily integrated into existing transport and storage processes.

Custom cavities

The cavities are designed specifically for your components. Requirements such as packing density (number of parts per tray), orientation, and component loading and unloading form the basis of the design.

Packing density

Packing density defines how many items can be accommodated per thermoformed tray. Optimized packing density reduces empty space and lowers transport costs.

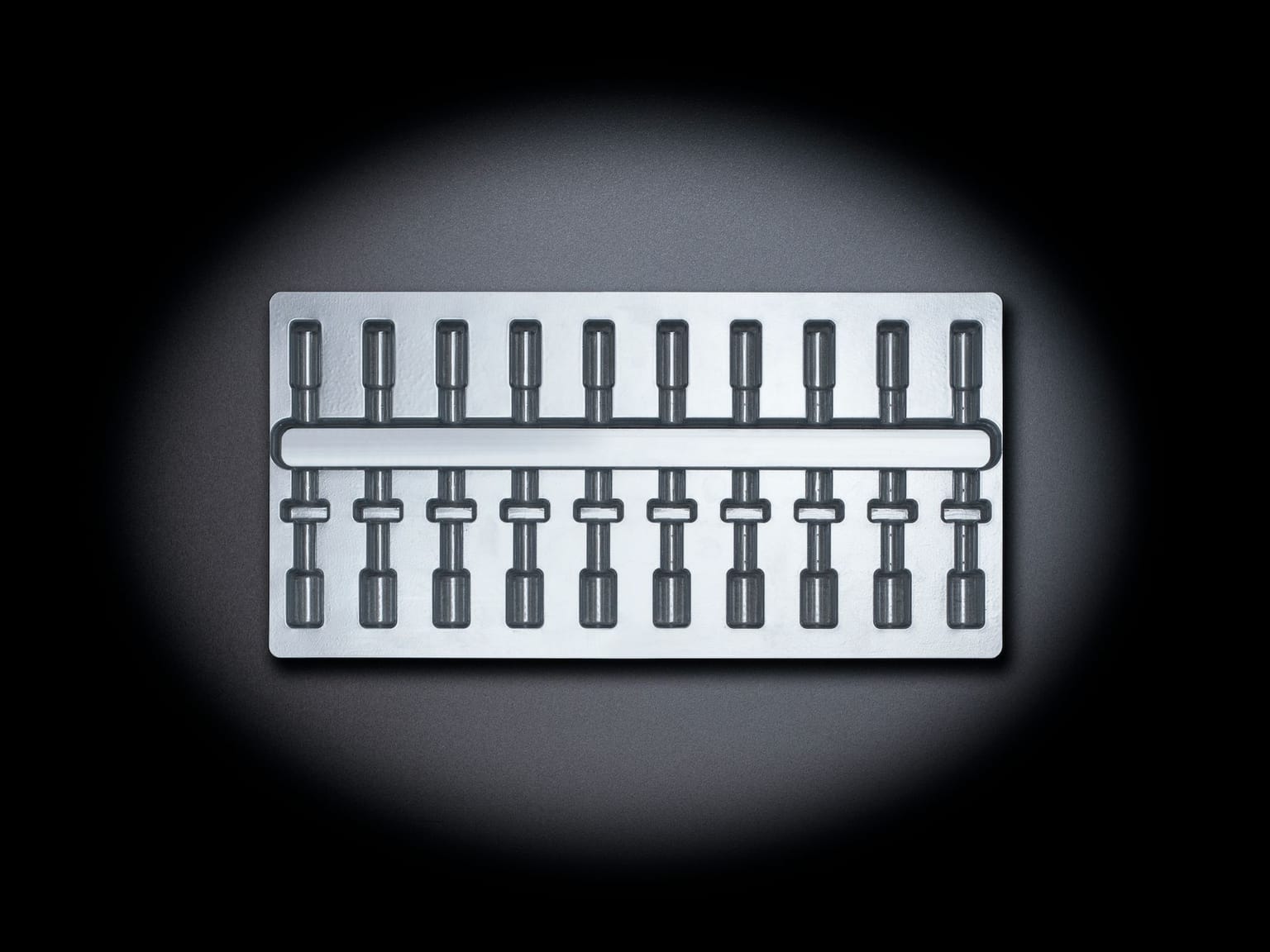

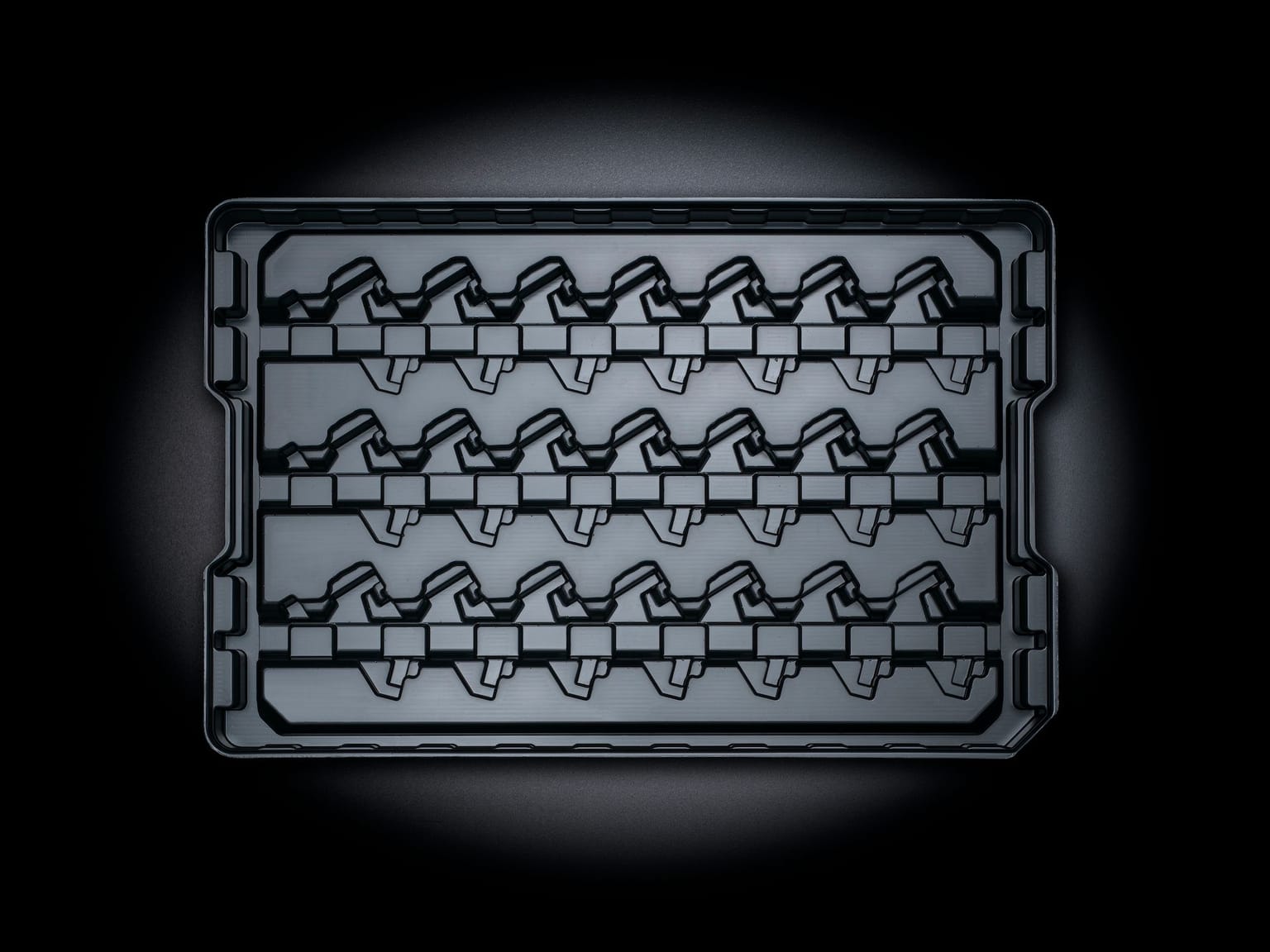

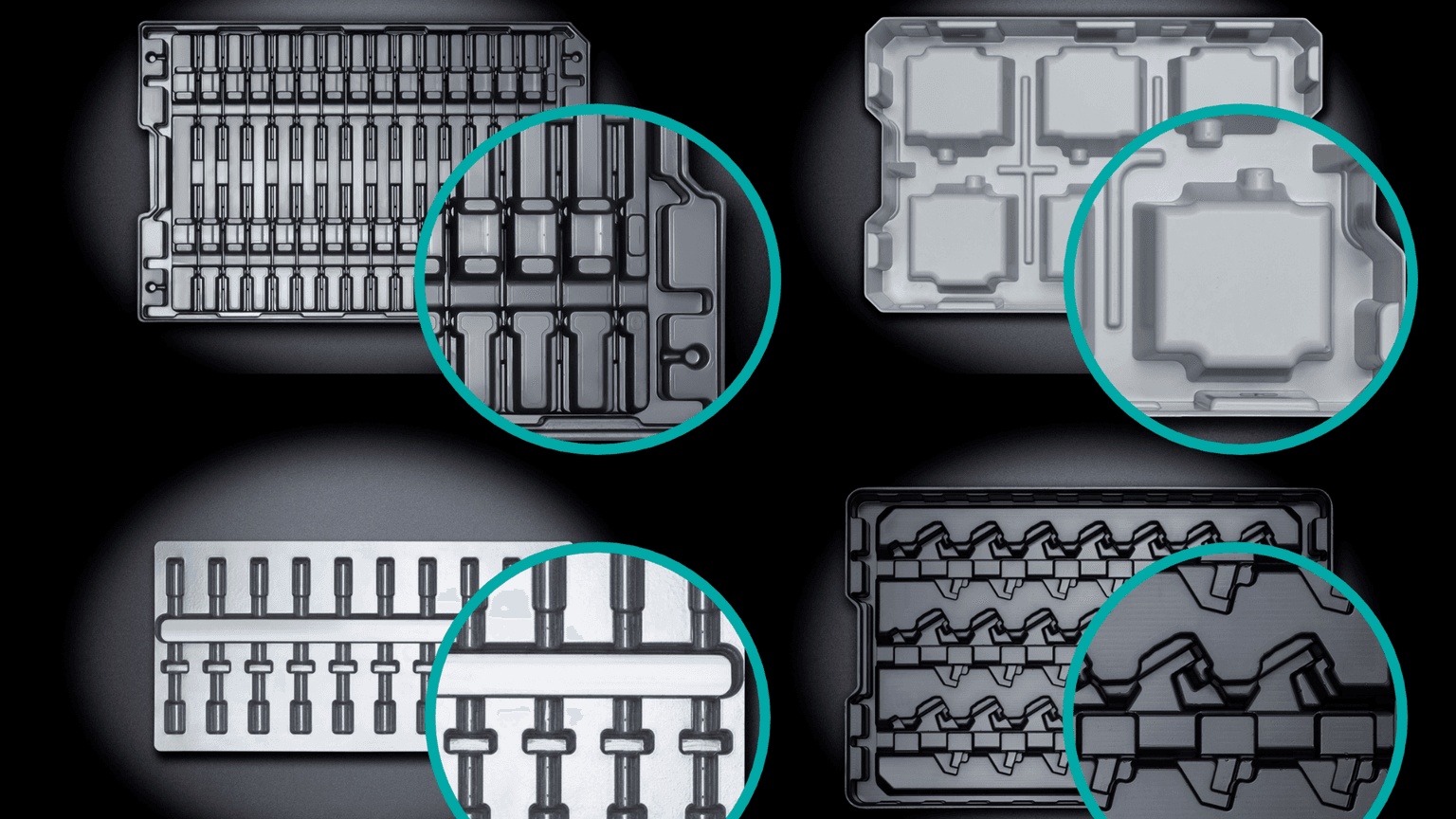

Product Examples of Plastic Trays

Here are a number of examples of thermoformed plastic trays that are used in different areas.

Project Process for Plastic trays: From Inquiry to Order

Inquiry

You configure your desired product in our configurator in the desired quantities, material and design.

Review & Offer

We check your data for feasibility and implementation. Then we provide you with an offer within 24 hours. At the same time, we also make suggestions for the data creation of your deep-drawn part as well as useful sampling options.

Data Approval

You approve our data for prototyping or the series tool.

Tool & Sampling

We create your tool and send you series samples for approval.

Series Production

After checking and approving the samples, we start manufacturing your deep-drawn parts.

Shipping

After completion and thorough inspection by our QA team, we will send your series delivery on its way.

Quickly find the right tray solution – download the white paper for free

In our white paper, discover how versatile thermoformed plastic trays are and how you can quickly develop a custom concept using the 3D Tray Generator or order a suitable standard tray in just a few clicks.

What you’ll learn:

✓ Advantages of plastic trays

✓ Our manufacturing standards

✓ Product examples & properties

✓ 3D tray concepts with the Tray Generator

✓ Standard trays in the online shop

Plastic trays for transport & storage

Download whitepaper for free

FAQ – Frequently asked questions about plastic trays

A tray is a thermoformed packaging solution that securely holds products in cavities. Plastic trays in particular protect sensitive components during transport and are stackable.