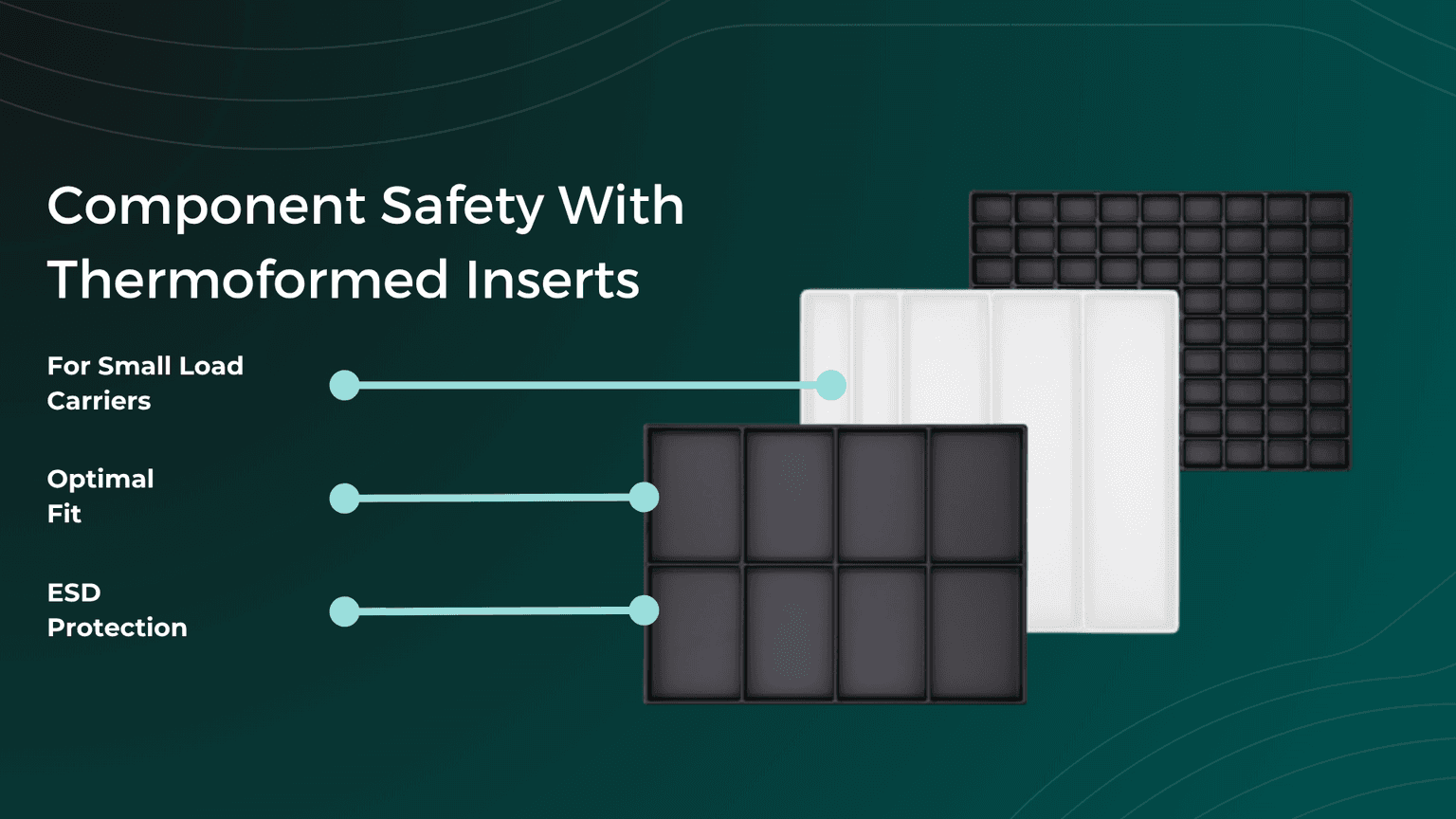

Thermoformed Inlays and Inserts

With thermoformed plastic inserts, you can securely protect and position your products in cases, drawers, packaging, or containers. Whether used as tool inserts, drawer inserts, packaging inlays, or medical blisters, we develop custom solutions that are perfectly tailored to your product.

What are thermoformed plastic inserts?

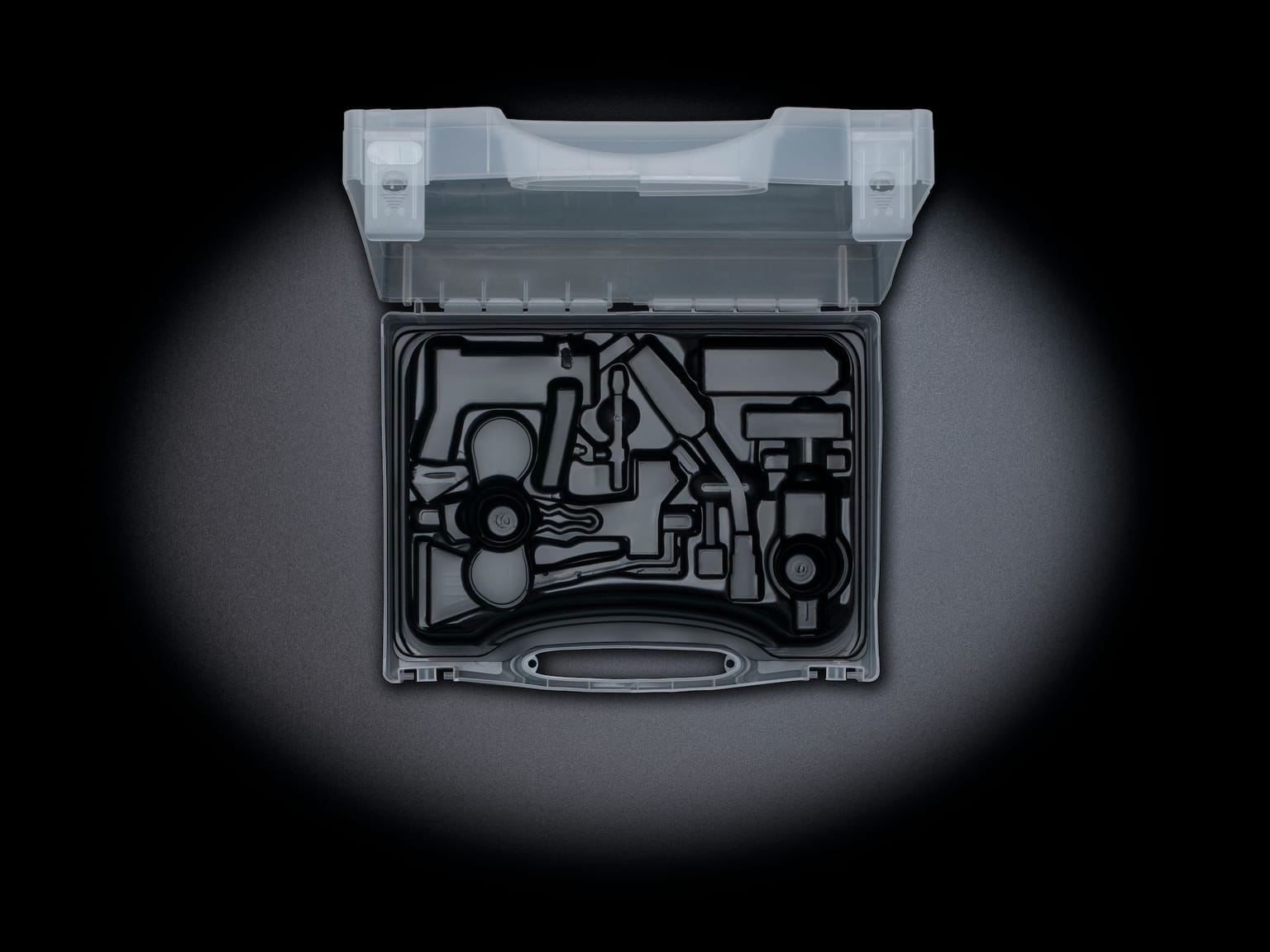

Thermoformed inserts, also known as plastic inserts or plastic inlays, are custom-fit molded parts that secure products in cavities or recesses. They are used in SLC containers, Euro containers, tool cases, drawers, folding cartons, medical packaging, or presentation boxes.

Areas of application for thermoformed inserts

Thermoformed inserts ensure precise positioning of components and are used in many areas, from internal logistics and storage to retail and packaging.

- Intralogistics: standardized plastic trays, custom KLT inserts, delicate plastic trays, or thermoformed inlays for cartons

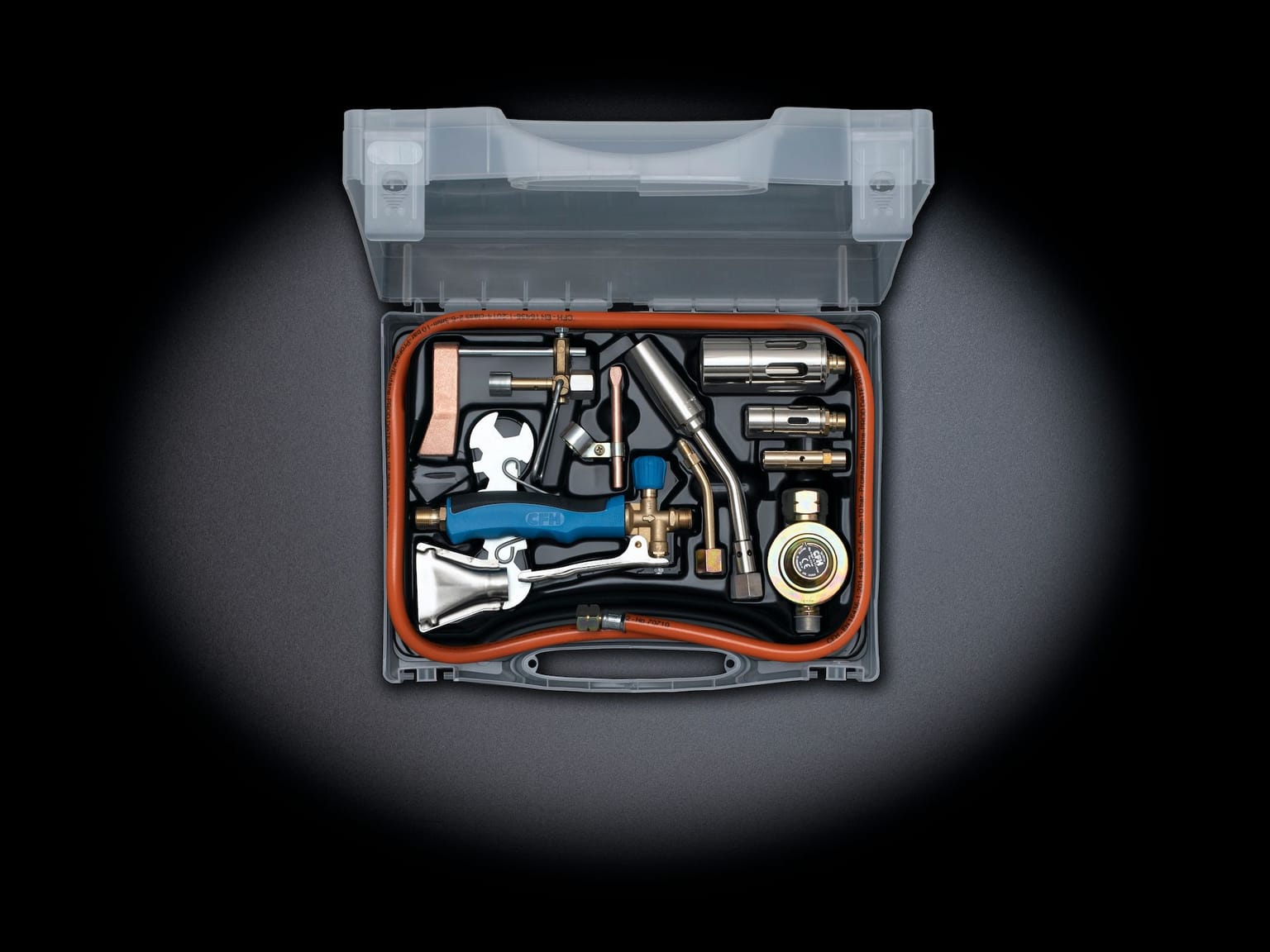

- Storage: boxes, protective cases, and cooler boxes for spare parts or food, drawer inserts, tool case inserts, plastic interlayers for instruments, cutlery, and small parts

- Retail: tool sets in toolboxes, folding boxes with form-fitted inlays, reusable packaging for end customers, display packaging, chocolate inlays, or blister packaging

- Packaging blisters: single-use or reusable inlays, inserts for product protection, presentation packaging, and visually appealing placement in secondary packaging

Advantages of Thermoformed Plastic Inlays

Protection

Prevents damage and scratches to your products during storage, presentation, or transport using thermoformed inserts.

Affordable Process

Custom or standard-sized thermoformed inlays are tailored to your needs.

Reusable Circulation System

Focus on durability and sustainability with long-lasting plastic inlays.

Your Corporate Design

Communicate through colors, text, and logos on the thermoformed insert to reflect your brand.

Specific Material Properties

Utilize industry-specific material selection for your plastic inlay.

Complex Geometries

Accommodate products with complex contours, heavy weight, or spare parts sets within the thermoformed insert.

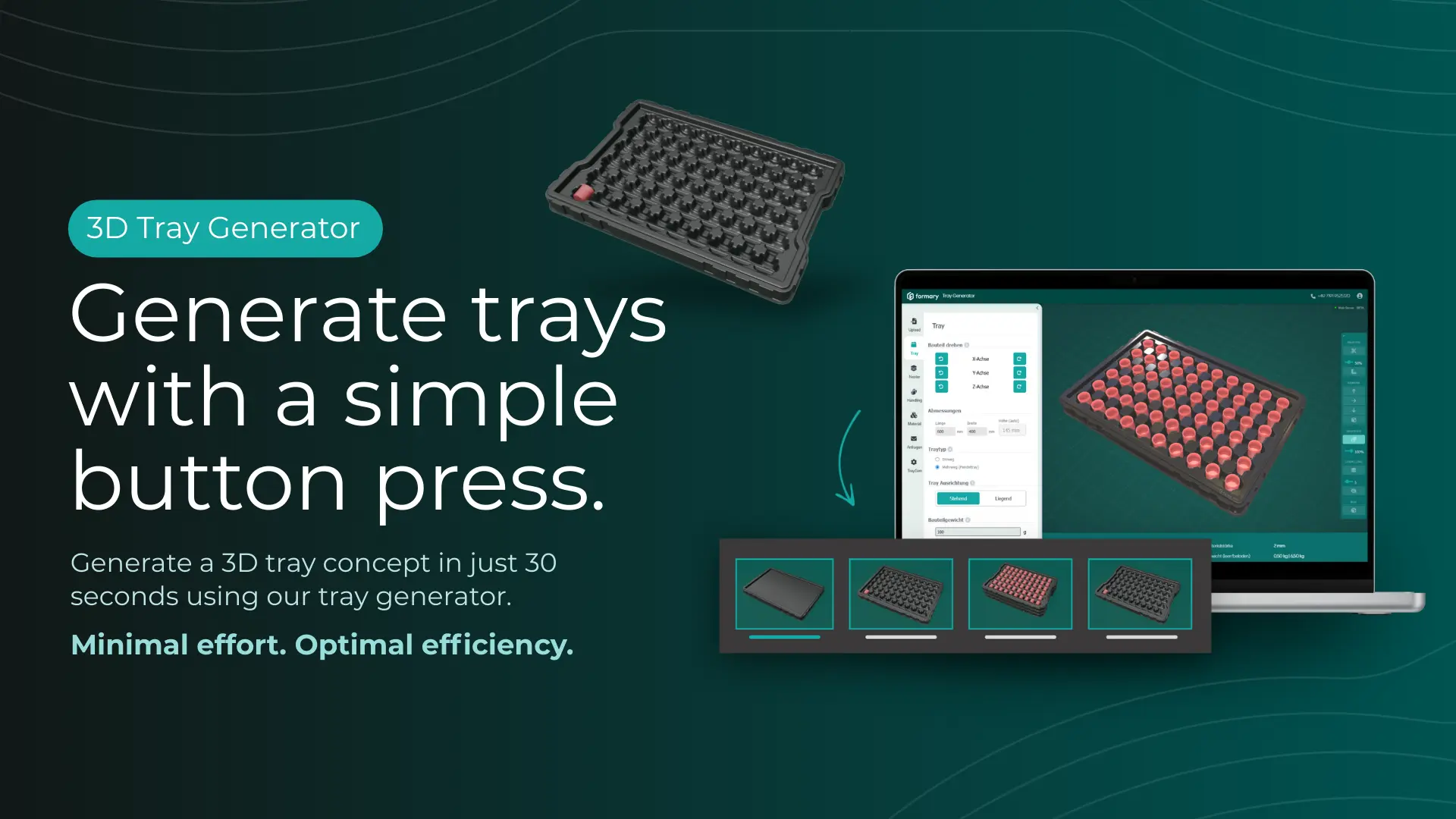

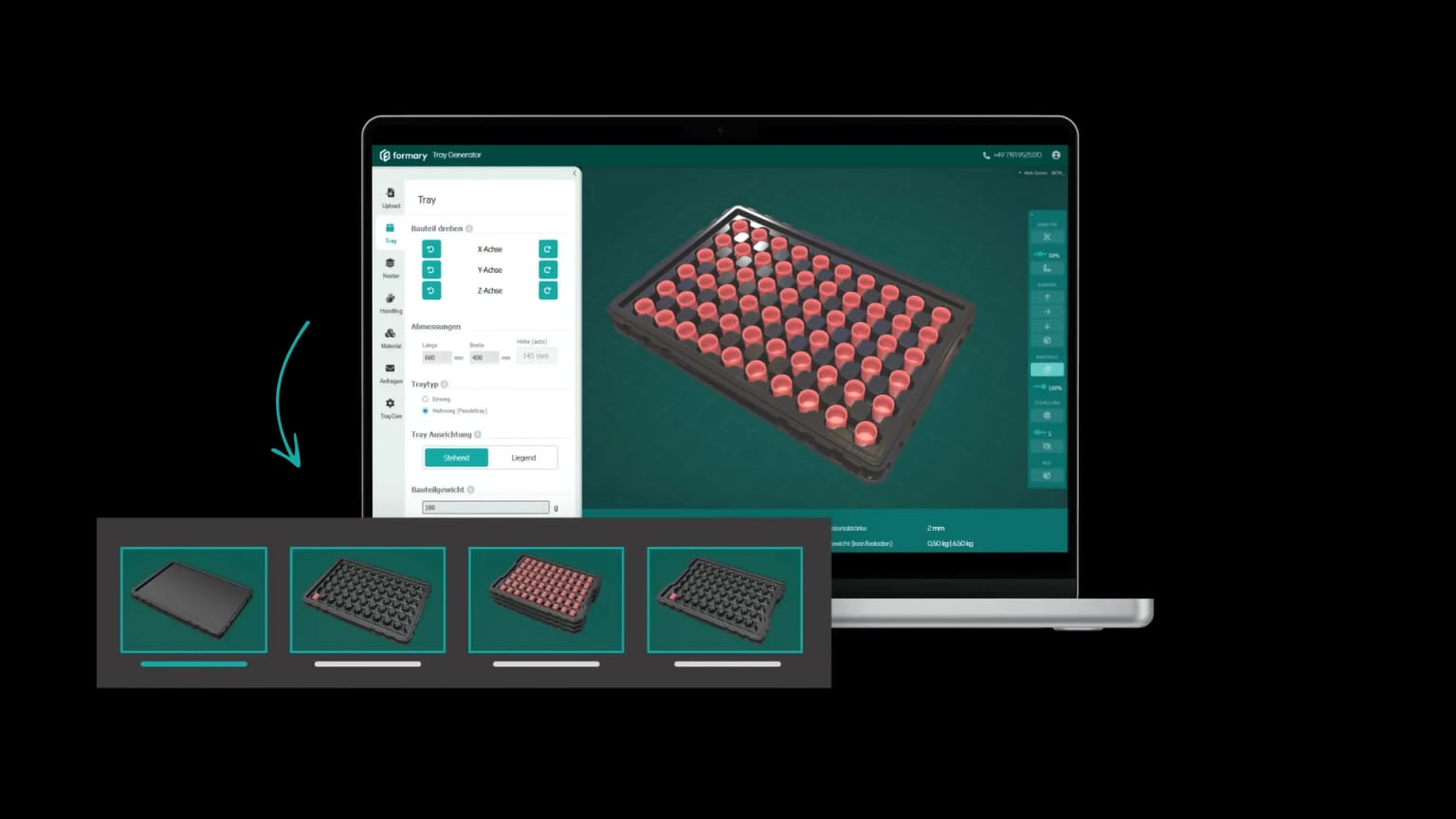

Smart thermoformed insert concept with the 3D Tray Generator

Do you have a CAD model of your component and want to see what a perfectly fitting plastic insert could look like?

Upload your component to our free 3D Tray Generator and receive a suitable inlay concept within 30 seconds. Simply book a demo, and we will create your thermoformed insert together with you based on your component.

Design options for thermoformed inserts

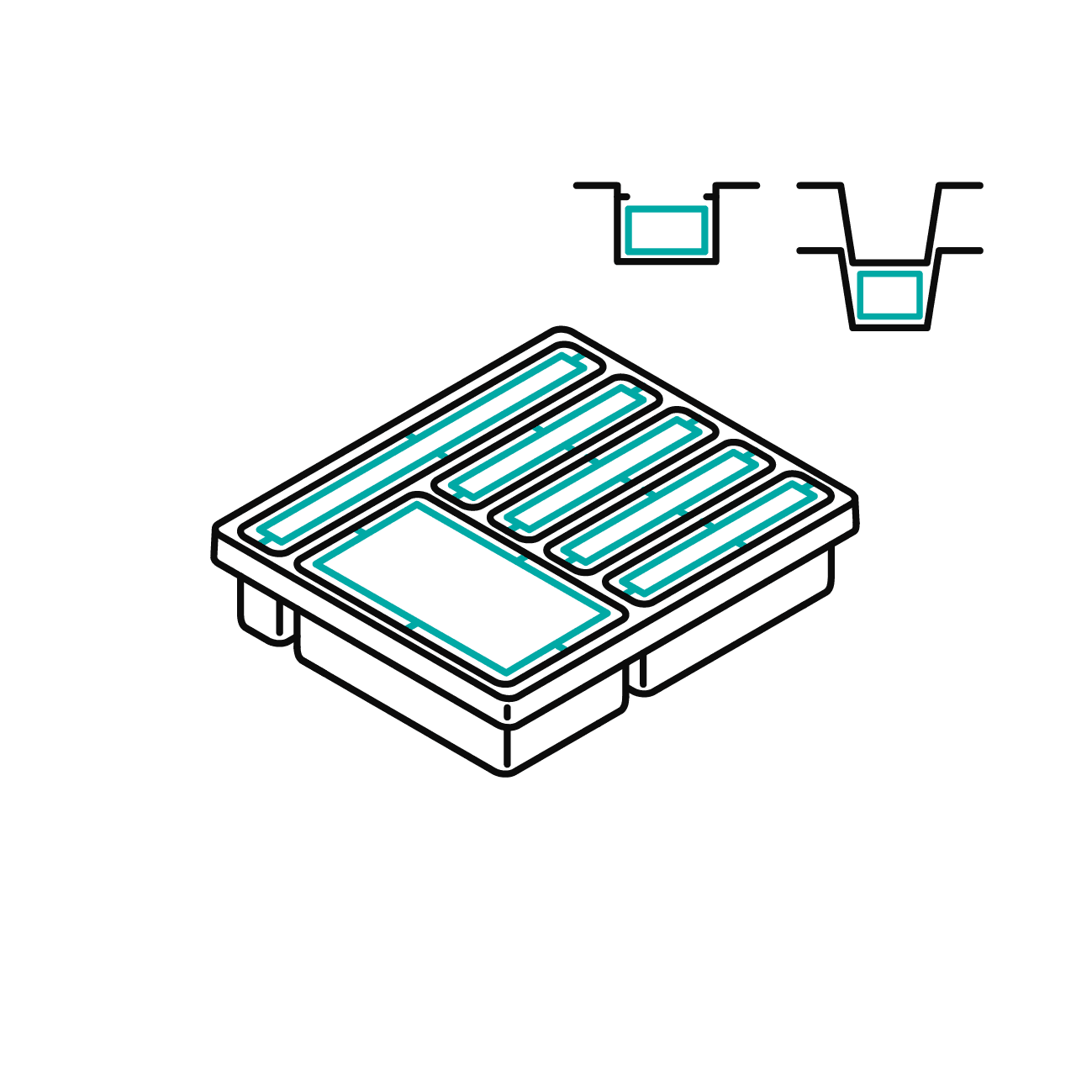

Radii & draft angles

Minimum dimensions ensure thermoformability. Radii prevent material weakening, and draft angles (approx. 3°) enable easy demolding of the inserts.

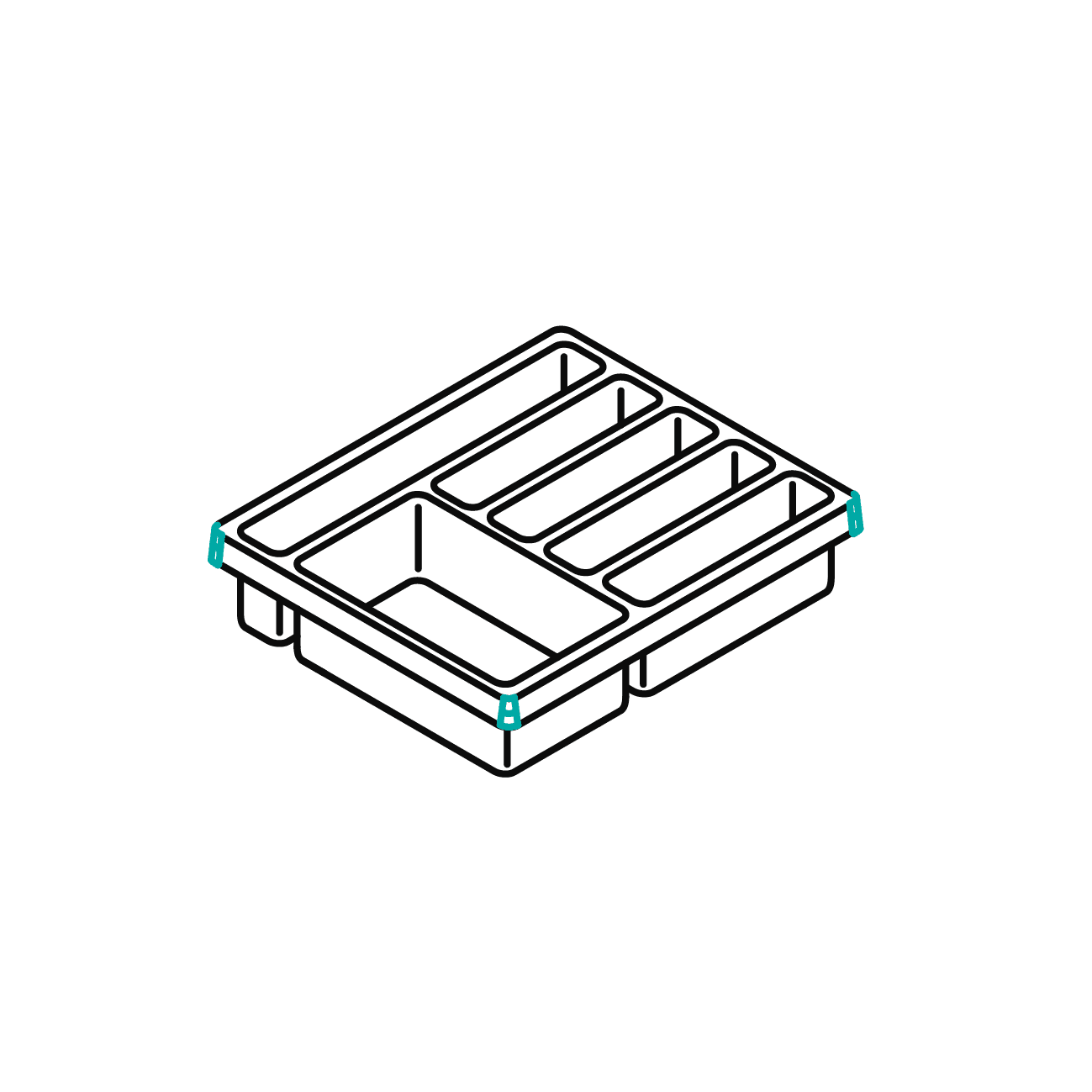

Grip recesses

Finger grip recesses support handling of the plastic insert in combination with the surrounding container. Size and positioning should be planned early, as they also affect cavity design and stackability.

Cavity design

The cavities of a thermoformed insert are precisely adapted to the respective component to ensure secure positioning. Spacing and arrangement of the cavities influence not only stability but also handling and packing density.

Component retention

Clamping features or undercut techniques reliably hold products in the thermoformed plastic inlay, even during transport or vibration.

Stabilization

To ensure thermoformed inserts remain dimensionally stable under high loads, ribs and reinforcements are integrated. The choice of material thickness and stiffening method depends on the weight of the components.

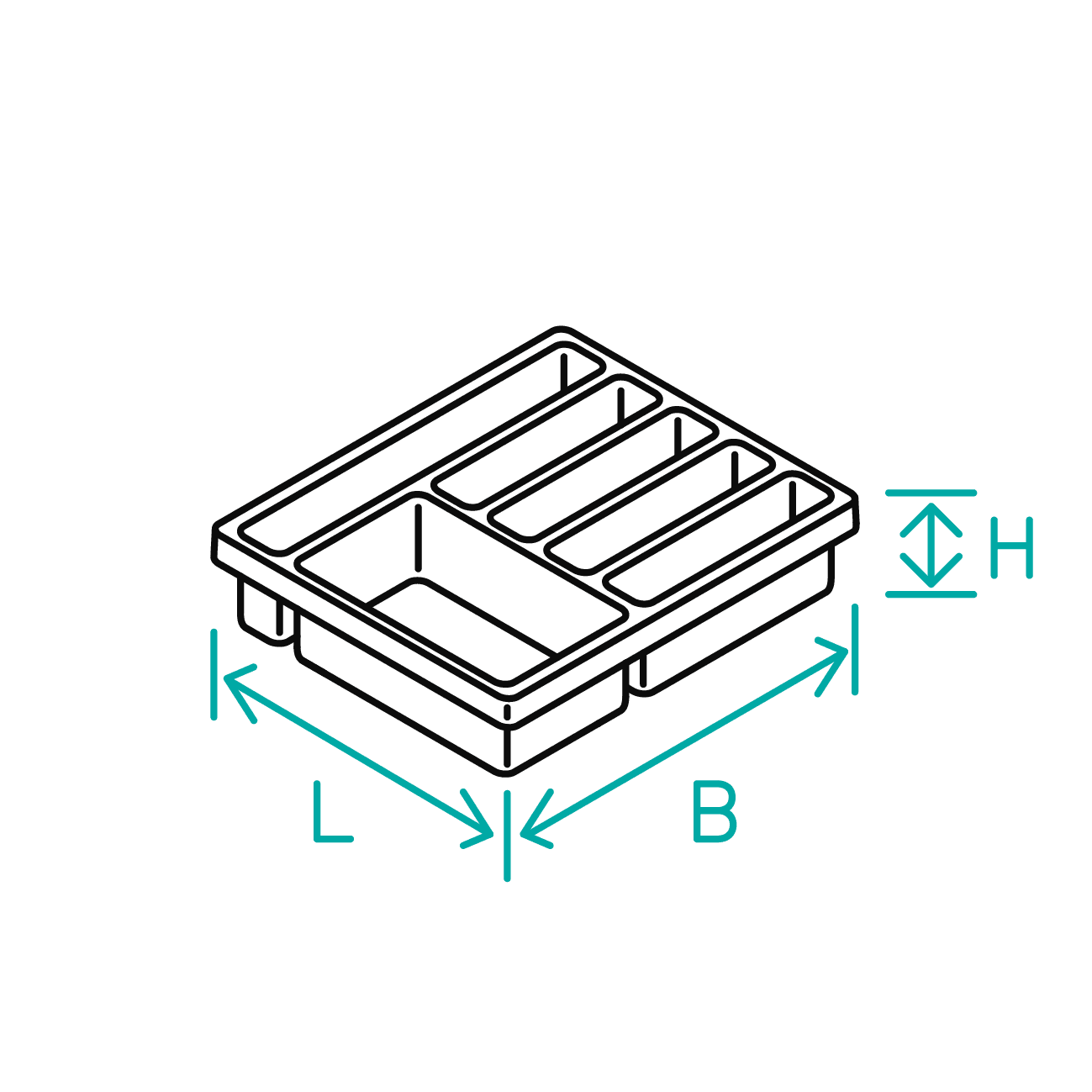

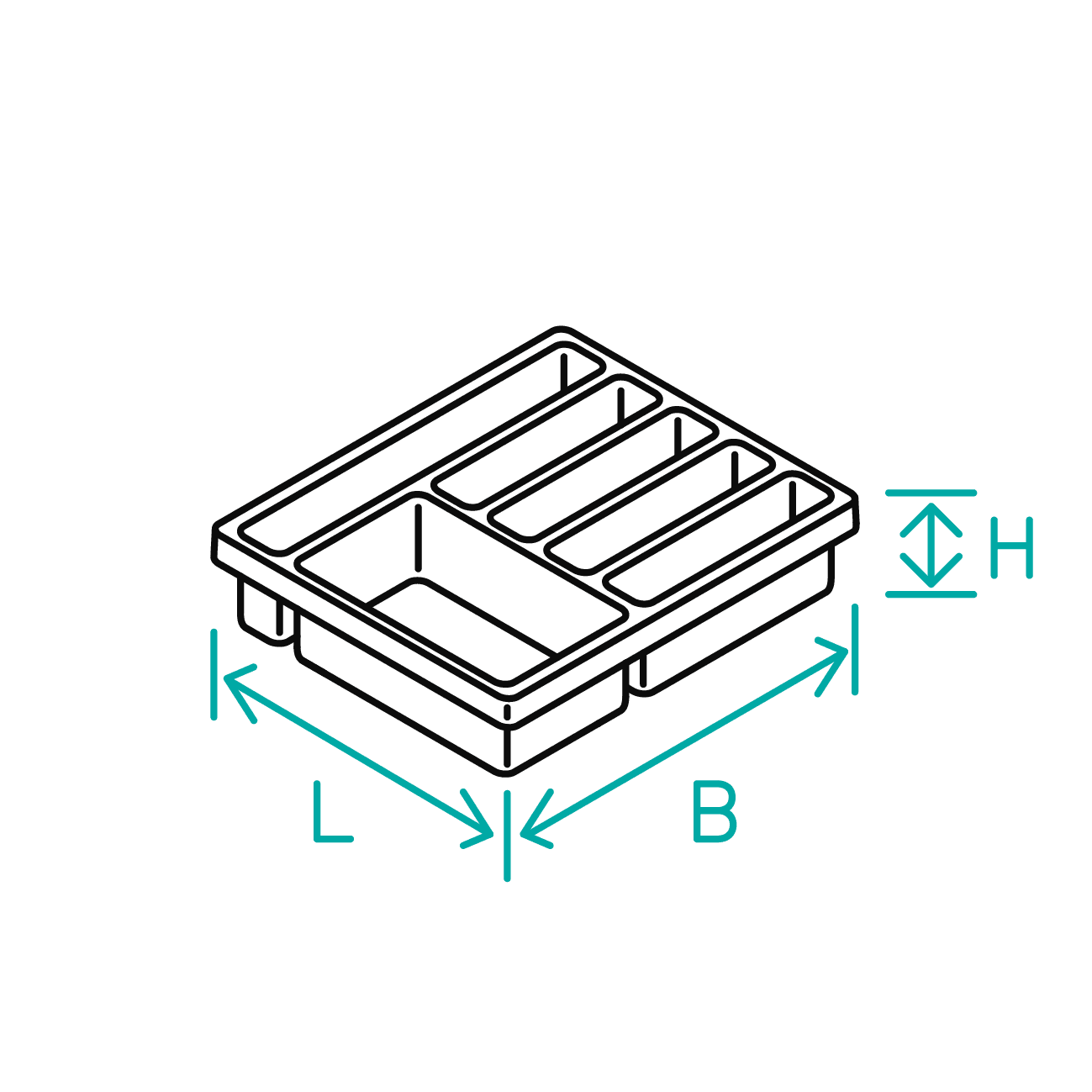

Fit & tolerances

As standard, dimensional accuracy is in accordance with ISO 2768-c. For higher requirements, we can also manufacture according to ISO 2768-m, ensuring a precise fit in drawers, cases, or containers.

How do thermoformed inserts fit into different containers?

We design each thermoformed insert to fit seamlessly into its respective outer container. For standardized Euro containers, we pay close attention to dimensions, trimming contours, and tolerances. Typical challenges are addressed already during the design phase.

Typical outer containers for thermoformed inserts include:

- Boxes & Cases

- Reusable Containers

- Standardized Containers

- Drawer Systems

- Folding Boxes

- Trays & Boxes

- Plastic Boxes & Containers

- Stackable Boxes & Containers

- Presentation Boxes

- Sliding Blisters & Folding Blisters

This ensures a perfectly fitting, thermoformed plastic insert for every type of container.

Product Examples of Thermoformed Plastic Inlays

Here are a few examples of thermoformed plastic inserts used in various fields:

Project Process for Thermoformed Inlays: From Inquiry to Order

Inquiry

You configure your desired product in our configurator in the desired quantities, material and design.

Review & Offer

We check your data for feasibility and implementation. Then we provide you with an offer within 24 hours. At the same time, we also make suggestions for the data creation of your deep-drawn part as well as useful sampling options.

Data Approval

You approve our data for prototyping or the series tool.

Tool & Sampling

We create your tool and send you series samples for approval.

Series Production

After checking and approving the samples, we start manufacturing your deep-drawn parts.

Shipping

After completion and thorough inspection by our QA team, we will send your series delivery on its way.

FAQ – Frequently asked questions about thermoformed inserts

A thermoformed insert is a thermoformed molded part that secures products in cavities or recesses. It is also referred to as a plastic insert or plastic inlay.