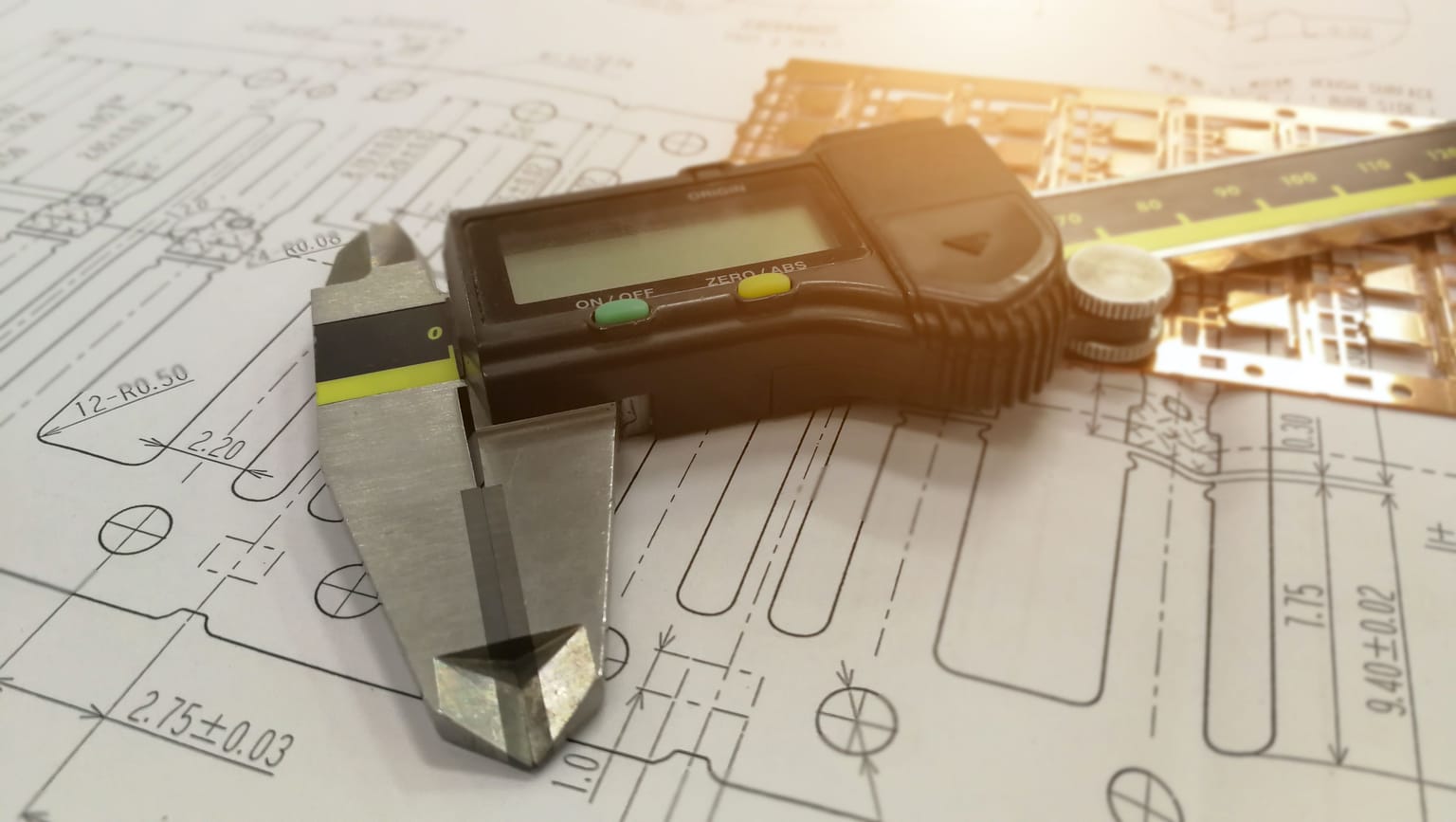

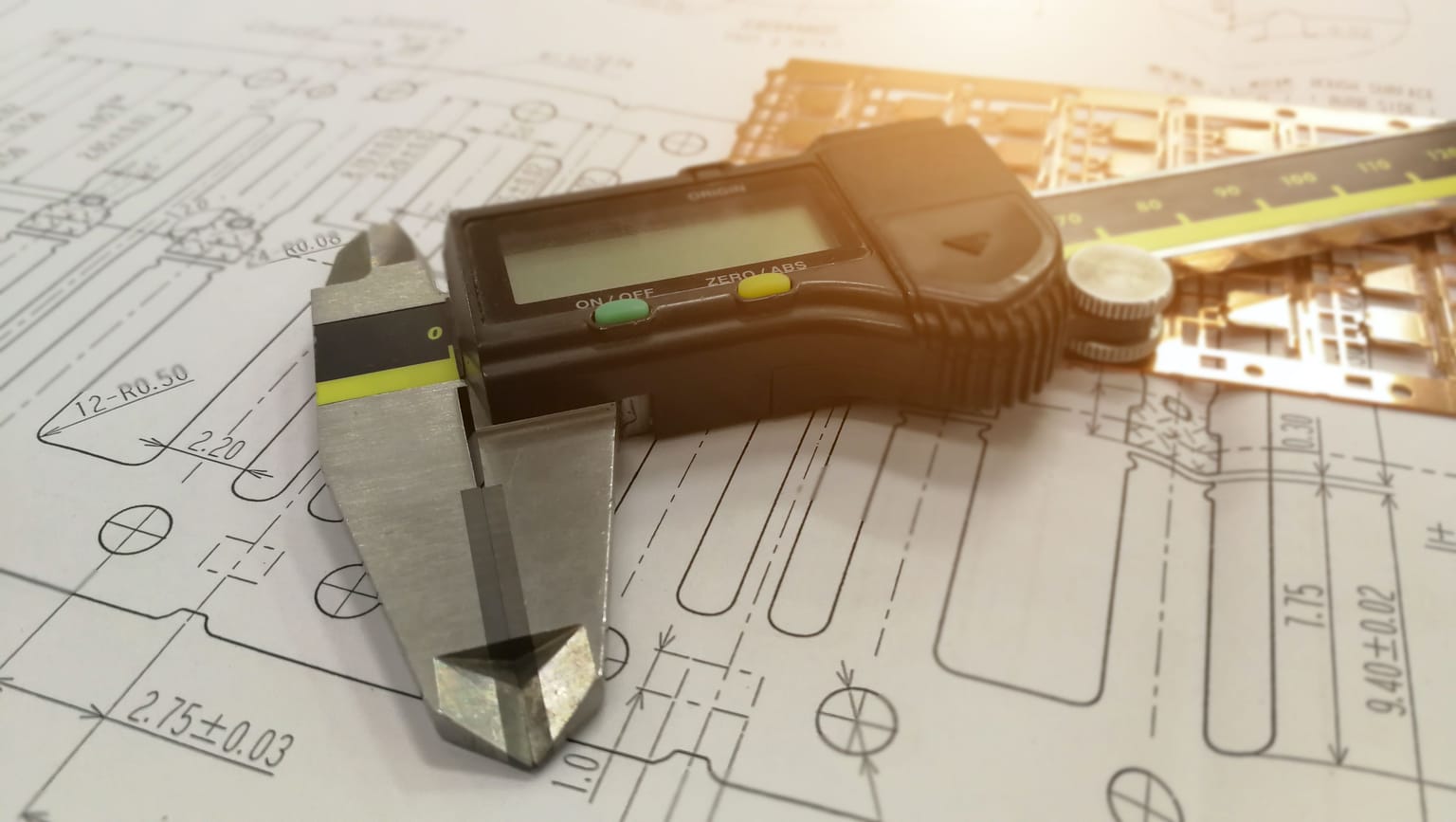

Quality & Safety

At formary, quality is our priority. Our quality processes are ISO 9001:2015 certified, ensuring flawless products before every shipment.

Our team ensures quality assurance throughout the supply chain of your thermoformed part.

In addition to working with ISO 9001–certified suppliers, we also inspect your samples and series parts in our own quality assurance department before they leave our facility.

Our Manufacturing Standards

DIN ISO 2768-1

| Tolerance Class | Permissible Deviation (mm) for Nominal Dimension Range (mm) (+/-) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| DIN ISO | 0,5 - 3 | >3 - 6 | >6 - 30 | >30 - 120 | >120 - 400 | >400 - 1.000 | >1.000 - 2.000 | >2.000 - 4.000 | >4.000 - 8.000 |

| 2768-m | 0,1 | 0,1 | 0,2 | 0,3 | 0,5 | 0,8 | 1,2 | 2,0 | 3,0 |

| 2768-c | 0,2 | 0,3 | 0,5 | 0,8 | 1,2 | 2,0 | 3,0 | 4,0 | 5,0 |

Our Partners

Our partners are ISO 9001 certified and undergo a rigorous onboarding process to ensure reliability and quality. We maintain close relationships with our suppliers, prioritizing quality over quantity.

Our Onboarding Process

Facility Inspection: We assess the partner’s machinery and production capacity.

Process Training: The partner becomes familiar with formary’s standards and communication protocols.

Test Production Run: A trial production, including tooling, samples, and small series manufacturing, is evaluated by our in-house QA team.

Confidentiality Agreement: Our partners sign an NDA to ensure the protection of sensitive information.

Continuous Improvement

We collaborate with our partners regularly to enhance our operations. By analyzing QA data and key performance indicators (KPIs) like on-time delivery, we provide constructive feedback to drive continuous improvement.

Quality Assurance Documentation

Auf Wunsch erhalten Sie sämtliche QS Dokumentationen für uns, die Sie für Ihre internen Zwecke benötigen.

Quality Management & Control

First Article Inspection Reports (FAIR) available upon request

All our suppliers are ISO 9001 certified

Material selection for specialized applications, including fire resistance, ESD protection, and UV stability

Reverse engineering of your samples if no CAD data is available

Regular audits to ensure the highest quality standards

Precision measurement of prototypes and production parts using a coordinate measuring machine (Faro Arm) upon request

Tight tolerances according to DIN ISO 2768-m are possible

High repeatability in trimming through CNC milling robots

Confidentiality Agreement (NDA)

Your data security is our priority. We handle all information related to your thermoforming project with strict confidentiality. Upon request, we provide a Non-Disclosure Agreement (NDA) to ensure complete data protection.

Have questions? Contact our Sales Team at info@formary.de.

More about the non-disclosure agreement (NDA)

Contact us now

FAQ – Quality Assurance in Thermoforming

Quality assurance takes place on several levels. All partners are ISO 9001:2015 certified, and samples as well as serial parts are additionally inspected in our in-house QA department, including dimensional checks and documentation.

Further information on quality assurance & efficiency in thermoforming

From Inquiry to Order

Inquiry Process

Easily configure your desired product using our inquiry tool. Select your preferred quantity, material, and specifications to receive a tailored offer.

Review & Offer

We analyze your data for feasibility and manufacturability, providing you with a quotation within 24 hours. At the same time, we offer recommendations for data preparation and optimal prototyping options for your thermoformed part.

Data Approval

You approve the data for prototyping or serial production tooling, ensuring a smooth transition to manufacturing.

Tooling & Prototyping

We manufacture your custom tooling and provide you with production samples for approval before full-scale production begins.

Serial Production

After sample inspection and approval, we proceed with the full-scale production of your series.

Shipping

Once production is complete and our quality assurance team has thoroughly inspected your order, we ship your series delivery promptly to your location.