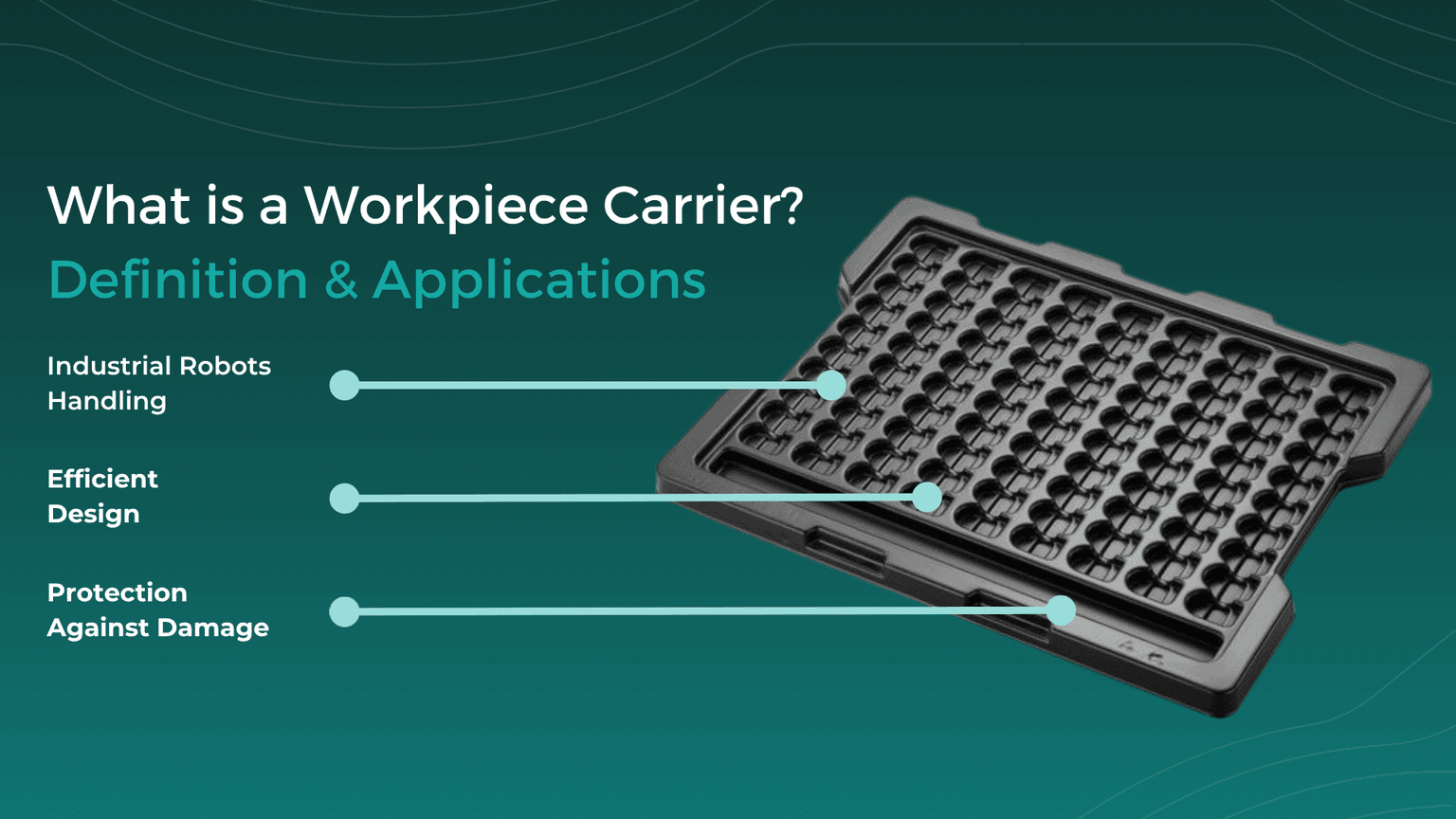

What Is a Workpiece Carrier? Definition & Applications

A constant challenge in the manufacturing industry is efficiently managing material flow throughout all assembly stages and departments. These logistical challenges can be optimally addressed by using product-specific workpiece carriers. Learn more in this article.

Sarah Guaglianone

13. Januar 2026

Contents

What is a workpiece carrier?

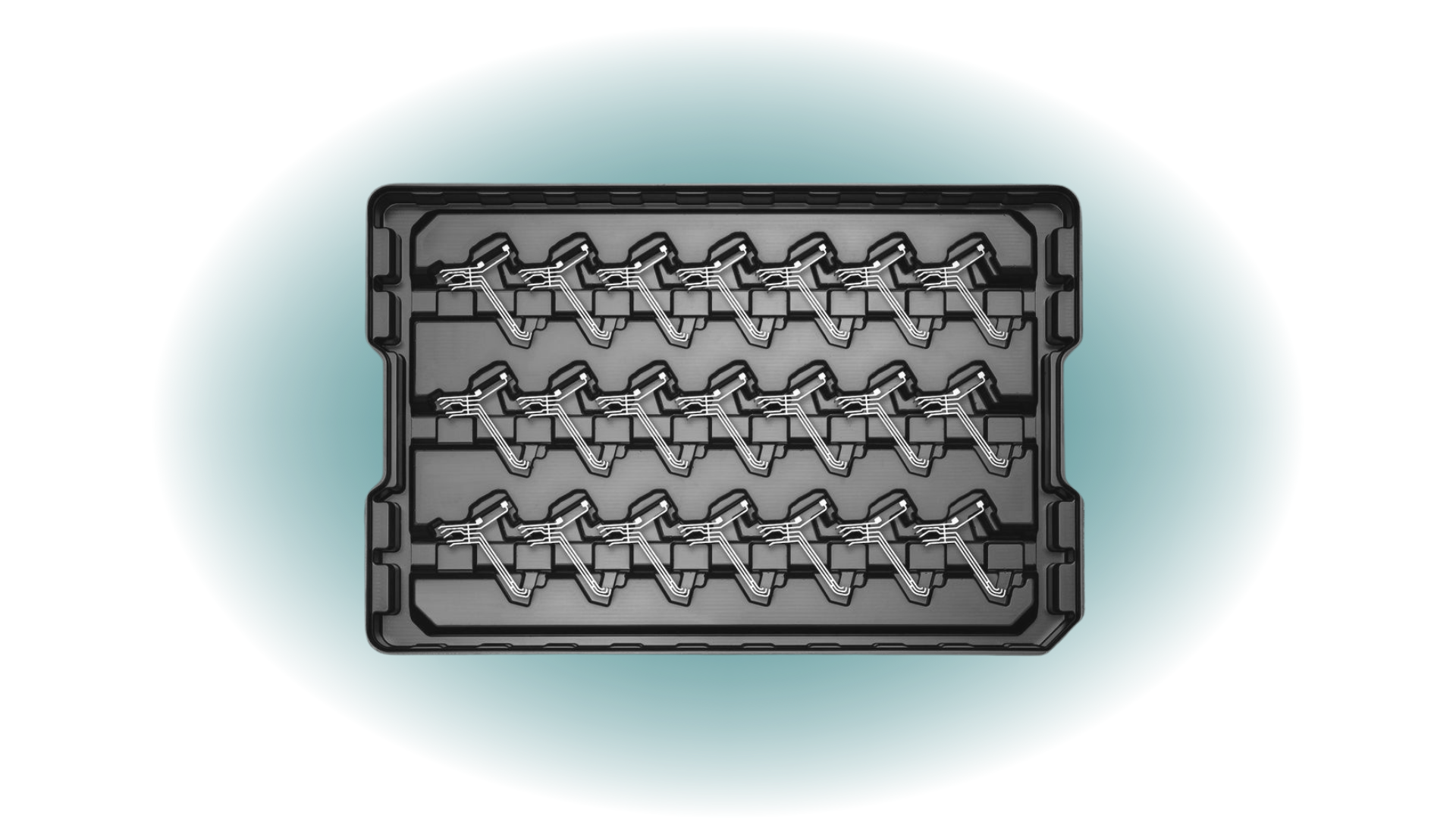

A workpiece carrier, also known as a parts carrier, load carrier, tray or workpiece holder, is used to transport, fix and protect workpieces during the manufacturing process. Workpiece carriers are used in various industries, including automotive, electronics, food production and others.

The functions of workpiece carriers explained in more detail:

Fixing and positioning

Workpiece carriers are used to hold the workpieces securely in place and keep them in the desired position. This is particularly important for sensitive parts.

Protection against damage

Workpiece carrier transport systems ensure that workpieces are protected during transport and storage. Components can be fixed in such a way that sensitive component areas do not come into contact with the wall. They are also protected from falling out and vibrations during transport by fixings and customised nests.

Automation and efficiency

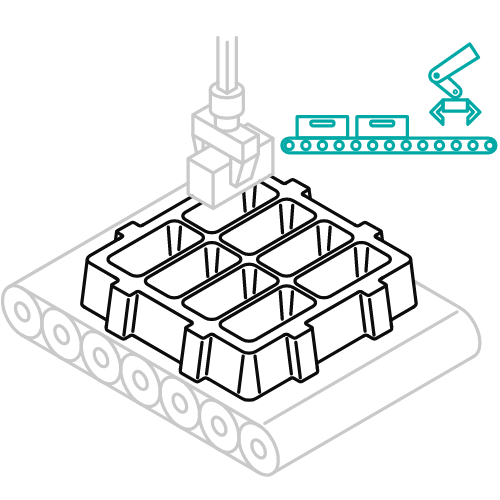

In automated production systems, workpiece carriers enable a smooth material flow. Workpiece carrier systems are often designed so that they can be seamlessly integrated into automated systems and enable robotic handling. You can find more on this topic under "Automation trays."

The role of workpiece carriers for Industry 4.0

Industry 4.0 requires consistent automation of production processes for cross-technology mergers of systems. Consistent production conditions are essential to ensure that all robots and automation components can optimally control, remove and process components and transfer them smoothly to the next production step.

These conditions are guaranteed by the use of flexible workpiece carriers, among other things.

Workpiece carriers can efficiently transport partially processed components, assemblies or products from one cell, machine or system to the next processing station. The tray is perfectly matched to the individual conveyor technology and the respective processes. The workpiece carrier usually moves along the production line on a conveyor belt or workpiece conveyor.

How do workpiece carriers ensure optimised production and logistics?

Workpiece carriers play a decisive role in the optimisation of manufacturing and logistics processes. Here are some aspects of how they can contribute to this:

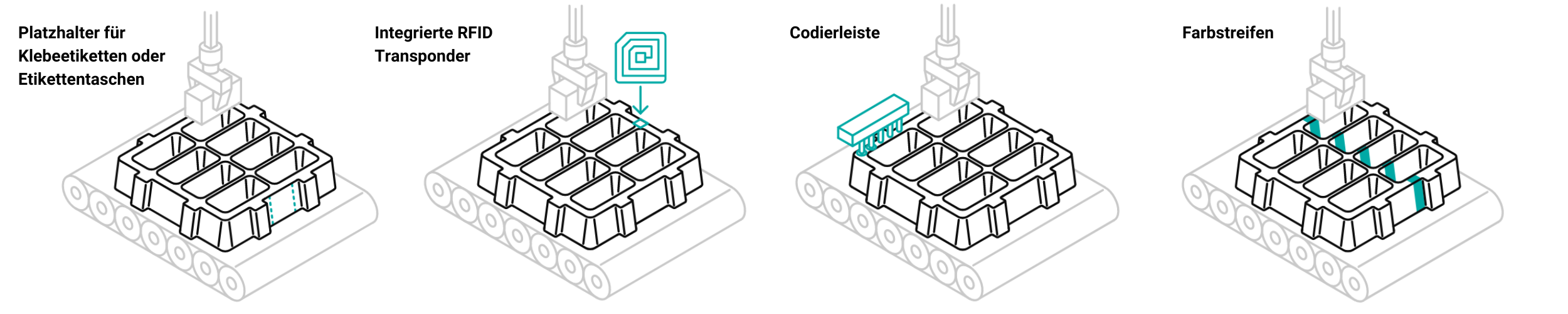

Coding and product recognition

Various electronic and optical methods are available to ensure that machines and systems can recognise both components and the workpiece carrier.

Placeholders for adhesive labels or label pockets

Replaceable or fixed labels are an effective and frequently used method of product labelling. For labels, space can be saved at an early stage on the tray edge and the stacking cams can be designed to fit around them.

Integrated RFID transponders

Electronic devices that transmit data wirelessly via radio frequencies can be integrated into the workpiece carrier. It is possible to provide space for an RFID transponder or alternative tracking devices at an early stage on the edge of the workpiece carrier.

Coding strip

For mechanical testing, BCD coding with moulded studs or milled cuts can be applied to the edge of the part carrier or the frame.

Colour stripes

An additional coloured stripe on the workpiece carrier can be used for visual alignment and orientation. Images and more information on trays with colour strips can be found on our product pages.

Alignment and positioning

To ensure that the sensor system reliably recognises components and prevents the robot gripper from colliding during loading and unloading, the workpiece carrier offers various solutions.

Gripper and fork recesses

If trays need to be separated individually (with a fork or grippers), recesses or grooves can be provided for dipping.

Recesses for centring cones

Recesses for centring cones can be attached to the edge of the nest to align the workpiece carriers. The centring bar is used to secure the workpiece carrier during loading and unloading or on the conveyor belt.

Poka-Yoke corners

The term "poka-yoke" comes from the Japanese and means "avoid mistakes". Poka-yoke corners are used for visual orientation to avoid errors such as incorrect insertion or alignment of the workpiece holder. For correctly aligned workpiece holder insertion, a chamfer can be made in one of the corners or a coloured stripe can be placed on one side.

Anti-twist protection / stacking protection

An anti-twist device guarantees correct alignment when stacking several workpiece carriers on top of each other by means of mechanical stacking protection. This can also be designed for different tray variants so that the workpiece carriers can only be stacked by type.

Transport

Workpiece carriers also support the transport of components. The transport of components using the trays is ensured by efficient stacking, adaptation to conveyor systems and ergonomic handling.

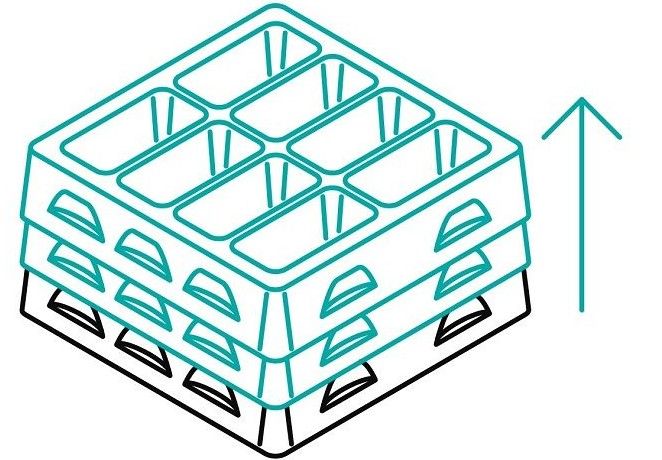

Stacking technology

Workpiece carriers are stackable. They can be stacked on top of each other effortlessly and stably without external aids. Various stacking techniques are available, including undercut or dimple stacking, which can be flexibly adapted to your transport and handling requirements.

It is important to consider the following aspects in the design:

- The sensitivity of the parts

- The desired number of layers

- The maximum height of the packaging unit

The deep-drawn workpiece carriers can be designed so that they can be stacked free-standing on Euro pallets or integrated into cartons or small load carriers. The stacking is adapted to the palletising system used and also includes an anti-twist device for stacking protection. You can find even more information on stacking techniques in our blog.

Adaptation to conveyor systems

Conveyor belt systems are used in the form of roller conveyors, belt conveyors and floor conveyors. The underside of your workpiece carrier is designed according to the requirements of your transport system.

Ergonomic handling

Ergonomically designed recessed grips on the sides of the workpiece carriers facilitate ergonomic loading of the trays in the KLT or outer carton. This means that the trays can be easily gripped, held, carried, removed from the carton or placed back into the carton.

It is advisable to consider the size and position of the handles on the workpiece carrier at an early stage, as this also influences the shape of the nests and the stacking.

Why plastic workpiece trays? The advantages

Workpiece carriers can be made of various materials, including plastic or metal. Plastic carriers are lighter and easier to handle than conventional metal cleaning baskets. The plastic material of the workpiece carriers therefore makes handling easier and, due to the plastic properties, promotes gentle handling of the sensitive workpieces.

Depending on the area of application, plastic workpiece carriers are usually made of materials such as PET-A, PS or ABS. Plastic trays often have special properties such as

- ESD protection

- resistance to chemicals

- or integration into cleaning processes.

The service life (disposable or reusable, over months or years) of the load carrier influences the design of the workpiece carrier. Thanks to variable material thicknesses, plastic pallets can be designed to be either very stable, durable and resilient for reusable use as returnable packaging.

This is achieved through increased material thicknesses and stabilising elements such as ribbing and struts. Alternatively, plastic workpiece carriers can be designed for single-use in an extremely material-saving and cost-effective way.

Areas of application for plastic workpiece carriers

Find out more about the areas of application for plastic workpiece carriers:

- ESD workpiece carriers for electronics

- Tray with colour stripes

- Workpiece carrier for automotive

- Tray packaging for metal parts

Workpiece carriers enable efficient processes - A summary

In the world of manufacturing, workpiece carriers are indispensable aids that ensure the smooth running of production processes. From fixing and positioning to protection against damage, they fulfil various functions to optimise the quality of the end products and increase efficiency.

Do you need workpiece carriers or thermoformed plastic packaging for your components? Then configure your plastic tray now!