Description

PET-G stands for Polyethylene Terephthalate Glycol and is a modified PET plastic known for its exceptional formability and transparency during thermoforming. Due to these properties, PET-G is often used for visible components and high-gloss blister packaging. However, its lack of UV resistance prevents its use in outdoor applications.

Processing and Thermoformability

The "G" in PET-G stands for glycol, which is added during polymerization to prevent crystallization under heat. This ensures that when PET-G film is heated in a thermoforming machine, it remains crystal clear even at high forming temperatures. This makes PET-G a plastic with maximum transparency, ideal for visible parts. Compared to PET-A, PET-G has better low-temperature performance. Glycol also enhances its thermoforming properties, making PET-G a preferred choice when ABS is insufficient. It enables highly detailed contours and sharp edges in thermoformed parts.

Material Options

Sealability

Sealability Weldable

Weldable Sterilizable

Sterilizable Printable

PrintableFacts

Price

Colors

Features

- Maximum transparency

- Good stretchability

- Very sharp contours possible

- Resistant to: oils, salts, acids

- More cost-effective than ABS, PC, PMMA for visible parts

Weaknesses

- No UV resistance

- Very low impact strength

- Highly brittle

- High density (heavy weight)

- Fluctuating market availability

- Long procurement time

Common Industries and Applications:

Automotive

- Flange covers

- Interior paneling

- Engine covers

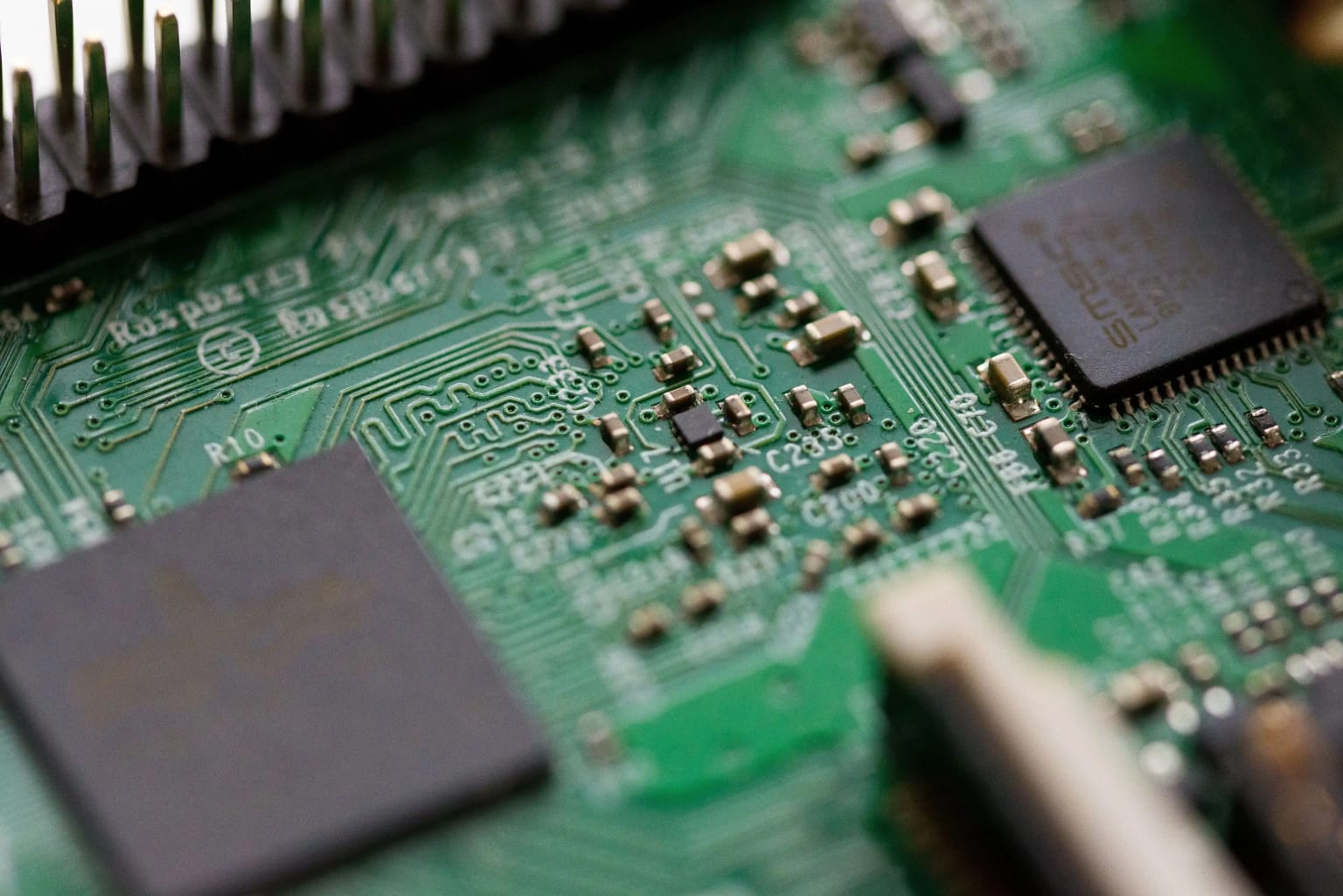

Electronics

- Electronic blisters

- Display protection

- Protective films for busbar mounting

Medical Technology

- Medical blister inserts

- Blister trays

- Slide blisters

Consumer Goods

- Protective covers

Mechanical Engineering

- Containers

- Plastic housings

- Thermoformed sleeves

- Outer casings

Facts and Figures:

| Group | Standard Thermoplastics |

| Structure | Semi-Crystalline |

| Density | 1.27 |

| Continuous Use Temperature Min. (in °C) | -40 |

| Continuous Use Temperature Max. (in °C) | 63 |

| Max. Temp. Short-Term (°C) | 70 |

| Max. Temp. Long-Term (°C) | 65 |

| Impact Strength (KJ/m^2) | 10 |

| Abrasion Resistance | - |

| Tensile Strength (N/mm²) | 50 |

| Tensile Modulus of Elasticity (N/mm²) | 1720 |

| Elongation at Break (%) | 54 |

| Flexural Strength (N/mm²) | 70 |

| Ball Indentation Hardness (N/mm²) | 97 |

| Dielectric Strength (kV/mm) | 16 |

| Volume Resistivity (Ω · m) | >10^15 |

| Surface Resistivity (Ω) | > 10^16 |

Additional Plastics in the formary Portfolio

Frequently asked questions about PET-G plastic

PET-G stands for polyethylene terephthalate glycol-modified and is a modified PET material. The addition of glycol ensures that PET-G remains crystal clear when heated and can be deep-drawn with particular precision. The plastic is known for its maximum transparency and sharp contours. Ideal for visible parts, displays and blister packaging.