Load Carriers for the Automotive Industry

Plastic load carriers for transport systems, automated handling and optimized production in the automotive industry.

Load Carriers for the Automotive Industry: Optimal Transport and Automated Handling

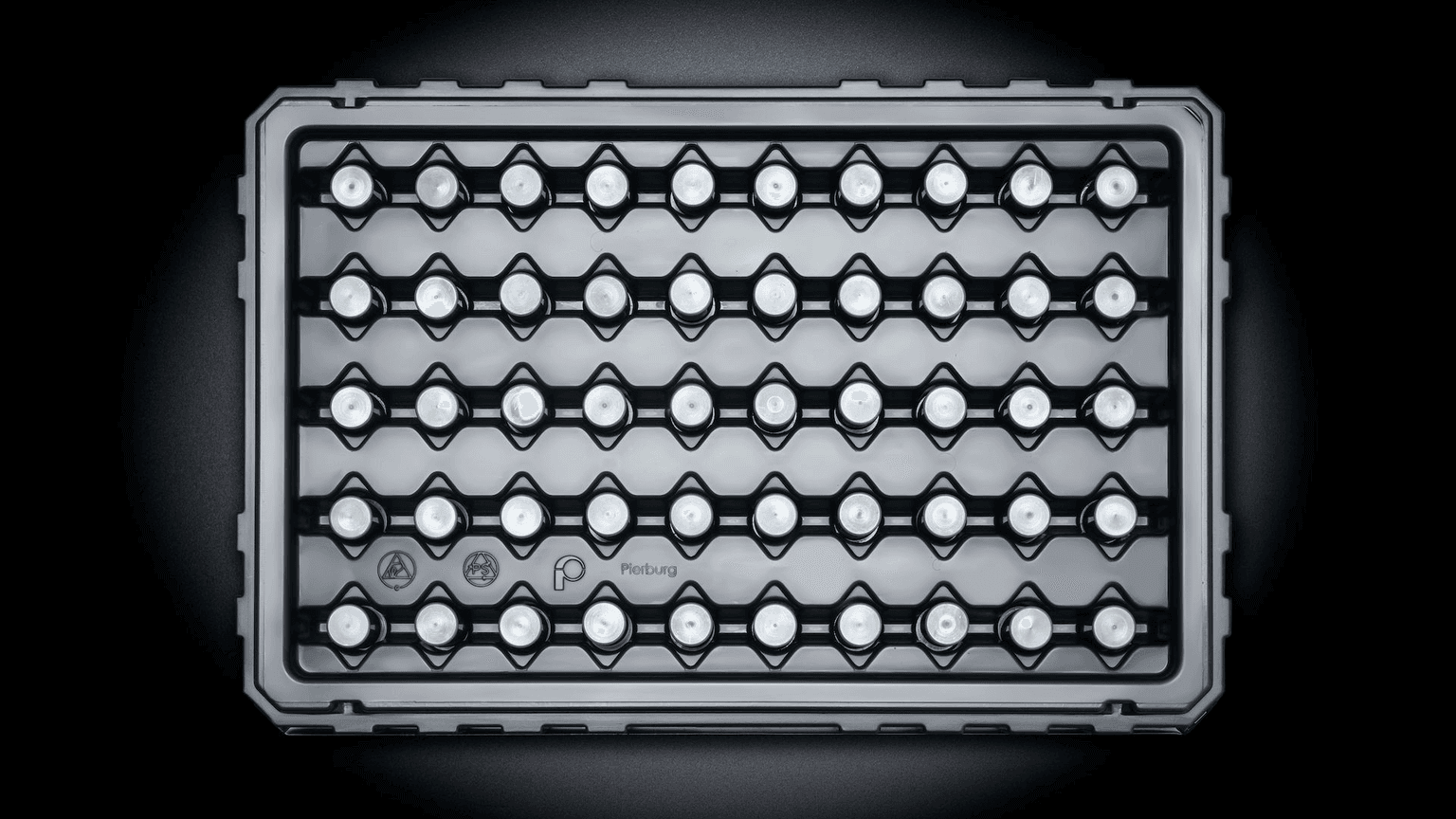

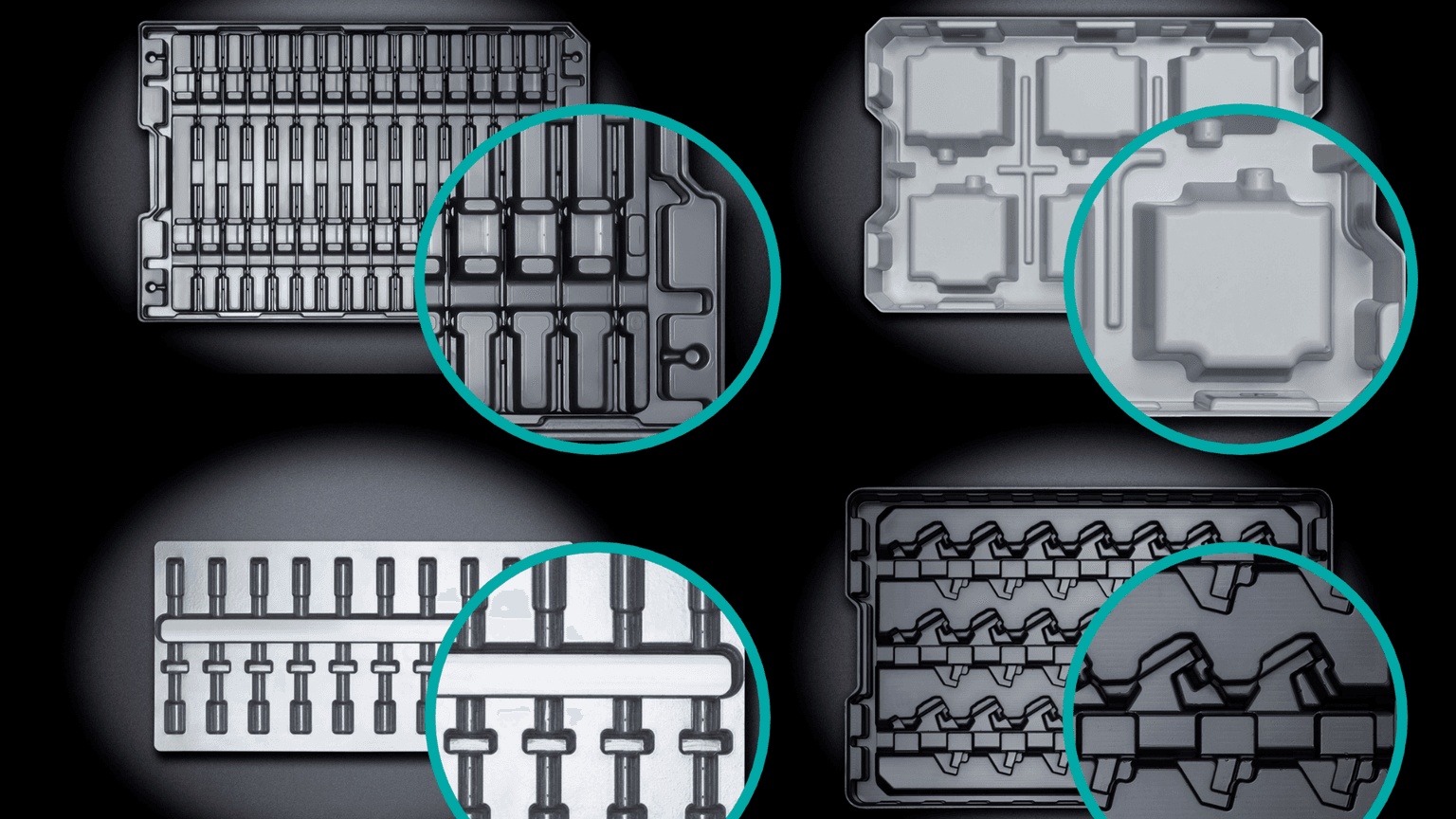

Thermoformed trays and load carriers for the automotive industry are key components for the smooth flow of materials. Automotive load carriers for the automotive industry feature precision molded inserts or receptacles that keep components stable and protected for automotive OEMs and suppliers to prevent damage during transport and storage. Automotive load carriers in production also enable manual and automated handling on production lines at automotive suppliers. Each load carrier for the automotive industry is individually manufactured, resulting in a customized solution for every need.

What is a load carrier used for?

Workpiece carriers in the automotive sector are used to securely fix components in place.

This also applies to automated handling with robots, conveyor belts or palletisers. Load carriers optimise packing density, prevent damage and ensure that processes in the supply chain of automotive OEMs and suppliers run smoothly.

Use of Load Carriers in the Automotive Industry

Plastic Load Carriers for Efficient Handling

Recessed grips for plastic load carriers in the automotive industry facilitate easy removal, support the loading of trays and offer customized solutions for manual and automated handling.

Load Carriers Ensure Stability in Logistics

Specially designed thermoformed trays for automotive applications ensure the safe stacking of automotive components and assemblies. The precisely fitting component nests and precisely adapted undersides of the load carriers for the automotive industry offer stability.

Plastic Load Carriers for Safe Transportation

Plastic automotive load carriers and inserts are specially developed to hold automotive components in the load carrier transport system in a space-saving, safe and sorted manner. Precisely fitting fixtures minimize damage during transport to and from automotive suppliers.

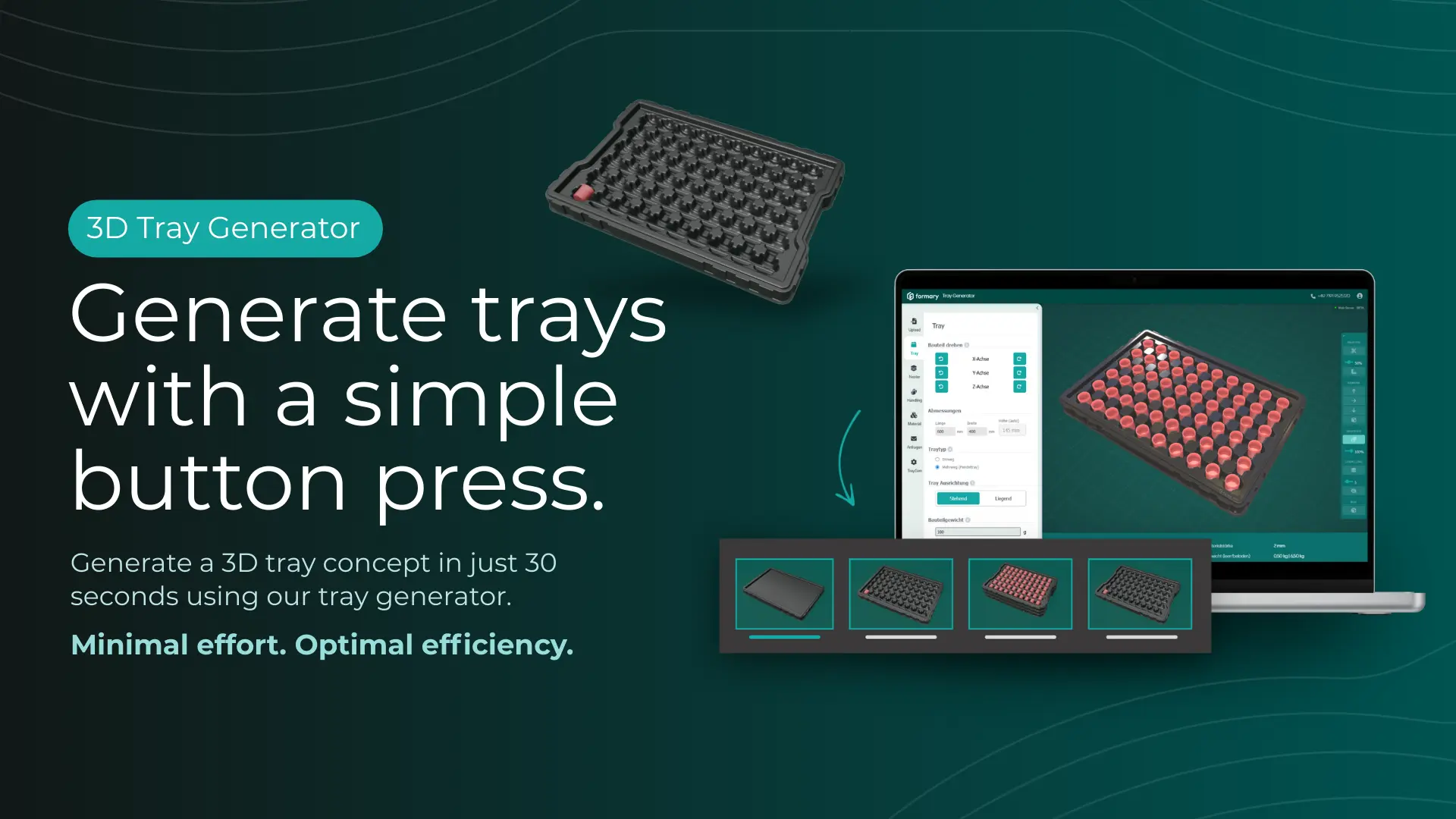

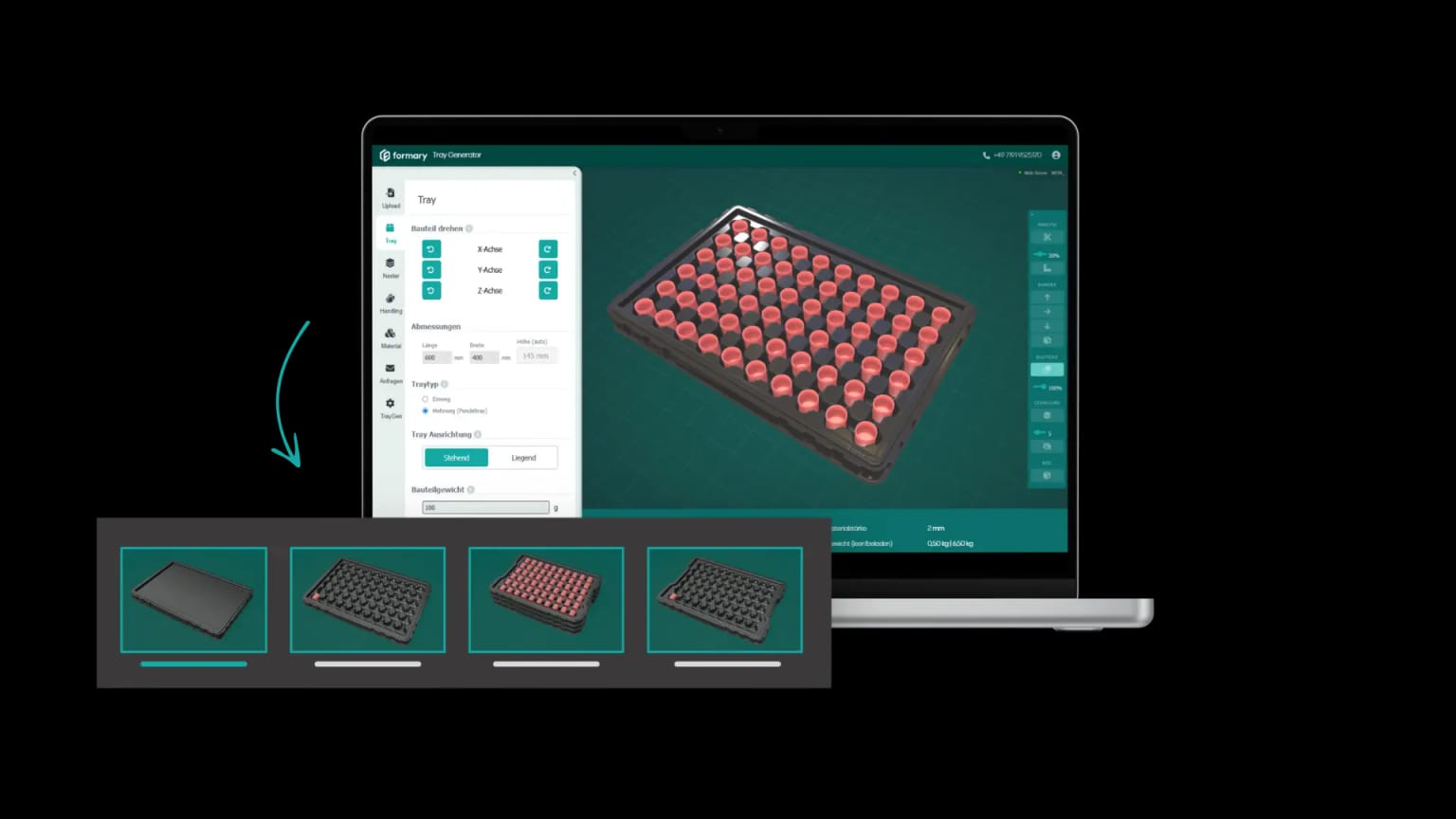

Smart development: 3D Tray Generator

Do you have a CAD model of a component for which your load carrier is to be designed?

With our 3D Tray Generator, you can upload it directly and receive a suitable 3D model of the load carrier in seconds, including a realistic 3D preview.

Areas of Use for Load Carriers for the Automotive Industry

Automotive

- Trays for engine components

- Trays for circuit boards

- Trays for pistons and pins

- Trays with ESD protection

- Trays for components

- Trays for spark plugsBattery trays

- Module trays Trays

- Trays for crankshafts

- Component carriers for cylinders

- Component carriers for brakes

- Control unitsTray for fuel injectors

- Tray for automotive parts

- Spare parts automotive

- Trays for pistons

- Component carriers for automotive turned parts

- Automotive cold extruded parts Tray

- Automotive precision parts Tray

- Component carriers for automotive injection molded parts

- Automotive stamped parts Tray

- Component carriers for automotive exterior

- Assemblies for automotive industry Trays

- Component carriers for automotive interior

Advantages of Load Carriers for the Automotive Industry

Optimized Packing Density

Thanks to component-specific holders, plastic workpiece carriers for the automotive industry not only provide a secure fit, but also enable a high packing density within the transport packaging.

Customized Solutions

Plastic load carriers for the automotive industry are highly versatile and can be flexibly adapted to both manual operations and automated production and assembly processes.

Secure Stacking

With precisely fitting component nests and accurately shaped undersides, load carriers for the automotive industry offer not only stability but also function as both base and lid.

Automated Handling

Due to their precise shaping and stable frame constructions, load carriers in the automotive industry are ideal for integration into automated production lines.

Damage Reduction

Plastic load carriers for the automotive industry prevent components from colliding or shifting, thereby minimizing damage during storage and transport.

Secure Transport

Load carriers for the automotive industry ensure safe transport of components and parts by protecting them from damage and displacement.

Suitable materials for automotive load carriers

Applications of Load Carriers in the Automotive Industry

Load Carriers for Transport and Storage Logistics

Thermoformed trays optimize logistical processes in the automotive industry as smart packaging solutions. Load carriers support the safe and damage-free transport of components from your suppliers or to your end customers.

Stackable plastic load carriers are used flexibly on automation systems and, as returnable packaging, ensure sustainable transport logistics. Sensitive components can be securely fixed and locked in form-fitting cavities of the load carriers for the automotive industry using precise seating and clamping mechanisms.

Plastic Load Carriers for Optimized Processes

Automotive load carrier systems are used for automated handling of your products in automotive production environments. The plastic load carriers are designed to optimally support the different processing stages. The use of robots, conveyor belts, and palletizers requires the load carrier to meet special tolerance requirements and to be specifically developed for its intended use.