Plastic Trays with Color Stripes

Plastic trays with colored stripes for efficient storage, quick identification, and error-free logistics

What are Plastic Trays With Color Stripes and What are They Used for?

Plastic trays with color stripes are stackable workpiece carriers or transport trays made of sturdy plastic that feature clearly visible color markings. The color coding is not only for visual design purposes, but above all for clear product identification in warehousing, production, and logistics. They enable faster assignment of components, reduce search times, and minimize handling errors, both in manual processes and in fully automated processes with scanners or robots.

Plastic Trays: The Use of Plastic Trays with Color Coding

Quick Identification

The clear color coding on plastic trays enables faster and more accurate identification of products, which optimizes work processes and minimizes search times.

Error Reduction

The visual differentiation of products by means of colored stripes minimizes errors in manual handling as well as in automation by scanners. This leads to greater accuracy and quality control.

Resilience

Plastic trays are resistant to moisture, chemicals, and other environmental influences, which increases their durability and extends their service life.

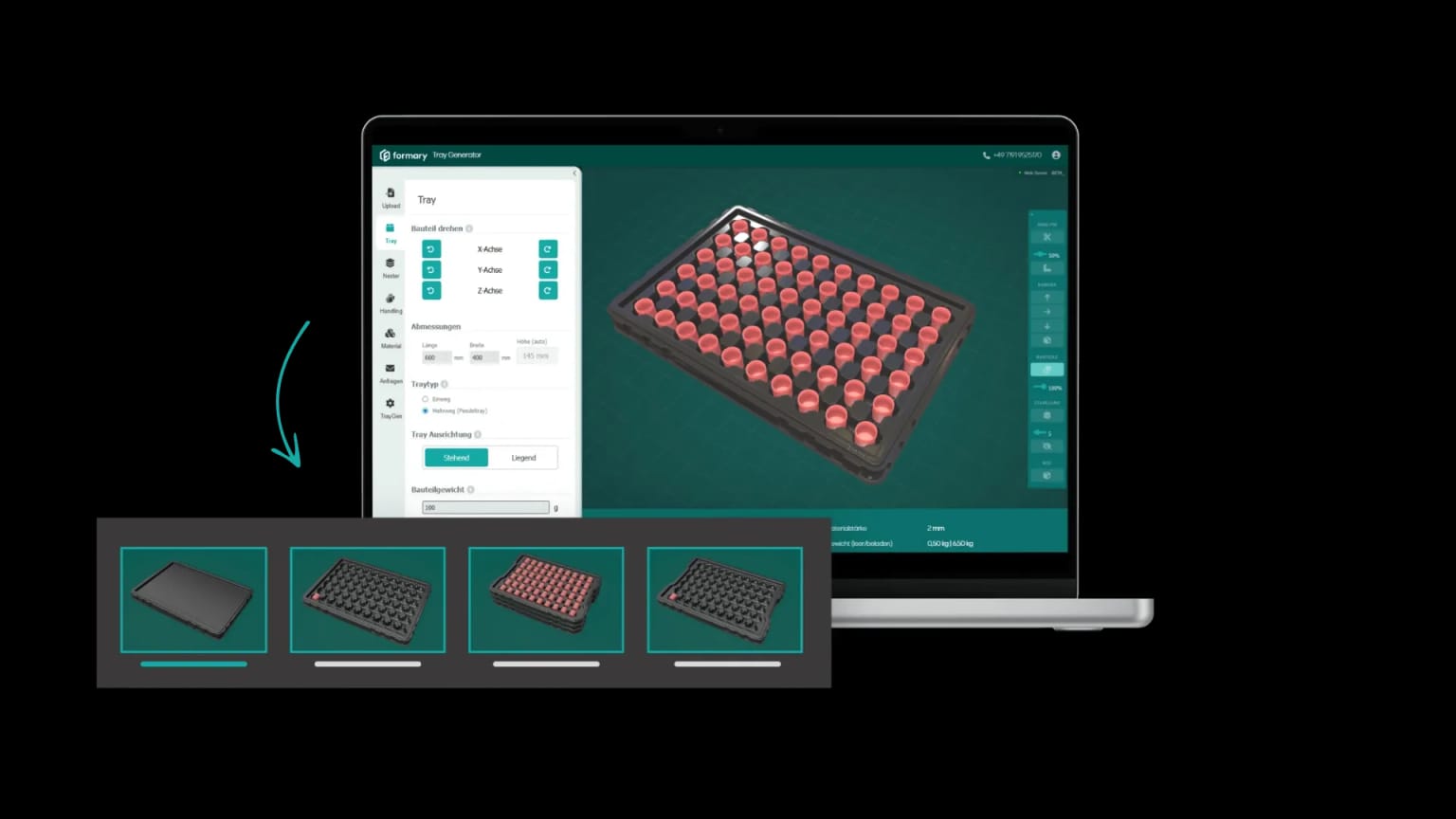

Smart Tray Development for Your Plastic trays are resistant to moisture, chemicals, and other environmental influences, which increases their durability and extends their service life.

Do you have a Component and want to know what a Custom-fit Plastic Tray for it might look like?

Upload the CAD-Model of your component to our 3D Tray Generator and receive a suitable 3D-Model of your plastic tray within seconds. This allows you to see what your tray could look like with colour coding before it is manufactured.

Areas of Application for Trays with Colored Stripes

Industrial Solutions

- Transport containers

- Reusable trays

- Transport boxes

- Workpiece carriers for light components

- Transport trays for small parts

- Traceable load carriers

- Identifiable transport containers

- Mandatory identification load carriers

- Traceable logistics containers

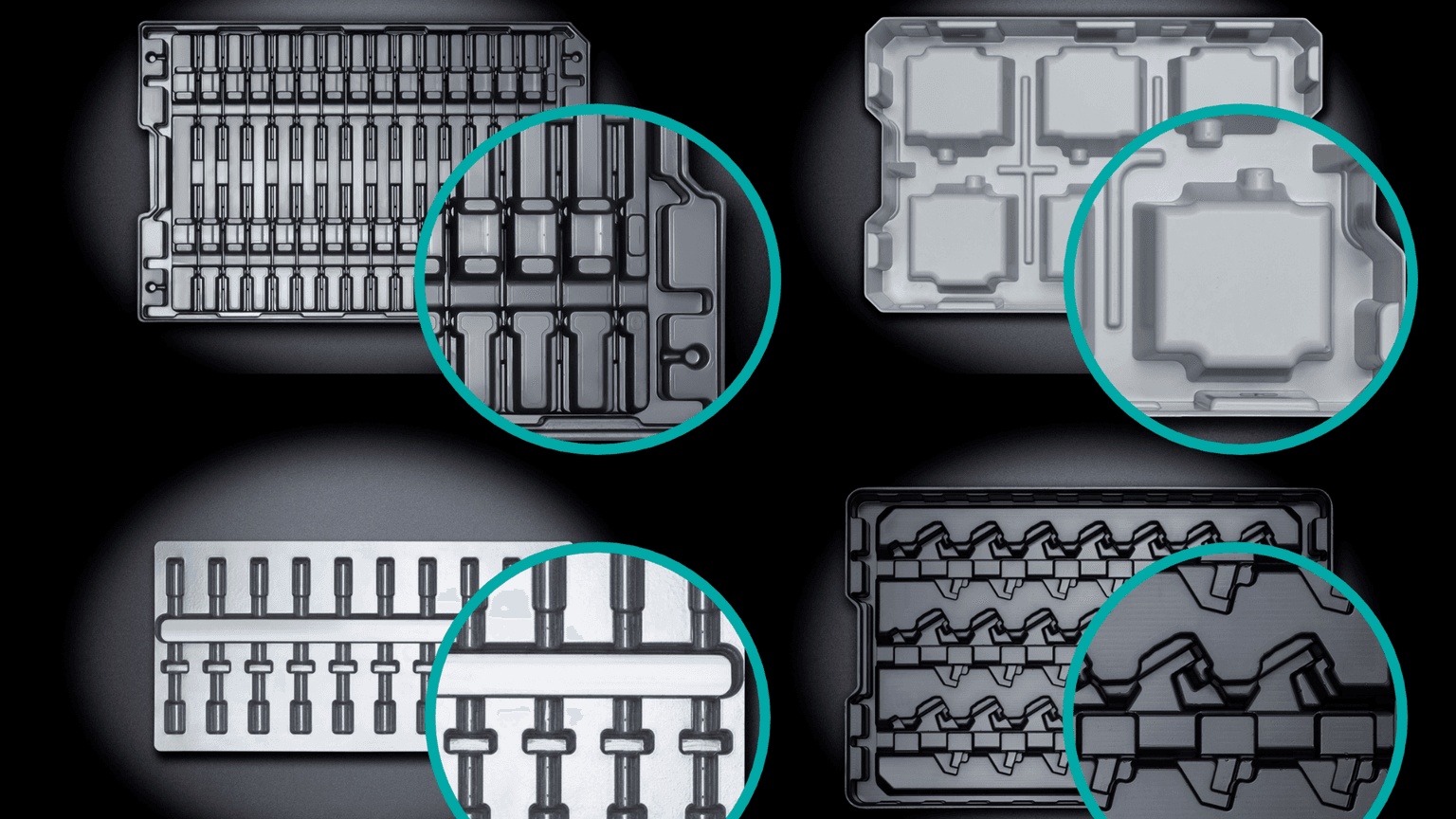

Mechanical Engineering

- Automation trays

- Workpiece carriers

- Trays with color stripes for components

- Trays for circuit boards

- Trays for metal parts

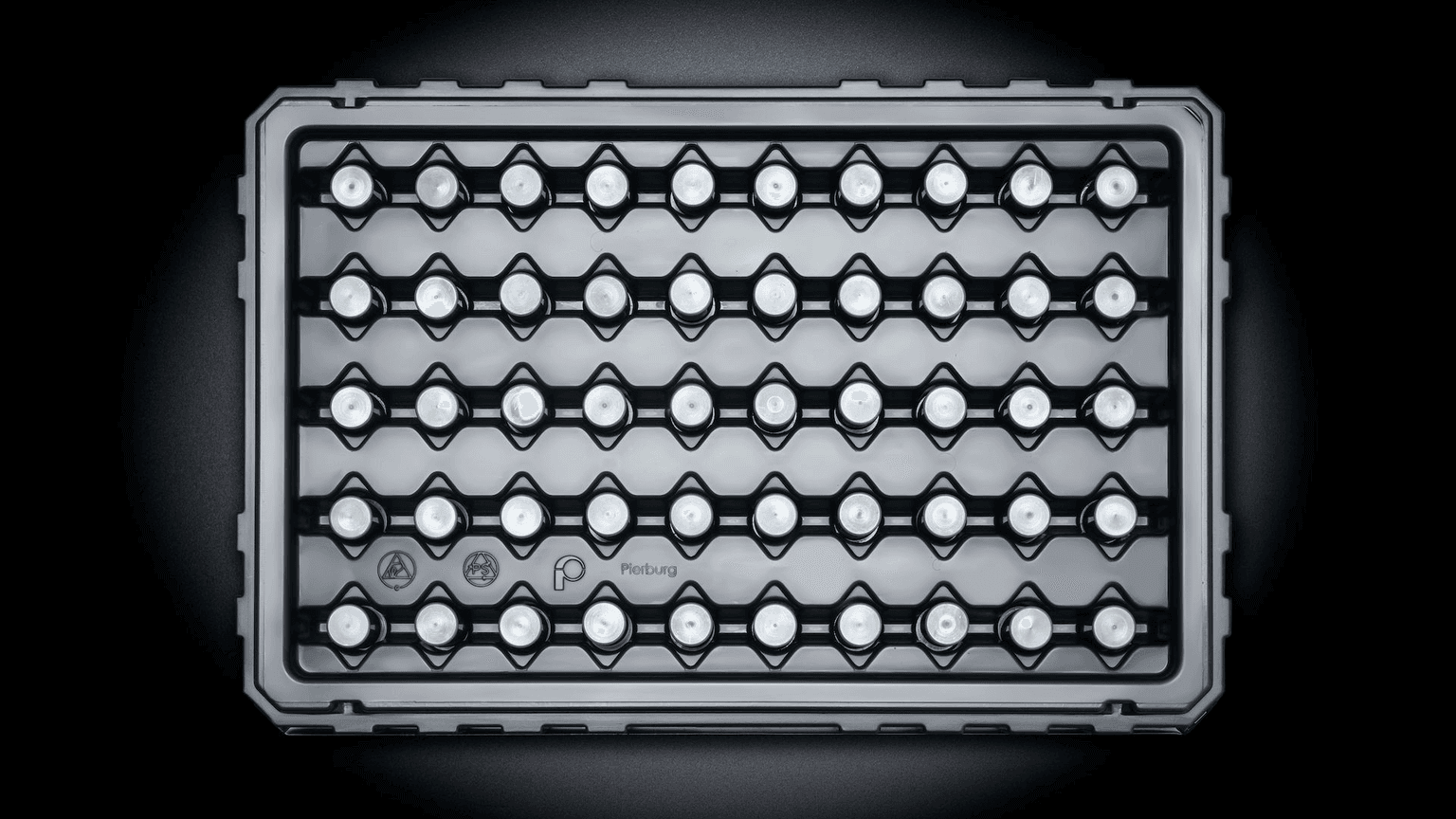

- Trays for valves

- Mandatory identification load carriers

- Load carriers for component Identification

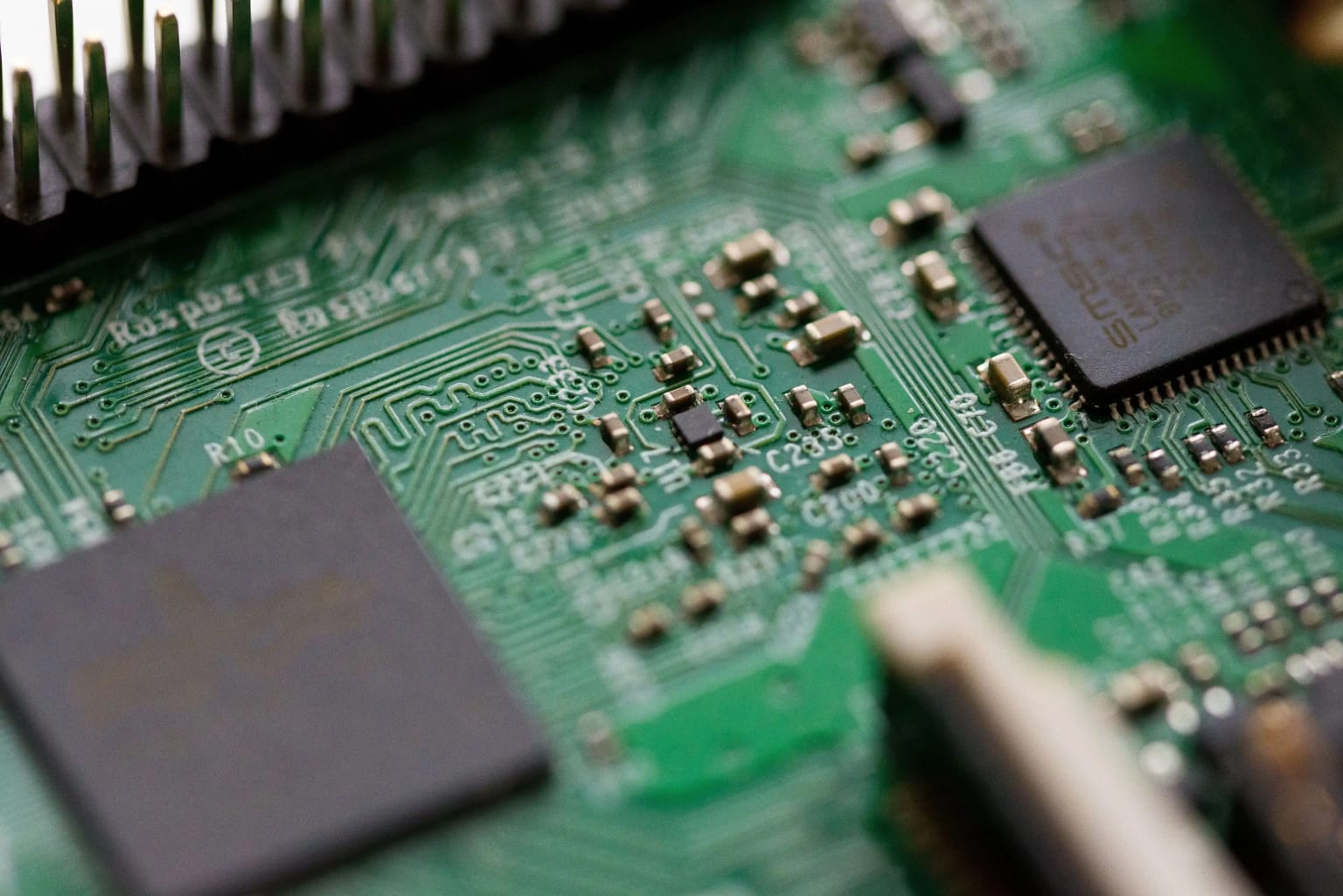

Electronics

- Battery tray

- Tray for electronic components

- Tray for acoustic filters

- Tray for ceramic measuring cells

- Tray for circuit boards

- Tray for solar cells

Advantages of Plastic Trays with Color Coding

Efficient Storage

Plastic trays with color coding make product identification easier, resulting in more efficient storage and logistics processes.

Temperature Resistance

Plastic trays maintain their properties at extreme temperatures, making them suitable for use in various industrial environments.

Process Optimization

The visual color coding of plastic trays can be used to mark specific workflows, enabling improved process optimization.

Suitable Materials for Plastic Trays With Coloured Stripes

Applications of Plastic Trays with Color Stripes

Color-Coded Plastic Trays in Logistics and Warehousing

Plastic trays with color coding are especially suitable for logistical processes. Color-coded workpiece carriers optimize product identification, simplify storage, and promote efficient transport in the logistics industry.

Plastic Trays with Color Coding in the Automotive Industry

Plastic trays with color stripes are used in the automotive industry to organize small parts and assemblies, helping to facilitate the assembly process.

Other Plastic Trays that May be of Interest to You

Industries that use Trays with Color Stripes

FAQ – Frequently Asked Questions About Plastic Trays With Coloured Stripes

A plastic tray with colour stripes is a sturdy plastic workpiece carrier with integrated colour marking for identifying and organising components.

How to quickly find the right Tray Solution

Deepen your knowledge of material selection, manufacturing, color coding, and applications for plastic trays. Our free white paper provides valuable insights, best practices, and checklists for selecting and designing the optimal transport and storage solution.

Whitepaper: Plastic Trays for Transport and Storage

Free Whitepaper download