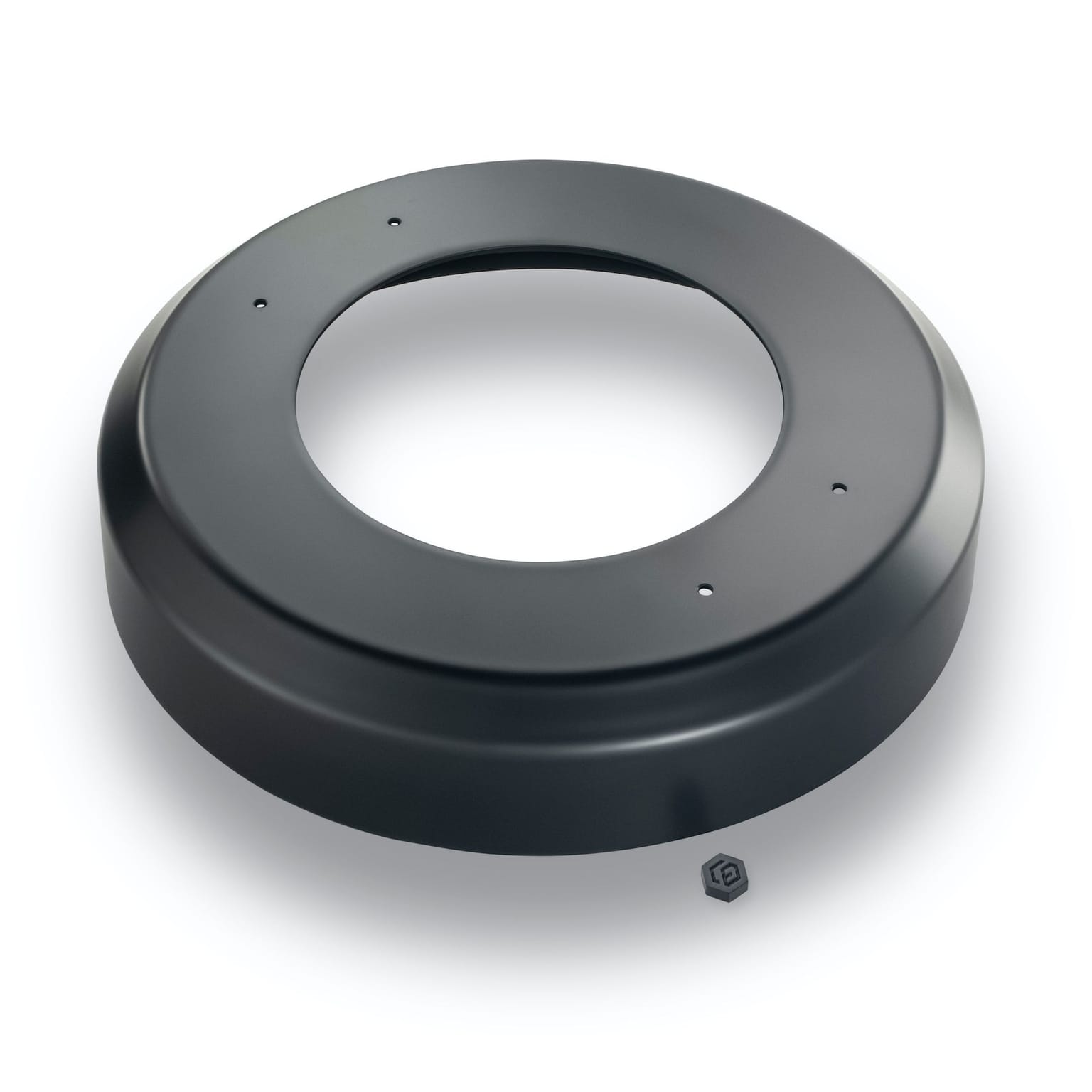

Plastic Covers and Enclosures

Protect, enclose, and enhance your components with custom plastic covers. Whether rectangular, round, transparent, white, or made to measure, we develop plastic covers, housings, and protective hoods that are functional, durable, and visually high-quality.

What is a plastic cover?

A plastic cover is a thermoformed component that protects and encloses machines, devices, or products. It can be designed as a protective hood, plastic housing, or plastic lid—rectangular or round, large or small. Since plastic covers are often visible components, surface finish, color, and aesthetics play an important role. Custom cut-outs, holes, or ventilation slots can be easily integrated.

Why use a plastic cover?

A plastic cover reliably protects components from dust, dirt, liquids, and mechanical impact. It conceals cables or electronics and ensures a clean, professional appearance.

Compared to metal, plastic covers and housings are:

- lighter and easier to install

- more cost-effective to manufacture, even in small quantities

- ore flexible in shape, color, and size

- impact-absorbing and noise-dampening

- resistant to chemicals and corrosion

- ESD-safe when using suitable plastics and additives

→ Learn more in our blog: Plastic vs. metal

Advantages of Plastic Covers

Complex Geometries

Plastic covers allow for complex shapes and geometries to be created without high tooling costs or large initial investments.

Cost-Effective Process

Thermoforming offers a cost-effective production method, even for small quantities of plastic covers, making it a great alternative to more expensive methods like injection molding.

Quick Delivery

Plastic covers can be processed with a fast time-to-market, offering quicker delivery compared to injection molding.

Custom Enclosures

Custom enclosures can be designed with machined cuts for openings, slots, and holes, tailored to your specific needs.

Plastic Assemblies

Plastic covers can also integrate assembly options, such as embedding fasteners, which allows for further customization and functionality.

Large, Stable Empty Housings

Thermoforming allows the creation of large, stable empty housings, with forming surfaces up to 3,460 x 2,260 mm.

High Quality

Thermoforming offers high-quality plastic covers, with reproducibility and process security that ensures consistent results without warping.

Specific Plastic Properties

The material selection for plastic covers can be optimized for specific properties, such as UV resistance, chemical resistance, and flame retardancy.

Transparent or Colored

Plastic covers can be made transparent (e.g., using Plexiglas for high transparency) or colored, with the option of using colored plastic films or sheets.

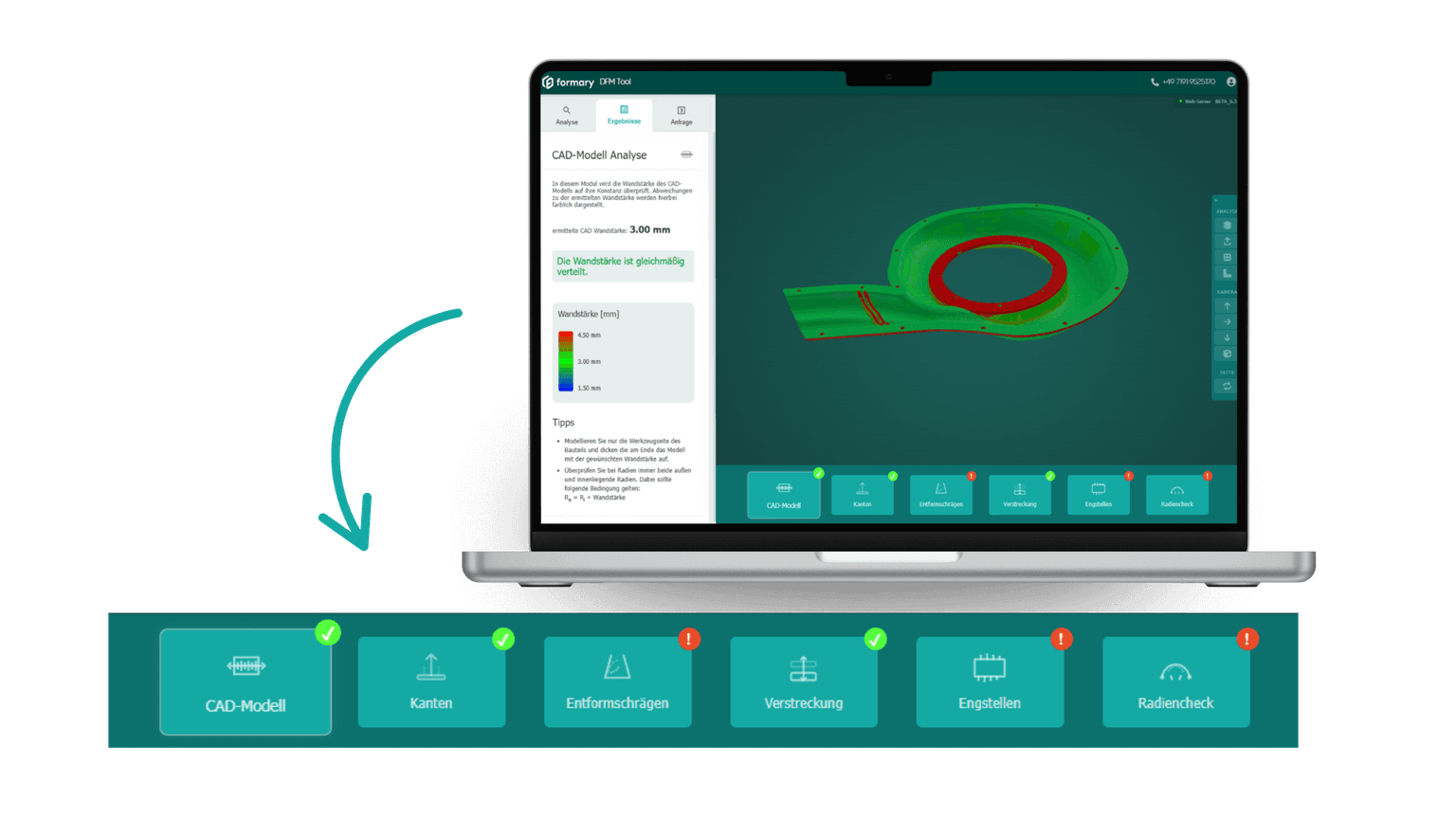

Do you already have a CAD model of your thermoformed housing?

Run the thermoforming check now!

Using our DfM analysis, we review your CAD data for wall thickness distribution, draft angles, radii, and other criteria to ensure the technical feasibility of your thermoformed container. Simply book a free demo and we’ll be happy to go through your data with you.

How you benefit from DfM for plastic covers

Weight Reduction

Save material by using thinner wall thicknesses for plastic covers and housings.

Cost-Effective and Better Recycling

Substitute steel or fiberglass with plastic covers to reduce costs and improve recyclability.

Higher Product Quality

Scratch-free surfaces and special material properties make the plastic covers high-quality and durable.

Longer Durability

Material selection ensures plastic housings and covers can withstand outdoor environments, offering extended resistance.

Assembly Creation

Create plastic assemblies by incorporating connection techniques into your plastic covers, enclosures, and housings.

Process Reliability

Ensure reliability and repeatability, even with large parts, thanks to our consistent manufacturing processes.

Easier Cleaning

Typical features of thermoformed plastic covers make them easier to clean and maintain.

Assemblies & mounting options

Upon request, we manufacture plastic covers as complete assemblies. Multiple thermoformed parts are joined by bonding, screwing, clipping, or sealing. In addition, the following options are available:

- Material Combinations: Incorporation of brass inserts, screws, ball pins, positioning lugs, and other fastening elements to enhance the functionality and strength of the plastic cover.

- Cutouts: Cutouts for handles or additional modules that can be attached to the plastic housing after production, offering flexibility in design and use.

- Premium Appearance: Sophisticated trimming techniques, such as inward-facing edges, provide a refined, high-quality look for the plastic covers, ensuring a professional and aesthetic finish.

Design of plastic covers

Radii

Radii describe the degree of edge rounding. Thermoformed plastic enclosures always require minimum radii to prevent material weakening or cracking.

Draft angles

Draft angles of at least approx. 3° are required for smooth demolding of a plastic cover. The exact angle depends on the material, thickness, and geometry and is defined individually by us.

Standards & dimensional tolerances

As standard, tolerances according to ISO 2768-m apply. If required, tighter tolerances can also be achieved—especially in connection areas that require high precision.

Fit accuracy

Plastic covers must fit precisely with machine interfaces or assemblies. That’s why we place particular emphasis on tolerance windows and functional interfaces.

Appearance & surface

Plastic covers can be designed in solid colors, with color stripes, and with smooth, grained, or textured surfaces. Logos, material markings, or date stamps can also be integrated directly.

Ribs & reinforcements

For short service life, we offer cost-effective lightweight solutions. For long-term use, covers are reinforced with ribs and stiffeners.

Material selection for your plastic covers

UV resistance

For outdoor enclosures, we use UV-stable plastics. This property can be achieved through additives or by selecting materials such as ABS or ASA, which are naturally UV-resistant.

Chemical resistance

For applications involving oils, greases, or cleaning agents, we select materials that offer long-term resistance, even in sensitive environments.

Temperature resistance

In automotive or mechanical engineering applications, plastic covers often have to withstand high temperatures. We select plastics with suitable continuous operating temperatures and resistance to temperature peaks.

Flame retardancy

For applications with fire safety requirements, we offer UL 94–certified, flame-retardant plastics that are self-extinguishing. Ideal for medical technology, mechanical engineering, or transportation applications.

Product Examples of Plastic Covers

Here are several examples of thermoformed plastic covers used in various applications:

Project Process for Your Plastic Cover: From Inquiry to Order

Inquiry

You configure your desired product in our configurator in the desired quantities, material and design.

Review & Offer

We check your data for feasibility and implementation. Then we provide you with an offer within 24 hours. At the same time, we also make suggestions for the data creation of your deep-drawn part as well as useful sampling options.

Data Approval

You approve our data for prototyping or the series tool.

Tool & Sampling

We create your tool and send you series samples for approval.

Series Production

After checking and approving the samples, we start manufacturing your deep-drawn parts.

Shipping

After completion and thorough inspection by our QA team, we will send your series delivery on its way.

FAQ – Frequently asked questions about plastic covers

A plastic cover is a thermoformed part that protects or encloses components. It can be designed as a protective hood, plastic housing, or lid. Also available in round or rectangular shapes, transparent or colored.