Trays for Automotation and Production

Thermoforming trays and workpiece carriers for production systems | Load carriers for robot handling | Thermoforming trays for automated production systems

Customized Thermoformed Trays According to Your Requirements

Thermoforming Trays Made of Plastic

Automation trays are used in modern production systems or assembly lines. The thermoforming trays and plastic workpiece carriers have functions and features that individually support your automation and processes.

Project Process for Thermoformed Trays: From Inquiry to Order

Inquiry

You configure your desired product in our configurator in the desired quantities, material and design.

Review & Offer

We check your data for feasibility and implementation. Then we provide you with an offer within 24 hours. At the same time, we also make suggestions for the data creation of your deep-drawn part as well as useful sampling options.

Data Approval

You approve our data for prototyping or the series tool.

Tool & Sampling

We create your tool and send you series samples for approval.

Series Production

After checking and approving the samples, we start manufacturing your deep-drawn parts.

Shipping

After completion and thorough inspection by our QA team, we will send your series delivery on its way.

What are Thermoforming Trays for Production and Automation?

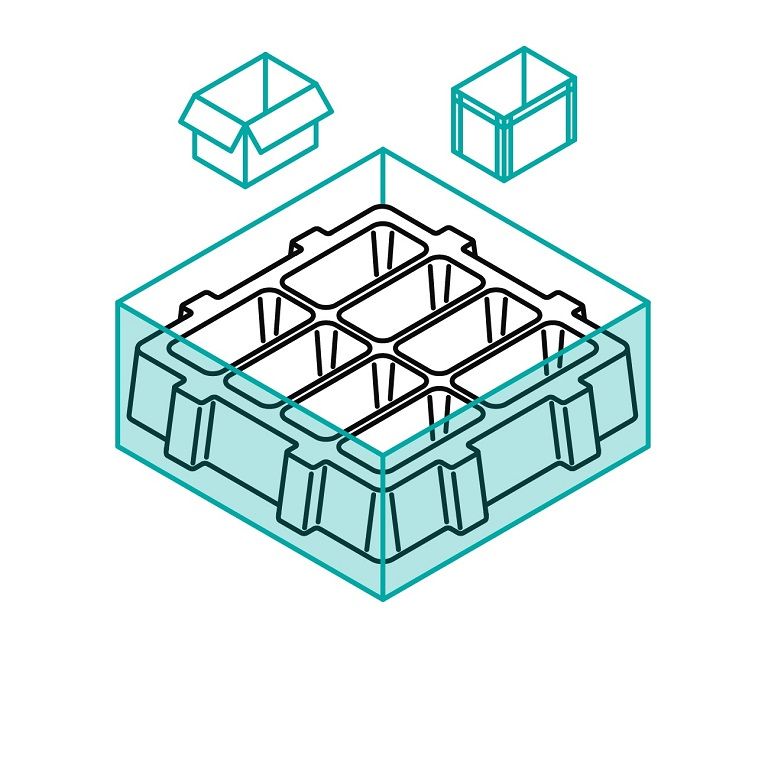

Thermoforming trays made of plastic are used for automated handling of your items in your production system. The aim is to automate production with the help of workpiece carriers.

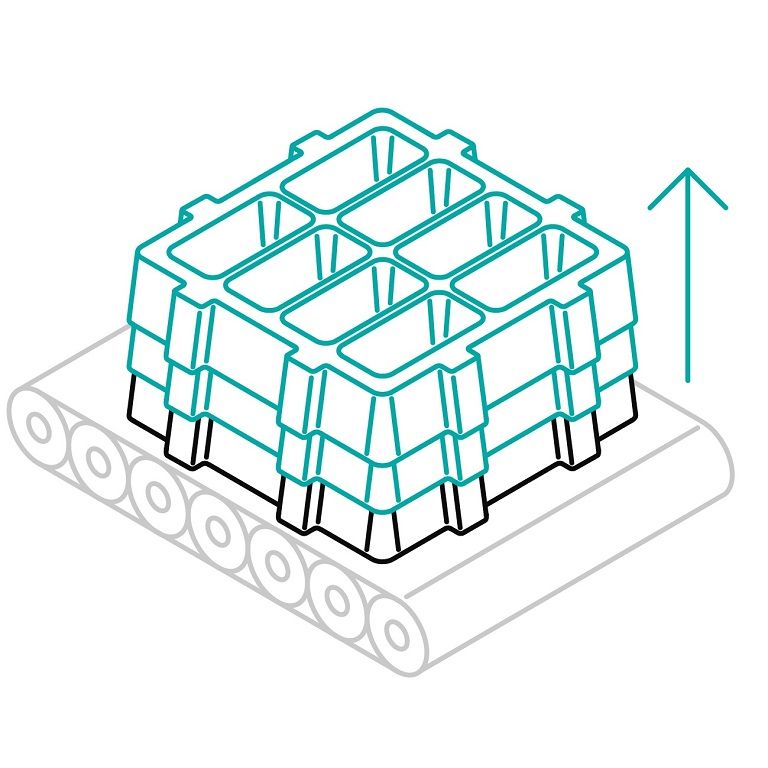

Your products and workpieces can be conveyed automatically using thermoformed trays and workpiece carriers.

Thermoformed trays are usually designed for existing industrial systems. The outer contour, nests and stacking technology of the thermoformed packaging is individually adapted to the conveyor technology. Optical/mechanical coding and positioning elements (poka-yoke) on the workpiece carrier are used for machine handling. Tolerance ranges are defined based on your machine.

In doing so, formary takes into account how your products in the thermoformed packaging will be shipped, transported and stored later. What duration of use, stability, grip systems and mechanical properties of the plastic are required? ABS is often the perfect material for long-term reusable use.

Product Examples of Automation Trays

Here are a number of examples of thermoformed plastic trays that are used in different areas.

Advantages of Automation Trays

Reliable Protection

with thermoforming trays to prevent damage and scratches on your components during transportation.

Improved Manufacturing Process

Optimized process chains through automated transport along the industrial assembly line using thermoform packaging.

Reusable Circulation System

Establish a reusable circulation system using thermoforming trays for your customers, suppliers, and company.

Efficient Design

A design that is perfectly aligned with your automation processes.

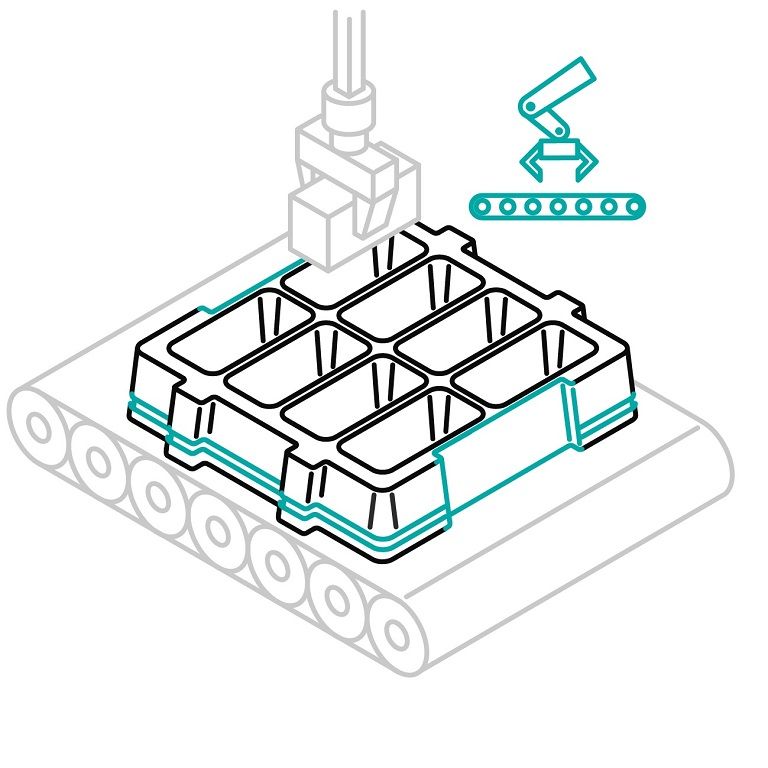

Industrial Robot Handling

With additional elements on the edge and bottom contours of the thermoforming trays.

Automated Stacking & Unstacking

Achieve automated stacking and unstacking of thermoforming trays without jamming, using the correct stacking technique.

Different Component Variants

Cover different component variants and production stages with universal nests in the thermoform packaging.

Specific Material Properties

Utilize specific material properties through careful material selection for your thermoforming tray to automate your production.

Trays for Conveyor Belts/Industrial Robots

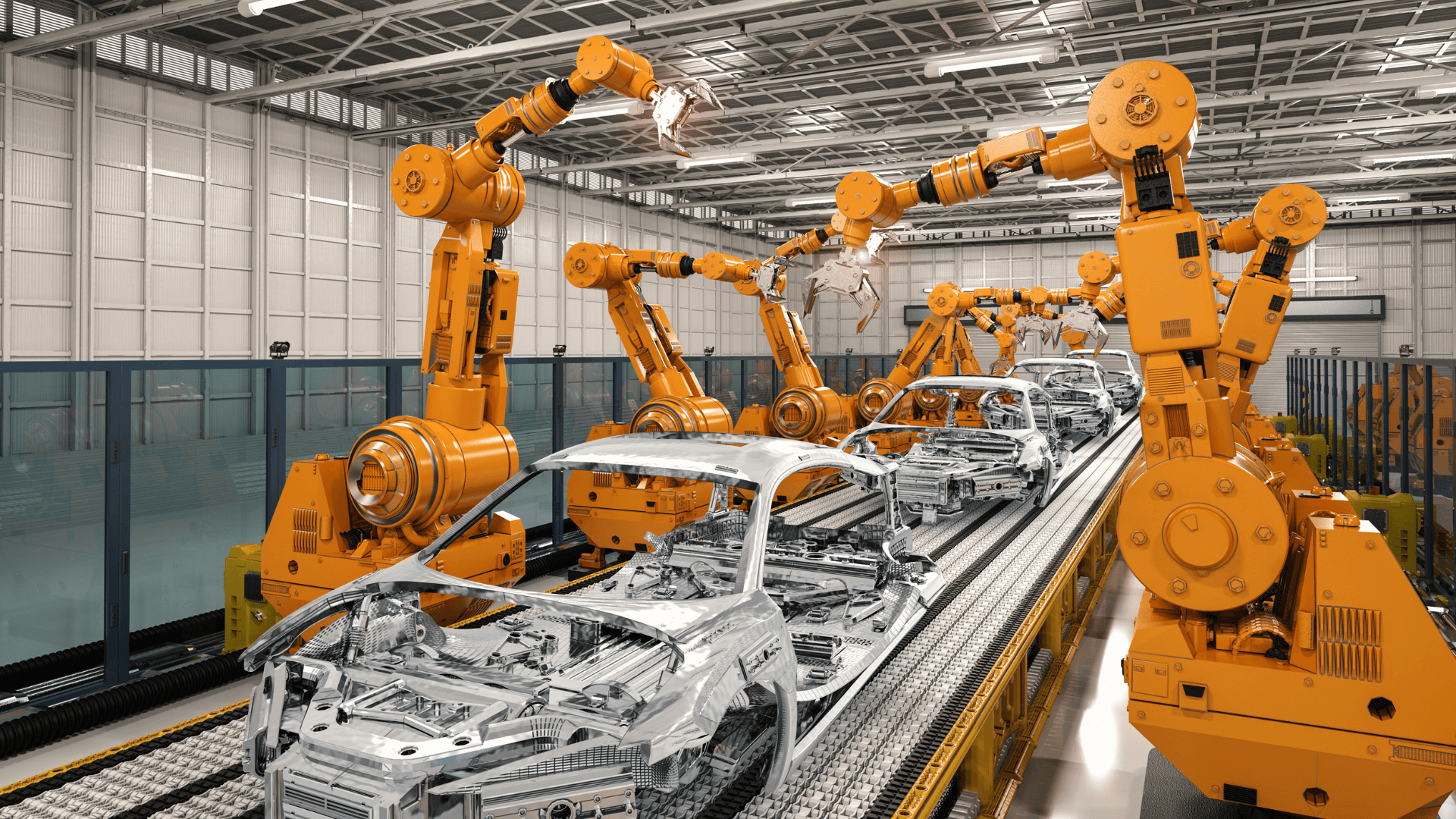

Trays for Automotive Assembly Lines

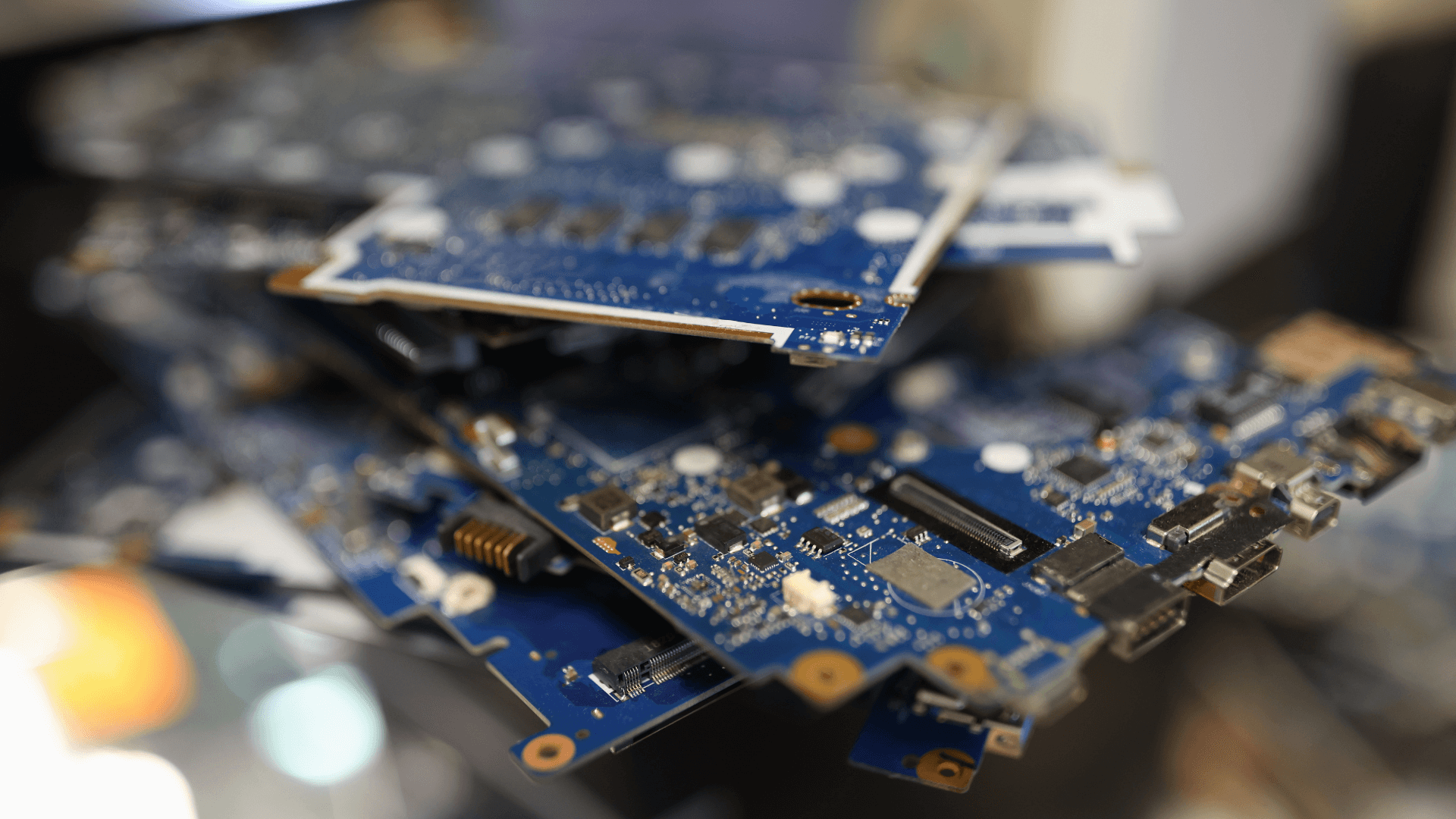

Trays for Electronics Assembly Lines

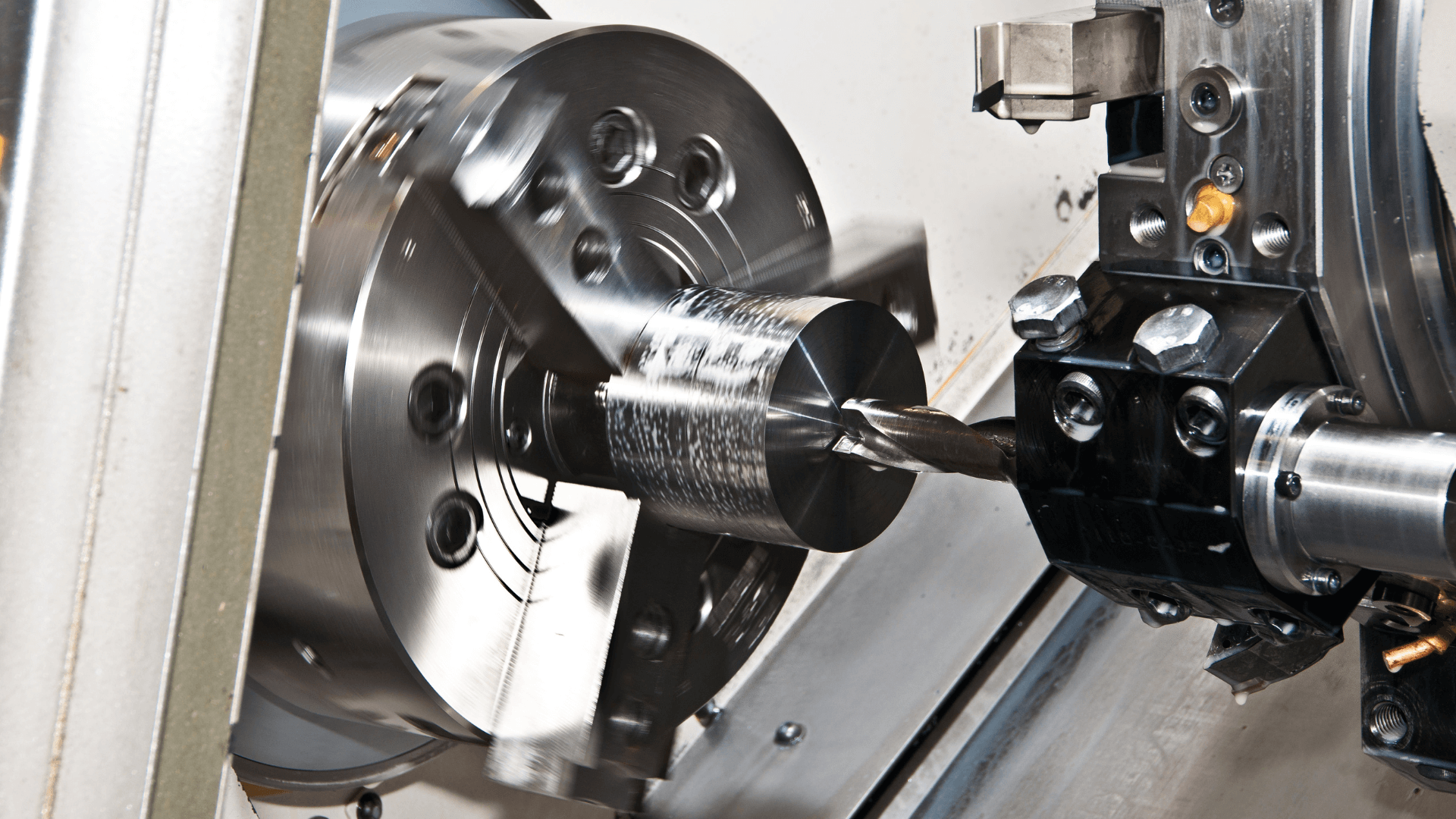

Trays for CNC Lathes

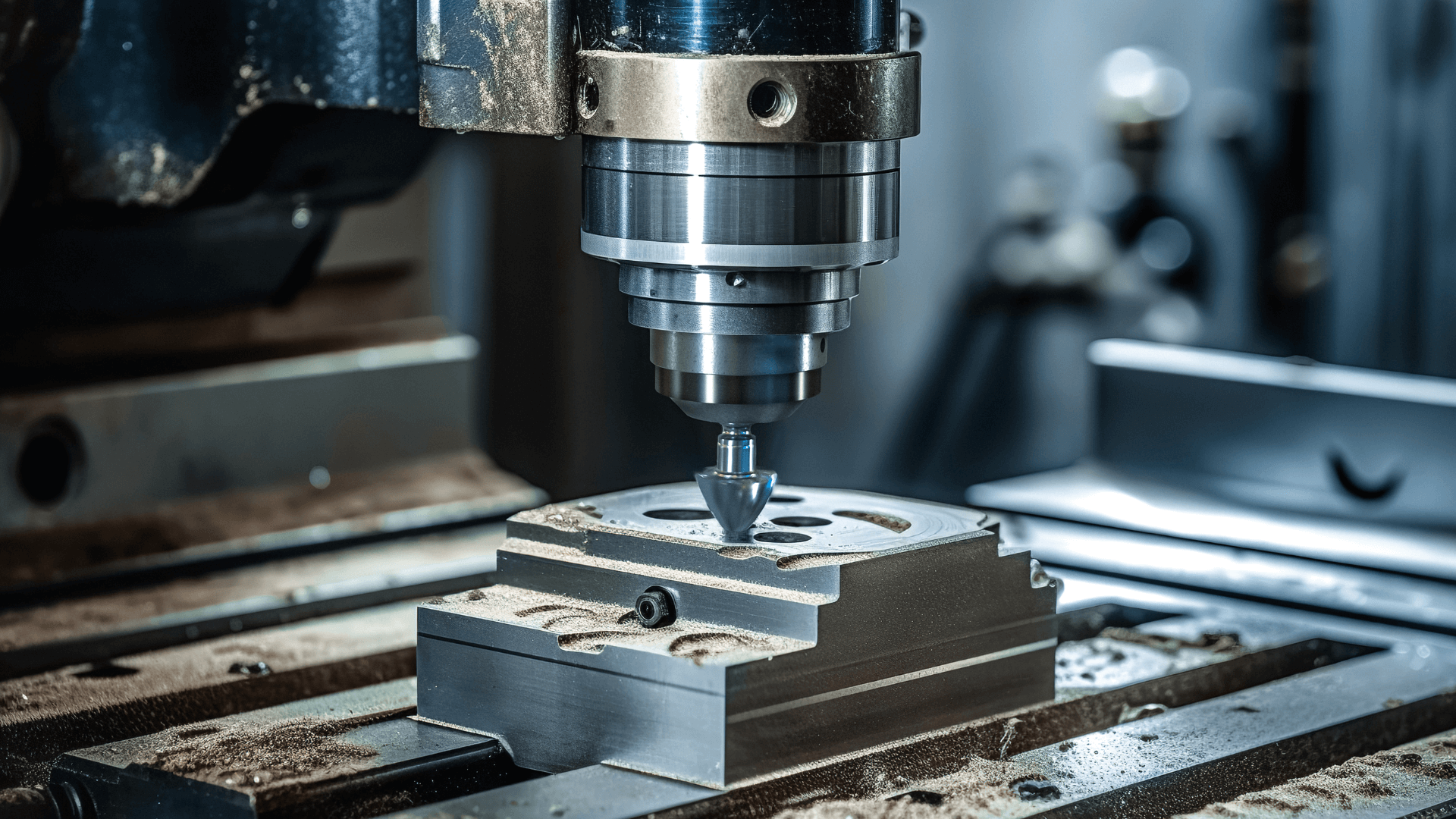

Trays for CNC Milling Machines

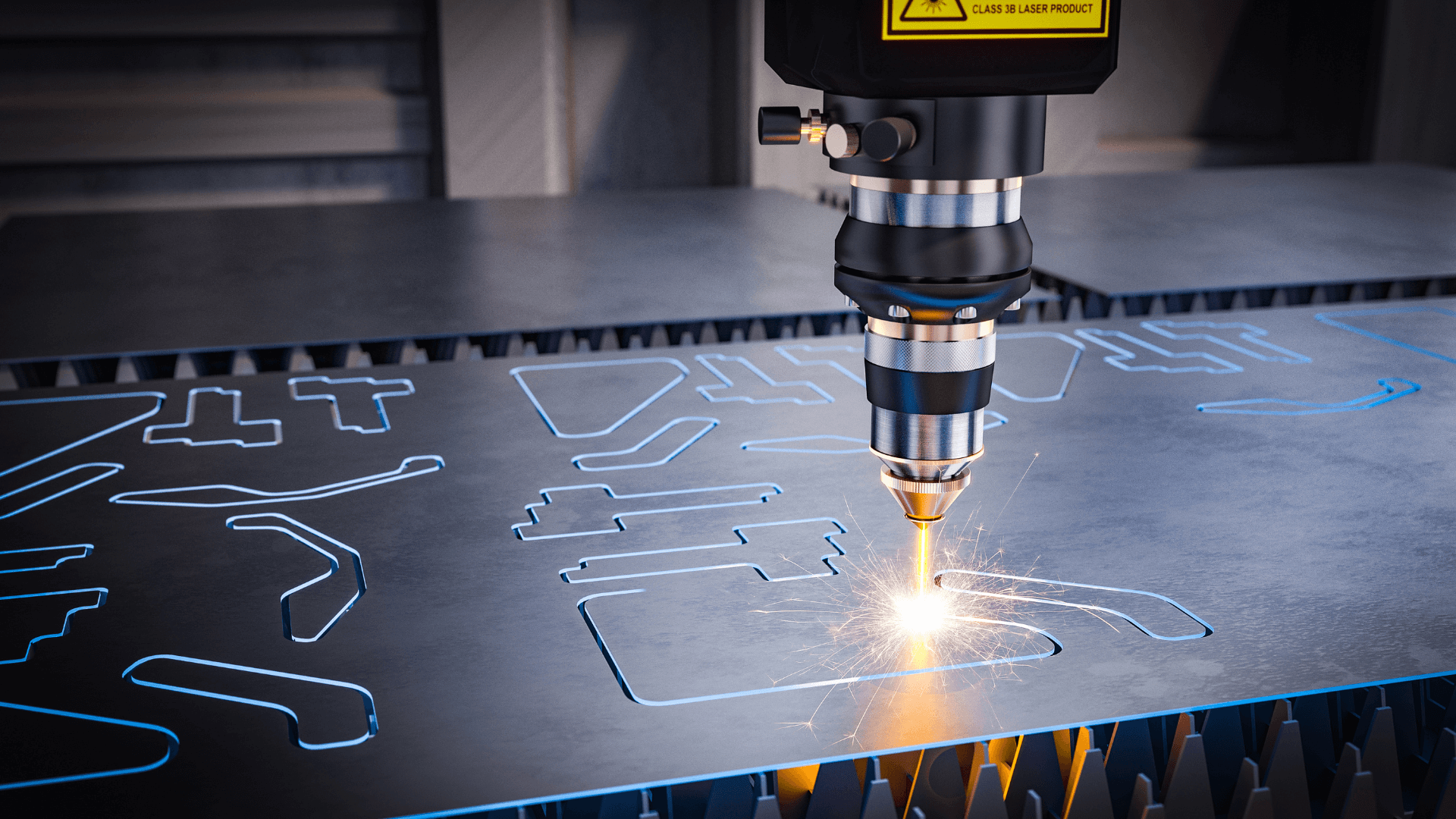

Trays for Laser Cutting Machines

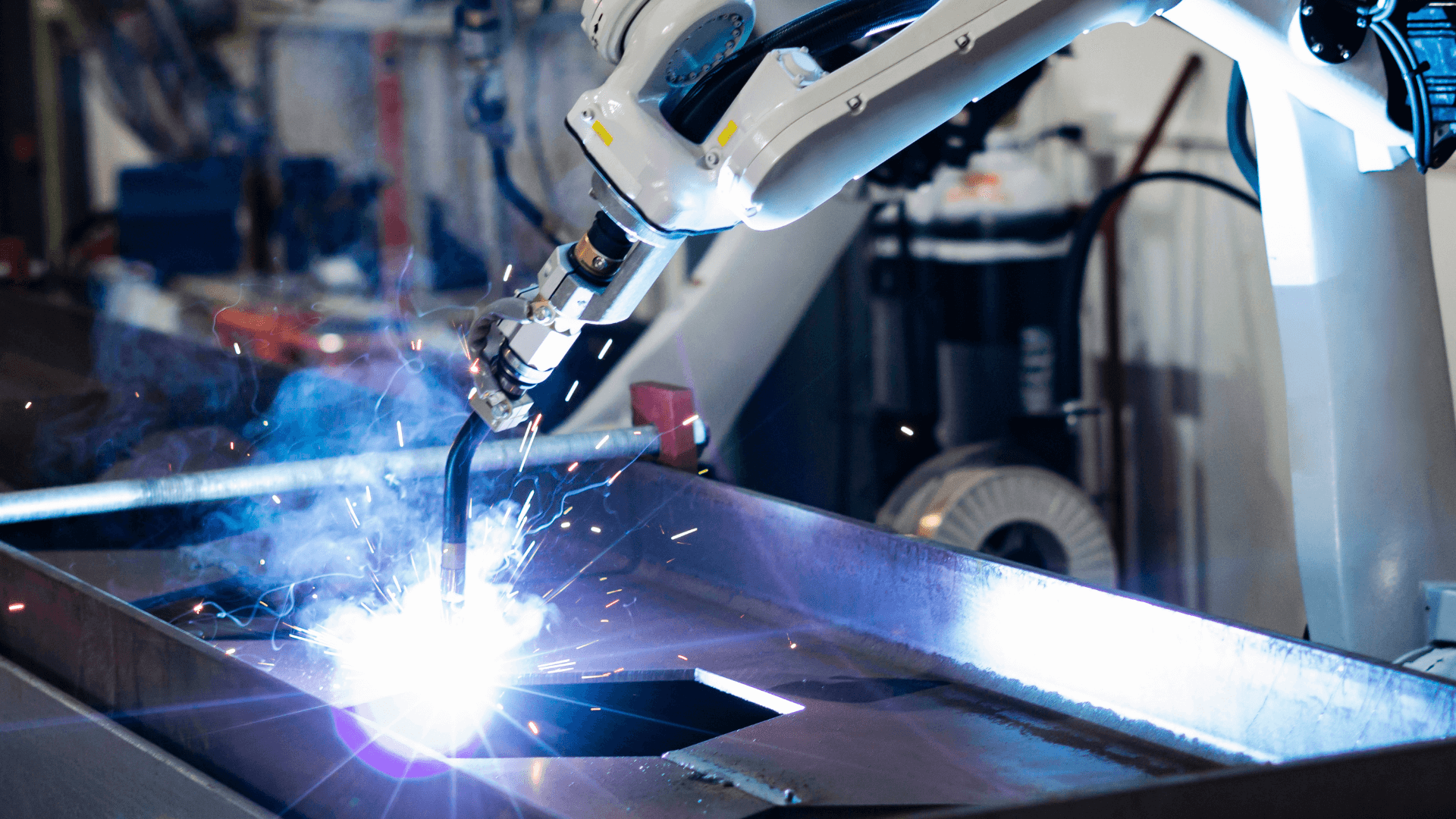

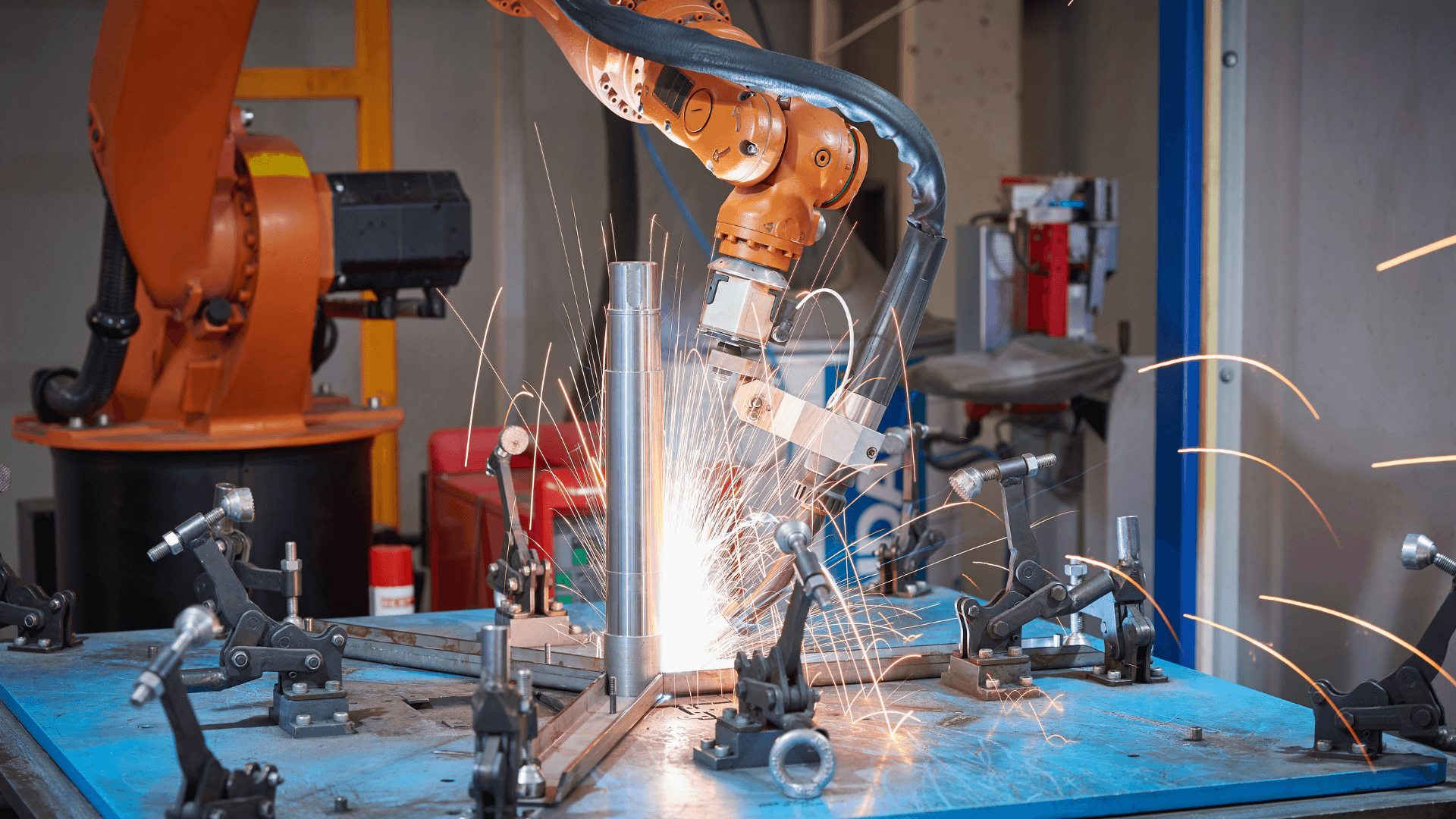

Trays for Robotic Welding Systems

Trays for Welding Robots

Trays for Automated Screwdriving Systems

Trays for Adhesive and Sealing Systems

Trays for Automated Testing Systems

Trays for Optical Inspection Systems

Trays for Ultrasonic Cleaning Machines

Thermoforming Trays Offer Diverse Applications

Production systems are diverse and specialized, varying by industry and application to accommodate different processes. From machining centers to testing and inspection systems, automation trays are used across a wide range of sectors. In production and automation, plastic thermoforming trays provide numerous benefits and play a crucial role in assembly lines and industrial robots by ensuring:

✓ Effortless Transportation

✓ Automated Handling

✓ Protection

✓ Stability

✓ Optimized Production Processes

Learn more about the functions of thermoforming trays in the sections above.

How is my Thermoforming Tray Designed?

Manufacturing Facility

When preparing for the commissioning of your system, there is often little time for a lengthy thermoforming tray development process. Therefore, formary gathers comprehensive information about your machine system during the design phase, including images, drawings, excerpts from the specifications, explanations of the transfer method, and details on tray stackers or palletizers. This ensures that the first design iteration provides an optimal overall concept for your thermoforming packaging.

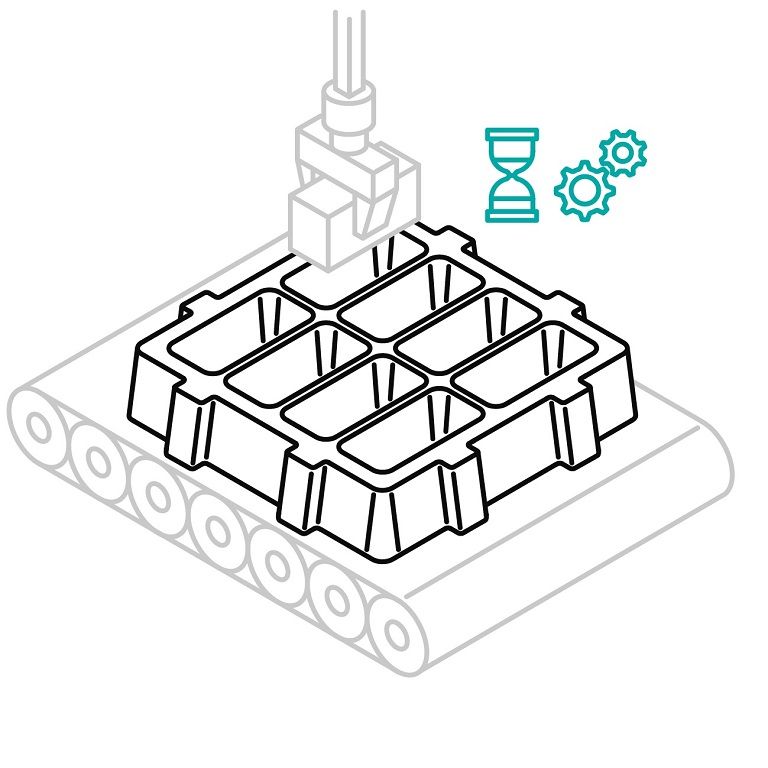

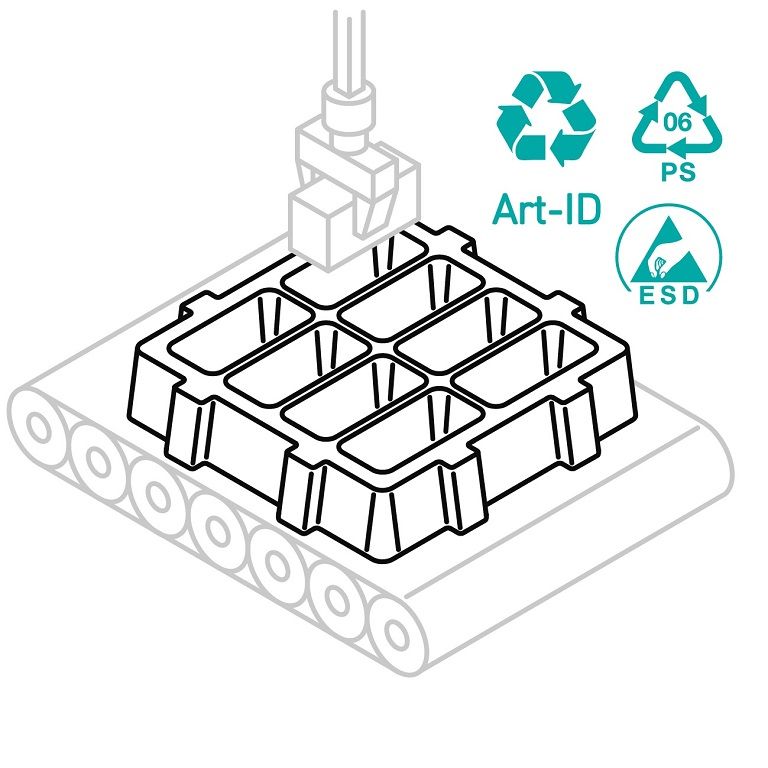

Robotics & Gripper Arms

Customers from various industries use grippers from different manufacturers and technologies. Nests are designed according to the sensitive areas of your component as well as the robotic arm being used. The precision of the robot during loading and unloading determines the spacing and arrangement of the nests.

Coding & Product Identification

To ensure your machine recognizes your products and the tray, there are electronic and optical options: RFID chips, adhesive labels, binary coding strips in the tray frame, etc. The placement of labels and/or codes, as well as coding knobs, should be planned from the start so that formary can optimize the design accordingly.

Handling & Positioning

To avoid collisions between the robot gripper during loading and unloading and ensure the sensor detects the components, the thermoforming tray offers various options. Surrounding grooves make it easier for the robot to grip, positioning pins lock the tray into place, and Poka Yoke corners align asymmetric components when feeding them into the palletizer.

Thermoforming Trays: Automating Processes in Production

Thermoforming trays are designed for effortless gripping, holding, and carrying, as well as for easy removal or re-insertion into cartons. Finger grip indentations on the sides of the automation tray aid in ergonomic loading into containers or outer cartons by your colleagues. These features can also be beneficial for robotic arms.

The size and positioning of these grip areas should be planned early in collaboration with the thermoforming tray manufacturer, as they directly impact the design of the nests and stacking configuration.