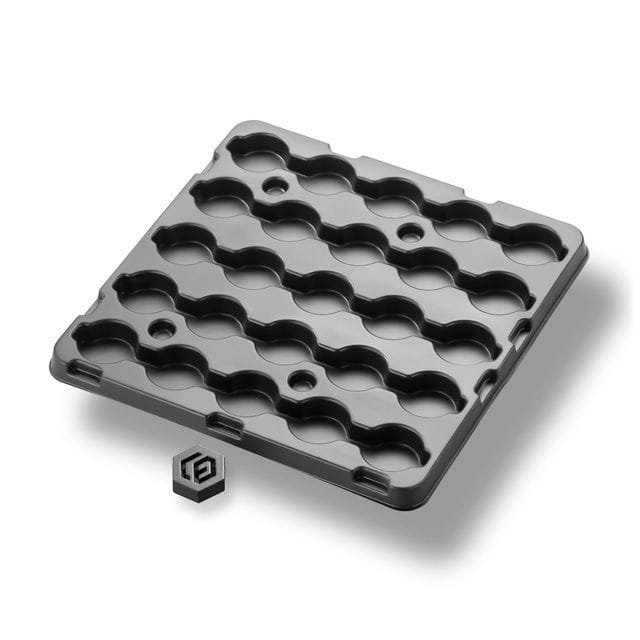

ESD thermoformed parts & blister packaging for electronics

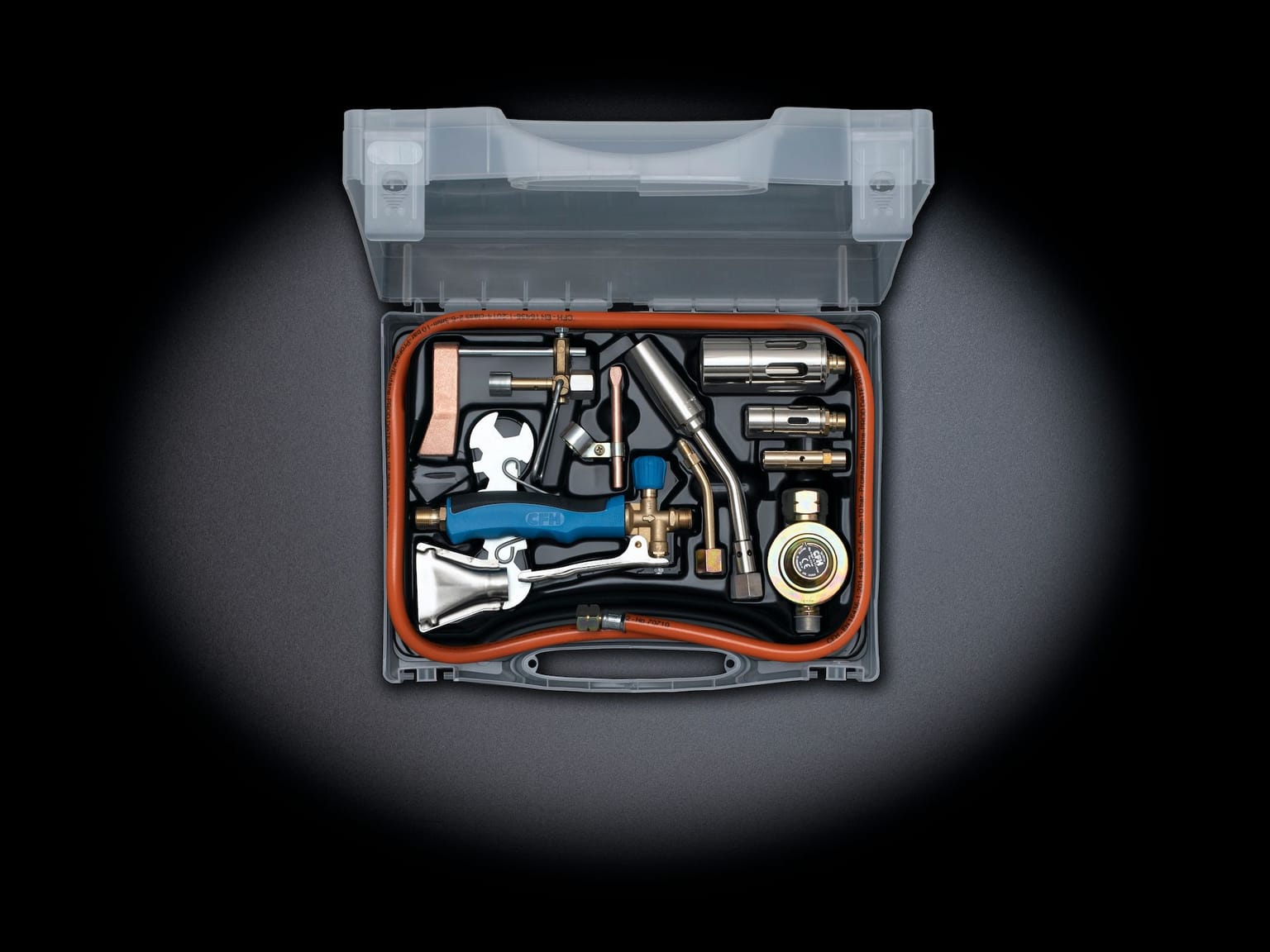

Custom ESD thermoformed parts and ESD blister packaging for electronics: from ESD trays for circuit boards to ESD enclosures and shuttle packaging. Protection against electrostatic discharge, efficient logistics solutions, and precise manufacturing.

What are ESD thermoformed parts?

ESD thermoformed parts are made of conductive plastic and reliably protect sensitive assemblies from electrostatic discharge (ESD). Typical solutions include blister packs for electronics, ESD trays, and ESD containers. They secure components during transport, storage, and production—with short cycle times and low unit costs.

What does ESD mean? – A Brief Explanation

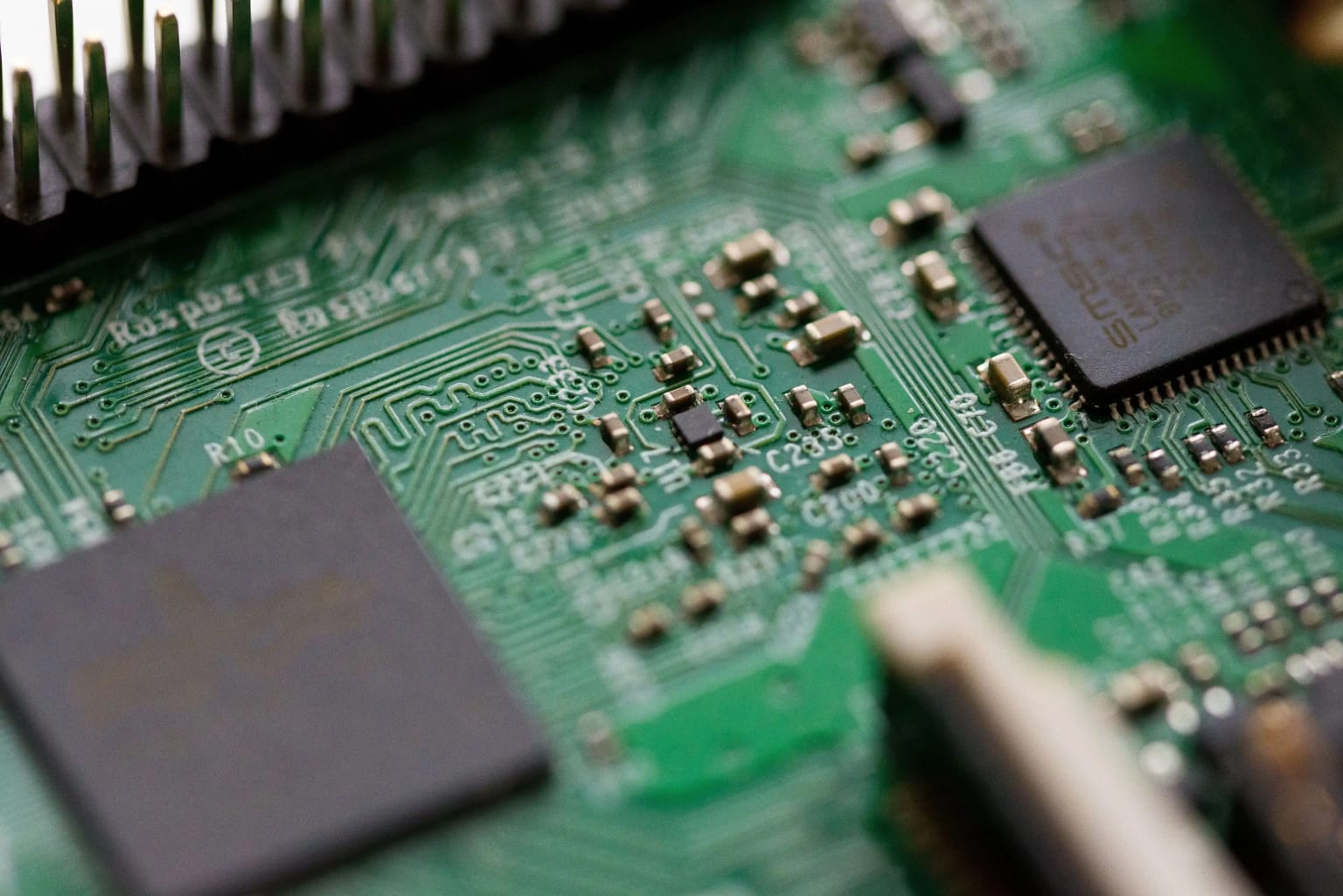

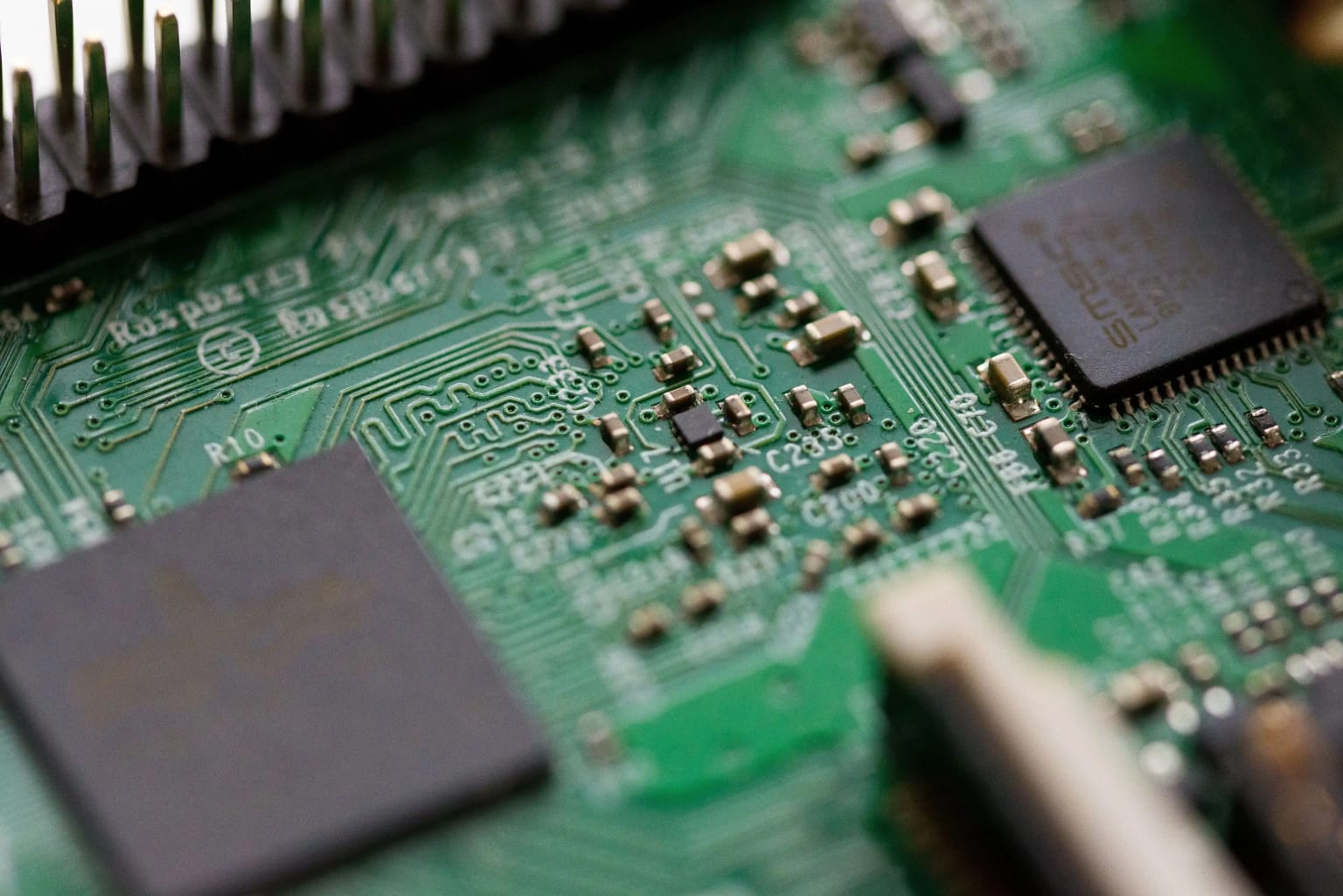

ESD stands for "Electrostatic Discharge." This process describes the equalization of electrical charge between two objects with different voltage potentials. The charge exchange occurs at the object with the lower voltage. Electrostatic discharge can occur, for example, when electronic components are transported in a blister package without sufficient spacing, especially if no ESD-capable plastic is used.

Top Applications for ESD Thermoformed Parts in Electronics

ESD Protection

Prevent electrostatic charging and discharging of sensitive components in ESD trays, ESD housings, or ESD containers using antistatic and conductive plastics.

Custom ESD Blister Packaging

For transport and storage, ESD thermoformed parts simplify production logistics for sensitive electronic components.

Smart Design in Development

Save material costs, use reusable ESD trays, stack efficiently, achieve a perfect fit for delicate electronic components, and allow empty stacking.

ESD Thermoformed Parts: The Universal Solution

Design universal ESD thermoformed parts for multiple electronic component variants, reduce tooling costs, and lower unit prices.

Use of ESD-Protected Thermoformed Parts in the Electronics Industry

Advantages of plastic parts for electronics

ESD-Sicherheit

Plastic parts with ESD protection prevent electrostatic discharge and reliably protect sensitive electronic components during transport, storage, and production.

Chemical resistant

The ESD plastics used are resistant to common cleaning agents and disinfectants, ensuring a long service life.

Lightweight & sturdy

Thermoformed ESD parts combine low weight with high dimensional stability, making them ideal for shuttle packaging and workpiece carriers in electronics manufacturing.

Design freedom

ESD blister packaging allows complex geometries, multiple cavities, and stackable shapes to be created that are precisely tailored to electronic components.

Economically

Thermoforming in electronics manufacturing is particularly economical for small series and reusable packaging solutions. Low tooling costs and rapid iterations reduce overall costs.

Process-reliable

Reproducible tolerances and precisely fitting hold-down devices ensure that electronic components remain protected during transport and production, even in automated handling with robotics.

ESD Thermoformed Parts – Common Plastics in Use

ESD Thermoformed Parts for Your Product: Benefits with formary

Fast Project & Delivery Times

With a large production network for ESD-protected thermoformed parts, available capacity is always ensured, protecting your supply chain.

Industry Expertise

formary knows the right partner in Germany specialized in your ESD application.

Quality & Reliability

All formary companies are ISO 9001:2015 certified. We also provide test reports, material data sheets, and certificates for your products.

Service & Support

Our team takes care of your needs. A dedicated expert will guide you through your entire ESD thermoformed parts project.

Other products with ESD protection

FAQ – Frequently asked questions about ESD thermoformed parts

ESD stands for "Electro Static Discharge." This is when two objects with different voltage potentials equalize their electrical charge. This process occurs, for example, when transporting electronics in blister packaging without sufficient spacing or without ESD-compatible plastic.