Description

HD-PE stands for High-Density Polyethylene and is the most commonly used thermoplastic in plastic processing. Due to its excellent resistance to oils and chemicals, HD-PE plastic is often used in thermoformed containers of all kinds. As an affordable standard plastic in thermoforming, HD-PE has relatively low strength, stiffness, and hardness, but is equipped with good stretchability.

Processing and Thermoformability

HD-PE plastic needs to be heated for a relatively long period to reach the processing temperature for thermoforming. During heating, the thermoplastic spreads across the surface and shrinks back together upon cooling. This creates several challenges when processing HD-PE thermoformed parts. Due to its low viscosity, HD-PE plastic is primarily thermoformed on platen machines with the help of support air to prevent the heated material from sagging. On roll machines, the extreme sag can regularly trigger light barriers and cause the machine to stop. If HD-PE is to be thermoformed from a roll, preheating and additional spreaders are used to better control the material. The high shrinkage during cooling must be taken into account when designing the thermoforming tool. The goal is to design the tool so that the finished part reaches the desired dimensions after shrinkage. Therefore, maintaining tolerances in thermoformed parts made from HD-PE is critical. HD-PE plastic is resistant to many solvents and cannot be glued.

Material Options

ESD

ESD Flocked

Flocked Sealability

Sealability Weldable

Weldable Sterilizable

Sterilizable Regenerate

RegenerateFacts

Price

Colors

Features

- Relatively low brittleness (compared to ABS, ASA)

- Electrical insulating properties

- Resistant to: Acids, alkalis, fats, gasoline, alcohol (all chemicals)

- Weather-resistant

- Recycled material content increases annually

Weaknesses

- No transparency (milky appearance)

- Difficult to process

- No sheet manufacturing possible

- Not suitable for low material thicknesses

- Extreme shrinkage: Tolerances hard to maintain

- Not UV-resistant

Common Industries and Applications:

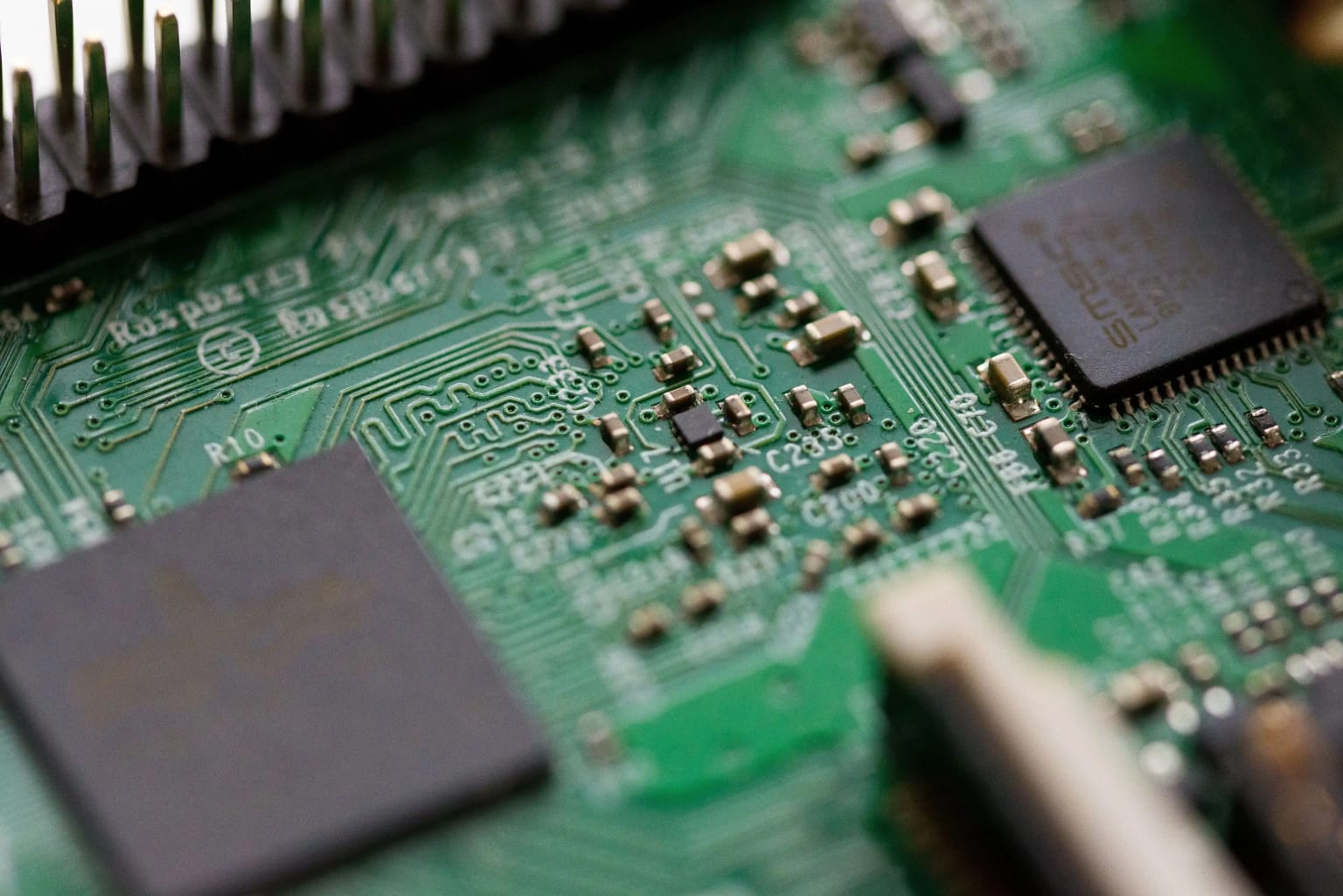

Electronics

- Heat exchanger covers

- Enclosures for scintillators

Consumer Goods

- Reusable trays for shelving systems

- Plant trays

- Reusable trays for shelving systems

- Waste containers

- Toy boxes

- Funnels for rain collectors

- Mounts/trays for photovoltaic modules

Mechanical Engineering

- Covers

- Protective caps

- Transport trays for aluminum enclosures

- Inlays for heat exchangers

- Covers for food machinery

- Cups for turning parts

Industrial Solutions

- Technical covers

- Pin trays

- Lids for pallet boxes

- Caustic tanks

- Basins for liquid disposal

- Oil collection pans

- Stacking containers

- Inlays for transport boxes

- Molds

Facts and Figures:

| Group | Standard Thermoplastics |

| Structure | Semi-Crystalline |

| Density | 0.95 |

| Continuous Use Temperature Min. (in °C) | -50 |

| Continuous Use Temperature Max. (in °C) | 85 |

| Thermal Expansion Transverse/Longitudinal to Flow Direction (10^-6 *K) | 120 - 150 |

| Melting Temperature (°C) | 135 |

| Max. Temp. Short-Term (°C) | 100 |

| Max. Temp. Long-Term (°C) | 90 |

| Impact Strength (KJ/m^2) | 20 |

| Abrasion Resistance | ++ |

| Yield Stress (N/mm²) | 30 |

| Tensile Strength (N/mm²) | 28 |

| Tensile Modulus of Elasticity (N/mm²) | 1100 |

| Elongation at Break (%) | 400 |

| Flexural Strength (N/mm²) | 22 |

| Ball Indentation Hardness (N/mm²) | 57 |

| Dielectric Strength (kV/mm) | 53 |

| Volume Resistivity (Ω · m) | >1E14 |

| Surface Resistivity (Ω) | >1E14 |

| Tracking Resistance CTI | 600 |

Additional Plastics in the formary Portfolio

Frequently asked questions about HD-PE plastic?

HD-PE (high-density polyethylene) is a widely used thermoplastic that is particularly resistant to oils, chemicals and moisture. HD-PE is mainly used for thermoformed containers, tubs, transport boxes, covers and industrial inlays.