Plastic Thermoformed Parts for Aerospace & Defense

Lightweight design, precision, and high durability – configure your plastic thermoformed parts for aerospace and defense now. From cabin panels and defense housings to workpiece carriers and ESD-protected electronic enclosures, developed for demanding A&D applications.

What Are Plastic Thermoformed Parts for Aerospace & Defense?

Plastic thermoformed parts for aerospace and defense are custom-made components such as defense housings, cabin panels, workpiece carriers, drone housings, and ESD-protected enclosures. They offer lightweight construction, flame retardancy compliant with aviation standards, EMC and ESD protection, and high chemical resistance. This makes them ideal for both civil and military applications.

Top Applications of Plastic Thermoformed Parts in Aerospace & Defense

High-Performance Plastics

Technical and high-performance plastics with temperature and chemical resistance, flame protection according to aviation standards, as well as high impact and abrasion resistance.

Lightweight Solutions

The low weight of defense housings and trays reduces energy consumption, increases range, and maximizes payload.

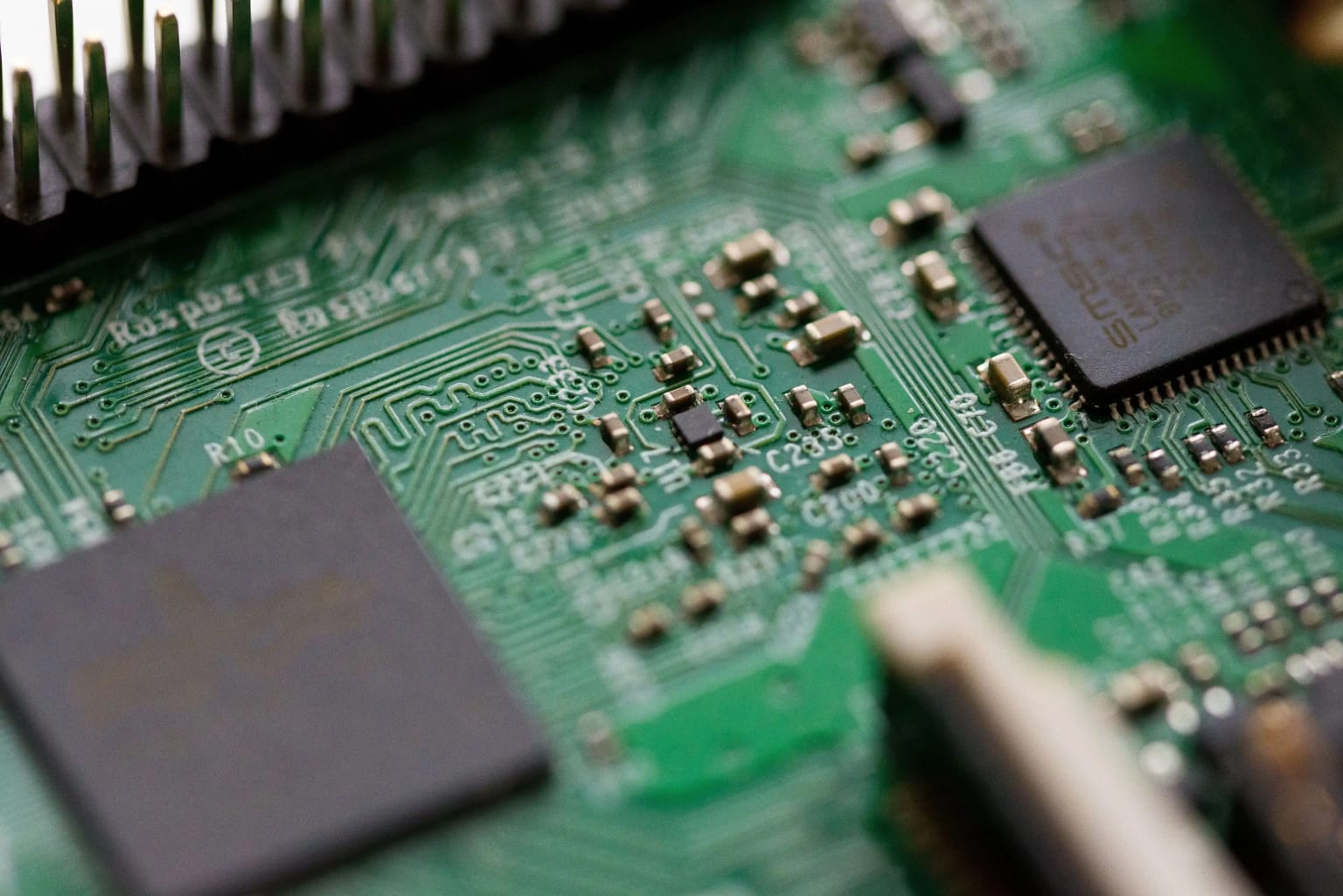

ESD & EMC Shielding

With conductive layers or coatings, thermoformed parts protect sensitive electronics from EMC interference and mechanical impact.

Form & Design Freedom

The design freedom of defense thermoformed parts allows complex geometries, aerodynamic surfaces, and ergonomic paneling.

Areas of Application for Plastic Thermoformed Parts in Aerospace & Defense

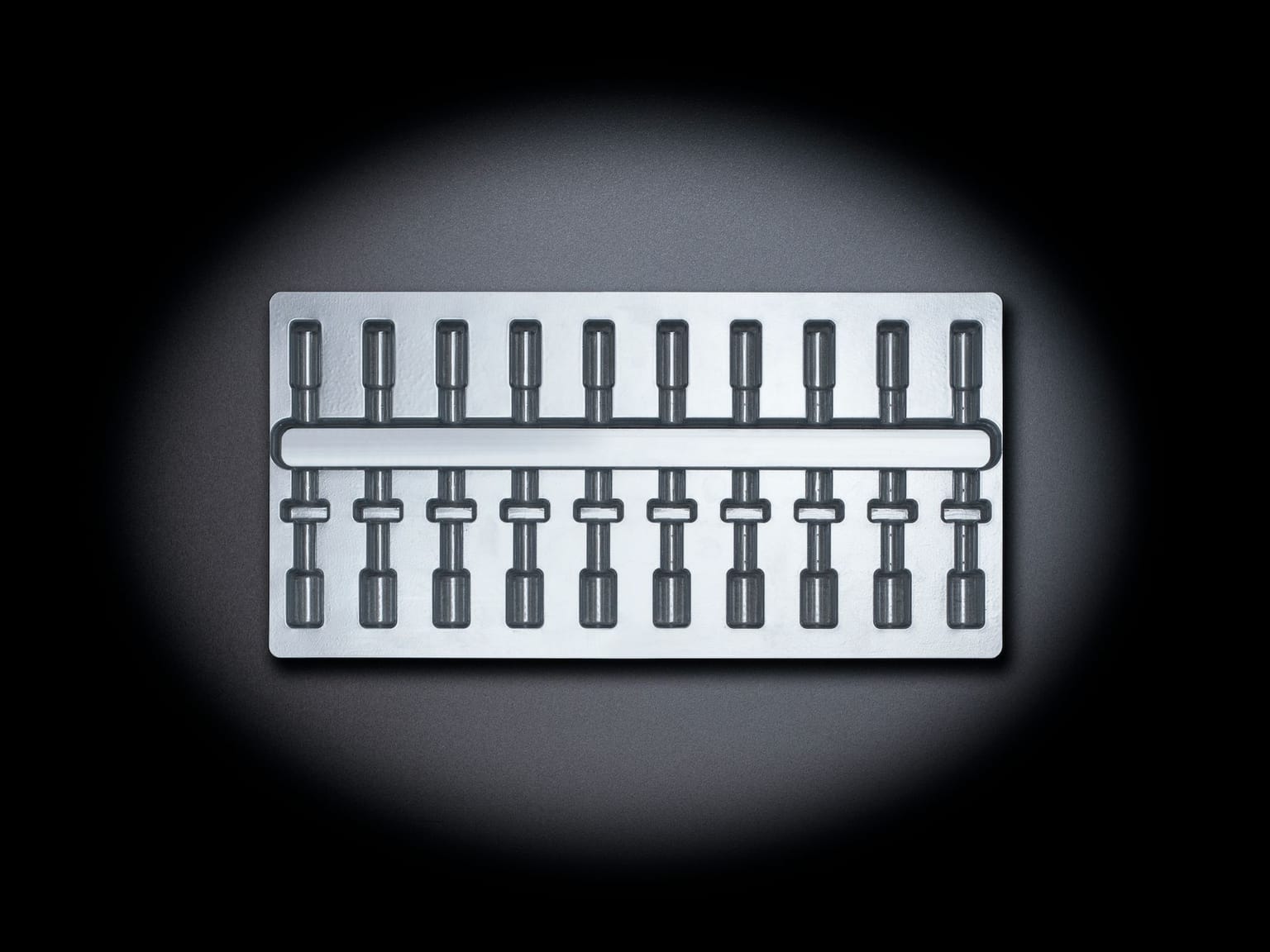

Workpiece Carriers & Trays for Defense Components

Defense trays and plastic workpiece carriers secure sensitive components such as electronic modules, UAV parts, or sensors. With form-fitted cavities, clamping mechanisms, and ESD protection, they reliably fix parts in manufacturing, logistics, and deployment.

Subcategories of defense trays:

- UAV trays: secure transport of delicate drone and UAV components

- Sensor trays: precise contours for circuit boards and radar modules

- Mechanics trays: robust carriers for structural and metal parts with high strength

- Optics trays: precise, padded contours for high-end sensor technology

- Logistics trays: modular kits for spare parts and warehouse logistics with labeling systems

Defense Housings & Electronic Enclosures

Plastic defense housings protect radio equipment, communication systems, and control units in vehicles, drones, or ground stations. With ESD and EMC protection, high impact resistance, and dust/moisture resistance, they meet safety-critical requirements.

Subcategories of defense housings:

- Sensor housings: for cameras, LiDAR, or infrared sensors

- Communication system housings: for radios and encryption modules

Protective & Paneling Parts for Interior & Exterior Use

Plastic paneling parts for aerospace and defense are used as outer and inner covers, device hoods, modular panels, or cabin panels. They are applied in military vehicles, cockpits, and aircraft cabins. Defense paneling parts are UV-stable, chemical-resistant, highly impact-resistant, and meet strict fire protection and design requirements.

Advantages of defense paneling parts:

- UV-stable & chemical-resistant for harsh environments

- vibration-resistant, noise-reducing (NVH improvement possible)

- quick to replace/repair thanks to modular design

Plastic Housings & Fuselage Panels for Drones & UAV Systems

Drone housings and fuselage panels made of plastic protect UAV systems in civil and military applications. Covers, fuselage parts, or payload carriers provide lightweight, precise protection against environmental and mechanical stress. They are light, robust, UV- and chemical-resistant, and can be flexibly adapted through fast iterations and small-batch production.

Advantages of fuselage panels and drone housings:

- lightweight = greater range/payload

- fast design iterations from prototype → pilot series → mass production

- optional ESD/EMC protection concepts for payload electronics

Advantages of Plastic Thermoformed Parts for Aerospace & Defense

Lightweight Design

Thermoformed plastic parts enable significant weight savings compared to metal parts while maintaining high impact resistance and stability.

Design Freedom

Thermoforming allows complex geometries, customized surfaces, and ergonomic designs. Cabin panels, defense housings, and drone housings can be tailored to technical and aesthetic requirements.

Cost Efficiency

Prototypes and small series are more economical to produce compared to injection molding or CNC. Low tooling costs and rapid iterations reduce both development time and overall costs.

Compliance With Standards

All materials used meet relevant aerospace and defense standards, such as flame protection according to UL94 V-0 or FAR 25.853, as well as ESD and EMC protection requirements and UV resistance.

Short Lead Times

Through digital processes and the use of bridge tooling, prototypes and series components can be produced quickly and reliably. A clear advantage for time-critical A&D projects.

Safety

Plastic parts for defense and aerospace are impact-resistant, chemical-resistant, and withstand extreme environments. They ensure reliable function in cockpits, UAVs, and military communication systems.

Key Plastics for Defense Applications

ABS/PC-Blend

High impact strength, good temperature resistance, dimensionally stable; used for device covers and electronic assemblies.

HIPS (High Impact Polystyrene)

Lightweight, impact-resistant, easy to form, cost-efficient; used for internal defense covers and prototypes.

PMMA/ABS (e.g. Senosan)

Excellent surface quality, scratch-resistant, UV-stable; used for visible housings and display protection.

PEEK

Extremely temperature- and chemical-resistant, flame-retardant, high-cost high-end material; used for high-security housings and sensor components.

FR-ABS (flame-retardant ABS)

UL94 V-0 flame protection, robust and dimensionally stable; used for interior panels requiring fire safety.

PVC/ASA

Chemical-resistant, UV-stable, suitable for outdoor use; used for external covers and communication modules.

PET-G

Transparent, shatterproof, dimensionally stable, food-safe; used for viewing windows and protective parts in laboratory environments.

Conductive ABS (e.g. ABS-ESD)

ESD-safe and conductive, specially developed for electronics protection; used for housings requiring EMC/ESD protection.

How Does formary Support the A&D Industry?

formary is your digital manufacturer for plastic thermoformed parts in aerospace and defense.

Prototypes & Small Series

formary enables cost-efficient production of aerospace components and defense housings.

Cost Advantages

Thermoformed defense parts offer significantly lower tooling costs compared to CNC or injection molding.

Fast Project Execution

formary provides digital processes, 100+ manufacturing partners, and reliable capacities for your defense housings and trays.

Confidentiality & Security

formary ensures that your project data and design plans are protected – a critical factor for safety-relevant industries like aerospace and defense.

FAQ – Frequently Asked Questions about Thermoformed Parts for Aerospace & Defense

They are used for cabin panels, defense housings, drone housings, workpiece carriers, trays, protective covers, and ESD-protected electronic housings.