Tolerances for thermoformed plastic parts

Precise, reproducible, and cost-effective: how to define the right tolerances for your thermoformed plastic part

Why are tolerances so important in plastic deep drawing?

During the manufacturing of formed parts, slight dimensional deviations can occur due to one-sided tool contact, material thickness variations in the blanks, and internal stresses within the material itself. Adhering to the maximum permissible tolerances is crucial, especially for technical formed parts and automation trays.

Function-oriented tolerance design in thermoforming

As a rule of thumb, the tighter the necessary tolerances, the more expensive the tools and manufacturing costs will be.

ℹ️ For the creation of your formed parts, we rely on function-oriented tolerance design. Based on the requirements you submit in the configurator, we derive the functions of the formed part. These functions are then described in the drawing with the necessary references and tolerances. After your review and approval, the manufacturing process begins.

Influencing Factors

Material: Plastic

Plastic parts have greater dimensional variations than metallic materials due to their lack of rigidity and high deformability.

- Despite advanced manufacturing techniques, processing is often empirical

- Key dimensional properties: Rigidity, hardness, processing shrinkage

- Warping can lead to deviations in shape, position, and angles, making standardization more difficult

- Variations in molecular weight between material batches affect flow behavior and processing shrinkage—fluctuations in industrial-grade material can be significant

- Deformation and flow behavior impact dimensional accuracy

Production-Related Dimensional Changes

Dimensional deviations may occur due to:

- Processing shrinkage variations

- Incorrect tool shrinkage compensation

- Different elastic recovery behavior

- Tool deformation and wear (standard steel dimensions: ±0.01mm)

Application-Related Dimensional Changes

Production-related length deviations can occur due to:

- Climate influences

- Mechanical deformations (external forces, relaxation of internal stresses)

- Operational energy exposure (e.g., heat in engine compartments)

- Diffusion contact (vapors, liquids)

- Material removal (friction)

- Molecular structure transformation

Allgemeine Toleranzen

Grenzmaße für Längenmaße

DIN ISO 2768-c

| Toleranzklasse | Grenzabmaße in mm für Nennmaßbereich in mm (immer +/-) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| DIN ISO | 0,5 - 3 | >3 - 6 | >6 - 30 | >30 - 120 | >120 - 400 | >400 - 1.000 | >1.000 - 2.000 | >2.000 - 4.000 | >4.000 - 8.000 |

| 2768-c | 0,2 | 0,3 | 0,5 | 0,8 | 1,2 | 2,0 | 3,0 | 4,0 | 5,0 |

Alle Längenmaße unterliegen DIN IS 2768. Normale Tiefziehteile fallen in die Toleranzklasse 2768-c (s. Tabelle):

DIN ISO 2768-m

| Toleranzklasse | Grenzabmaße in mm für Nennmaßbereich in mm (immer +/-) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| DIN ISO | 0,5 - 3 | >3 - 6 | >6 - 30 | >30 - 120 | >120 - 400 | >400 - 1.000 | >1.000 - 2.000 | >2.000 - 4.000 | >4.000 - 8.000 |

| 2768-m | 0,1 | 0,1 | 0,2 | 0,3 | 0,5 | 0,8 | 1,2 | 2,0 | 3,0 |

Alle Längenmaße unterliegen DIN IS 2768-1. Auf Wunsch können Tiefziehteile nach Toleranzklasse 2768-m gefertigt werden (s. Tabelle). Hierfür müssen wir allerdings erst alle Toleranzbereiche auf tiefziehbare Herstellung prüfen und freigeben.

Toleranzen für Bohrungen und Öffnungen:

- Formteil: 0,5mm

- Bohrlochdurchmesser: 0,13mm für Löcher kleiner als 25mm

- Bohrlochdurchmesser: 0,25mm für Löcher zwischen 25 und 125mm

- Schlitze: 0,25mm für Löcher kleiner als 25mm

- Schlitze: 0,5mm für Löcher zwischen 25 und 125mm

- Fräsen: 0,5mm für Löcher auch größer als 125mm

Thermoformable features you should pay attention to

Plastic thermoforming is a complex process with many variables that can influence tolerances. By observing these rules, errors in CAD design and in the end product can be avoided.

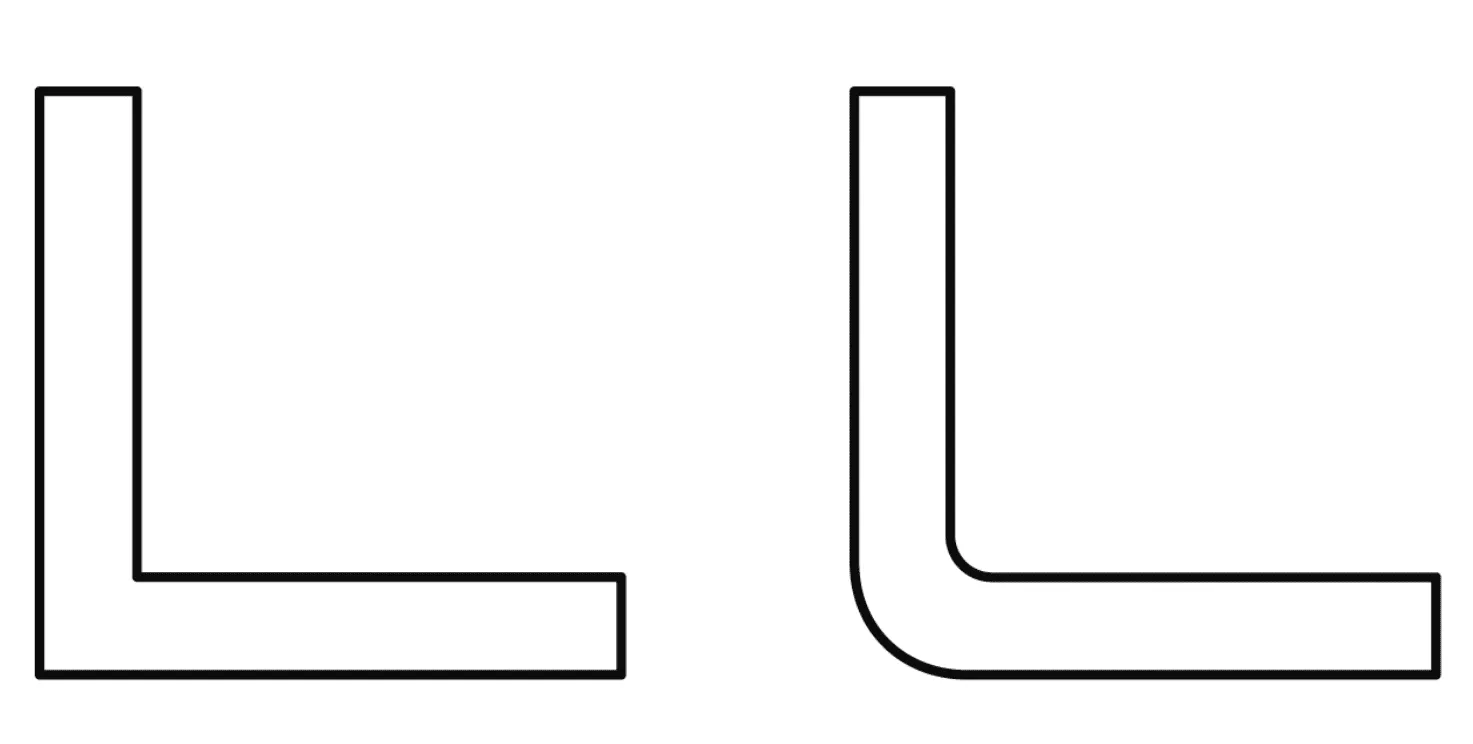

Corner and Edge Radii

A minimum radius of 1.5mm is required. Larger radii are recommended to improve material stretchability.

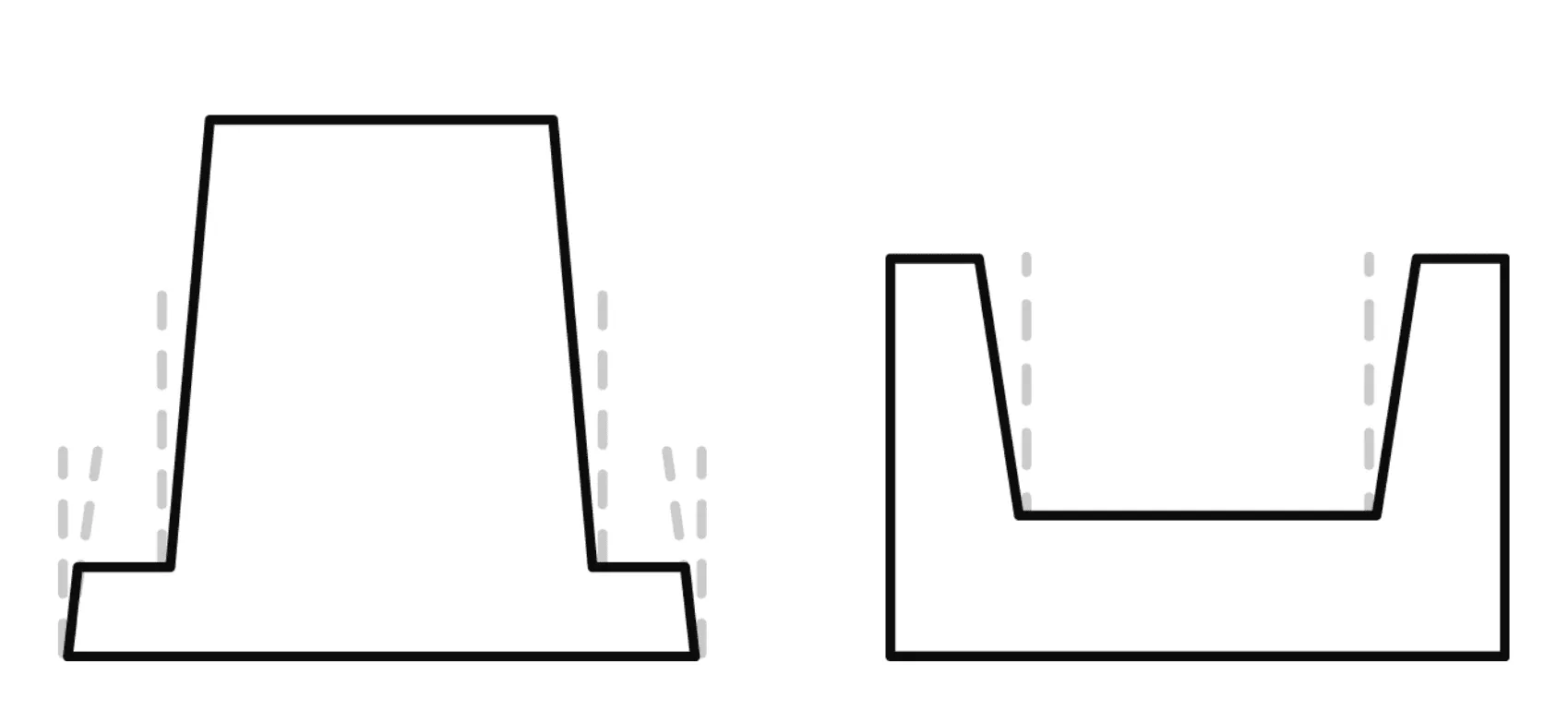

Wall Angles

A wall angle is always necessary to ensure demolding.

✓ Negative molds: Minimum 1.5 - 2°

✓ Positive molds: Minimum 4 - 6°

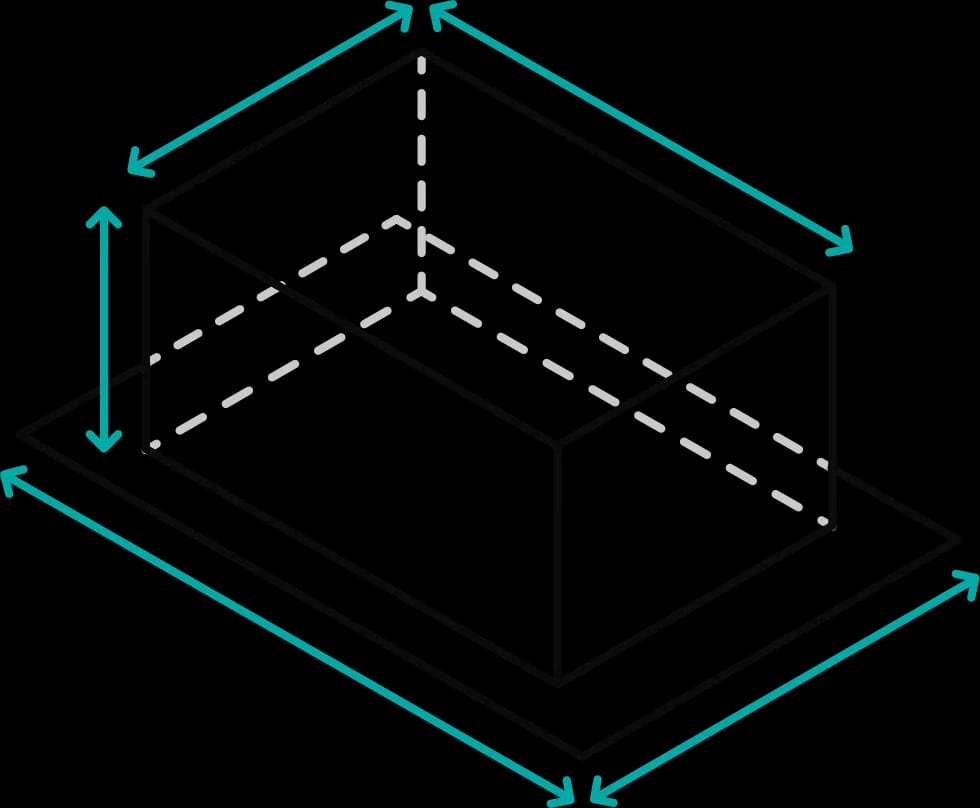

Forming Ratio

Wall thickness varies along the formed part due to material stretching. The resulting thickness can be estimated using specific formulas.

ℹ️ You can calculate the expected wall thickness in advance, or enter details in the configurator, and we will determine the necessary starting material thickness.

Further information on design & tolerances in thermoforming

Design rules for thermoformed plastic parts

Read our article to learn which design rules you should follow when manufacturing thermoformed plastic parts in order to ensure thermoforming-capable tolerances.

Design guide for thermoformed plastic parts

In our thermoforming design guide, you will find not only design rules for thermoforming-friendly components, but also information on the thermoforming process, materials, and more.

Frequently asked questions about tolerances in plastic thermoforming

Plastics expand more and react to temperature and humidity, which is why tolerances in thermoforming are larger than those of metal parts.