Automation of Production - How Trays Support Automation in Industry 4.0

Trays for automation are workpiece carriers that pass through an automated industrial system or production line, fulfilling various functions along the way.

Moritz Bittner

13. Januar 2026

Contents

What is Automation?

In Industry 4.0, automation of production is crucial. It is based on the networking of machines and systems to create a smart factory where processes run autonomously and in real time. Production automation enables the use of modern technologies that make production processes not only more efficient and flexible but also better aligned with individual needs.

Technologies like industrial robots, computer-controlled machines (CNC), and sensors improve operational safety and ensure consistently high production quality. In industrial manufacturing, many processes, from production to logistics, can be automated. This autonomy increases efficiency, reduces errors, and is a key element of automation technology. In the following sections, you’ll learn how trays enable production automation.

Which Processes Can Be Automated in Industrial Production?

Modern manufacturing presents many challenges in automating production, especially when optimizing key processes. Below are some of the central processes that are commonly automated:

Inbound Logistics

The supplier delivers components just-in-time. These parts are added to production and packaged in sensible quantities on pallets.

Production

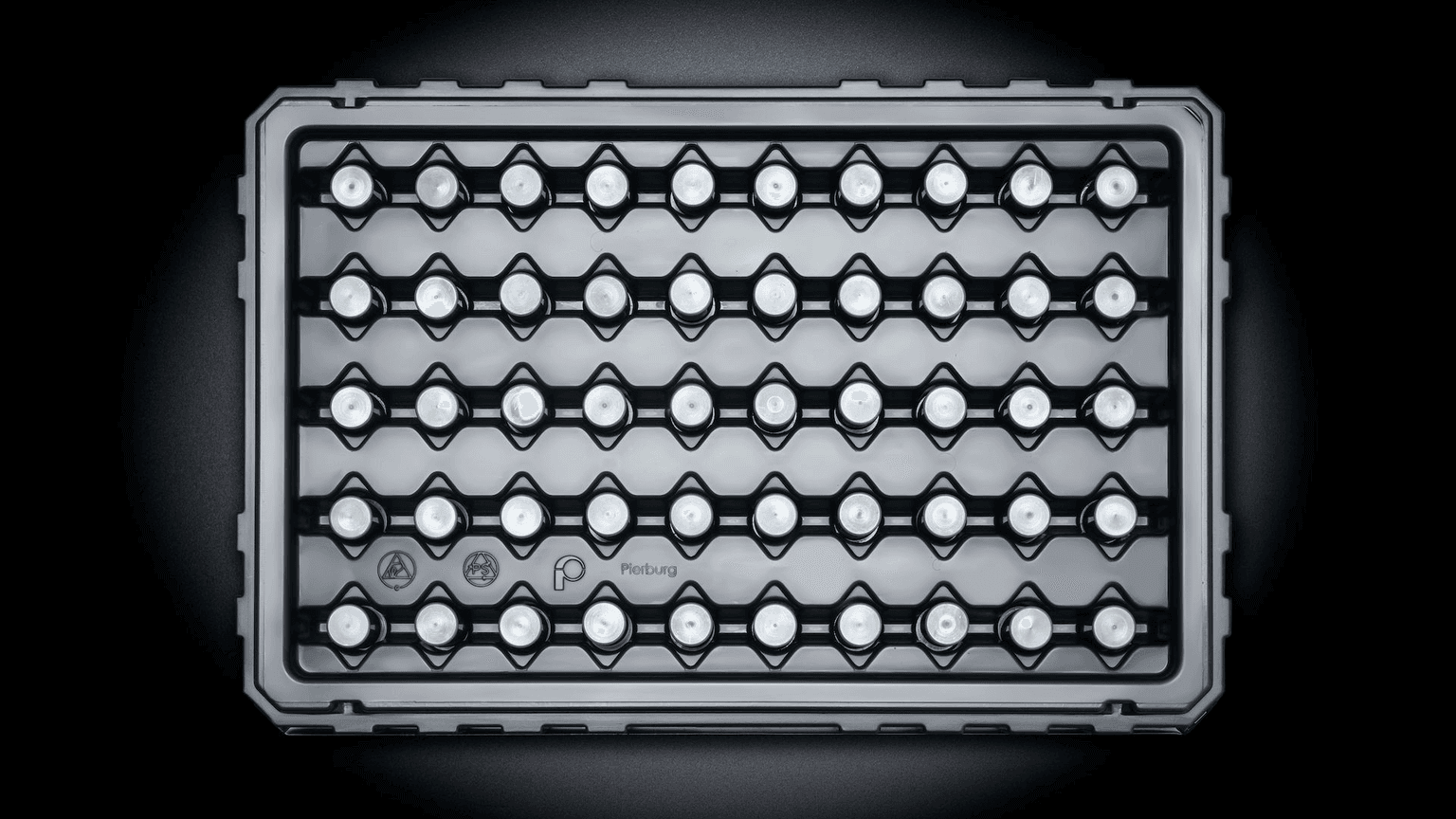

Once on the production line, parts are automatically fed into production in a plastic tray (also called a workpiece carrier), designed for automation. This workpiece carrier is constructed to ensure the parts pass through all processing stages, and it can accommodate different versions of the part.

Outbound Logistics

Once the part has passed through the production line, the automation tray provides the perfect solution. The tray, designed for production automation, serves for transporting precise packaging units and is used as a reusable transit package to your end customers.

Fully or Semi-Automated Production – How Trays Are Used for Automation

Within the system, the part and tray autonomously pass through various production stages, including measuring/testing, loading and assembly, and packaging and removal from the tray.

Production Automation in the Manufacturing Line

The automation tray is adapted to the dimensions of the transport belts in the system. Usually, the dimensions also match standard industrial containers. All common "standardizations" are stored in the formary database. The tray is autonomously handled by a palletizer, which loads and removes it from the system.

Optimal Tray Design for Automation in Production

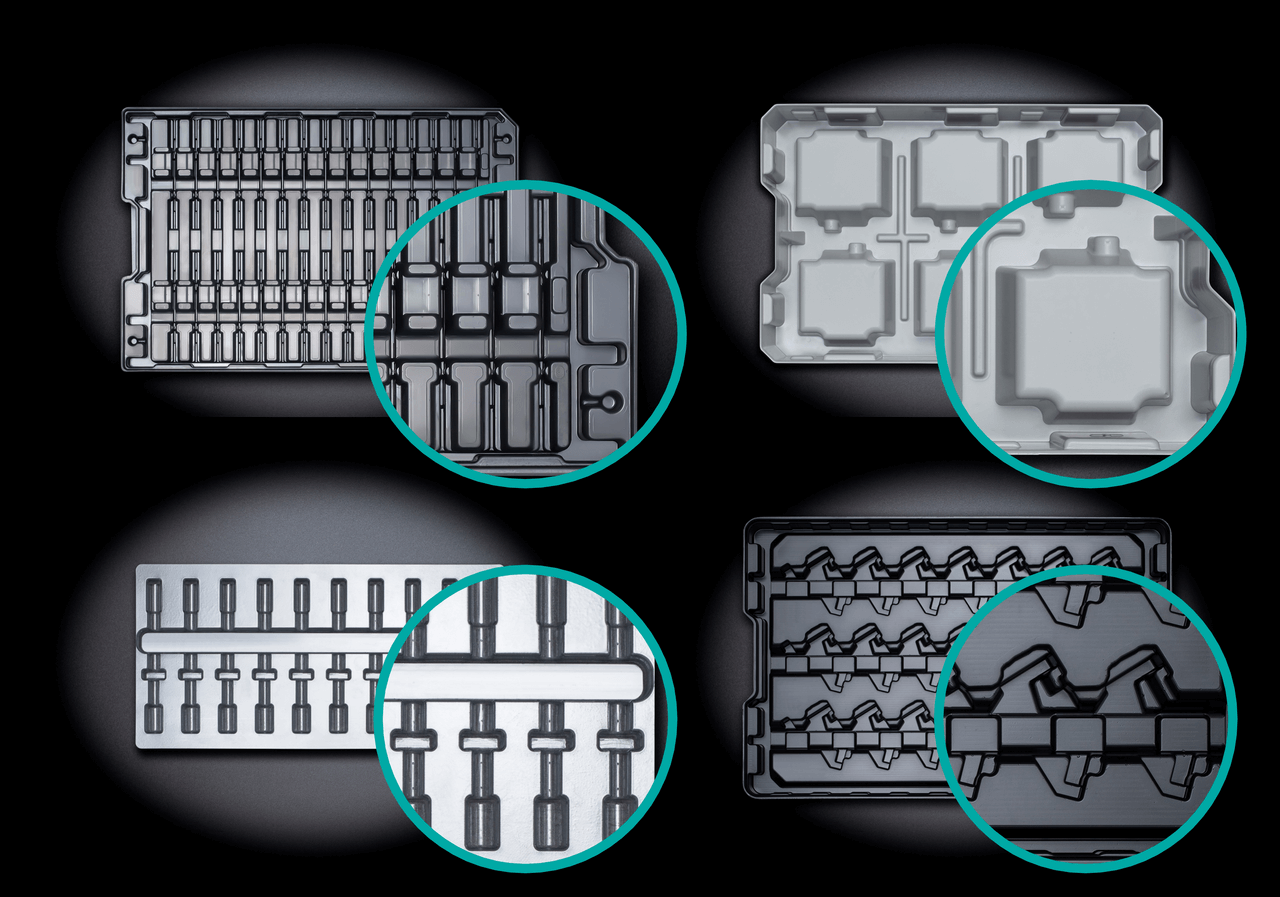

Before development, consideration must be given to how many and what type of parts the tray needs to accommodate. The tray for production automation and the part cavities must be multifunctional to handle every step of the automated production process.

Various external shapes, depths, and edges support automated processes and provide space for each part version. The cavity shape in the tray is also determined by the technology or robotics that removes and loads the parts.

The desired packing density (parts per tray) also plays a role in the design, as well as how their positioning is defined. Many production systems require parallel and non-offset positioning of all parts to allow industrial robots to handle them efficiently in the automation process.

How Trays Further Support Process Automation

Industrial robots are key in production automation. Primarily, they are responsible for loading and unloading parts in and out of the tray. The edge contour and wall construction depend on the symmetry of the parts and can be supported both visually and mechanically. To position the parts, elements like Poka-Yoke pins can be added to the tray.

The design of the automation tray is based on the robot used: Where should the robot arm grip the part to ensure a secure hold, considering the size, weight, and geometry of the part? The nesting contour is adapted to the optimal stroke of the gripper fingers. The gripper jaw coating should be adapted to the pick-and-place task.

Robot arms have different capabilities. Simple grippers follow the same path, while more complex systems work with integrated image processing and path measurement systems that can approach contours and parts more easily. Depending on the system, the tolerance range of the tray interacts with the system.

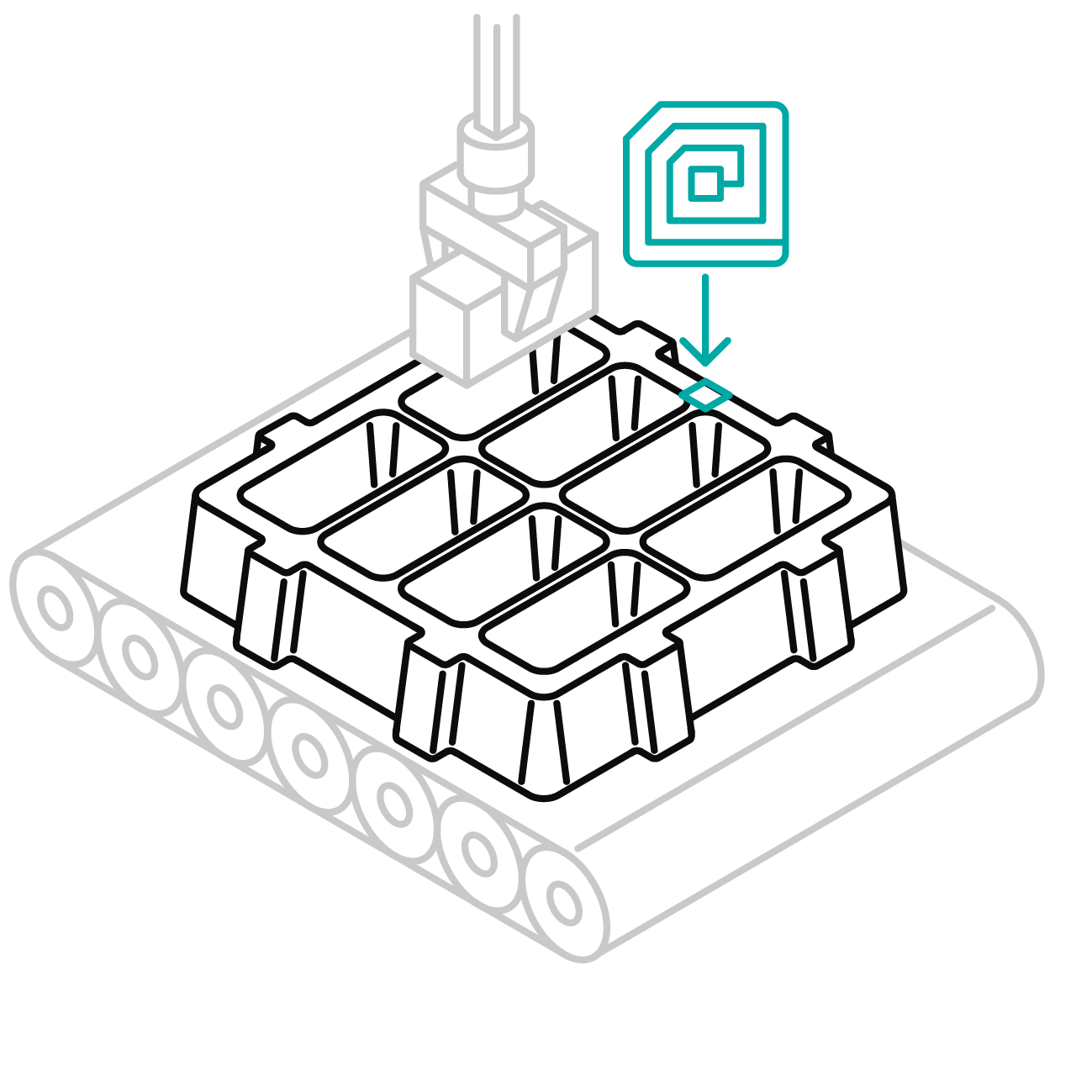

How does the system capture tray data for production automation?

Automation trays can be encoded so that sensors can capture them and collect essential data. Options include binary detection systems in the tray frame and applying markings such as RFID chips, transponders, or fixed engravings that can be recognized and tracked. More information can be found under “Plastic Automation Trays.”

Automation of Industry 4.0 Manufacturing through Trays – A Conclusion

The integration of trays into automated manufacturing processes offers an efficient solution to the challenges faced by modern industries. The adaptability to different manufacturing systems, as well as support for robotics, helps increase efficiency and precision. Ultimately, trays for production automation support and optimize Industry 4.0 in many areas.

Request Now – Quickly Get the Perfect Tray for Automating Your Production

Let us design your tray for automating your processes. Simply click "Automation" in the formary configurator. formary will ask for all the relevant information.

If you already have 3D data, you can also visualize it in our 3D Tray Generator. Simply book a live demo and we will show you how it works and whether your data is suitable for deep drawing.

Still have something to say or more questions? Contact us via live chat or call us at: +497191 9525170.