Plastic manufacturing processes compared: thermoforming vs. injection molding, 3D printing, CNC milling, and foam

When manufacturing plastic parts, thermoforming is often compared with injection molding, milling, 3D printing, and foam solutions. The decisive factors are speed, cost, design freedom, material requirements, and process reliability. This article highlights the key differences between these processes.

Talida Eichhorn

13. Januar 2026

Contents

Comparison of plastic manufacturing processes - The most important facts in brief

- Plastic manufacturing processes differ primarily in terms of time-to-market, costs, design freedom, robustness, material diversity, and automatability.

- Thermoforming is particularly advantageous for small to medium series and offers short project lead times.

- Injection molding is worthwhile for large quantities, but incurs high tooling costs.

- Milling and 3D printing are suitable for prototyping, but are expensive in series production.

- Foam and standard solutions are cost-effective, but technically limited.

What are the most important plastic manufacturing processes?

In plastics engineering, different plastic processes are used depending on the component geometry and quantity.

| Process | Category | Typical applications |

|---|---|---|

| Thermoforming | Forming | Housings, covers, trays, packaging |

| Injection molding | Casting | Mass-produced products, precision components |

| CNC milling | Machining | Precision components, prototypes |

| 3D printing | Additive | Prototypes, small series, complex geometries |

| Foam solutions | Foaming | Upholstery, simple packaging |

In plastics engineering, these processes are primarily differentiated according to the molding method, quantity, precision, and material properties.

How do key plastic manufacturing processes work?

Here is a brief overview of how they work:

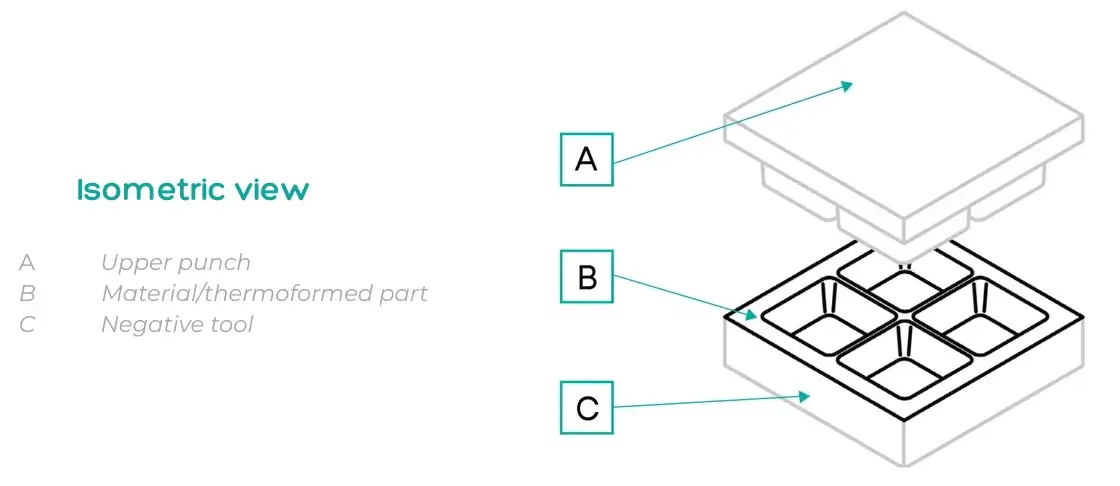

Plastic Thermoforming

In thermoforming, a plastic sheet is heated and then drawn into a mold. The process is suitable for containers, housings, packaging, and inlays.

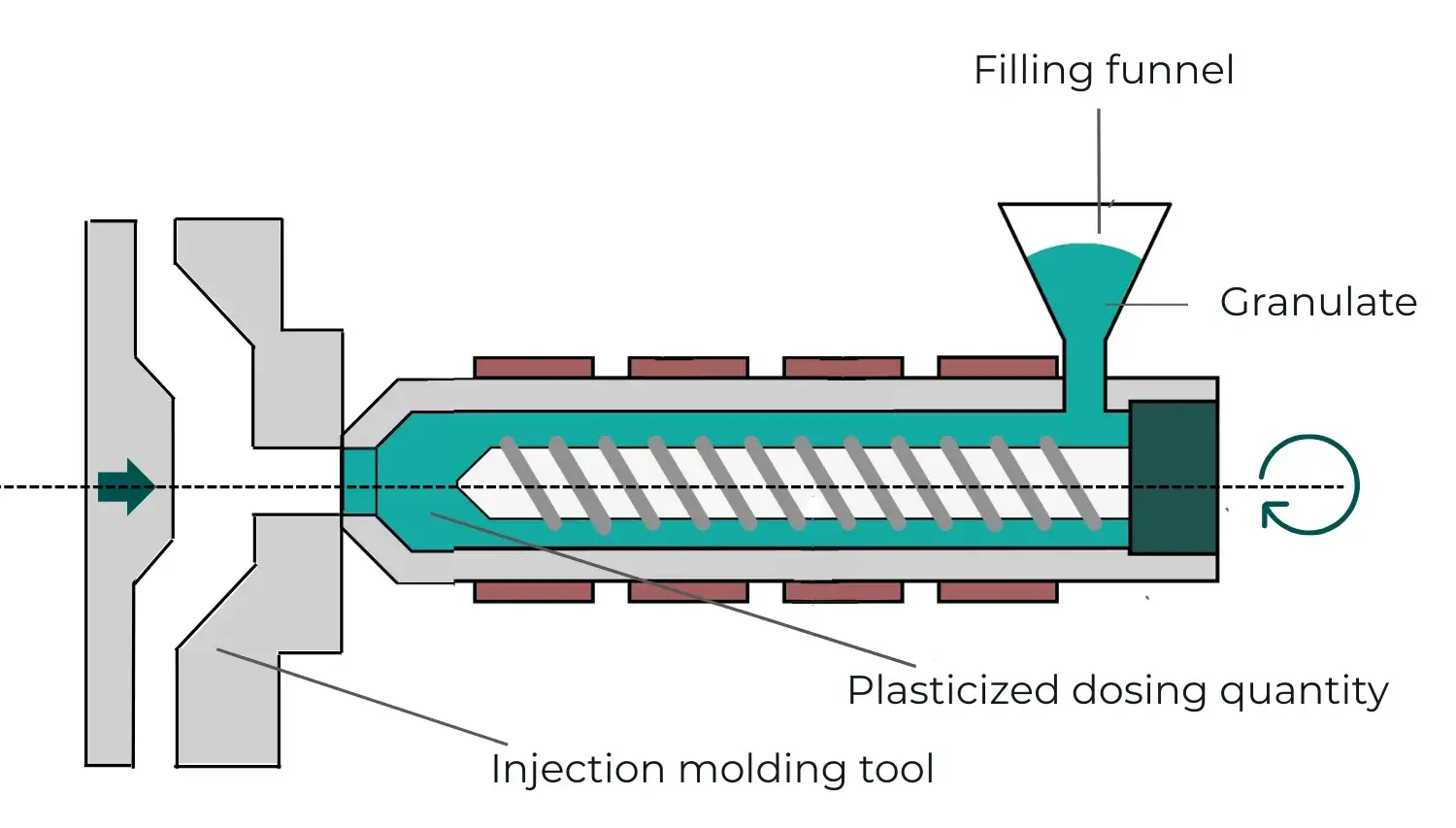

Injection molding

In injection molding, plastic is first melted and then injected under pressure into a closed mold. There, the material solidifies through controlled cooling before the mold is opened and the component is removed.

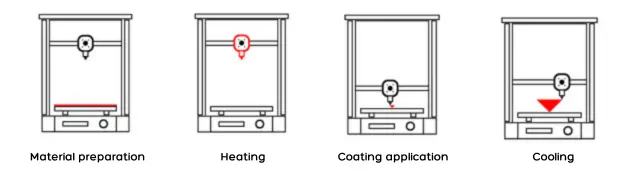

Milling / 3D printing

In CNC milling, a component is carved out of a plastic block by a computer-controlled milling head that precisely removes material along predetermined paths.

In 3D printing, also known as additive manufacturing, a component is built up layer by layer from plastic.

Foam and standard solutions

Foam can be produced both chemically and physically. In chemical foaming, typical components such as polyol and isocyanate react with each other, producing CO₂ among other things. This gas causes the mass to foam. In physical foaming, a blowing agent is added which expands or evaporates when heated, thus forming the pore structure.

After foaming, the foam block hardens and can then be cut, punched, or CNC-machined. The foam parts produced in this way are particularly suitable for simple packaging, upholstery elements, or standard solutions.

The top 5 factors to consider when deciding which plastic manufacturing process is best suited to your application

The processes are compared in five categories that are often decisive when it comes to the production of plastic parts:

- Time to market

- Cost structure (for small and medium series)

- Design freedom & modification effort

- Mechanical robustness

- Material selection

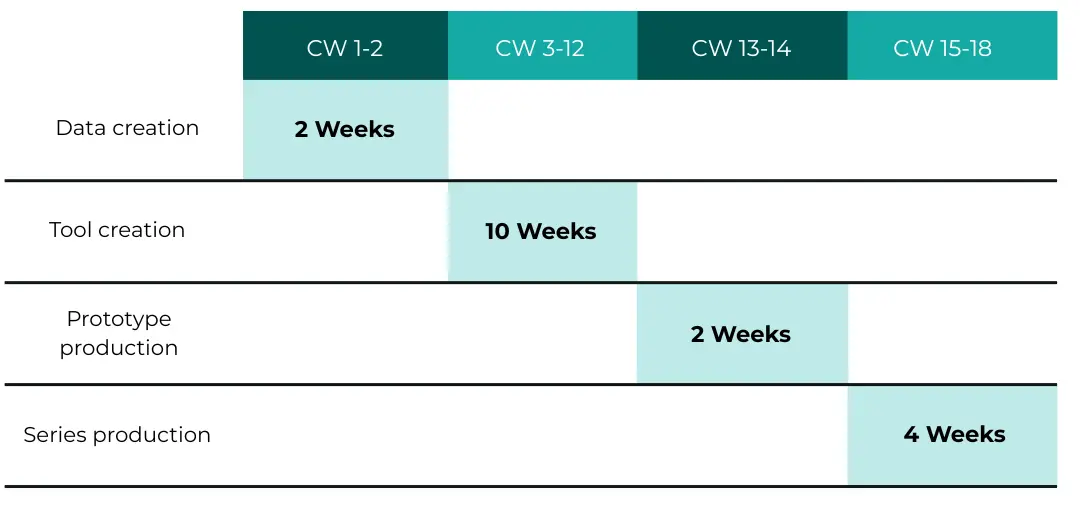

1. Time-to-market

Fast development and production start-ups enable you to respond to market requirements. Especially in dynamic markets, a short time-to-market can be crucial for securing competitive advantages or meeting project deadlines.

Plastic Thermoforming

In the best case scenario, a thermoforming project can be delivered in less than 6 weeks. This includes 1-2 weeks for creating the design based on the requirements and data in consultation with the company. Once the design data has been approved, production of the aluminum series tool begins. Depending on the urgency, this can be done in 3 weeks.

As soon as the tool is ready, it is taken to the thermoforming manufacturer and the first samples are drawn from the series tool and material. Once the series samples have been approved, series production begins. Depending on the quantities and provided that the manufacturer has sufficient capacity, (partial) delivery can take place after just two weeks.

Injection molding

In injection molding, the long tooling times of usually six to twelve weeks lead to a significantly delayed start of series production.

Milling / 3D printing

Milling and 3D printing are becoming increasingly complex in series production, which means that production times are longer overall. 3D printing is very fast for smaller quantities or prototypes, as no tools are required. This means there are no lead times. Once the CAD data is available, parts can be manufactured within a few days.

For large series, 3D printing or milling is limited due to slower production speeds, poor scalability, and higher material costs.

Foam / Standard solutions

Foam and standard solutions are ready for immediate use, but often do not offer the precision required for technically demanding applications.

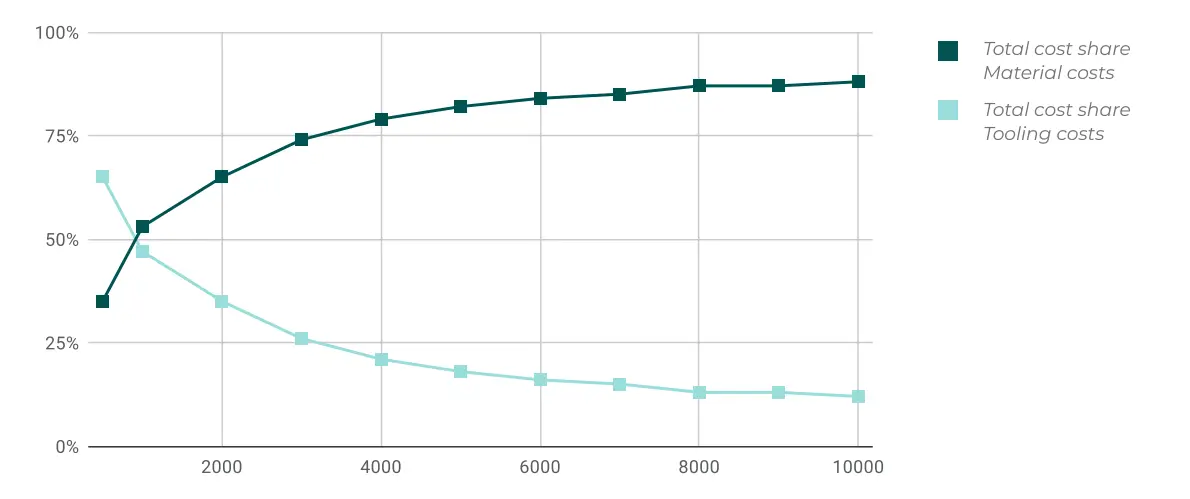

2. Cost structure for small and medium series

In moderate quantities, fixed costs have a direct impact on profitability, as they significantly increase the unit price. Processes with low fixed costs enable more efficient unit costs and reduce the risk of an uneconomical series.

Plastic Thermoforming

A key cost driver in a thermoforming project is the tooling costs, which represent a one-time investment in the four to five-digit range. These costs are amortized as the number of units increases. Since economies of scale do not apply to the same extent to material costs, the proportion of material costs per thermoformed part increases with increasing quantity and thus becomes the largest cost center.

Compared to other plastic manufacturing processes, thermoforming occupies the “sweet spot” between several hundred and 10,000 parts, as the initial tooling costs are significantly lower than for injection molding and the unit prices are significantly lower than for 3D printing.

Injection molding

Injection molding requires a costly initial investment in the tool, but is more cost-effective in terms of total costs due to low unit prices for quantities of around 10,000 or more. This means that the manufacturing process only pays off for very large series.

Milling / 3D printing

3D printing has no initial tooling costs, but due to consistent production times, there is little scope for economies of scale in terms of quantity. Milling also incurs high unit costs, which quickly makes the process uneconomical for small and medium-sized series.

Foam / standard solutions

Foam solutions and standard solutions are cost-effective, but in many cases do not offer sufficient technical durability.

3. Design freedom & modification effort

A manufacturing process that can respond flexibly to product changes, especially in the development phase, and does not make adjustments expensive or time-consuming reduces development risks. This allows updates and optimizations to be implemented without high additional costs.

Plastic Thermoforming

Deep drawing offers a high degree of flexibility and allows for adjustments, even for special requirements such as ESD or STANAG compliance.

Injection molding

Injection molding allows for design freedom, but changes to the tool often result in considerable effort and high adjustment costs.

Milling / 3D printing

Milling and 3D printing allow for changes. However, milling has geometric limitations, which reduces the scope for design. 3D printing allows for a great deal of creative freedom.

Foam / standard solutions

Foam and standard components offer little scope for customization and are limited to standard shapes.

4. Mechanical robustness

Thermoformed parts such as housings or panels must be resilient in real-world use. An unsuitable process will result in components that deform, break, or are unsafe, which can lead to high follow-up costs in assembly and service.

Plastic Thermoforming

Thanks to adjustable wall thicknesses and the materials used, thermoforming offers high rigidity and excellent mechanical strength.

Injection molding

Injection-molded parts also achieve high strength and are mechanically equivalent to thermoformed parts in terms of robustness.

Milling / 3D printing

3D-printed components have significant limitations in terms of mechanical load capacity.

Foam / standard solutions

Foam solutions also have low mechanical load capacity and are therefore usually unsuitable for functional technical applications.

5. Material selection

Materials determine both functionality and durability. Requirements such as ESD protection, UV resistance, temperature behavior, or chemical resistance are often crucial to a project. Processes with a limited selection of materials can severely restrict the area of application.

Plastic Thermoforming

Thermoforming allows for a wide range of materials, including specialized variants such as ESD-compatible or flame-retardant materials, covering many technical requirements.

Injection molding

Injection molding offers a certain variety of materials, but is limited by process-specific requirements in the selection and combination of plastics.

Milling / 3D printing

The choice of materials for milling and 3D printing is highly dependent on the respective machine, meaning that not all engineering plastics can be used.

Foam / Standard solutions

Foams are difficult to specify and therefore only meet simple material requirements.

Plastic manufacturing processes in tabular comparison:

| Advantages | Plastic thermoforming | Injection molding | Milling / 3D printing | Foam / Standard solutions |

|---|---|---|---|---|

| Time-to-Market | quickly achievable, depending on geometry & tooling | long tooling times (6–12 weeks) | quick for samples, but time-consuming for series production | immediately available, but lower precision |

| Costs for small/medium series | very efficient, low tooling costs | high fixed costs, only worthwhile for large series | high unit costs | inexpensive, but short service life |

| Design freedom & adaptability | high flexibility (also for ESD, STANAG, etc.) | high adaptation costs | geometrically limited (milling) / very free (3D printing) | hardly customizable |

| Mechanical robustness | high rigidity due to wall thickness adjustment | high strength due to compacted plastic melt | limited with 3D printing; CNC robust | low stability |

| Material selection (e.g., ESD, PC, STANAG) | wide selection, including specialized materials | limited by process-related requirements | depends on machine & process | hardly specifiable |

Which plastic manufacturing process is right for my project?

The choice of the appropriate process depends largely on the number of units, the type of component, and the cost requirements. A quick basis for decision-making:

Recommendation of the appropriate plastic process based on number of units

| Quantity | Recommended plastic process | Why? |

|---|---|---|

| 1–20 pieces | 3D printing or CNC milling | Maximum flexibility, no tooling costs, ideal for prototypes or functional samples. |

| 20–500 pieces | Thermoforming | Very low tooling costs, fast implementation, economical for small series. |

| 10,000 - 100,000 pieces | Thermoforming or injection molding (to be considered individually) | Thermoforming is most cost-effective for thin-walled, large components; injection molding is useful for high precision/detail requirements. |

| 100,000+ pieces | typically injection molding (or thermoforming with appropriate tools) | High tooling costs are offset by minimal unit costs. |

FAQ - Frequently asked questions about manufacturing processes for plastic parts

What plastic manufacturing processes are available?

The most important plastic manufacturing processes include thermoforming, injection molding, CNC milling, 3D printing, and foaming (e.g., foam solutions). The most suitable process depends on the number of units, geometry, material requirements, and budget.

Which plastic manufacturing process is the most cost-effective?

For small and medium series, thermoforming is the most economical process. For large series, injection molding remains unbeatable.

Which process is suitable for complex geometries?

- Filigree details → injection molding

- Complex free forms → 3D printing

- Large, thin-walled housings → thermoforming

Which is the most flexible process?

Thermoforming: low tooling costs, quick changes, large components possible.

When is thermoforming more suitable than injection molding?

Thermoforming is more economical for small and medium-sized series, as tooling and adjustment costs are significantly lower and projects can be started more quickly.

Why is milling or 3D printing often unsuitable for series production?

Both processes require long machine times and result in correspondingly high unit costs, which quickly makes series production uneconomical.

How does design freedom affect manufacturability?

Greater design freedom facilitates adjustments but can lead to manufacturing risks. A DFM analysis ensures that geometries are suitable for deep drawing and can be implemented efficiently.

How do I find the right material for my component?

The Material Guide provides a compact overview of available plastics, their properties, and their suitability for various applications.

Which industries benefit particularly from thermoforming?

Typical areas of application include mechanical engineering, medical technology, robotics, electronics, and horticulture.

Are there sustainable alternatives?

Yes, with our fiber casting and paper injection molding solutions, we offer completely biodegradable products, or through the use of recyclates and bioplastics.

Select the right manufacturing process for your project now

Choosing the right process determines costs, speed, and technical performance. With formary, you not only receive high-quality products, but also support in selecting materials, surfaces, and the optimal process.

On request, we can also check whether a combination of several plastic manufacturing processes makes sense—for example, prototyping using 3D printing and subsequent series production using thermoforming. Start now with your inquiry via the formary configurator and realize your next project quickly and efficiently.