Thermoforming Tool for Plastic Thermoformed Parts: Structure, Types, and Manufacturing

Plastic thermoforming is a process in which a plastic sheet or film is heated and shaped over a mold to create various three-dimensional objects. A crucial element in the thermoforming process is the tooling used to achieve the desired shape.

Sarah Guaglianone

13. Januar 2026

Contents

Thermoforming Tools for Plastic Thermoformed Parts – Key Facts at a Glance

- Thermoforming tools are indispensable in the thermoforming process, as they precisely shape plastic sheets and films, cool them, and define the surface quality. Each tool is individually designed for the specific product.

- Aluminum is the standard material for durable production tools, while Ureol, 3D printing, and wood are mainly used for prototypes or small quantities to reduce costs and development time.

- Negative and positive thermoforming tools differ in shaping and level of detail: Negative molds allow smooth surfaces and good wall thickness distribution, while positive molds are more cost-effective but less detailed.

What Is a Thermoforming Tool?

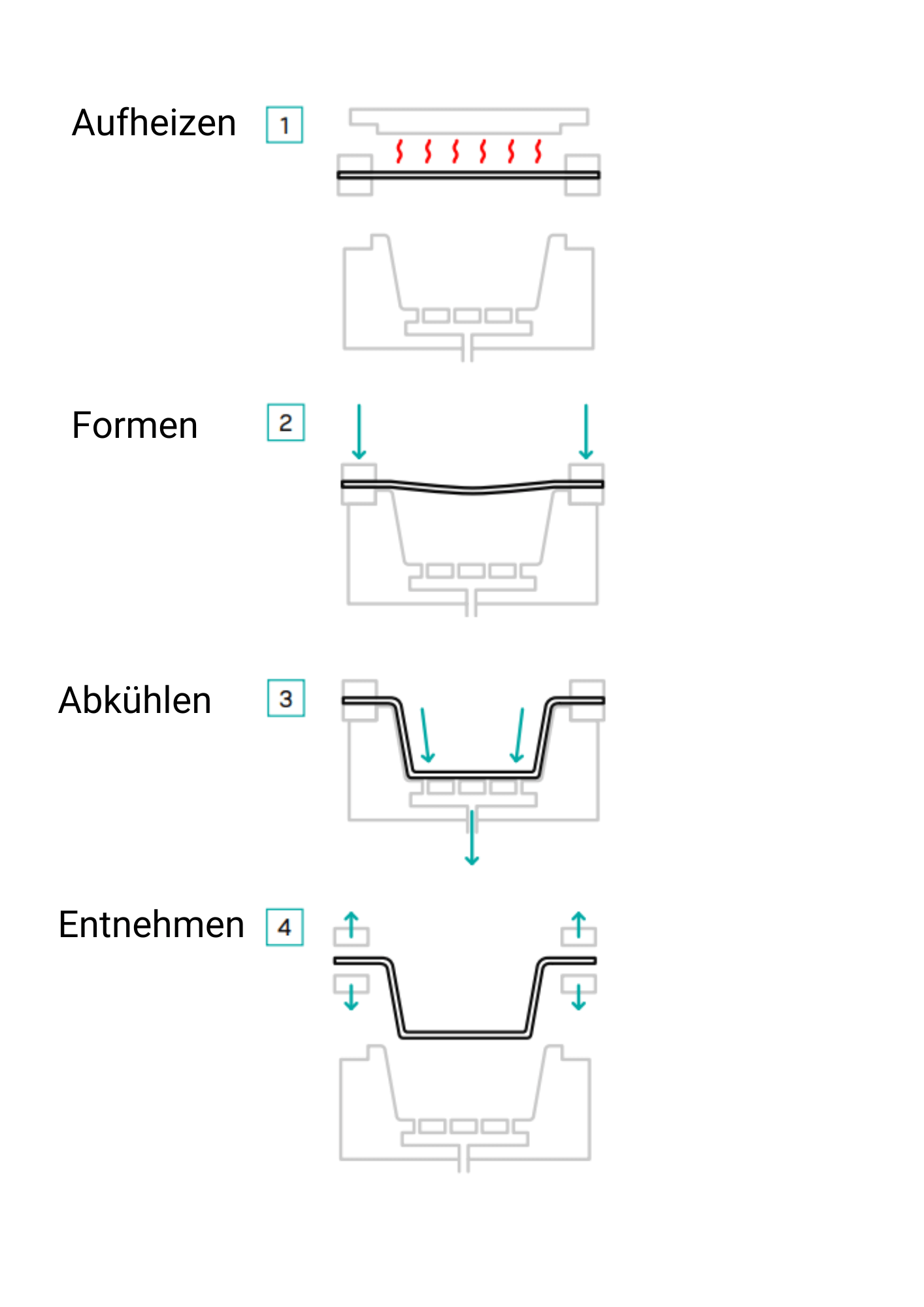

A thermoforming tool is a specialized tool used in the single-sheet or twin-sheet process to shape thermoplastic sheets or films, which are produced through plastic extrusion, into molded plastic components. The material is softened by heating and then formed into a shape using vacuum forming or pressure forming.

Why Is a Thermoforming Tool Necessary?

Thermoforming tools are essential for the deep-drawing process. Without a precise thermoforming tool, plastic cannot be shaped into the desired form. Each tool is custom-made for every product development, designed to meet specific requirements, and then installed in the machine for production—a process known as machine setup.

Since thermoforming tools are tailored for each product, they are typically unique and adapted to the specific project’s production volume, quality standards, and tolerances.

Functions of Thermoforming Tools

Thermoforming tools serve multiple functions in the manufacturing process:

- Shaping – The tool gives the heated plastic its final shape.

- Cooling – It facilitates cooling to stabilize the form.

- Surface Finish – The tool influences the texture and quality of the finished product’s surface.

Do You Need a New Thermoforming Tool for Every Product?

Yes, since thermoforming tools are custom-made for each product. However, once a tool is created, it can be used for tens or even hundreds of thousands of production cycles, especially if made from aluminum and properly maintained.

Single-Cavity vs. Multi-Cavity Tools

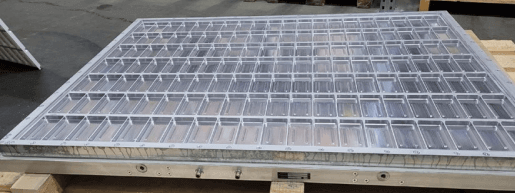

A single-cavity tool forms one part per production cycle, suitable for small batch production. A multi-cavity tool forms multiple identical parts in a single cycle, reducing production time and per-unit cost for high-volume manufacturing.

What Happens to Thermoforming Tools After Use?

After production, the tool is removed, cleaned, and inspected for any necessary repairs before being stored for future use.

Materials Used in Thermoforming Tools

Aluminum (Industry Standard for Serial Production)

- Most commonly used due to its high precision, durability, and lightweight properties.

- Water-cooled aluminum tools allow for fast cooling times, making them ideal for high-speed production.

Ureol (Polyurethane Foam)

- Used for prototypes due to its low cost and easy machining.

- Not as durable as aluminum and suitable only for limited production runs.

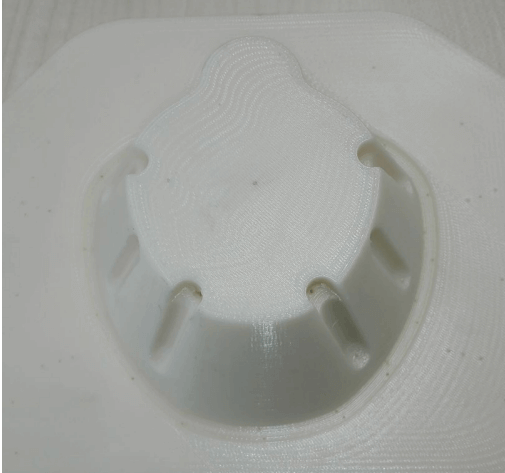

3D-Printed Plastic

- Fast and cost-effective for prototyping and testing.

- Only capable of producing a small number of samples due to heat resistance limitations.

Wood

- Rarely used, as it wears out quickly and lacks precision.

- Can be utilized for simple forming stamps or pre-stretching components.

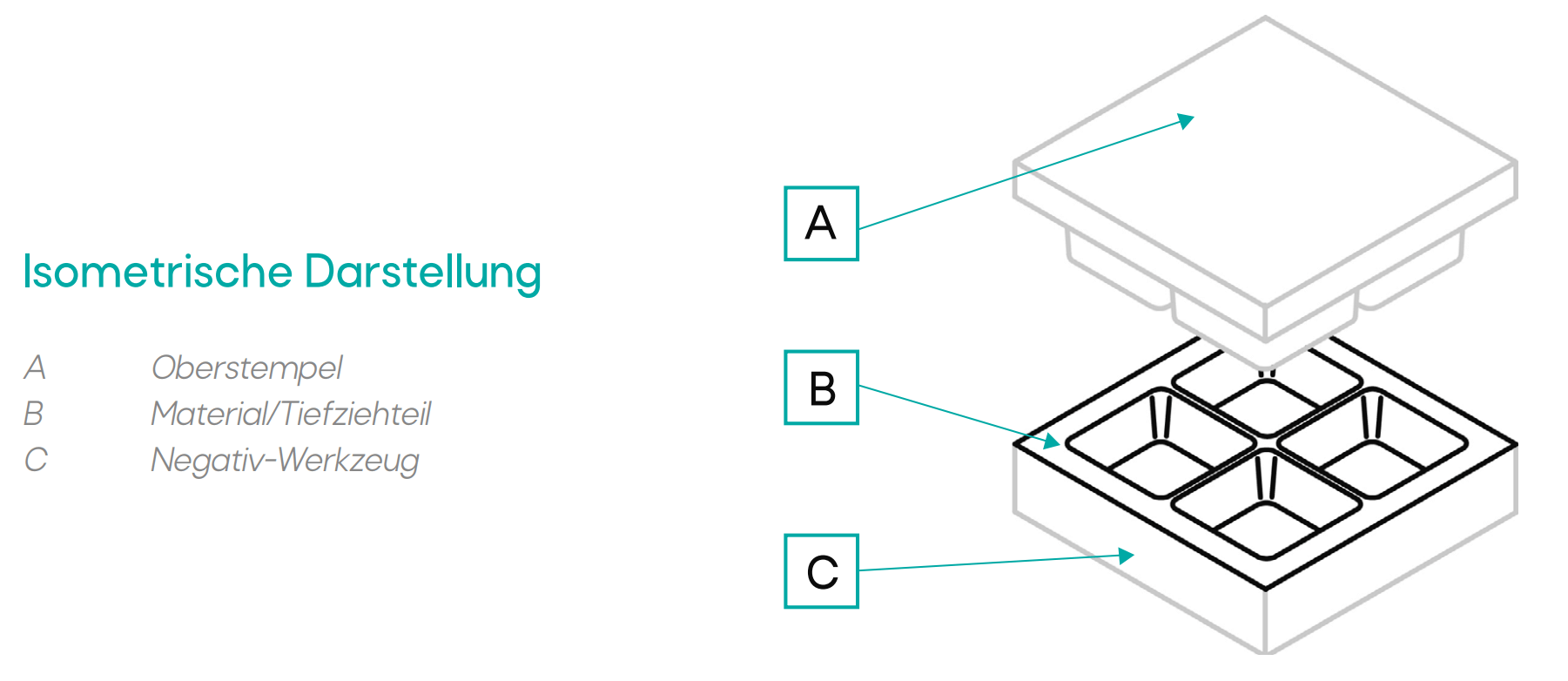

Construction of deep-drawing tools

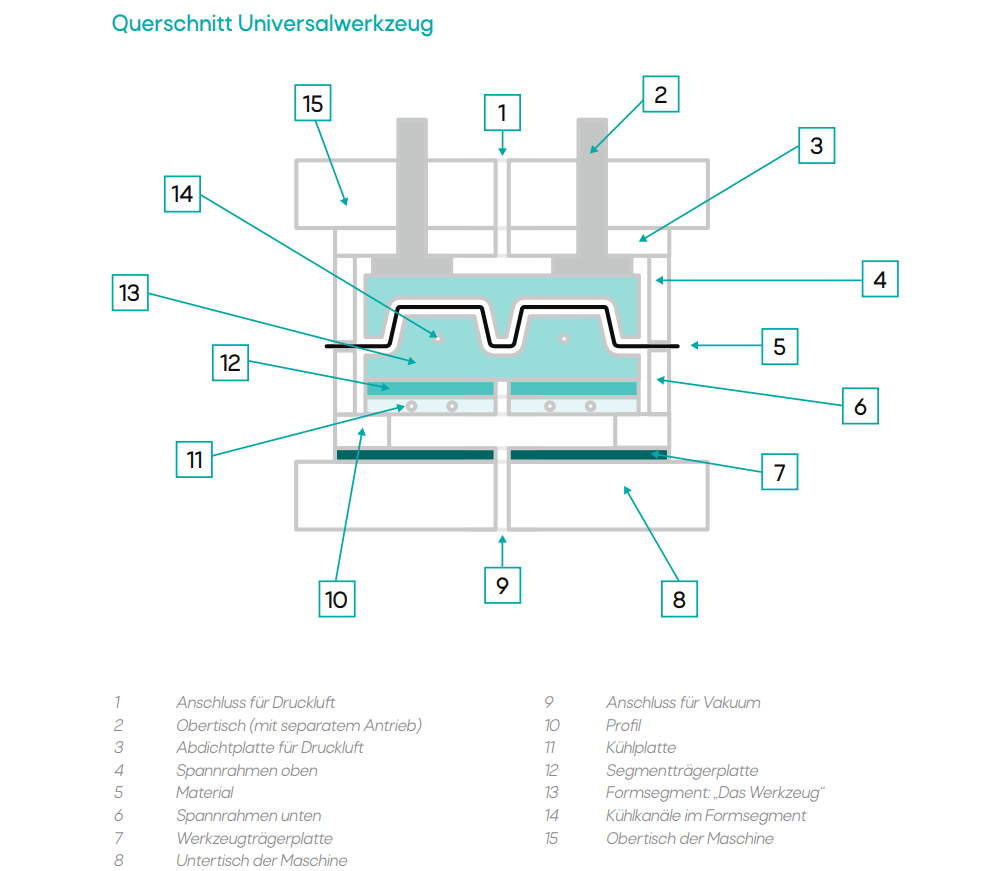

The deep-drawing tool consists of several components, including the mold itself, cooling channels that ensure uniform cooling, and holding devices that keep the plastic in position during the process. These elements work together during deep drawing to ensure precise and efficient shaping.

The aim is to keep the deep-drawing tool within a constant temperature range in order to achieve a uniform result.

The illustration shows a cross-section of the entire structure of a tool, including some standard tool components. Shown here are the machine base (8) and the carrier plate (7 in petrol), on which the positive mold (13) is mounted, which works with compressed air (1) and vacuum (9). The material (5), i.e. the plastic roll or sheet, is marked in black here.

Additional components of deep-drawing tools

In addition to the mandatory tool set (which of course also varies from machine to machine), further tool components can be created. Each of these components fulfills a specific purpose. When designing the deep-drawing tool, a decision is made as to whether and in what form separate components need to be created.

This depends primarily on the optical and mechanical requirements of the deep-drawn part. In some cases, additional components are used “only” to optimize the result, while in others, additional components are essential for a functional part. It is important to consider the tool options available.

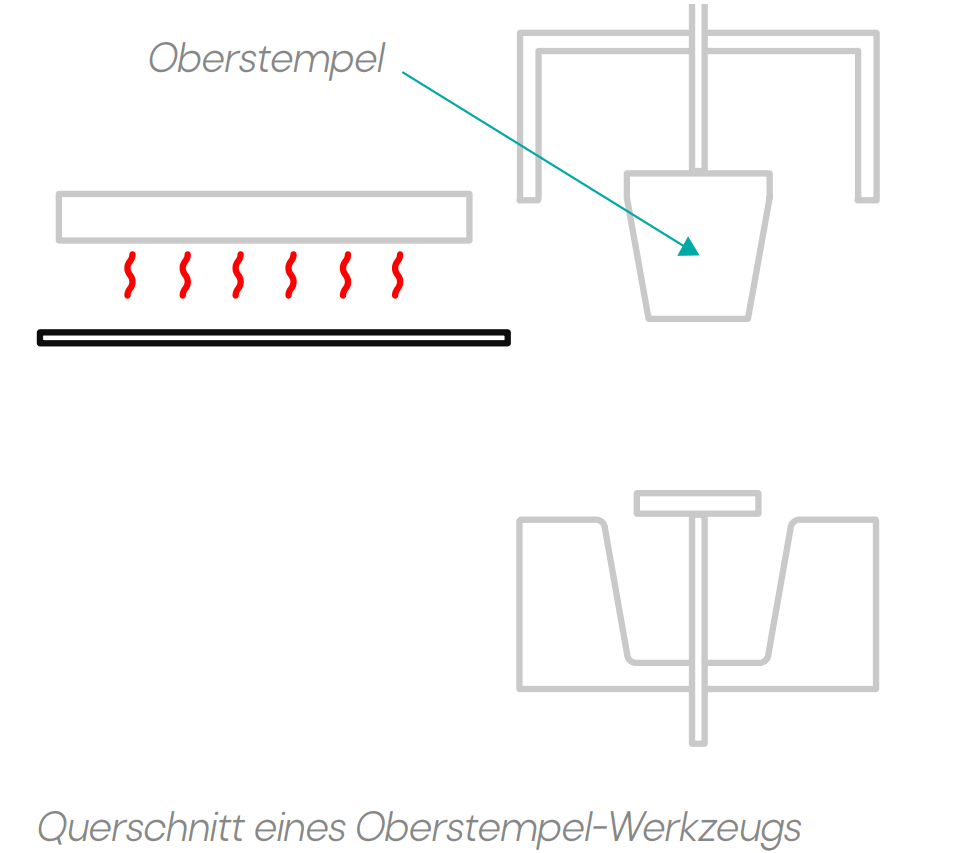

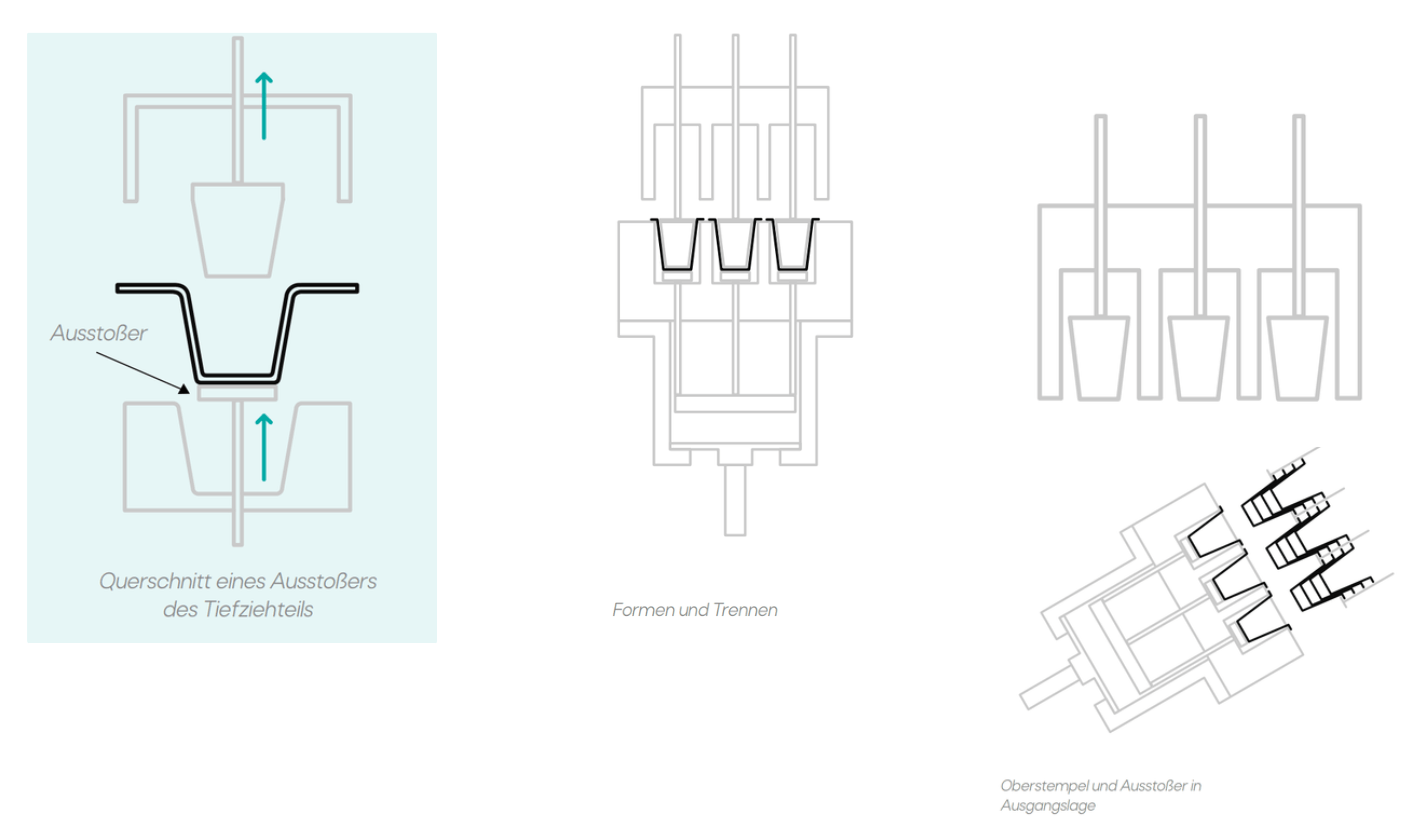

Pre-stretching punch

The pre-stretching punch, also known as the upper punch, is used to pre-stretch and shape the material in order to achieve better forming sharpness. Pre-stretching distributes the material more evenly, which allows for deep, complex shapes and the use of thinner starting thicknesses.

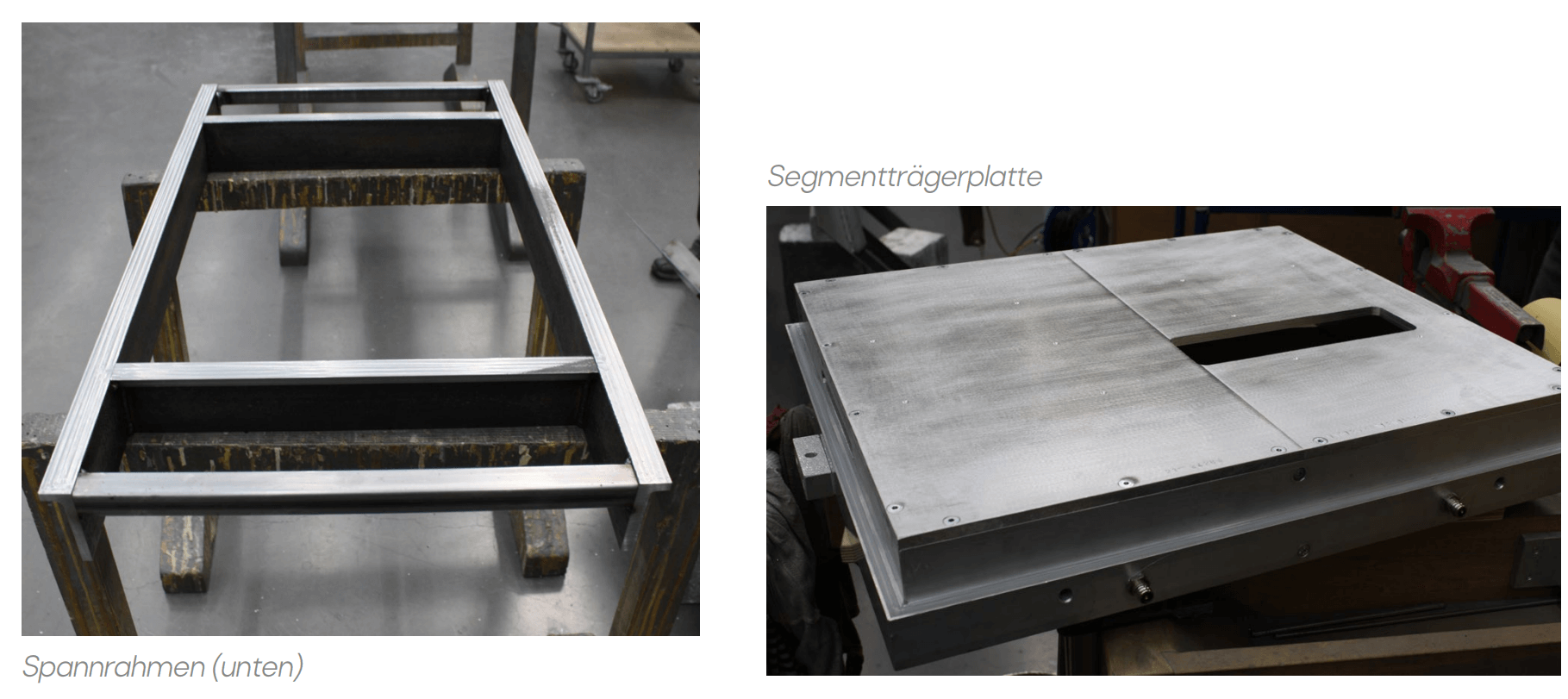

Spanning frame components

Spanning frames clamp the material during deep drawing from the plastic sheet during processing to hold it in place during forming.

Ejectors

Automated ejectors support demolding. These are used to achieve faster cycle times and to automatically feed the deep-drawn parts to a stacking unit.

Stacking stations

After the deep-drawn part has been removed from the deep-drawing tool, stacking stations can automatically stack the parts into stacking units. This facilitates the removal and packaging process from the machine.

What is the difference between positive and negative tools in plastic deep drawing?

Basically, during the forming process, the semi-finished product is stretched into the desired shape by placing the heated material in a rubber-elastic form on the tool and allowing it to cool.

The forming process can be divided into two types: positive and negative molding. The choice of process depends primarily on which side of the deep-drawn part must be dimensionally accurate and whether the required stability must be maintained at the bottom or at the edge of the plastic deep-drawn part.

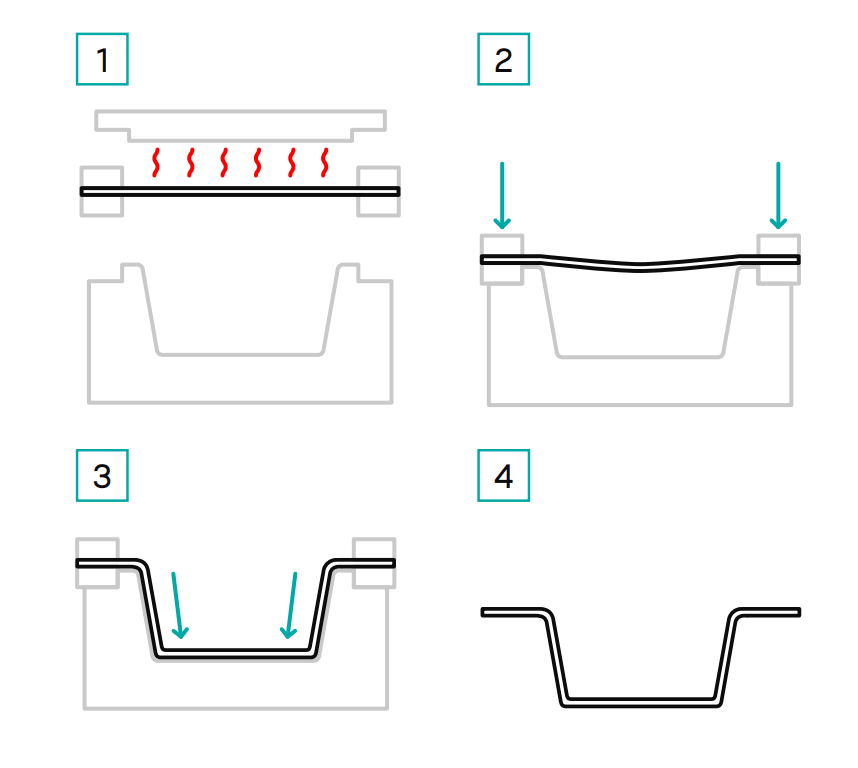

Negative tool

In negative molding, the semi-finished product is pressed into the concave mold cavity. This can be done using vacuum or additional compressed air. To ensure uniform wall thicknesses, an upper punch made of an insulating material can also be used, which pushes material into thinning areas of the deep-drawn part during molding.

Advantages and disadvantages of negative deep-drawing tools

| Advantages of negative deep-drawing tools | Disadvantages of negative deep-drawing tools |

|---|---|

| Good wall thickness distribution | Increased material costs |

| Smooth, flawless surface | Increased risk of material cracks and wrinkling |

| Good demoldability | Top punch usually required |

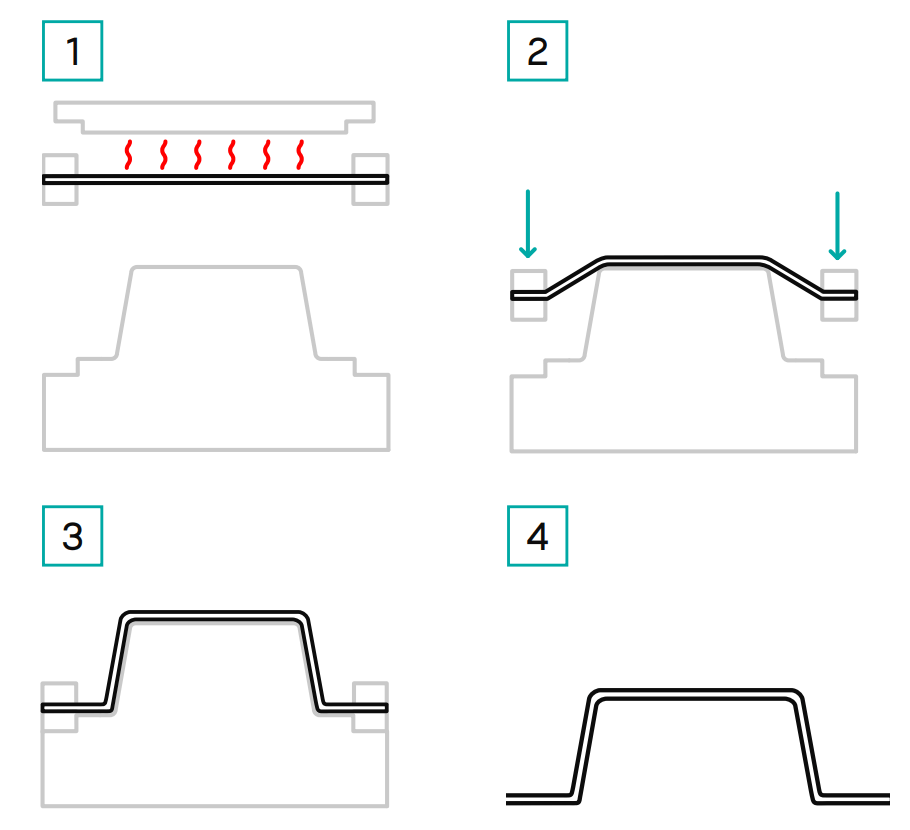

Positive tool

In positive molding, the semi-finished product is pulled over a convex elevation. To avoid thin spots at the edges, the material is often pre-blown with compressed air from below.

Advantages and disadvantages of positive deep-drawing tools

| Advantages of positive deep-drawing tools | Disadvantages of positive deep-drawing tools |

|---|---|

| Simple and cost-effective production | Lower level of detail |

| Improved wall thickness distribution compared to negative tools without upper punch | Limited surface quality, the outside of the part may be less smooth, which affects aesthetics |

| Good surfaces on the outside | Difficult demolding with complex geometries |

Manufacture of deep-drawing tools

Deep-drawing tools for plastics processing are manufactured in the following steps:

- Design

- CNC milling

- Manual re-milling

More on this in the following sections.

Designing a deep-drawing tool

The first step in the manufacture of a deep-drawing tool is the design, which is usually done using CAD data that shows the deep-drawing tool sketch. The exact specifications and designs of the tool are developed to ensure that the thermoforming tool meets the requirements. Read more about this here.

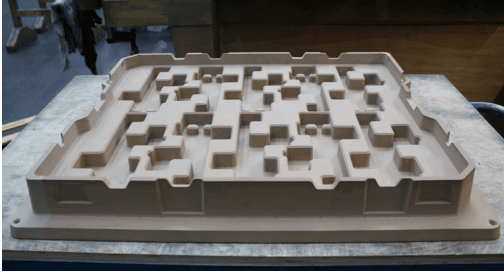

CNC milling

After design, the deep drawing tool is machined from the selected material using 5-axis CNC milling. CNC milling offers high precision, which is essential for the manufacture of high-quality tools.

Manual re-milling

CNC milling is often followed by manual reworking to optimize fine details, create very precise vacuum holes, and improve the surface quality. These reworking steps are essential to ensure that the deep-drawing tool meets the high requirements of production.

Frequently Asked Questions About Thermoforming Tools

What is the main purpose of a thermoforming tool?

It shapes heated plastic, ensures uniform wall thickness, and influences surface quality.

What materials are used for thermoforming tools?

Aluminum for series production, Ureol for prototypes, 3D-printed plastic for small quantities, and wood for simple or special applications.

What is the difference between male and female thermoforming tools?

Female tools use concave molds for better wall thickness distribution; male tools use convex shapes and are simpler but less detailed.

When does a multi-cavity tool make sense?

For high production volumes to reduce cycle times and unit costs.

How is a thermoforming tool manufactured?

Via CAD design, CNC milling, and manual finishing for precision and surface quality.

Is tool transfer to another supplier possible?

Yes, a tool transfer is possible, if the tool is the customer’s property, it can be transferred to another thermoforming supplier without issues.

Deep-drawing tools in plastic thermoforming – a conclusion

Deep-drawing tools are essential for the production of plastic deep-drawn parts. When designing the tool, it is important to consider which additional components are required to meet the requirements of the deep-drawn part in order to meet the quality standards. The optimal deep-drawn part is therefore designed to suit the material, process, and tool.

Would you like to get started with your deep drawing project and have further questions about deep drawing tools? Then read our design guide, which answers all your questions about thermoforming.