ESD Trays Made of Plastic – Applications and Benefits

Electrostatic discharge (ESD) can irreparably damage sensitive components and incur high costs. To ensure that electronic components are optimally protected during manufacturing, storage, and delivery, ESD trays made of plastic are used.

Sarah Guaglianone

13. Januar 2026

Contents

What is an ESD Tray?

An ESD tray is a plastic workpiece carrier designed to protect electronic components from damage caused by electrostatic discharge (ESD). ESD, which stands for "Electrostatic Discharge," can cause significant harm to sensitive electronic parts. ESD trays are specially designed to prevent electrostatic discharge, ensuring a safe environment for the components.

Protection is ensured through the material composition of the tray, which consists of plastics enriched with conductive or antistatic additives. This combination helps to dissipate static charges before they can reach sensitive components.

How Does an ESD Tray Work?

The function of an ESD tray relies on three key material properties:

- Electrical Conductivity: The addition of additives like carbon black or graphite makes the plastic electrically conductive, allowing static charges to be efficiently dissipated.

- Antistatic Effect: Antistatic additives prevent static charges from forming on the surface of the ESD tray.

- Surface Protection: The smooth, specially treated surface of the ESD workpiece carriers not only protects against scratches but also prevents dust or particles from accumulating, which could otherwise lead to static buildup.

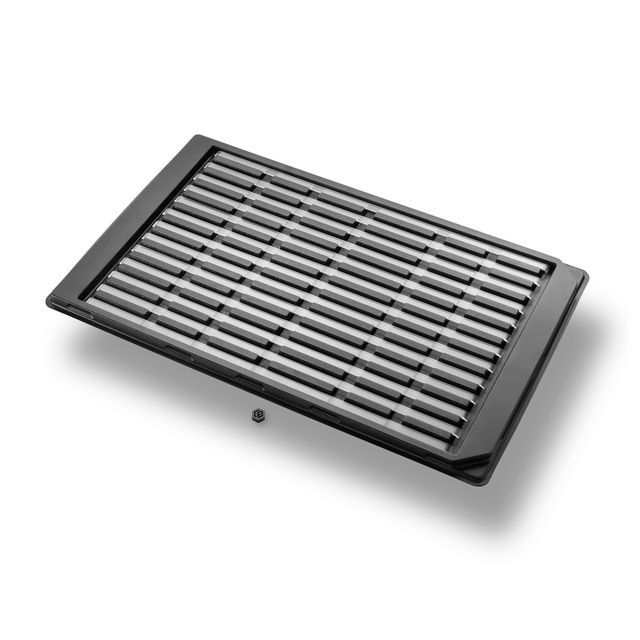

Materials and Manufacturing Processes for ESD Workpiece Carriers

The base material of an ESD tray is a thermoplastic plastic, modified to be electrically conductive or antistatic. Commonly used thermoplastics include ABS (Acrylonitrile Butadiene Styrene Copolymer) and PS (Polystyrene). These plastics are combined with conductive additives like carbon black or graphite and antistatic substances to achieve the desired properties.

How are ESD Trays Made?

- Material Preparation: During plastic extrusion, plastic granules are carefully mixed with additives and antistatic agents to ensure the desired material properties.

- Shaping: The plastic is heated and molded into its final form through thermoforming.

- Quality Control: Finally, the ESD packaging is tested for electrical conductivity, antistatic properties, and mechanical stability.

Applications of ESD Trays

ESD trays are used across various industries to ensure safe storage and reliable transport of sensitive electronics:

Typical Fields of Application for ESD Trays

- Electronics Manufacturing: In the electronics industry, ESD trays are used to transport and safely store components such as semiconductors, circuit boards, or chips between different stages of production.

- Automotive: Modern vehicles contain sensitive control units and sensors that need protection during production and delivery.

- Medical & Pharma: Diagnostic devices and their components also require high protection from electrostatic discharge.

Typical Components that Require ESD Trays

- Electronics Manufacturing: Semiconductors, circuit boards

- Automotive Industry: Control units, sensors

- Medical & Lab Technology: Diagnostic chips, modules

Overview of ESD Workpiece Carrier Applications

Areas of application for ESD trays | Typical components that require ESD trays |

|---|---|

Electronics manufacturing | Semiconductors, printed circuit boards |

Automotive | Control units, sensors |

Medical and laboratory technology | Diagnostic chips, modules |

Advantages of Plastic ESD Trays

Plastic ESD workpiece carriers offer several additional benefits for handling sensitive components. Their function is similar to that of conventional plastic trays, with added advantages:

Durability

Plastic ESD trays are made from high-quality materials that provide excellent strength and durability. Compared to traditional cardboard or foam trays, plastic ESD trays are more resistant to impacts, vibrations, and moisture.

Customization for Your Needs

Electronic components come in various sizes and shapes. ESD trays are highly customizable and can be designed to meet specific customer requirements. This allows components to be safely and efficiently positioned and transported in the ESD packaging, making it an ideal packaging solution.

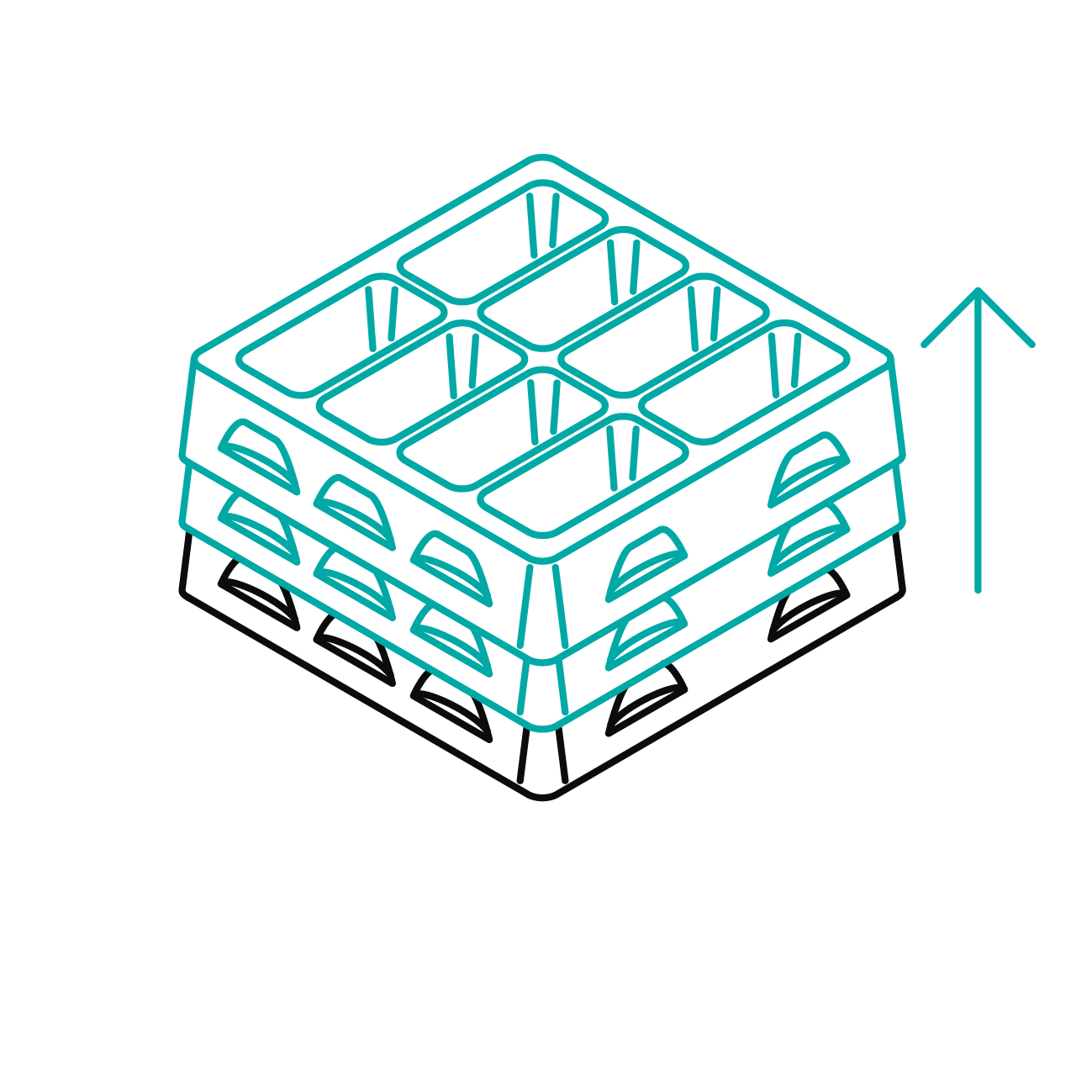

Optimierte Lagerung und Transport

ESD trays are ergonomically designed and easy to handle. They can be equipped with integrated handles for easy gripping and transport.

Additionally, plastic ESD trays are stackable, ensuring optimal storage and shipping. Transparent ESD trays also allow easy identification and organization of electronic components.

Reusability

Compared to single-use packaging, plastic ESD trays offer a more sustainable option. ESD workpiece carriers can be designed for multiple uses, reducing waste and the need for single-use materials like cardboard or foam. At the end of their lifecycle, plastic trays can also be recycled to further improve resource efficiency.

ESD Trays for Your Application

Are you looking for a tailored solution to protect your valuable electronic components? There are more options than just ESD trays for protecting your electronics, such as plastic enclosures for electronics, ESD transport packaging, and more.

Use our configurator to design your personalized thermoformed part in ESD execution.