Description

PVC plastic, short for polyvinyl chloride, has relatively high rigidity and strength, making it highly suitable for thermoforming. Thanks to its high transparency and resistance to various chemicals and substances, PVC plastic is often used in the packaging industry and medical technology for blister packaging and thermoformed parts.

Processing and Thermoformability

PVC plastic excels in thermoforming due to its excellent moldability. Experience shows that PVC can be easily thermoformed into various shapes and sharp contours. Blisters made of PVC plastic can also be bonded very well in post-processing. This makes polyvinyl chloride a high-quality material in terms of processability and thermoformability. Challenges arise with PVC plastic during recycling. When PVC is incinerated for energy recovery, environmentally hazardous substances such as gaseous hydrogen chloride or heavy metal stabilizers are released. As a result, incineration plants must be equipped with advanced filtration technology to neutralize these substances and prevent harmful emissions. Since this energy recovery process comes with high environmental protection costs, polyvinyl chloride is often replaced by PET whenever the application allows.

Material Options

Sealability

Sealability Weldable

Weldable Printable

PrintableFacts

Price

Colors

Features

- Very high transparency

- High stiffness and hardness

- Excellent mechanical properties

- Excellent processability

- Resistant to: Acids, alkalis, detergents, alcohols, oils, and gasoline

- Highly sealable

- Cost-effective

Weaknesses

- Difficult to recycle

- Not suitable for use in the food industry

Common Industries and Applications:

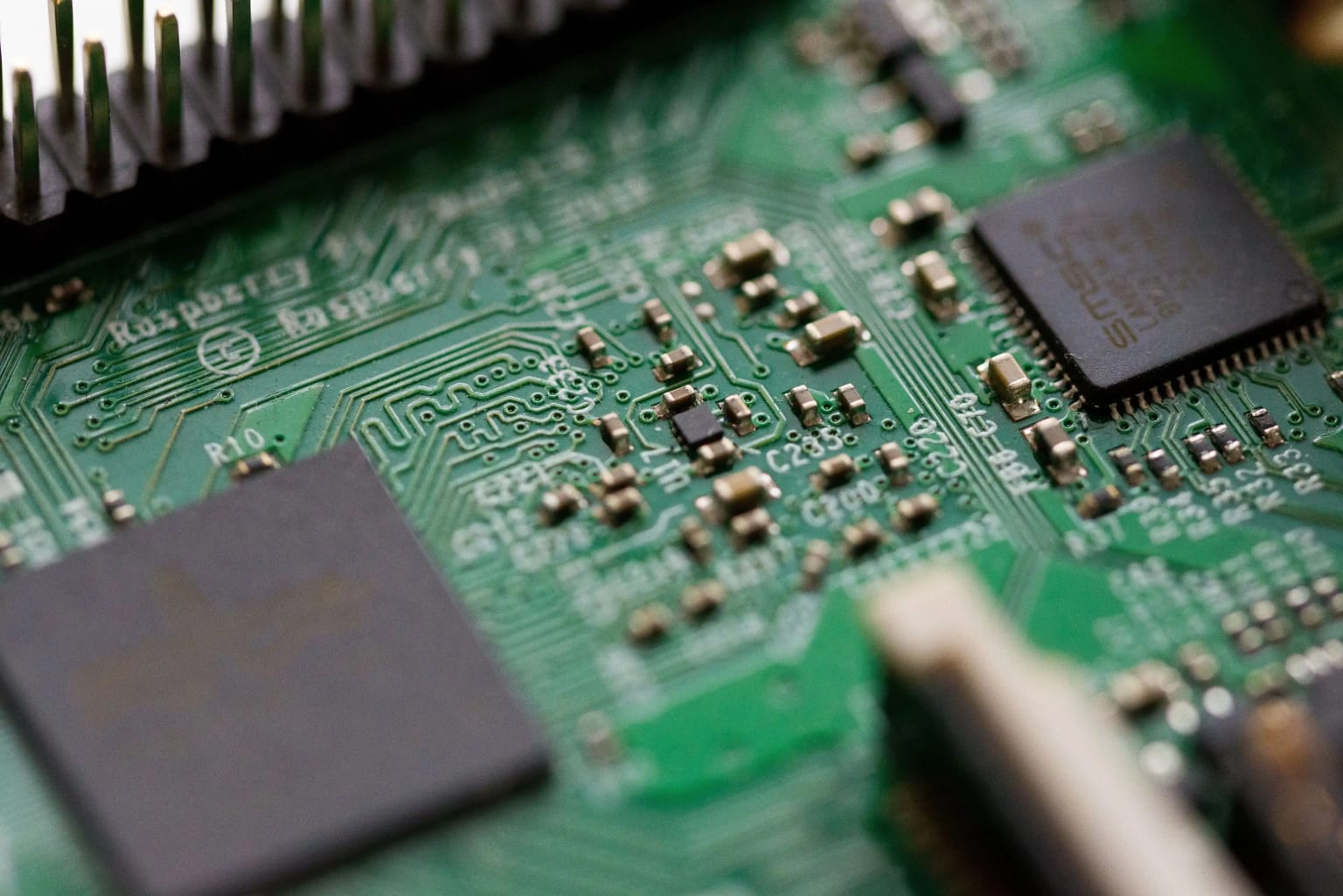

Electronics

- Transparent covers for distribution boxes

- Lampshades

- Drone covers

Consumer Goods

- Fasteners for raised garden beds

- Poster back panels

Mechanical Engineering

- Collection trays

- Washing tubs

- Protective covers for pumps

- Filling systems

- Simulation trays for surgeries

Food

- Secondary packaging in the food sector

Industrial Solutions

- Transport boxes

- Covers for thread grinding machines

- Inlays for abrasives

- Collection trays for acids

- Seat shells

- Formed parts in the construction sector: Pipes and ducts, ventilation grilles

Facts and Figures:

| Group | Standard Thermoplastics |

| Structure | Amorphous |

| Density | 1.39 |

| Continuous Use Temperature Min. (in °C) | -5 |

| Continuous Use Temperature Max. (in °C) | 65 |

| Thermal Expansion Transverse/Longitudinal to Flow Direction (10^-6 *K) | 80 |

| Melting Temperature (°C) | 80 |

| Max. Temp. Short-Term (°C) | 70 |

| Max. Temp. Long-Term (°C) | 60 |

| Impact Strength (KJ/m^2) | 80 |

| Yield Stress (N/mm²) | 58 |

| Tensile Strength (N/mm²) | 58 |

| Tensile Modulus of Elasticity (N/mm²) | 2900 |

| Elongation at Break (%) | 15 |

| Flexural Strength (N/mm²) | 85 |

| Ball Indentation Hardness (N/mm²) | 130 |

| Dielectric Strength (kV/mm) | 40 |

| Volume Resistivity (Ω · m) | 1E13 |

| Surface Resistivity (Ω) | 1E13 |

| Tracking Resistance CTI | 600 |

Additional Plastics in the formary Portfolio

Frequently asked questions about PVC plastic

PVC plastic (polyvinyl chloride) is a rigid, solid thermoplastic that is very easy to thermoform. Due to its high transparency and resistance to chemicals, PVC is often used for blister packs, packaging, transparent covers, machine covers and medical thermoformed parts.