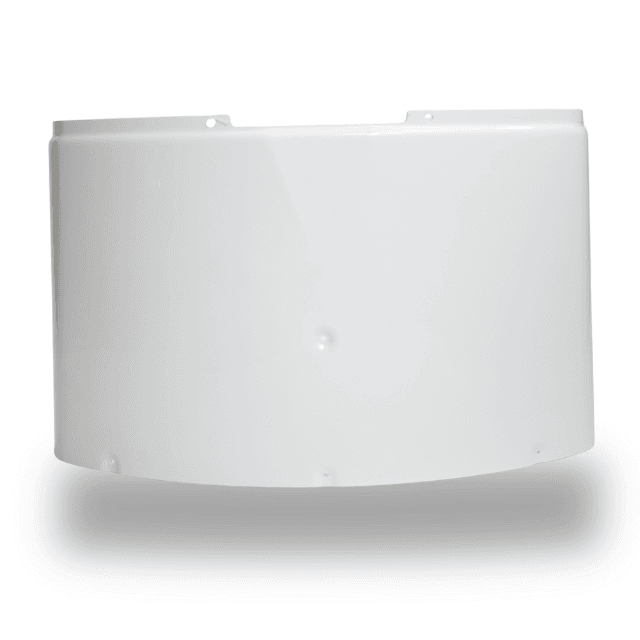

Plastic Robot Housing

Robot enclosures, cladding and covers made of plastic for greater safety, efficiency and protection for your robotics application

What are Robot Enclosures?

Robot housings are functional and aesthetic plastic cover parts that protect robots from external influences such as impacts, scratches, dust or moisture. At the same time, they meet important requirements in terms of hygiene, design and ergonomics.

Where are Robot Housings used?

Robot enclosures are used in almost all areas of robotics:

Service robots: Cladding for humanoid robots in nursing, catering or retail, with hygienic, scratch-resistant and easy-to-clean surfaces.

Industrial robots: Protective covers for grippers, sensors or control units, adapted to automated production processes.

Medical robots: Enclosures with EMC coating and flame retardant for surgical robots, diagnostic devices or assistance systems.

Mobile platforms: Cladding for autonomous transport robots, including recesses for cameras, sensors and interfaces.

Functions & Characteristics of Robot Cladding

Lightweight Construction

Plastic housings are lighter than metal casings. This significantly reduces energy consumption and increases the efficiency and mobility of robotic systems.

Technical Options

Robot housings can be flexibly adapted with assemblies, CNC milling, EMC coatings and modular clip-in systems.

Design Options

From high-gloss ABS/PMMA to matt or textured surfaces, chrome finishes and branding with colours, printing or logo embossing – anything is possible.

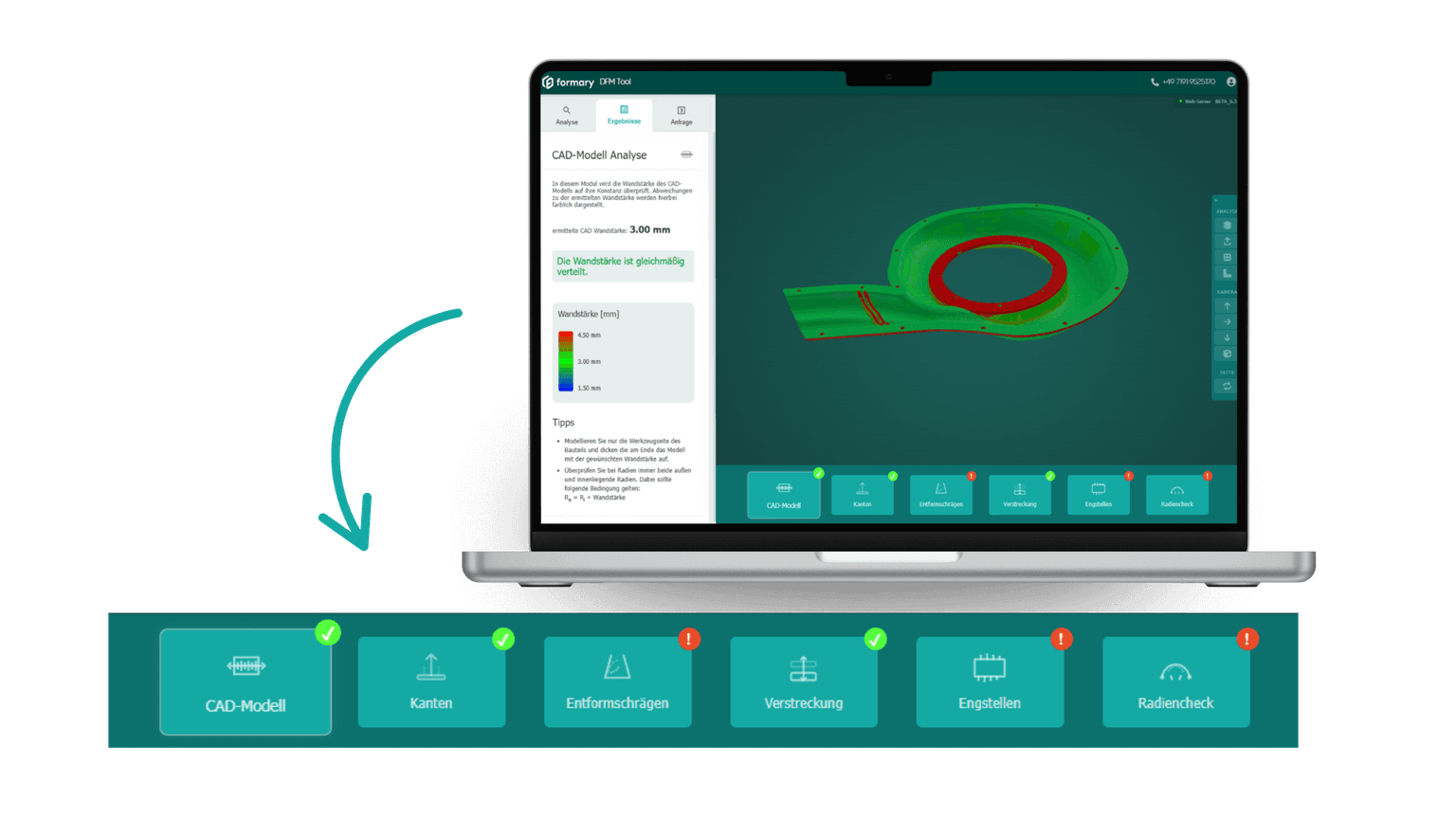

DfM Analysis for Robot Housings: Is your Design suitable for Deep Drawing?

Do you already have a CAD model for your plastic robot casing? We will check it for you – free of charge and without obligation.

With our DfM analysis (Design for Manufacturability), we can determine at an early stage whether your design can be technically implemented using the thermoforming process. We would be happy to go through your data with you.

Areas of Application for Plastic Robot Housings

Industrial Solutions

- Industrial protective enclosures

- Robot cladding

- Robot covers for grippers

- Robot covers for monitors

- Industrial protective enclosures

- Covers for robot controllers

- Protective panels for robot cells

- Protective screens for gripper sensors

- Robot maintenance flaps

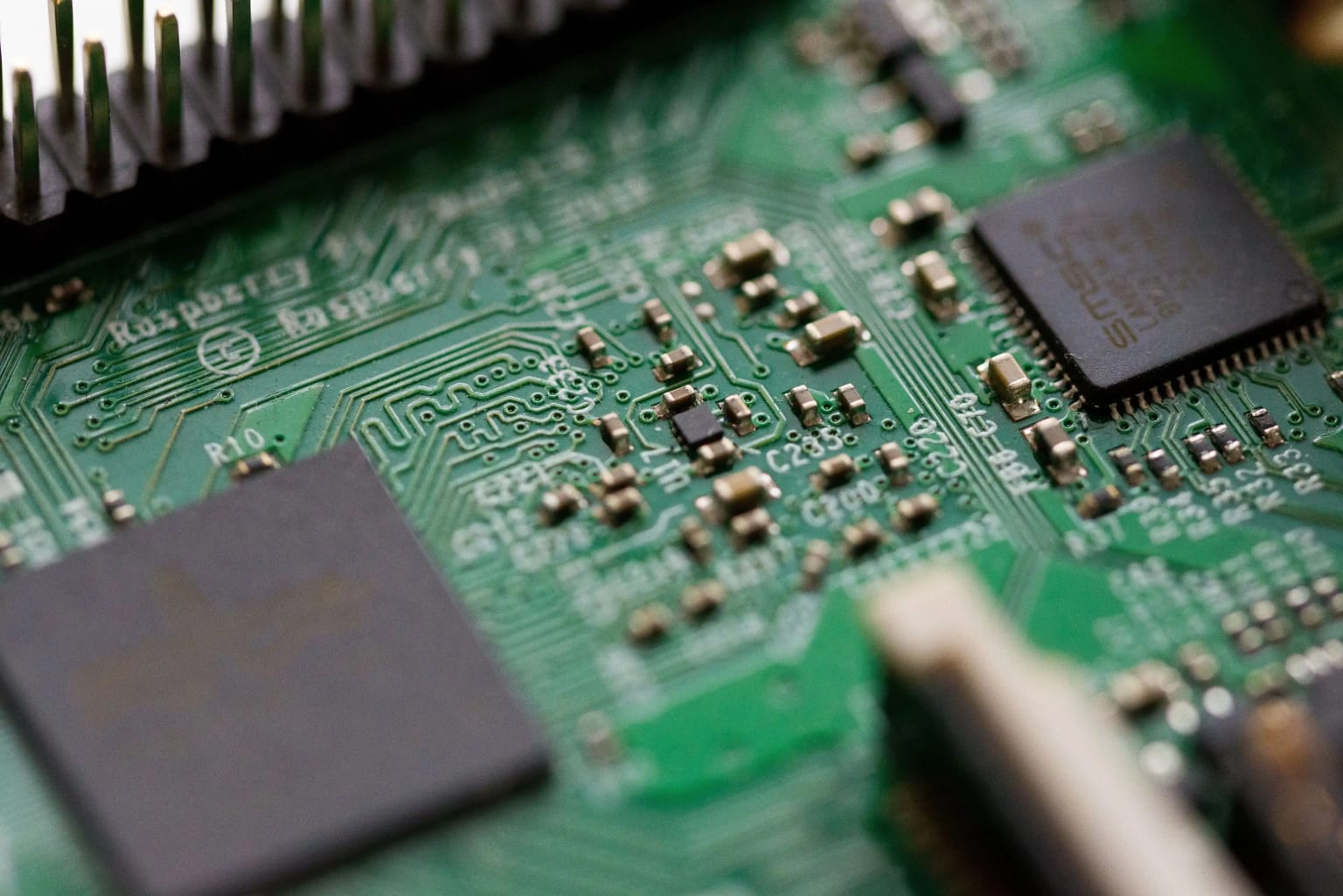

Electronics

- Dust and splash protection hoods

- Heat-resistant robot covers

- Chemical-resistant robot cladding

- Modular robot enclosures

- Control panels for robots

Robotics

- Covers for robot arms

- Lightweight cladding for industrial robots

- Chemical-resistant protective covers

- Sensor covers for robotics

- Chassis for logistics robots

- Covers for user interfaces

- Cladding for service robots

Medical Technology

- Surgical robots

- Diagnostic assistance systems

Advantages of Plastic Robot Enclosures

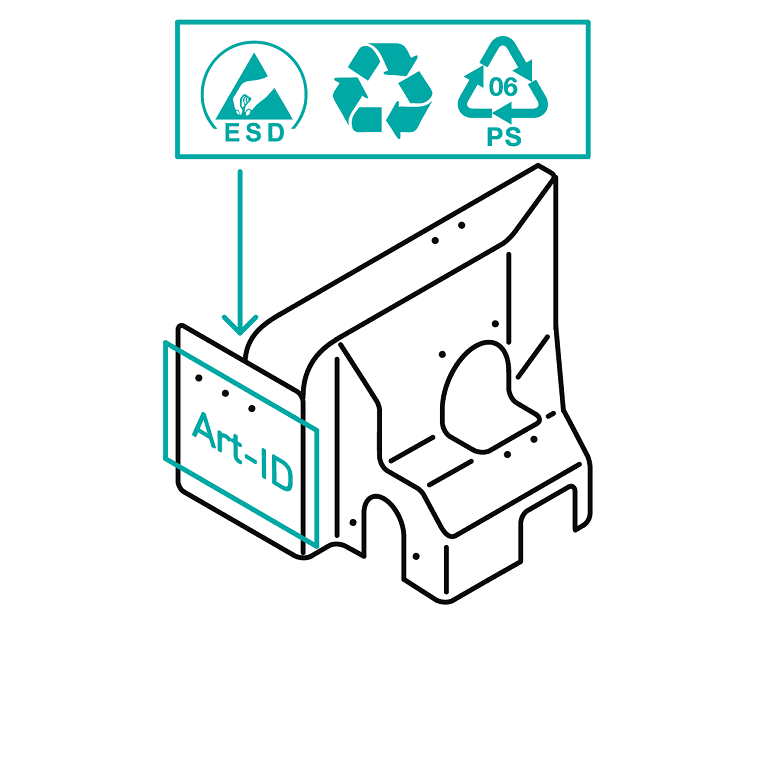

ESD & EMC protection

Enclosures for robots with ESD and EMC protection ensure a particularly high level of safety.

Hygienic

Thanks to specific plastic properties, robot housings offer scratch-resistant surfaces that are also easy to clean.

Design Freedom

The thermoforming process enables the implementation of complex geometries, individual surface structures and transparent components for your robotics application.

Cost Efficiency

In contrast to injection moulding, the tooling costs for plastic thermoformed parts in robotics are significantly lower, making them particularly attractive for prototypes, small series and customised robot components.

Short Delivery Times

Rapid prototyping enables projects to be implemented quickly and helps robotics manufacturers to significantly shorten their development cycles.

Durability & Resilience

Thanks to their specific plastic properties, plastic parts for robotics are ideal for continuous operation in industrial production facilities and mobile robot systems.

Fields of Application for Plastic Robot Covers

Industrial Manufacturing & Automation

Robot housings protect motors, joints and control modules in production or assembly systems. Thanks to UV- and chemical-resistant plastics, the covers are suitable for continuous use.

Service and Assistance Robotics

Robot housings are often used in humanoid service robots, for example in care facilities, hotels or in retail. As a rule, the housing components must be particularly hygienic, scratch-resistant and easy to clean, as the robots are in direct contact with staff and possibly also patients on a daily basis.

Electronics & Sensor Protection

ESD- and EMC-protected robot housings for circuit boards, sensors and control systems are used to protect sensitive electronics from static discharge and electromagnetic interference. Robotics cladding parts play a key role in diagnostic and imaging devices, ensuring the reliable integration of displays, cameras and interfaces.

Other enclosure applications that may be of interest to you

Industries that use Plastic Robot Cladding

More Products for Covers and Enclosures

Plastic thermoformed parts are used for robot housings, robotics covers, workpiece carriers, protective covers and ESD-protected components in industrial, service and mobile robots.