Description

ABS serves as an entry point into the world of engineering plastics. It is considered an all-around performer in thermoforming, offering enhanced mechanical and thermal properties compared to PS plastic. Thermoformable ABS plastic is noted for its excellent impact strength, stiffness, and tensile strength, alongside high hardness. The abbreviation ABS stands for Acrylonitrile-Butadiene-Styrene copolymers.

Processing and Thermoformability

ABS is known for its ease of processing due to good flow characteristics. Because of the butadiene in ABS, which creates a strong bonding structure, it is highly suitable for coating, painting, printing, and metal plating. This includes producing ABS parts with a chrome-plated finish. Adding special additives to ABS to achieve specific part properties might affect its thermoformability, such as TPU for delicate components or flame retardants for fire resistance in blister packaging. ABS thermoformed parts can be readily glued and welded thanks to their high heat resistance. When storing ABS raw materials, remember it's hygroscopic, meaning it absorbs moisture over time, which can deteriorate quality and processability. Consequently, ABS is generally not stockpiled but sourced on-demand to meet customer needs. You should factor in lead times when procuring ABS thermoformed parts.

Material Options

Antistatic

Antistatic Printable

Printable Regenerate

RegenerateFacts

Price

Colors

Features

- Good impact resistance

- Good scratch resistance

- High temperature resistance

- Antistatic (without additives)

- Resistant to: oils, organic chemicals, organic acids

- Additives: flame retardants, stiffness, cold resistance

- Ideal for coating, painting, metal plating

Weaknesses

- Poor tensile strength

- Not suitable for use with solvents

- No "clear view" (natural beige color)

- Poor storage stability due to hygroscopic nature

Common Industries and Applications:

Automotive

- Body panels & covers

- Air conditioner covers

- Water deflectors

- Housing components: hoods, back parts, front parts, tail parts

- Fender extensions

- Tail light overlays

- Engine covers & housings

- Mudguards

- Column covers

- Wheel covers

- Vehicle covers

- Steering column covers

- Battery covers

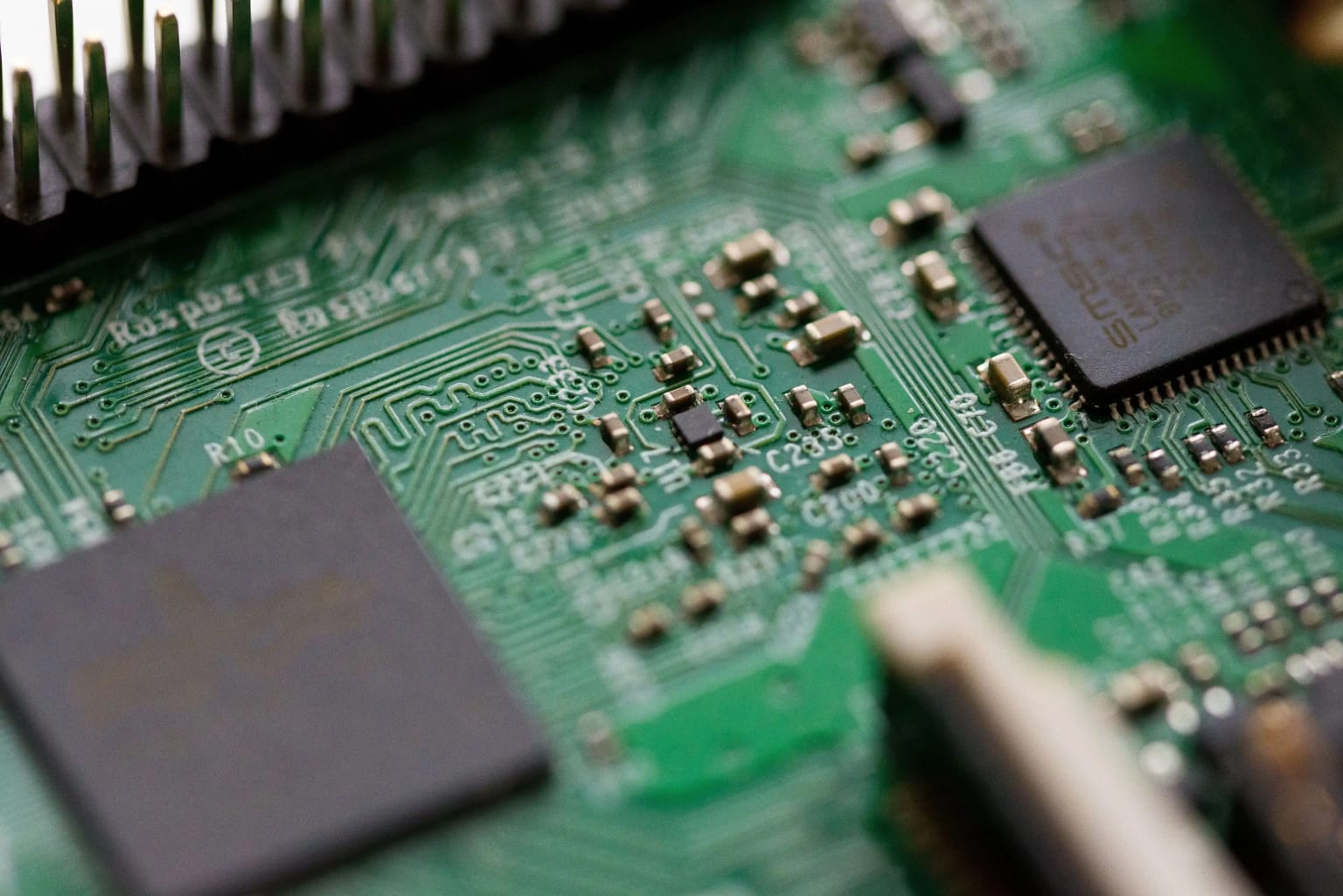

Electronics

- Housings for electrical installations

- Printer housings

- Computer housings

- Battery holders

- Battery trays

- Disposable electronic trays

- PCB covers

- Circuit board trays

- Robotic covers

- Electronic housings

- Covers with EMC shielding

- Monitor covers

- Conveyor housings

- Industrial printer housings

Medical Technology

- Case enclosures

- Sanitary components

- Dental chair covers

- Medical device housings

- Laboratory equipment enclosures

- Medical blister packs

- Medical technology device covers

- Medical laser housings

- Dental chair covers

- Wash basins

Consumer Goods

- Household appliance covers

- Ice tanks for beverage coolers

- Bath bombs

- Shower trays

- Bottles

- Tampon dispensers

- Toilet separators

- Dart housings

- Kitchen sink tubs

- Small furniture

- Hairdresser sinks

- Plant trays

- Shelf board inserts

- Flower water tanks

- Balcony irrigation water tanks

- Steam cooker inlays

- Kitchen appliance parts

- Plastic doors

Mechanical Engineering

- Automation trays: workpiece carriers for automated handling

- Aluminum cast covers

- End caps

- System case covers

- Control panels

- Touch protection

- Knob covers

- Fill level sensor housings

- Heater covers

- Cable channels

- Cable trays

- Monitor covers

- Control panel covers

- Protective flaps

- Protective covers

- Chute covers

- Side & distance covers

- Spiral housings

- Thermoformed inserts

- Carrier shells

- Interior lining for transport boxes

- Universal trays

- High-pressure hose reels

- Workpiece carriers for automation

- Tape roll carriers

- Frame covers

- Towel dispenser covers

- Robotics enclosures

- Column housing

Industrial Solutions

- Transport containers for heavy mechanical loads

- Reusable trays

- Transport and presentation boxes

- Intermediates for heavy workpieces

Facts and Figures:

| Group | Technical Thermoplastics |

| Structure | Amorphous |

| Density | 1.07 |

| Continuous Use Temperature Min. (in °C) | -40 |

| Continuous Use Temperature Max. (in °C) | 75 |

| Thermal Expansion Transverse/Longitudinal to Flow Direction (10^-6 *K) | 95 |

| Melting Temperature (°C) | 110 |

| Max. Temp. Short-Term (°C) | 100 |

| Max. Temp. Long-Term (°C) | 95 |

| Impact Strength (KJ/m^2) | 22 |

| Abrasion Resistance | - |

| Yield Stress (N/mm²) | 45 |

| Tensile Strength (N/mm²) | 50 |

| Tensile Modulus of Elasticity (N/mm²) | 2500 |

| Elongation at Break (%) | 10 |

| Flexural Strength (N/mm²) | 75 |

| Ball Indentation Hardness (N/mm²) | 90 |

| Dielectric Strength (kV/mm) | 41 |

| Volume Resistivity (Ω · m) | 1E13 |

| Surface Resistivity (Ω) | 1E13 |

| Tracking Resistance CTI | 600 |

Additional Plastics in the formary Portfolio

Frequently asked questions about ABS plastic

ABS stands for acrylonitrile butadiene styrene and is an engineering thermoplastic. It is considered a robust all-round plastic with very good impact strength, rigidity and temperature resistance. ABS is often used in thermoforming to produce stable, durable components.