Manufacturing Process – Thermoforming from Plastic films

For plastic rolls up to 960 x 650mm forming area | Up to 3mm starting thickness | Various pattern options | Fast production

What does thermoforming of plastic film mean?

Film thermoforming has the fastest cycle times in the plastic thermoforming process and is therefore ideal for high quantities and cost-effective products.

Thermoforming from film is the thermoforming process for small thermoformed parts, such as packaging materials, blister packs, and transport containers. The standard forming area is 960 x 650 mm. A thermoforming tool with multiple cavities can be used on this area. This means that as many thermoformed parts as possible are thermoformed during each machine cycle, which significantly reduces the throughput time.

Roll-to-roll machines are often fully automated, from the feeding of the material to the stacking of the finished thermoformed parts. Film thermoforming therefore allows for a high degree of reproducibility in product quality. Modularly adjustable preheating and pre-stretching processes optimize this.

How does the thermoforming of plastic film work?

- Plastic film is transported by a conveyor chain (through all processes)

- Film is heated

- Tool forms the thermoformed part

- Punching tool separates the thermoformed part from the film

- Thermoformed parts are stacked

Key Facts about Thermoforming of Plastic Film

960 x 650mm

100 to > 1.000.000

150mm

3mm

From 4 weeks

Film vs. sheet: Which process is best suited to your application?

| Criteria | Thermoforming of films | Thermoforming of sheets |

|---|---|---|

| Material thickness | up to 3 mm | up to 15 mm |

| Component size | small-medium (trays, blister packs) | large-volume (covers, housings, containers) |

| Quantities | 1.000->1.000.000 | 100->10.000 |

| Tooling costs | low | low-medium |

| Cycle times | very fast (multiple uses) | longer (individual plates) |

| Advantage | affordable, highly scalable | large parts, robust |

| Disadvantage | thin-walled parts only | longer delivery times |

Advantages of Thermoforming Plastic Film

Cost-Effective Unit Prices

For small to medium production runs, thermoforming from plastic roll stock has lower overall costs compared to injection molding or 3D printing.

Fast Cycle Times

Multi-cavity tools and combined forming-punching tools enable quicker cycle times.

Precise Reproducibility

High repeatability and tight tolerances are easily achievable with the right thermoforming equipment.

Material Versatility

Nearly unlimited options for materials, colors, and finishes when thermoforming from plastic roll stock.

Scalable Tooling

Tools can be designed as stand-alone concepts or as base tools with interchangeable inserts.

Recycling

Efficient closed-loop systems enabled by downstream punch grid mills for post-industrial recycling.

Post-processing options for thermoforming plastic films

Product Applications for Thermoforming from Plastic Roll Stock

Transportation of Goods / Storage of Goods

- Automotive,

- Electronics,

- Medical Technology,

- Industrial Solutions,

- Consumer Goods

Automation

- Automotive,

- Electronics,

- Industrial Solutions

Containers

- Medical Technology,

- Mechanical Engineering,

- Consumer Goods

Interior

- Industrial Solutions,

- Electronics,

- Consumer Goods,

- Medical Technology,

- Food

Covers

- Automotive,

- Industrial Solutions,

- Electronics,

- Consumer Goods,

- Cosmetics,

- Mechanical Engineering,

- Food,

- Medical Technology

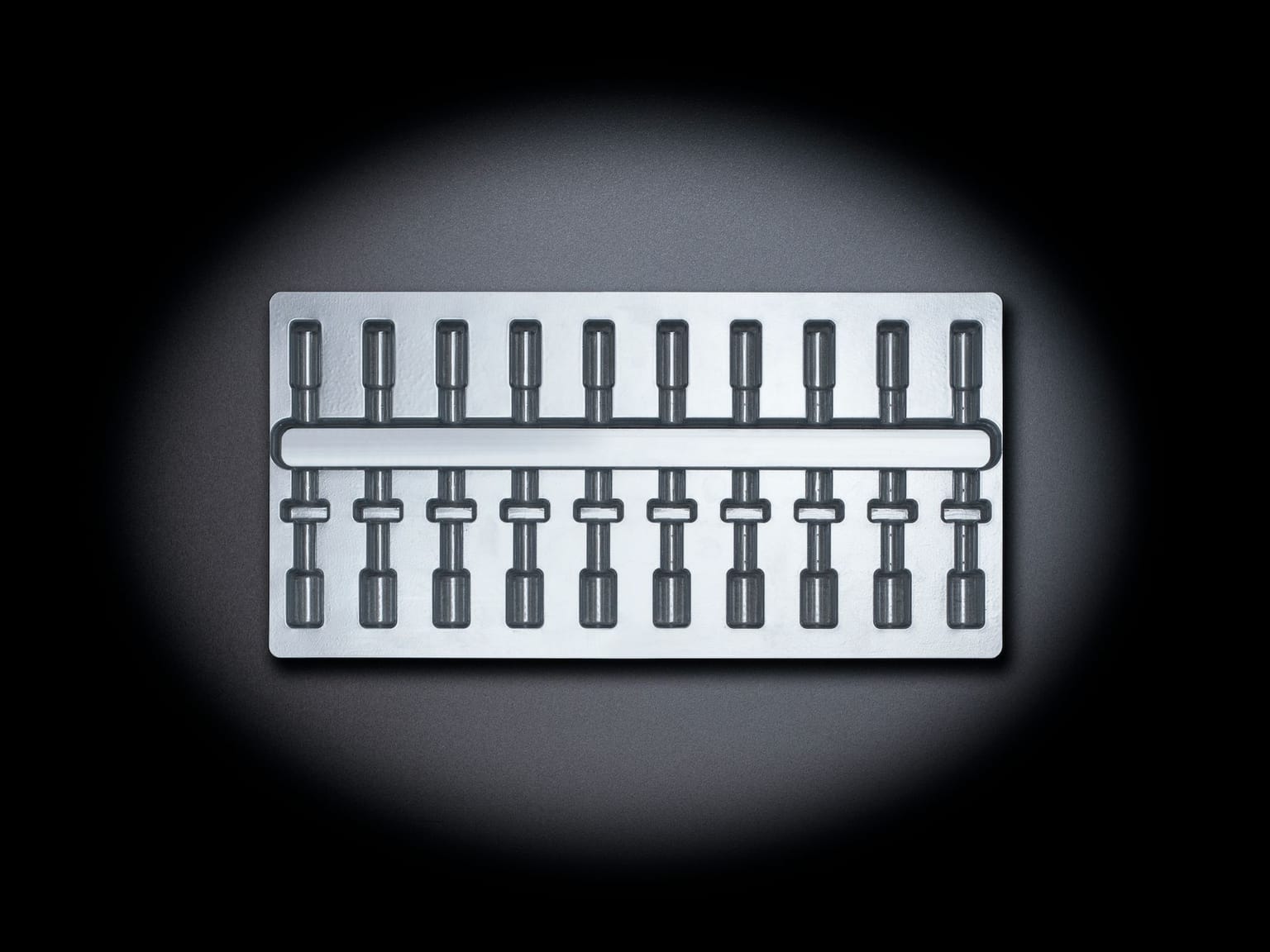

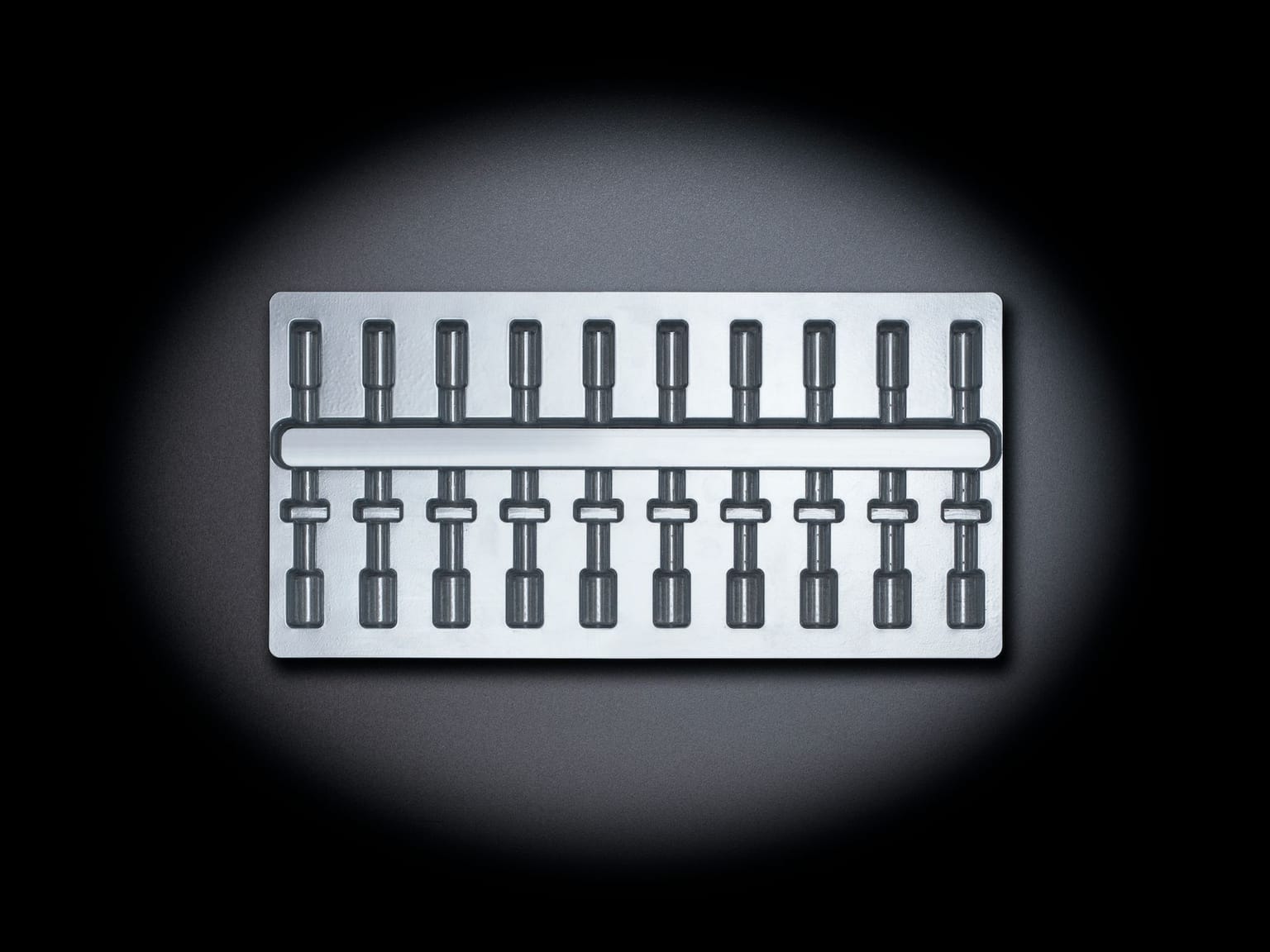

Product examples from roll production

Available Thermoplastics for Thermoforming

The formary network offers plastic roll stock in various materials to meet the demands of different industries and applications.

Tooling Setup for Thermoforming Machines Using Plastic Roll Stock

In forming machines for small plastic parts, plastic rolls are unwound, heated, and fed into the forming station.

To transport the roll material, chains engage with the edges of the heated plastic and move the film through the machine. To prevent the plastic roll from sagging due to heat exposure, the chains apply slight tension to spread it. Additionally, they function as a clamping frame, securing the material during forming and sealing it during vacuum forming. To allow the chain to grip the film edge effectively, the edges are often preheated.

More Information on Thermoforming Plastic Roll

Key Factors in Your Part Cost Calculation for Thermoforming from Plastic Roll

Cycle Time

Setup Time

Product-Specific Machine Equipment

Digital Control

Preheating

Cooling

Energy Consumption

Data Storage

Complex Geometries

Quality and Tolerances in Plastic Roll Thermoforming

| Part Locations | Relevant Points and Tolerances |

|---|---|

| Length Measurements | Tolerances according to DIN ISO 2768-c or -m |

| Material Thickness | Semi-finished product: Material manufacturers typically have a tolerance range that allows up to +/-10% variation in material thickness. This must be checked by the processor before manufacturing to proactively address thickness variations and respond to narrower tolerance ranges. Variations must be proactively managed within the tolerance window. |

| Trimming Edge | - Milling: Milling cuts are deburred. The trimming accuracy and cleanliness of the milled edge depends on the size of the selected milling head and the milling speed - Knife-cut punching: With the knife-cut punching process, attention must be paid to angel hairs in the trimming contour - Shear cut punching: When using the shear-cut punching process, attention must be paid to the formation of beards on the trim edge |

Frequently asked questions about thermoforming plastic film

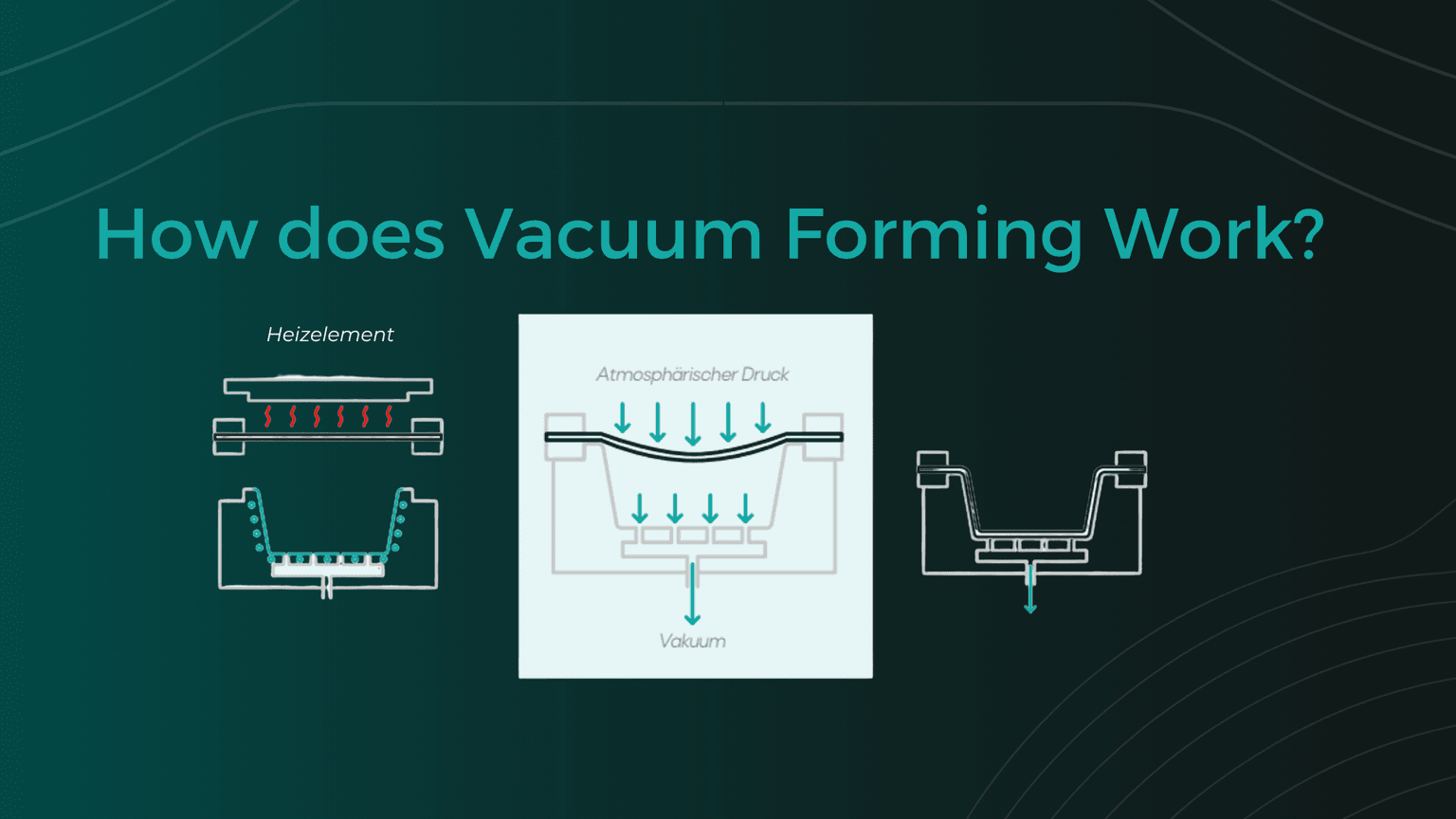

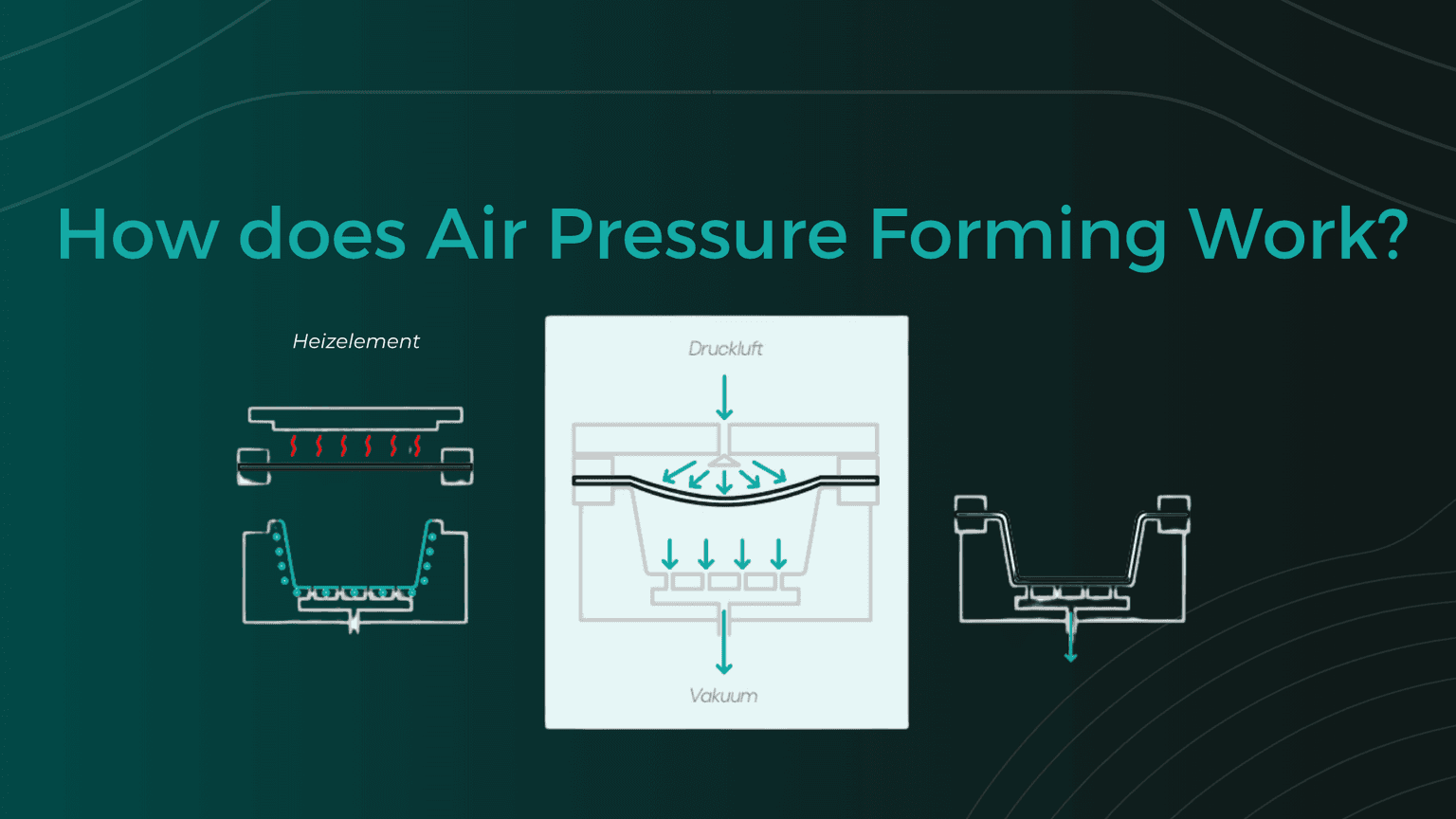

When thermoforming plastic film, heated roll stock is drawn into a mold using vacuum or compressed air. The process produces thin-walled, precision molded parts and is therefore ideal for packaging, trays, or technical applications.

Further resources you might be interested in

Do you have any further questions about thermoforming plastic film?

Contact us!