Prototype Development for Thermoformed Plastic Parts

Thermoforming: Prototypes and Tools

We provide prototypes and samples for your thermoformed plastic parts before mass production. To ensure fast turnaround times, we use cost-effective 3D-printed tools, Ureol tools, and segmented tools for rapid prototype tooling.

Advantages of Prototypes in Thermoforming

Time Savings

Prototype tools can be quickly and directly manufactured from digital models, ensuring high efficiency in development.

Reduced Investment Risk

Early-stage testing helps detect and fix potential design flaws, reducing costly errors in mass production.

Continuous Optimization

Prototypes undergo iterative improvements to meet functional and quality standards before full-scale production.

What does Prototype Construction for Thermoformed Plastic Parts Involve?

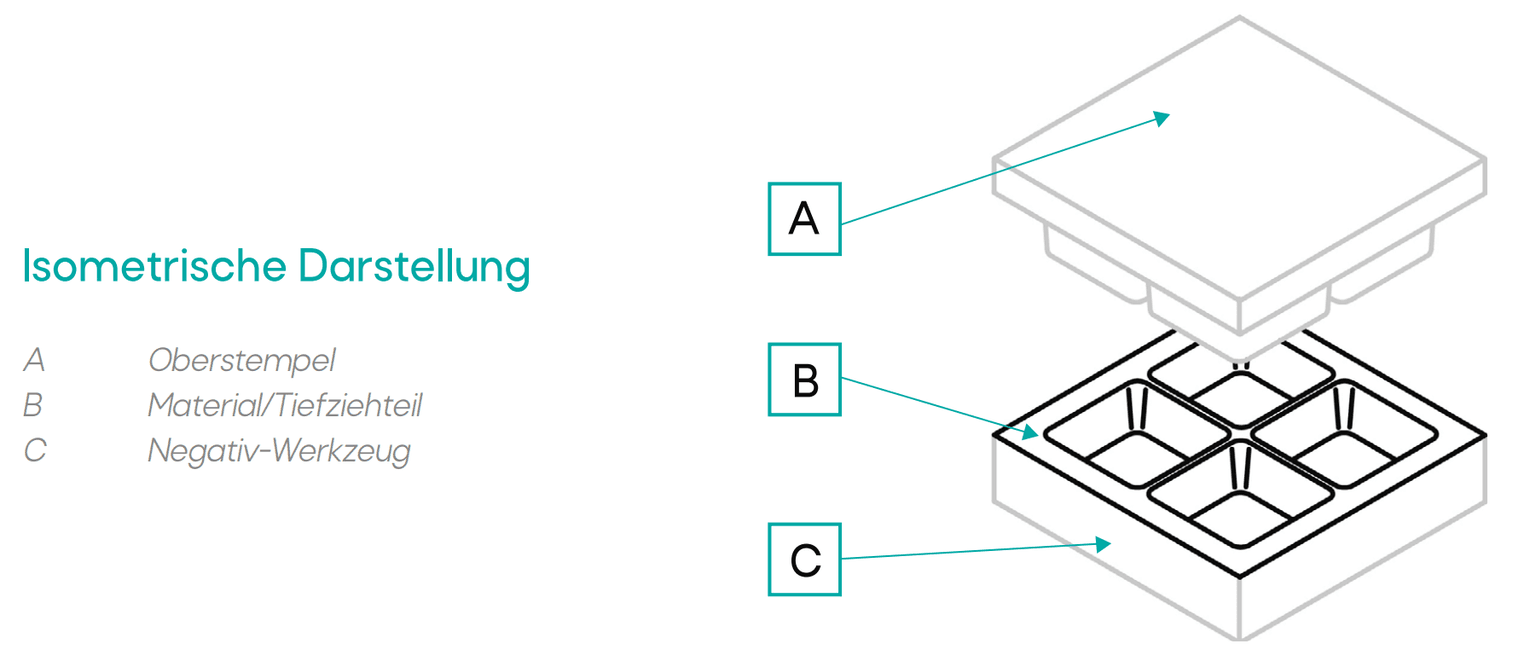

Prototype development for thermoformed parts involves creating functional prototype tools.

Since forming plastic requires precision-engineered molds, each new product requires a custom toolset. Once produced, thermoforming tools offer long service life and can be used for multiple production runs.

Prototype Tool vs. Series Tool in Thermoforming

In thermoforming, there are differences between prototype tools and series tools in the materials from which they are made.

Prototype Tool

- Purpose: Used for producing prototype plastic parts.

- Features: In plastic thermoforming, prototype tools are often easier and faster to produce than series tools. They can be made from less cost-intensive materials and are designed to enable quick adjustments and changes to the design.

- Lifespan: The service life of a prototype tool is generally limited, as it is used for the early development stages of the deep-drawn part and is not designed for long-term series production.

Series Tool

- Purpose: A series tool is used to produce large quantities of parts or products in series production.

- Features: Series tools for plastic deep-drawn parts are highly precise and robust. They are made from high-quality materials such as aluminum that can withstand the demands of series production. The design and manufacture of the tools is geared towards a long service life and repeated use in order to produce high quantities with consistent quality.

- Adaptability: Series tools are generally less flexible for changes compared to prototype tools. Changes to prototypes in thermoforming often require more complex adaptation or even the production of a new tool.

Prototype Tools in Thermoforming

Prototyping with 3D-Printed Tools

3D-printed tools are commonly used for sampling critical sections of your thermoformed part. Due to the high temperatures and stresses involved in thermoforming, these tools are typically suited for producing a limited number of prototypes.

Prototyping with Ureol Sample Tools

Ureol is a modeling block material used for prototype tooling in thermoforming. It allows for the creation of partial or full-scale prototypes that closely resemble final thermoformed parts produced with aluminum tools.

While milling times for Ureol tools are similar to those of aluminum, Ureol itself is a more cost-effective material. However, due to its lower heat and pressure resistance, only a limited number of samples can be produced.

Prototyping with Partial-Series Aluminum Tools

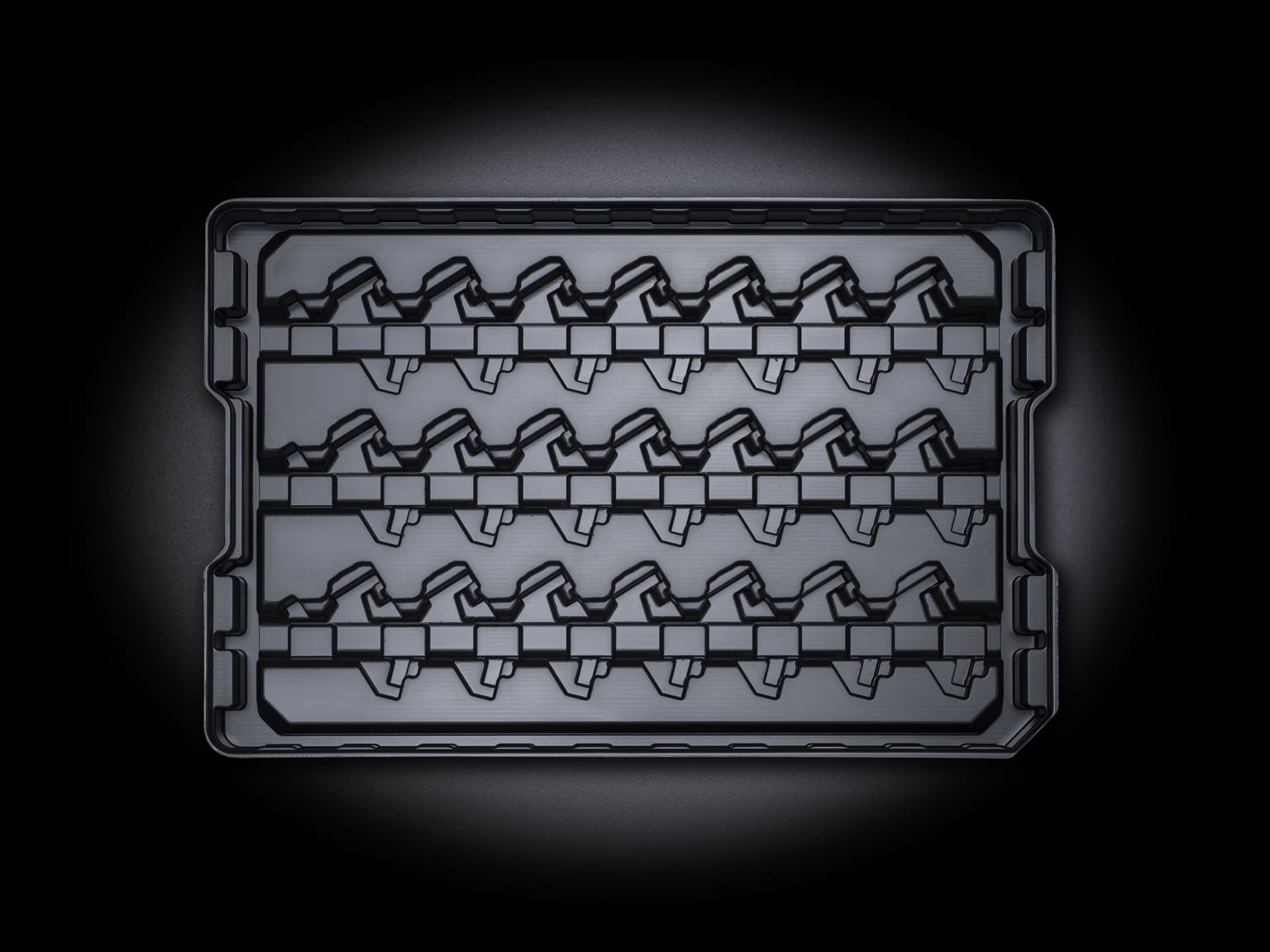

A partial-series aluminum tool is an advanced prototype solution that replicates final production results with high accuracy. It offers cost savings by using a single-cavity tool instead of a multi-cavity series mold.

Important: This prototype tool is a preliminary step before full-series aluminum tooling, so additional lead time must be factored into the project timeline.

Prototyping with Full-Scale Production Tools

A full-series aluminum tool is used for both prototyping and mass production. The prototype thermoformed parts are produced under optimized stretching, heat, and cooling conditions, ensuring final production quality from the outset.

For mid-to-high volume production, multi-cavity tools are commonly used to improve output efficiency and reduce per-unit costs.