Determining the Mold Nests of Your Workpiece Carrier

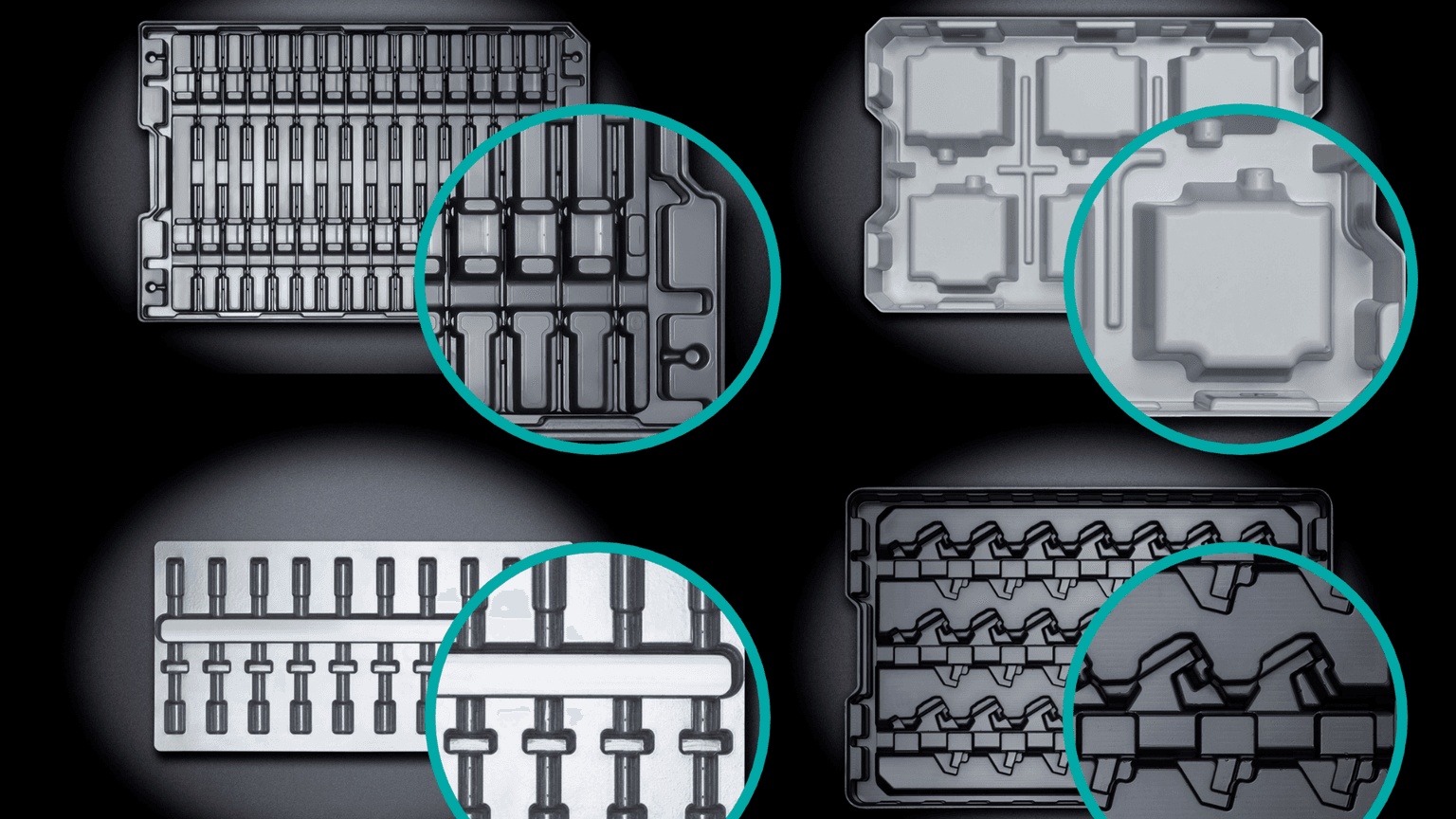

Mold nests or cavities can be diverse: rectangular, round, custom-shaped, tracks, ribs, or domes. So how is it decided which mold nest is the right one? More on this in the article.

Moritz Bittner

13. Januar 2026

Contents

The shape of the cavity that holds the component is often the critical point for its functionality. Whether for inlays, blisters, transport trays, or workpiece carriers—how well the cavity fits the product determines the efficiency and safety during handling, transport, and storage.

What are mold nests? What is a cavity?

Mold nests are cavities that hold the component. The term "cavity" comes from the Latin "cavum," meaning hollow. In simple terms, mold nests are recesses in the workpiece carrier designed for secure transport of the component and to simplify loading and unloading of the trays.

The shape of the cavity that holds the component is often the key to functionality. Whether for inlays, blisters, transport trays, or workpiece carriers, the better the cavity fits the product, the more efficient and safe the handling, transport, and storage will be.

Typical requirements for mold nests and cavities

In both intralogistics and extralogistics, the primary goal is cost savings.

One way this is achieved is by saving volume and using space more efficiently. For transporting components on trays, a high packing density is essential. This means achieving a minimal transport volume by placing as many components as possible per tray. Therefore, the mold nests and cavities must be designed to maximize the packing density.

At the same time, costs can be saved if as many different components as possible can be transported in a universal tray. This means fewer tray variants and lower investment and handling costs. In this case, the mold nests are designed as universal nests.

What affects the maximum packing density of mold nests and cavities?

The maximum packing density is usually determined by your application specifications, thermoforming limitations, and, if the trays are used on automated production lines, the capabilities of the system/robot. Based on these specifications, the goal is to fill the available space as efficiently as possible with mold nests.

1.) Users often specify a minimum distance for the cavities:

- Distance between mold nests

- Distance from mold nest to the outer edge of the tray These specifications have ergonomic reasons for non-automated processes. Manual loading and handling of the trays should be simple. For example, components should be easily removed from the cavity, or trays should be quickly placed into a secondary container.

2.) What do the mold nests require?

- The mold nests need a draft angle of at least 2-5°. This draft angle is needed for thermoforming so the tray can be lifted off the deep-drawing tool.

This impacts the arrangement of the cavities on the tray, as well as the distances between the mold nests. CAD programs have a draft angle analysis feature to optimize the packing density of tightly packed trays.

3.) What requirements does the automated system have for the cavities?

- Edge geometry of the nest opening

- Gripper type and gripper technique

- Nest depth In automation projects, there are additional requirements for nest production. The maximum packing density is always the result of the equation of the above factors.

How are universally usable mold nests designed?

When investing in the development of a transport tray, the design of a universal tray is often required. A universal tray can transport different component variants or families of components. This saves on tool costs, which would be incurred for each tray variant.

This means the mold nests must be adapted to various components.

What should be considered when developing universal mold nests?

- Position: If placing the components in a horizontal position is not possible due to different dimensions, much space can be wasted.

- Unequal outer sizes and/or contours: The contours must roughly match, or else it will be difficult to design.

- Sensitive areas: If certain parts of the component need to be free, it is often hard to find a middle ground.

- Placing components at different levels: Steps and tight contours in some materials, like PC, are difficult to form.

How are mold nests 100% adapted to the component?

A cavity is always aligned with the original component. This is done using the CAD data of the components, a component prototype, or an existing tray.

How are nest data created?

- CAD data: The best way for the customer and formary is to create data from the CAD files of the component. This allows for optimal measurement of all sides of the component. No time-consuming adjustments to the data are necessary. Additionally, finer details, such as the gap between the component and the nest's inner wall, can be adjusted in advance. Before data creation, a confidentiality agreement (NDA) is signed.

- Component prototype: The second option is to create nest data based on a component prototype. Depending on the component's design, we can either manually measure or use more sophisticated optical measuring devices.

- Existing tray: As a third option, we can reverse-engineer the data based on an existing tray prototype. Here, we measure the part with a Faro arm. A disadvantage is that imperfections on the tray's surface are also transferred to the data model. It is always important that other requirements, such as centering distances (for automated trays), grid dimensions, and desired measurements at the nest's bottom, are communicated. The more details are aligned in advance, the fewer errors will occur in the data construction.

Can I test the fit of the cavity before tool creation?

Yes. Once the nest design has been created in the CAD program, its functionality can be tested with different variants (see also prototypes or our blog post on rapid prototyping).

Options for testing mold nest samples

Testing mold nest samples can be done with 3D printing or thermoforming from an Ureol tool.

3D printing is the fastest option but provides less insight regarding the deep-drawing result. Thermoforming from an Ureol tool is slower but much more indicative, as it allows the direct transfer of learnings about the stretching behavior for the series.

The appropriate option depends on the requirements profile, which consists of the following three factors:

Speed: How quickly are the samples and their review required?

Relevance: How comparable does the sample need to be to the series production? Does it need to use the original material and thickness? Should it be deep-drawn (tested method), or can an alternative method (3D printing) be used?

Effort: Is there a larger budget available for sample testing before starting production? Is it only the fit being tested, or should the tray be replicated as realistically as possible for series use

What happens if the components do not fit in the mold nests?

If the components do not fit in the cavities, mold nests can be quickly modified. We offer various sample levels that differ in speed, relevance, and effort.

The 3D print and Ureol thermoforming sample options take advantage of naturally fast development times and are the quickest and most cost-effective options for fixed insights. After testing the samples with your components, adjustments can be made promptly.

If adjustments are only noticed during the prototype's production or the first real handling tests, that's not a problem. The following guidelines apply:

Options for adjusting mold nests and cavities

| Tool design | Mold pockets can be adjusted in this direction | Mold pockets cannot be adjusted in this direction |

|---|---|---|

| Negative mold tool | Deepen the mold nests

| Increase the nest height |

| Positive mold tool | Increase the nests

| Deepen the mold nests |

Determining mold nests and cavities - A conclusion

The selection of appropriate mold nests for workpiece carriers is crucial for efficient transport and storage. Mold nests ensure that the component is securely held in the workpiece carrier and safely undergoes all production and logistics processes. In designing mold nests, cavities for gripper cutouts, as well as factors such as minimum distances, draft angles, and automation system requirements, should be considered. Overall, suitable mold nests are an essential component of product safety and process optimization.

Any questions? Contact us now via live chat or call: 07191 9525170.