Plastic Thermoforming

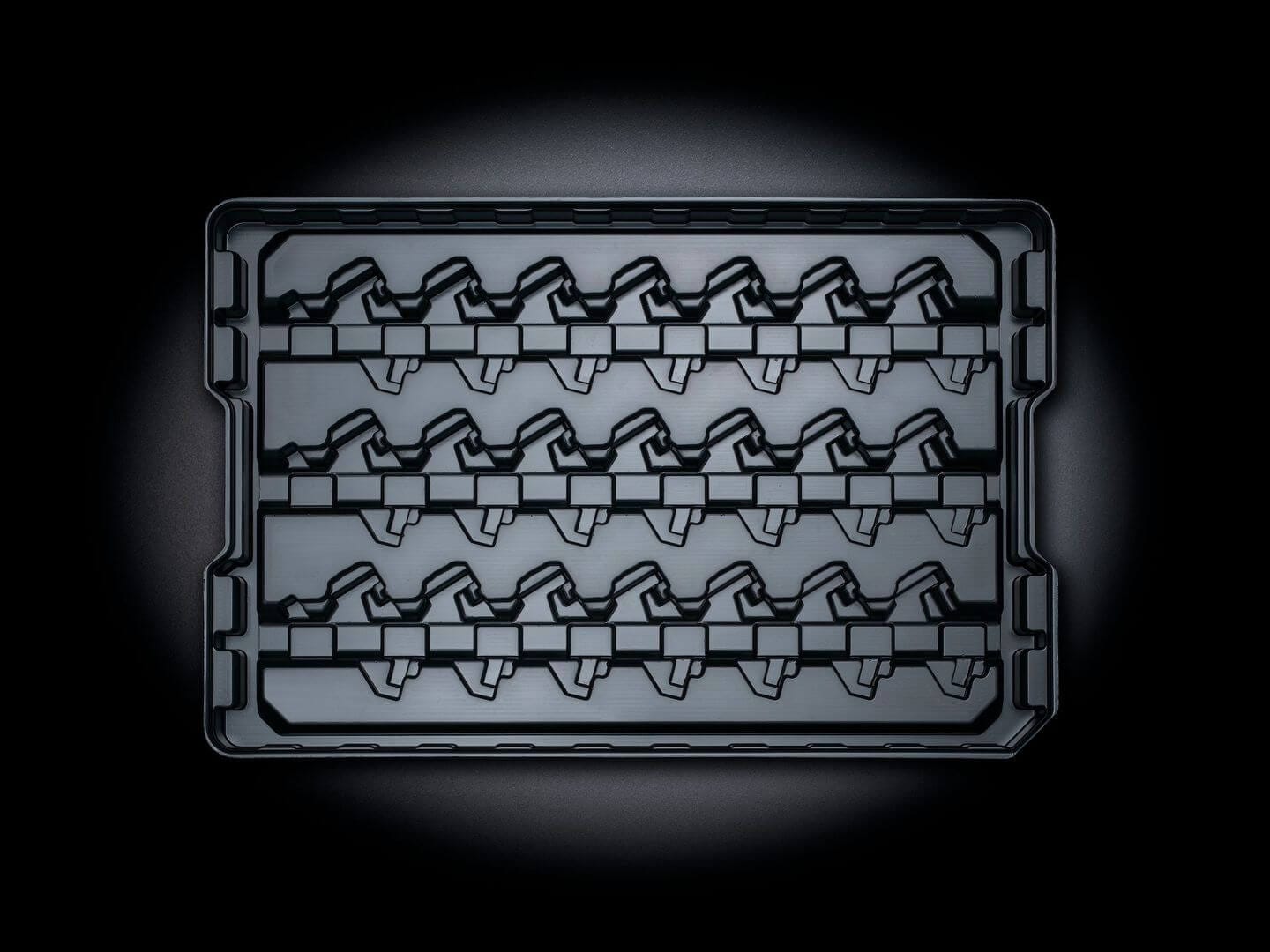

Plastic deep-drawing for small and large series | Prototype & production runs | New plastic, recycled materials, and compounds | deep-drawn enclosures and covers | Plastic blisters, inlays, containers | Deep-drawn workpiece holders and load carriers | Plastic thermoforming, Vacuum deep-drawing

What is plastic thermoforming?

Plastic thermoforming is a manufacturing process used for (almost) all applications requiring thermoplastic plastics. In this process, plastic is heated, shaped through thermoforming, and then trimmed to the desired shape after cooling.

Plastic thermoforming is known by various names: plastic thermoforming, thermoforming, vacuum thermoforming, vacuum forming, and vacuum molding. In this process, a thermoplastic plastic sheet or film is heated and shaped in a mold to create specific geometries. The thermoforming process allows for the quick and cost-effective production of lightweight yet durable components.

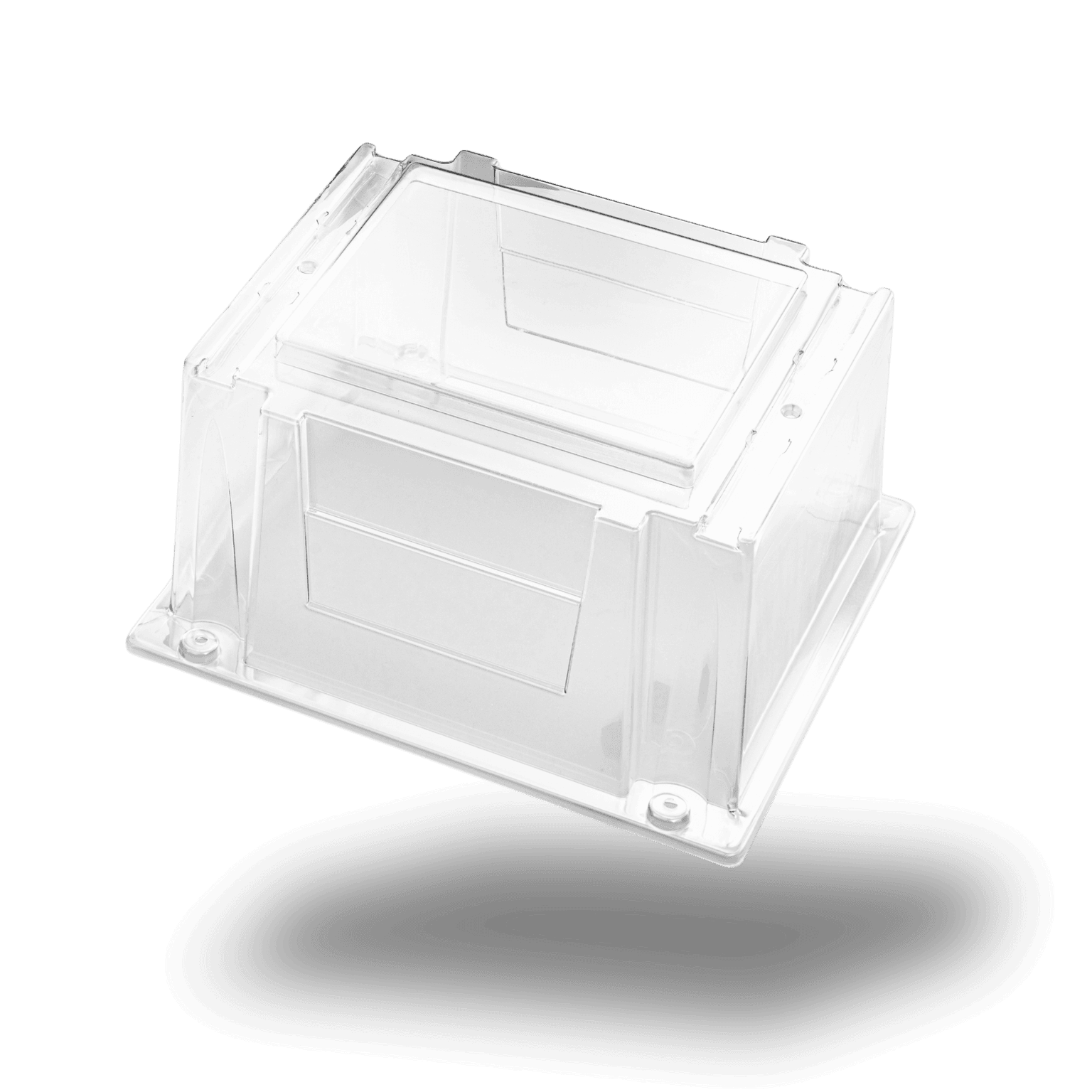

Thermoformed parts from formary

formary provides plastic thermoformed parts for a variety of applications. Using the thermoforming process, custom plastic products are produced according to customer specifications.

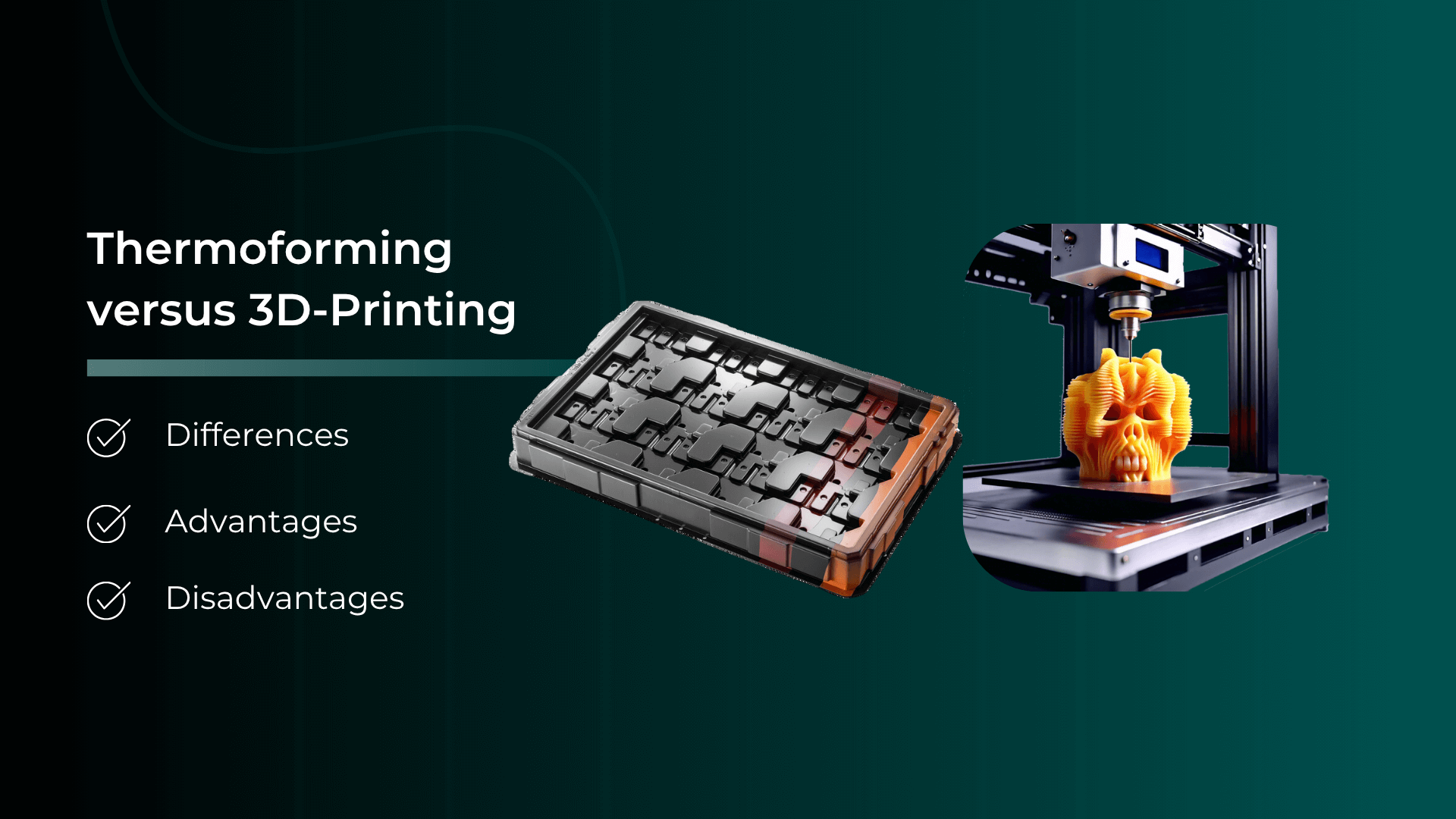

Plastic thermoforming in comparison

Thermoforming plastic is unrivaled, especially for medium-sized series with tight lead times. Thermoforming combines fast implementation with cost-efficient tools and a wide variety of materials.

Developments in machine and material technology in recent years have led to plastic thermoforming increasingly replacing other applications and processes:

- Injection molding: only worthwhile for very large series, high tooling costs.

- 3D printing: flexible for prototypes, but significantly higher unit costs.

- Thermoforming: smaller series from approx. 100 pieces possible with low initial investment.

This makes thermoforming the “go-to” process between 3D printing (flexible, expensive) and injection molding (cost-effective for series production, high start-up costs).

Advantages of plastic thermoforming

Fast project and delivery time

Plastic thermoforming allows small series, including tool manufacturing, to be completed in as little as 2 weeks.

Low tooling costs

Compared to injection molding, tools for plastic thermoforming are significantly more affordable.

Small production runs

Plastic thermoforming is ideal for smaller quantities starting from a few hundred units.

Wide material selection

A broad range of plastics, recyclates, color options, material thicknesses, and mechanical properties are available for thermoforming.

Prototyping & samples

Plastic thermoforming offers various options for rapid prototyping or quick production of sample series.

High precision

Tolerance dimensions for thermoformed plastic products can meet DIN and ISO standards in many applications.

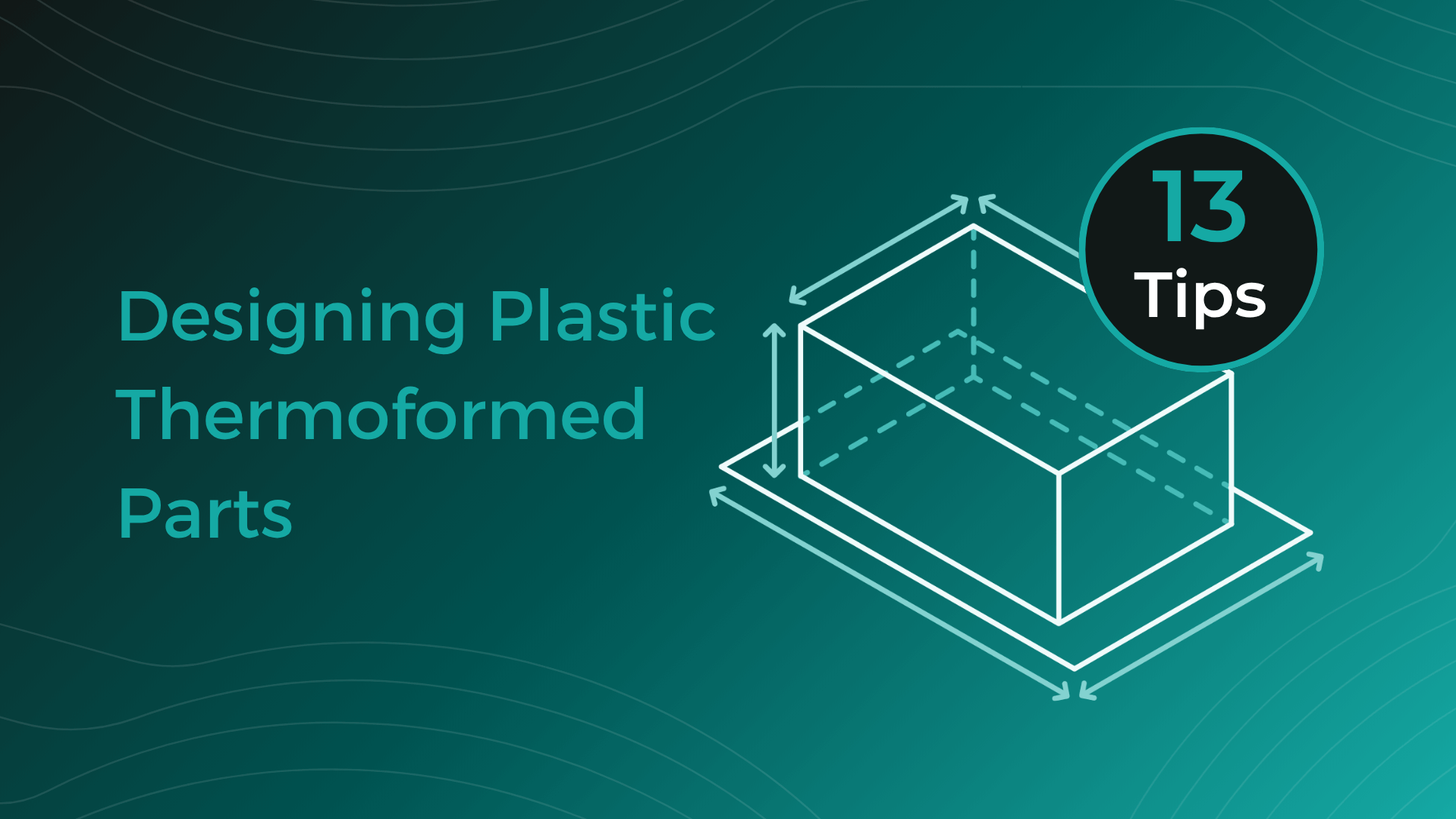

Plastic thermoforming: How the manufacturing process works

Two manufacturing methods are used in plastic thermoforming. The choice of method depends on the specific application.

Which materials are suitable for plastic thermoforming?

Industries benefiting from plastic thermoforming

Plastic thermoforming with formary: 5 easy steps

Here’s how the project works with formary to create your custom thermoformed product.

Choose your custom thermoformed part’s application case using the formary configurator.

During the guided process, provide all necessary thermoforming requirements for your plastic part.

You will receive a quote within 24 hours for your thermoformed part, including tiered pricing and tooling costs.

An experienced project manager will review your request for thermoformability and suggest optimizations.

The matching algorithm assigns your thermoformed part to the ideal thermoformer. The thermoforming process begins immediately.