Thermoformed Plastic Containers

How do you transport and store your products safely and efficiently? With thermoformed plastic containers that are tailored to your requirements: from small to large plastic bins, optionally with lids, as stackable containers, or for use in industry and logistics.

What are thermoformed plastic containers?

Thermoformed containers are thermally formed plastic containers. They can be produced as plastic bins, plastic boxes, plastic crates, or stackable containers and securely hold products during transport, storage, or production.

What are Thermoformed Plastic Containers Used for?

Thermoformed containers are versatile and used across many industries. They ensure safe storage, efficient transport, and protection of sensitive products.

Typical applications of thermoformed plastic containers include:

- Industry & manufacturing: as stackable containers, transport crates, or storage bins for components

- Logistics & retail: as plastic containers with lids for shipping and warehousing

- Agriculture & horticulture: in the form of planting trays, planting tubs, or casting molds

- Chemical industry: as robust drip trays and liquid containers, resistant to oils and chemicals

- Automotive & engineering: as battery trays, tool containers, or custom-made special containers

Advantages of Thermoformed Plastic Containers

Custom Geometries

Individual geometries for plastic containers without high thermoforming tool costs.

Cost-Effective Manufacturing

An affordable manufacturing process for thermoformed plastic containers, even for smaller quantities.

Shape Stability

Large and shape-stable containers, with forming areas of plastic boxes up to 3,460 x 2,260 mm.

Save Time and Effort

Fast delivery: Quick processing and time-to-market for thermoformed plastic containers.

Parts with Color Variations

Colored plastic films/sheets for parts, without requiring additional painting.

Specific Material Properties

Utilize material selection for your plastic trays, thermoformed containers, and plastic boxes for tailored properties.

High Quality

Excellent quality in thermoforming through reproducibility and process reliability without distortion.

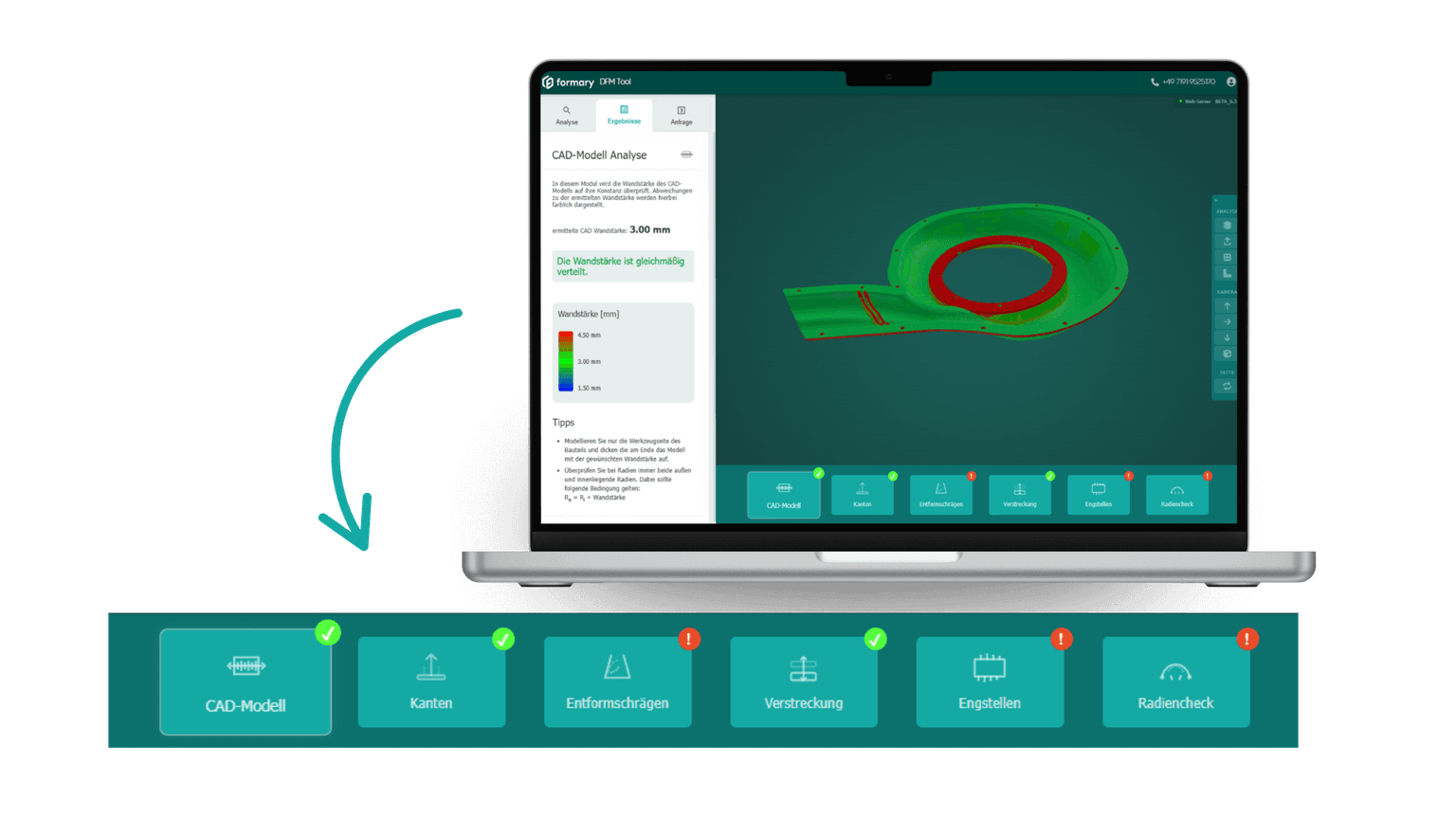

Do you already have a CAD model of your thermoformed container?

Run the thermoforming check now!

Using our DfM analysis, we review your CAD data for wall thickness distribution, draft angles, radii, and other criteria to ensure the technical feasibility of your thermoformed container. Simply book a free demo and we’ll be happy to go through your data with you.

Design of thermoformed containers

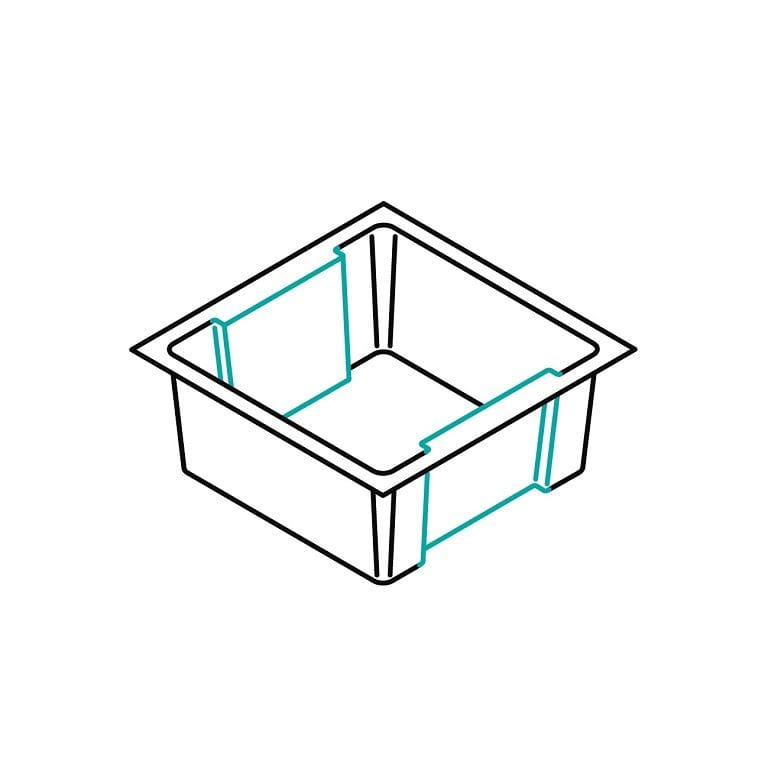

Grip recesses

Grip recesses make handling plastic bins and containers easier. They enable safe gripping, carrying, and stacking, both empty and loaded. Size and position are individually planned to support ergonomic work while ensuring structural stability.

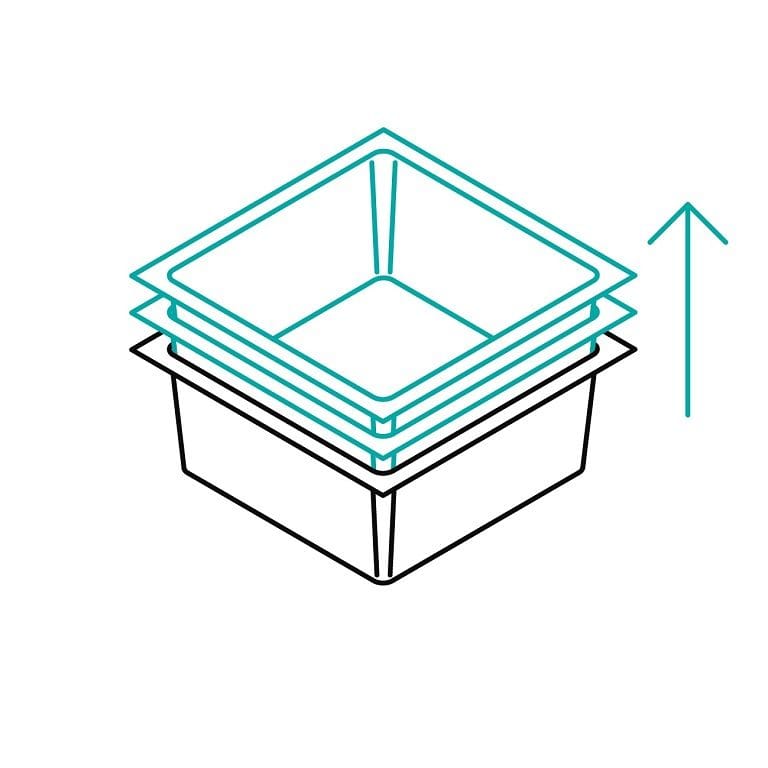

Stacking techniques

Thermoformed containers can be stacked in a space-saving way. Conical side walls and stacking features allow plastic containers to be easily nested and separated again. With nestable stacking, storage volume can be reduced by up to 75% without compromising functionality.

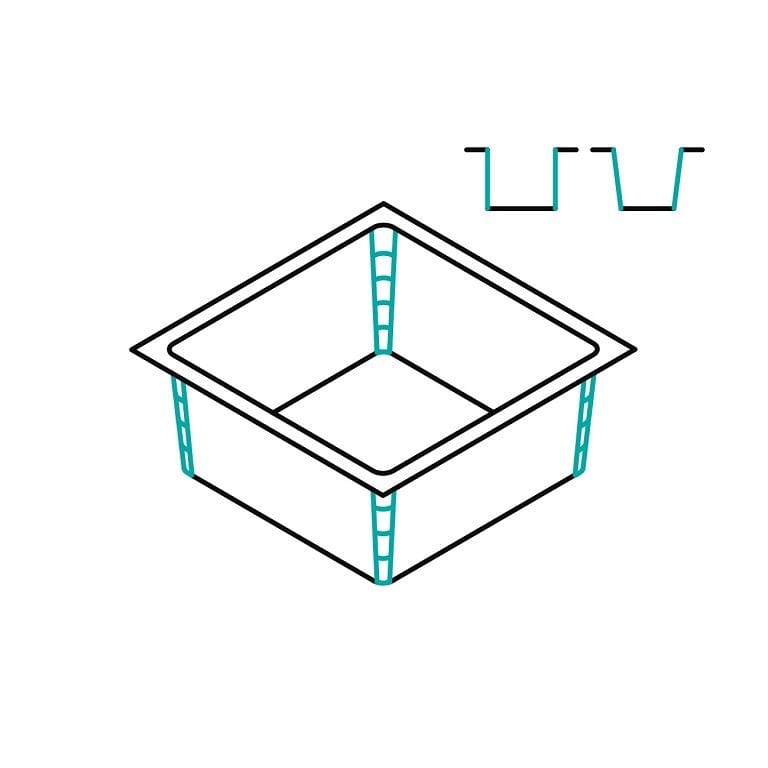

Radii & draft angles

Radii prevent material weakening and cracking at edges. Draft angles ensure that the thermoformed container can be easily released from the tool. This results in plastic containers without thin spots that remain dimensionally stable even under high loads.

Appearance & surface

In addition to functional design, thermoformed plastic containers can also be visually customized. Options include colored sheets, textured surfaces, embossing, or logos, allowing containers to be integrated into a corporate design.

Ribs & reinforcements

For larger plastic containers or heavy loads, ribs and reinforcements are integrated. These further stabilize the plastic box and increase its service life, even under industrial conditions.

Material resistance

UV-resistant materials are used for outdoor applications, while chemically resistant plastics are often required in industrial environments. Additives can also increase temperature resistance, ensuring the containers remain stable even under high thermal or mechanical loads.

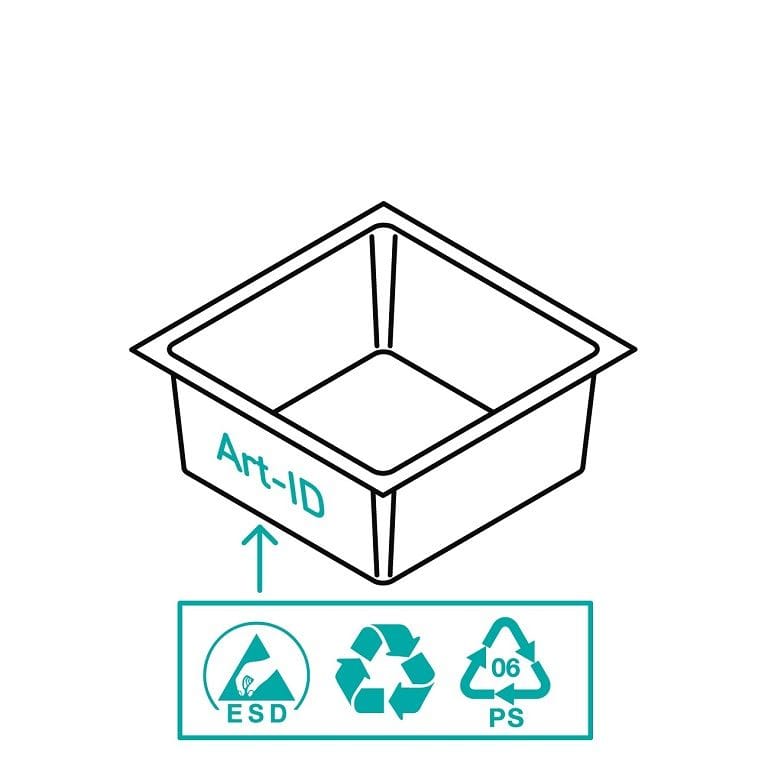

Material for Your Container

Depending on the application, the appropriate plastic is selected. ABS and ASA are particularly robust, durable, and UV-resistant, making them ideal for outdoor use. PS is a cost-effective and versatile solution for many standard applications. When transparency and recyclability are required, A-PET is often used. Learn more in our material overview.

Functions of Thermoformed Plastic Containers

Chemical Resistance

For use with liquids in plastic containers.

Long Service Life

Durable plastic boxes, even for outdoor use, thanks to UV resistance.

Liquid Containment

Retaining liquids securely, even when holding large volumes.

Storage Volume Reduction

Achieved with thermoformed stackable plastic containers.

Abrasion and Scratch Resistance

Ideal for transport containers, production, and shipping.

Form-Fitted Edge Contours

For lids, grip handles, and other elements of thermoformed containers.

Stability under Heavy Load

Enhanced by ribs and reinforcement elements in thermoformed containers.

Ergonomic Design

For easy manual handling of thermoformed plastic containers.

Product examples of thermoformed plastic containers

Here is a selection of examples of thermoformed plastic containers used in a wide range of applications

Project Process for Plastic Containers: From Inquiry to Order

Inquiry

You configure your desired product in our configurator in the desired quantities, material and design.

Review & Offer

We check your data for feasibility and implementation. Then we provide you with an offer within 24 hours. At the same time, we also make suggestions for the data creation of your deep-drawn part as well as useful sampling options.

Data Approval

You approve our data for prototyping or the series tool.

Tool & Sampling

We create your tool and send you series samples for approval.

Series Production

After checking and approving the samples, we start manufacturing your deep-drawn parts.

Shipping

After completion and thorough inspection by our QA team, we will send your series delivery on its way.

Interested in learning more about thermoformed plastic containers?

Discover how you can extend the service life of your thermoformed containers with our tips.

Industrial thermoformed containers must be resistant to mechanical, chemical, and long-term stresses in order to support your operations and employees. We explain how to avoid cracks and improper handling of your plastic bins, helping you extend their lifespan.

FAQ – Frequently asked questions about thermoformed containers

A plastic bin is a thermoformed container that securely holds products or liquids. It can be rectangular or round, large or small, shallow or deep, and is stackable.