What are Caravan Cladding Panels?

Caravan cladding consists of precisely fitting plastic components that protect and enhance the interior or exterior of a motorhome, camper, or caravan. They serve as a protective layer against weather, dirt, impacts, and scratches, increase the vehicle's longevity, and offer design freedom for customization.

What are Caravan Cladding Panels Used for?

Plastic panelling in caravan and motorhome construction serves several purposes:

- Protective function: Shielding sensitive vehicle parts from weather, impacts and scratches

- Design & brand impact: Colour matching and high-quality surfaces for a uniform look

- Function integration: Installation of lighting, sensors, mirrors or insulation material

- Weight reduction: Lighter components increase range and fuel efficiency

Design options for Caravan Covers

Colored Materials

Plastic caravan cladding can be colored during the extrusion of the semi-finished product. This makes the color less susceptible to abrasion, scratches, and fading.

Surface Appearance

Various surfaces can be applied to the plastic cladding of caravans during post-treatment. These include, for example, glossy, matte, textured, embossed, and scratch-resistant surfaces.

Component Integration

Ready-to-install components can be easily installed directly into the camper's paneling. The following options are available:

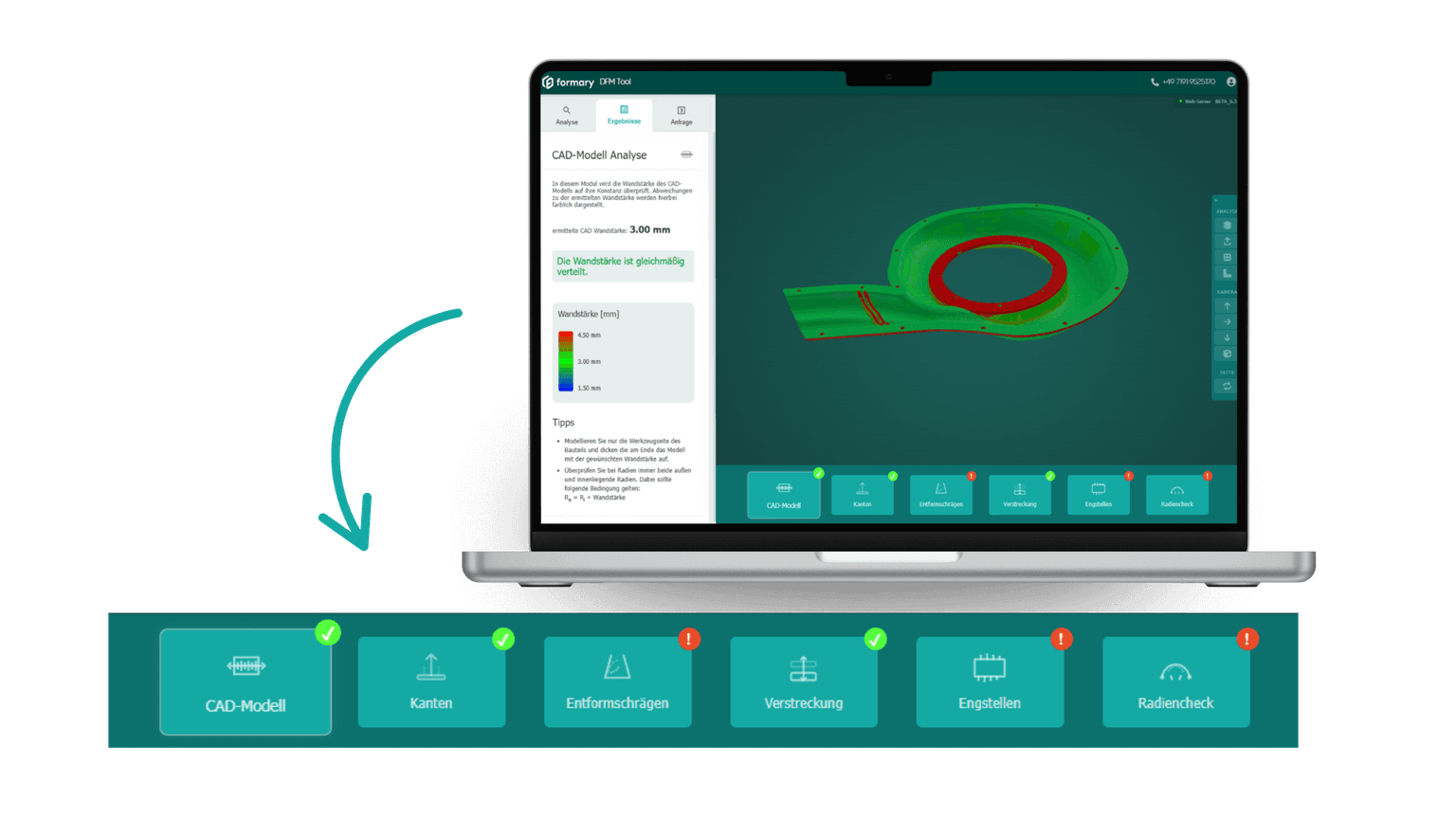

DfM Analysis for Caravan Claddings: Is Your Design Suitable for Thermoforming?

Do you already have a CAD-Model of your Motorhome Cladding for Indoor or Outdoor use?

With our free DfM-Analysis, we check whether your CAD design is feasible in terms of deep drawing technology. Simply book a demo and we will go through your CAD data with you.

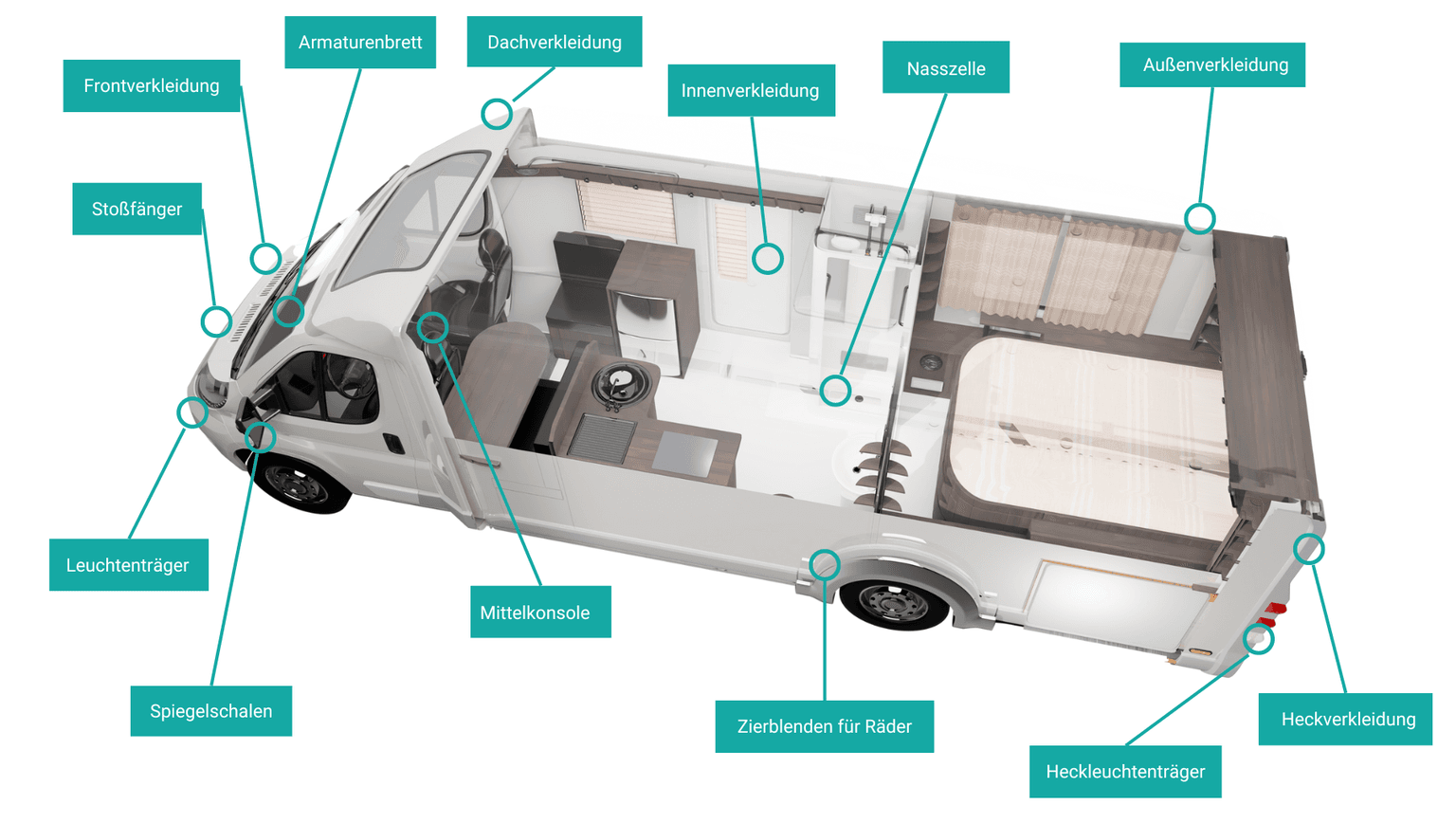

Applications of Caravan Covers

Automotive

- Exterior Caravan Cladding

- Exterior Motorhome Cladding

- Interior Caravan Cladding

- Interior Motorhome Cladding

- Motorhome Cover

- Caravan Wheel Arch Trim

- Exterior Roof Cladding

- Motorhome Access Flaps

- Front Motorhome Cover

- Light Brackets, Fenders

- GRP Wet Cells for Motorhomes

- Mirror Housings

- Front Cladding

- Side Cladding

- Bumpers

- Dashboards

- Decorative Wheel Trims

- Trim Molding for Caravans

- Rear Light Bracket for Caravans

Advantages of Plastic Caravan Covers

Lightweight

By using plastic parts, the weight of camper cladding is reduced, contributing to better range and fuel efficiency.

Durable Materials

Plastic motorhome cladding is scratch-resistant, impact-resistant, and weatherproof thanks to UV resistance. The aesthetics are enhanced with gloss, color, perforated surfaces, or metallic finishes.

Surface Finishes

Motorhome cladding made of plastic can be colored in any RAL color. Due to semi-finished product coloring, the color is resistant to wear, scratches, and fading. Additionally, the subsequent painting process and the need for checking paintability are eliminated.

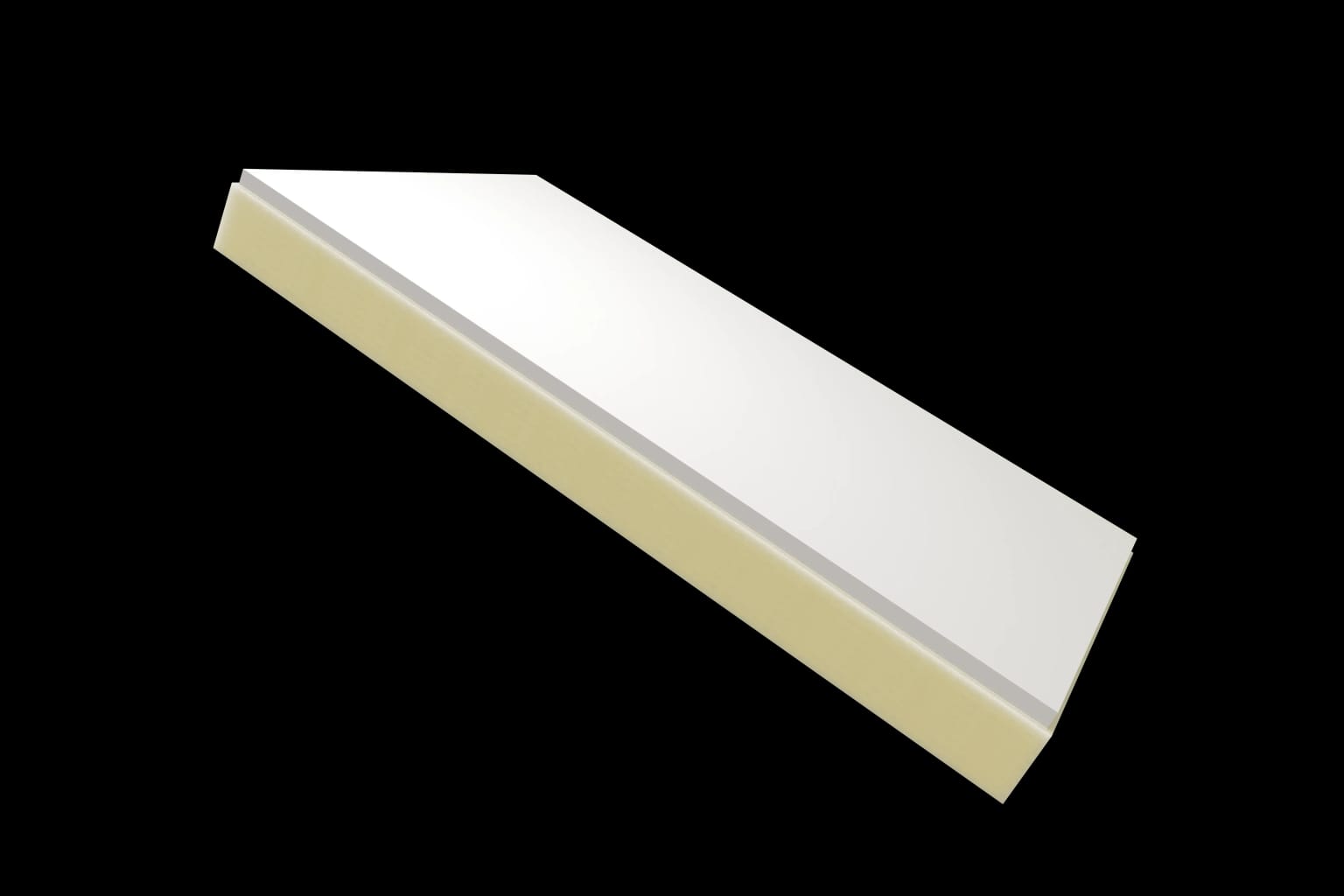

Integral Components

Foams for noise and vibration damping absorb unwanted sound waves and vibrations in the vehicle. During manufacturing, these foams are added as a standalone layer or integrated into the structure of the plastic.

Versatile Applications

Interior and exterior cladding for campers have a wide range of applications, such as exhaust covers, trim molding, and rear light brackets. With various material options, the plastic parts meet diverse material requirements.

Formability & Design

Thanks to the thermoforming process, complex shapes and designs for ready-to-install components like mirror housings, dashboards, and center consoles in plastic caravans and motorhome cladding are possible.

Suitable Plastics for Caravan Claddings

Areas of Use for Plastic Caravan Covers

Decorative Trims for Caravans

Plastic exterior caravan cladding in the form of decorative trims is a cost-effective solution to enhance the appearance of your caravan. These trims are flexible, durable, and long-lasting, providing optimal protection against weather elements for underlying openings. We manufacture decorative trims from high-quality thermoplastics and incorporate desired finishes like chrome, gloss, or matte effects.

Caravan Noise and Insulation Damping

Foam materials provide optimum protection for caravans against noise and vibrations, thereby contributing to the comfort of the caravan. High-quality insulation materials consisting of various polymers ensure effective sound absorption and vibration damping.

Plastic Shells as Caravan Covers

Plastic shells are ideal components for integrating luminaires and cable sets, for example, and protecting sensitive electronics from the weather. Thanks to precise production, they can be manufactured ready for installation or combined with other plastic parts. Variable mounting options, such as gluing, offer many possibilities for integrating the components in a beneficial way.

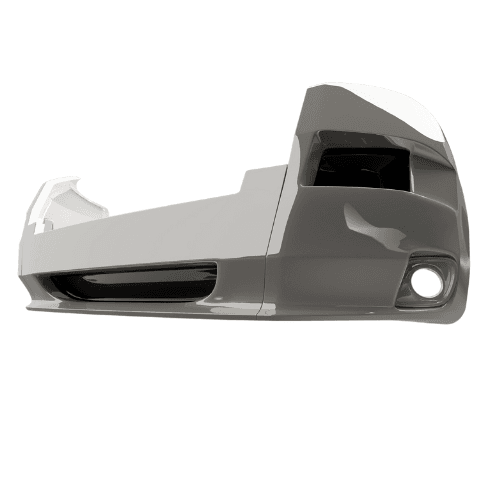

Bumpers for Motorhome Exterior Cladding

Caravan bumpers protect essential components from impacts and corrosion. The Class-A surfaces offer various textures and meet all design requirements. Chrome finishes, ABS casting with a lacquer film, or glossy or matte surfaces are easily achievable.

The colors can already be incorporated during the manufacturing process via semi-finished products, offering several advantages over conventional painting, such as scratch resistance and longer-lasting colors.

Related Thermoformed Products in the Cladding Sector

Industries that Use Cladding for Caravans

FAQ – Frequently Asked Questions About Caravan Claddings

Caravan cladding is a plastic component used as a protective and design element in the interior and exterior of motorhomes, campers and caravans.