Thermoformed plastic packaging

Thermoformed plastic packaging for efficient product protection and safety during transport, storage, and manufacturing

What are thermoformed plastic packagings?

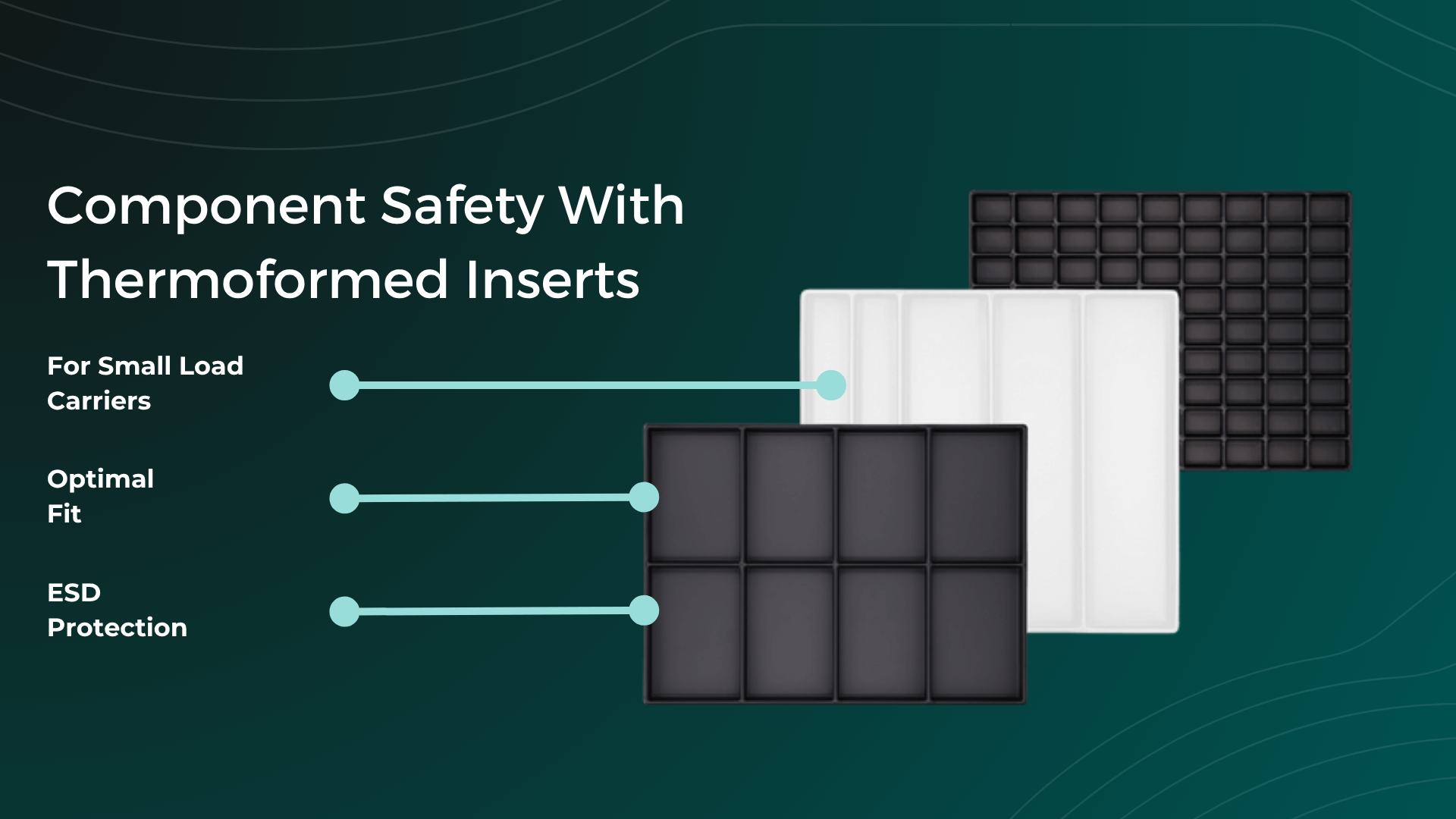

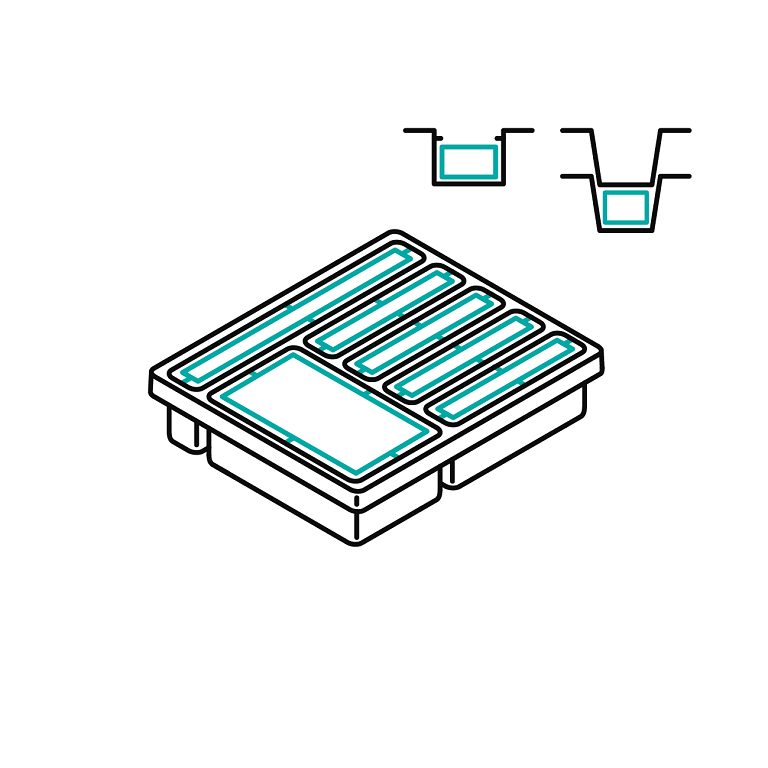

Thermoformed packaging is a dimensionally stable packaging solution manufactured from plastic using a thermoforming process. It reliably protects components from damage, for example during transport, in warehouse logistics, and in automated manufacturing processes. As a manufacturer of thermoformed packaging, formary develops customized solutions tailored to the shape, size, and design requirements of your products.

Features and characteristics of thermoformed plastic packaging

Protection & Securing

Plastic packaging prevents your goods from slipping and being damaged.

Individual adaptation

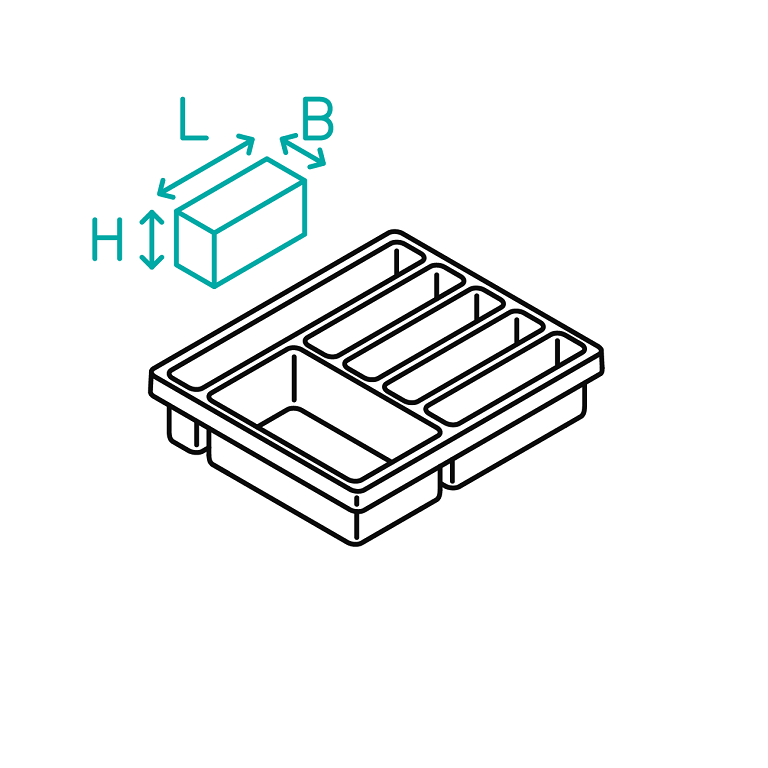

Each package is precisely tailored to the geometry of your products and your requirements, enabling a customized solution.

Aesthetics & Appearance

Thermoformed packaging impresses not only with its functionality, but also with its design. Elegant packaging ensures high-quality, professional product presentation.

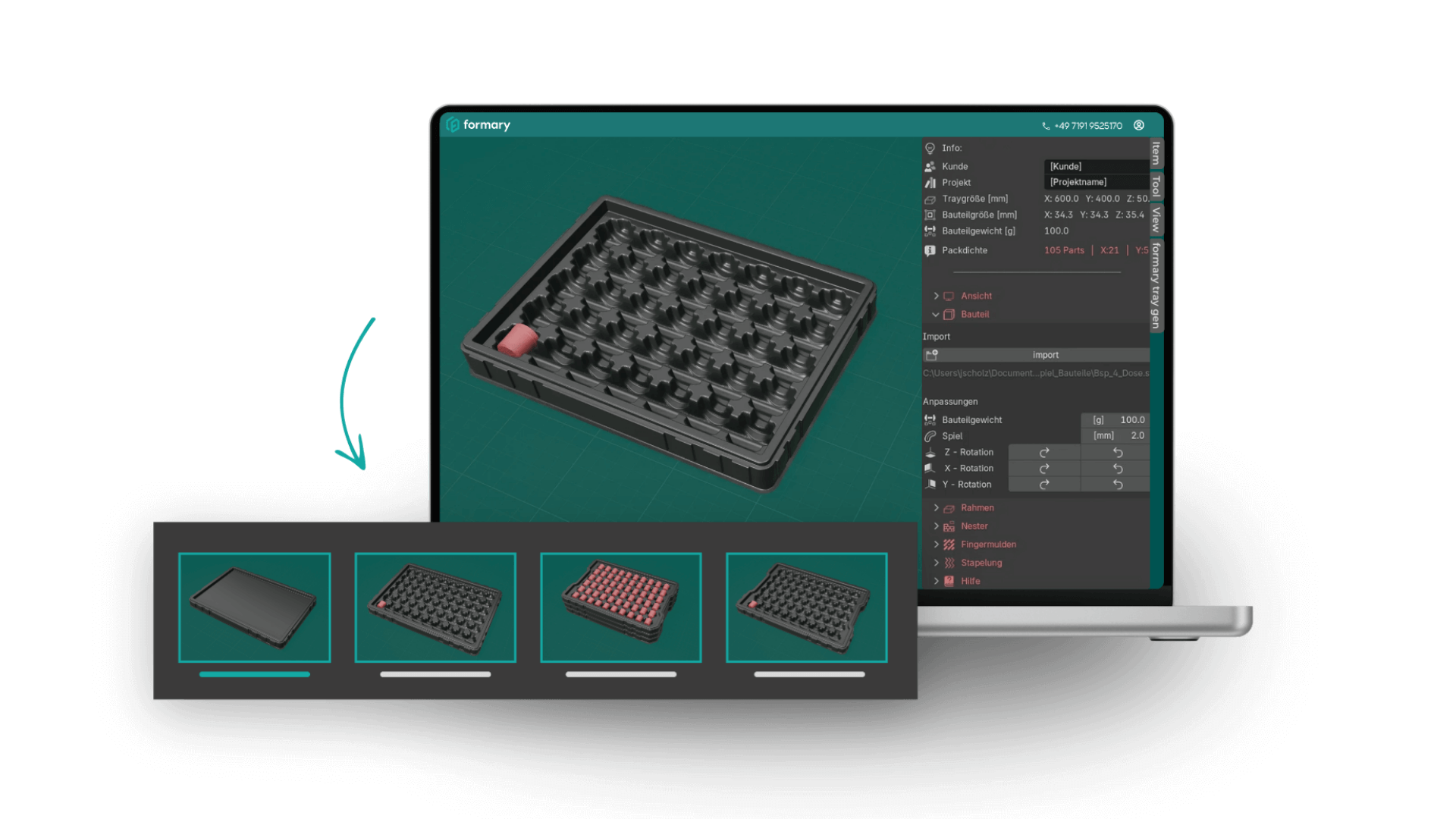

Smart packaging solutions with our 3D Tray Generator

Do you need a concept for your thermoformed packaging, but don't know exactly what it should look like?

With our 3D Tray Generator, you can simply upload your component for which you need thermoformed plastic packaging and create a packaging concept in 30 seconds. This gives you an idea of what your end product will look like.

Specific areas of application for thermoformed packaging

Medical Technology

- Sterile packaging for disposable instruments (scalpels, syringes, catheters)

- Blister trays for surgical sets or implants (e.g., hip joints, screws)

- Sterile inner packaging for laboratory samples or diagnostic kits

- Packaging carriers for clean rooms to transport components without generating particles

- Protective packaging for sensitive optical or electronic components (sensors, endoscopes)

Industrial Solutions

- Reusable workpiece carriers in automated production lines

- Component inserts for temporary storage or transport of precision parts

- Protective packaging for sensitive CNC components or seals

- Sorting inserts in assembly and testing systems

- Customized packaging for spare parts or maintenance kits

Robotics

- Component trays for sensors, grippers, or camera modules

- Assembly trays in automated production lines (precise position detection by robots possible)

- Workpiece carriers for reusable internal logistics in assembly

- Packaging for calibration tools or spare parts

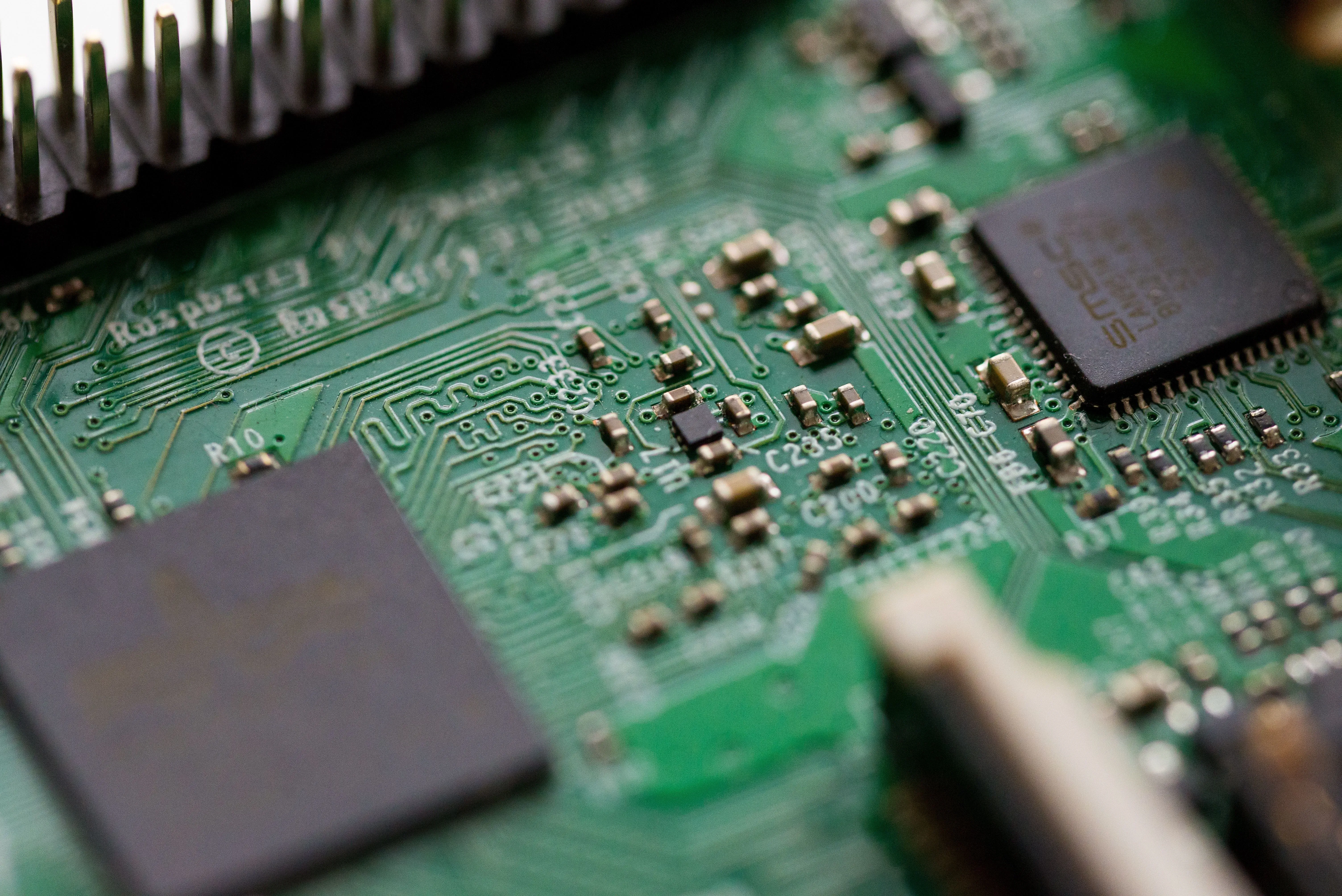

Electronics

- ESD trays (antistatic materials, e.g., PS-C, PET-C) for circuit boards or chips

- Blister packaging for electronic components (resistors, sensors, microchips)

- Packaging inserts for end devices or modules

- Transport packaging in the production chain (e.g., from assembly to installation)

- Display packaging for small electronics in retail (headphones, adapters, batteries)

Benefits of thermoformed plastic packaging

Cost-effective manufacturing

The thermoforming process is more cost-effective than other processes such as injection molding, especially for smaller production runs, as the tooling costs are lower.

Barrier effect

Thanks to their plastic properties, thermoformed plastic packaging offers protection against moisture, grease, oxygen, and dirt.

Low weight

The ability to manufacture thin-walled thermoformed packaging saves weight, which reduces transport and logistics costs.

Efficient storage

On the one hand, the precise arrangement of the parts allows optimal use of the space in the plastic packaging, and on the other hand, the stackable thermoformed packaging offers space-saving storage.

Material diversity

Depending on the application and requirements, there are many options available, such as ESD-safe packaging or a wide range of colors and transparencies.

High hygiene standards

Thermoformed plastic packaging ensures a high standard of hygiene, as it is particularly easy to clean.

Fields of application for thermoformed plastic packaging

Tray packaging for metal components

Tray packaging provides a perfect fit for metal components and protects them from external influences such as scratches, impacts, and surface damage. Thanks to their precise shaping and robust plastic properties, sensitive components can be transported, stored, and even processed automatically without slipping or being damaged.

Sustainable alternatives to plastic packaging

In addition to our thermoformed plastic packaging, formary also offers sustainable packaging solutions such as fiber casting and paper injection molding.

Further industries that use thermoformed packaging

FAQ - Frequently asked questions about plastic packaging

Thermoformed products are plastic parts that are molded using heat and pressure. They are used, for example, as trays, housings, or packaging components.