DfM Analysis for Thermoformed Plastic Parts

Optimize CAD models right from the design phase with the smart thermoforming check for maximum manufacturability. Upload your thermoformed part to our 3D analysis and get an automatic Design for Manufacturing (DfM) thermoforming check.

Your DfM Analysis for Deep-drawing-compatible Components

From concept to production-ready design – with the formary thermoforming check.

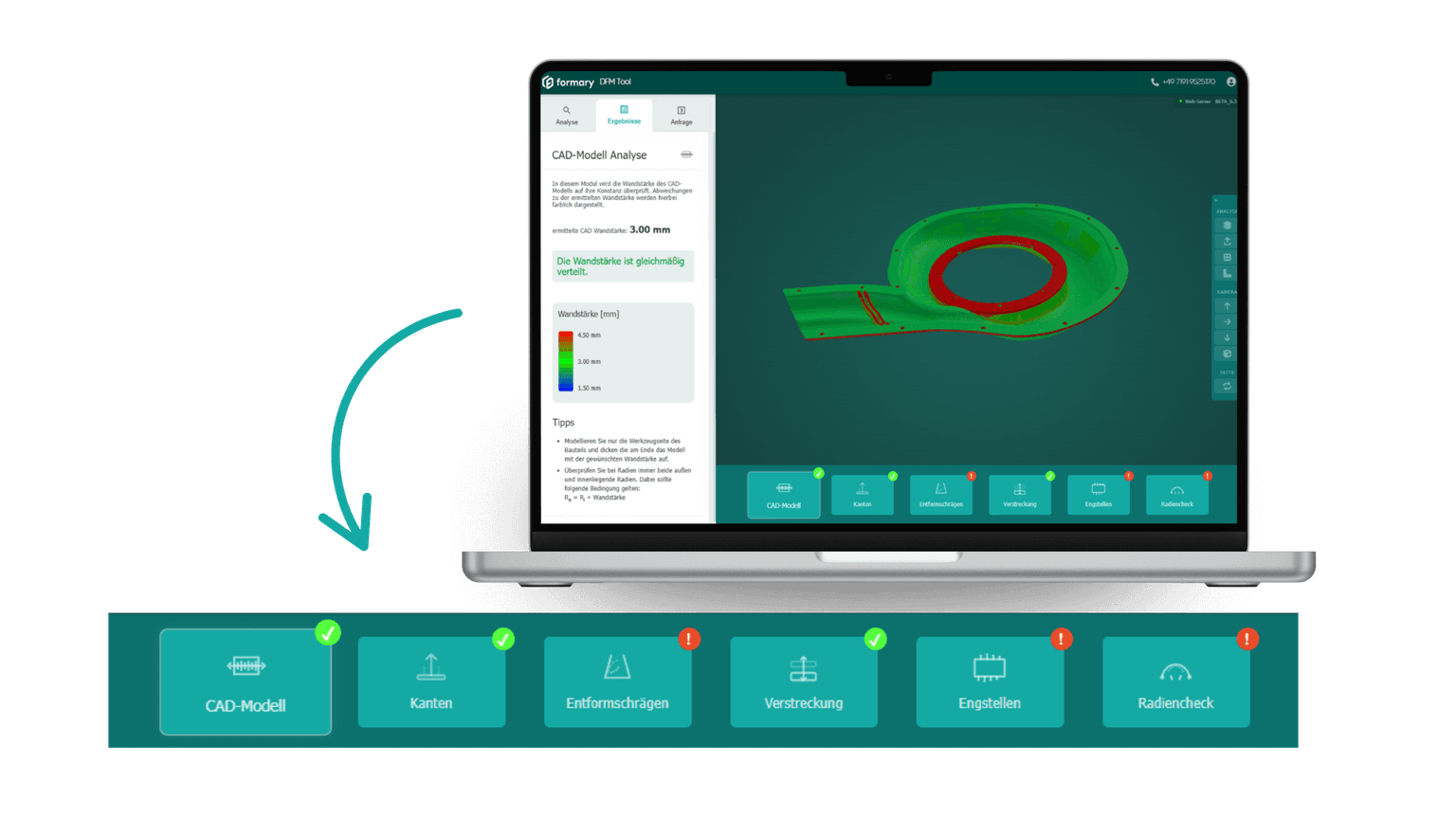

Safety right from the design process: Check your components for manufacturability immediately: without waiting times, manual queries, or error-prone assessments. The formary thermoforming check analyzes your CAD model within seconds for all relevant thermoforming criteria. The DfM analysis is fully automatic, color-coded, and ready for direct processing in toolmaking.

How the DfM Analysis Works

Upload 3D Data of Your Thermoformed Part

Simply upload your CAD data (e.g., STEP files) using our web tool. Once uploaded, the DfM analysis starts automatically—no installation or manual preparation required. Your component is checked directly against all relevant manufacturing parameters.

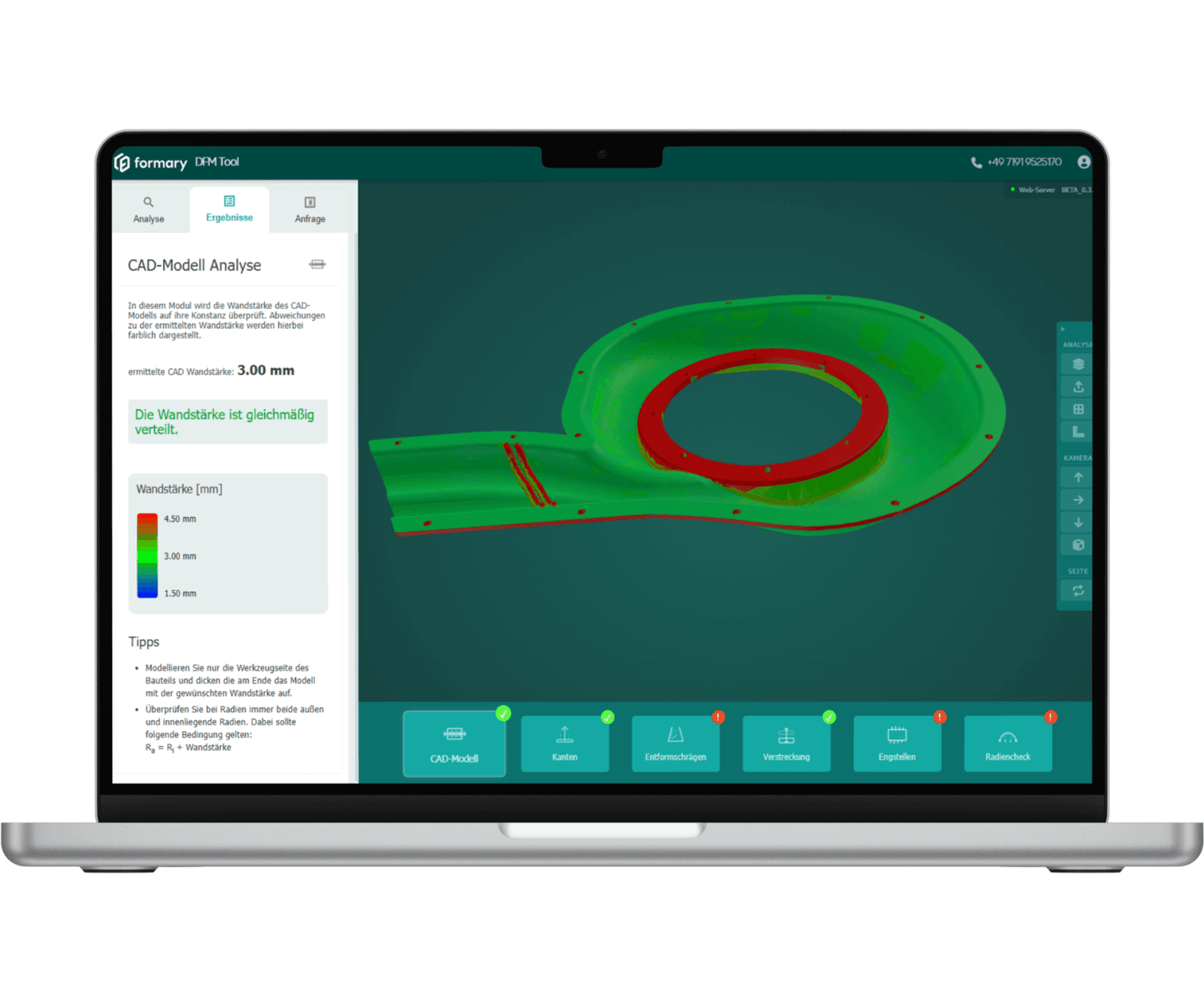

Analyze Wall Thickness Distribution

The Design for Manufacturing software automatically detects the main wall thickness of the 3D model and highlights deviations in color. Areas that are too thin or too thick are visible at a glance. This is ideal for identifying potential weak points or material accumulations at an early stage.

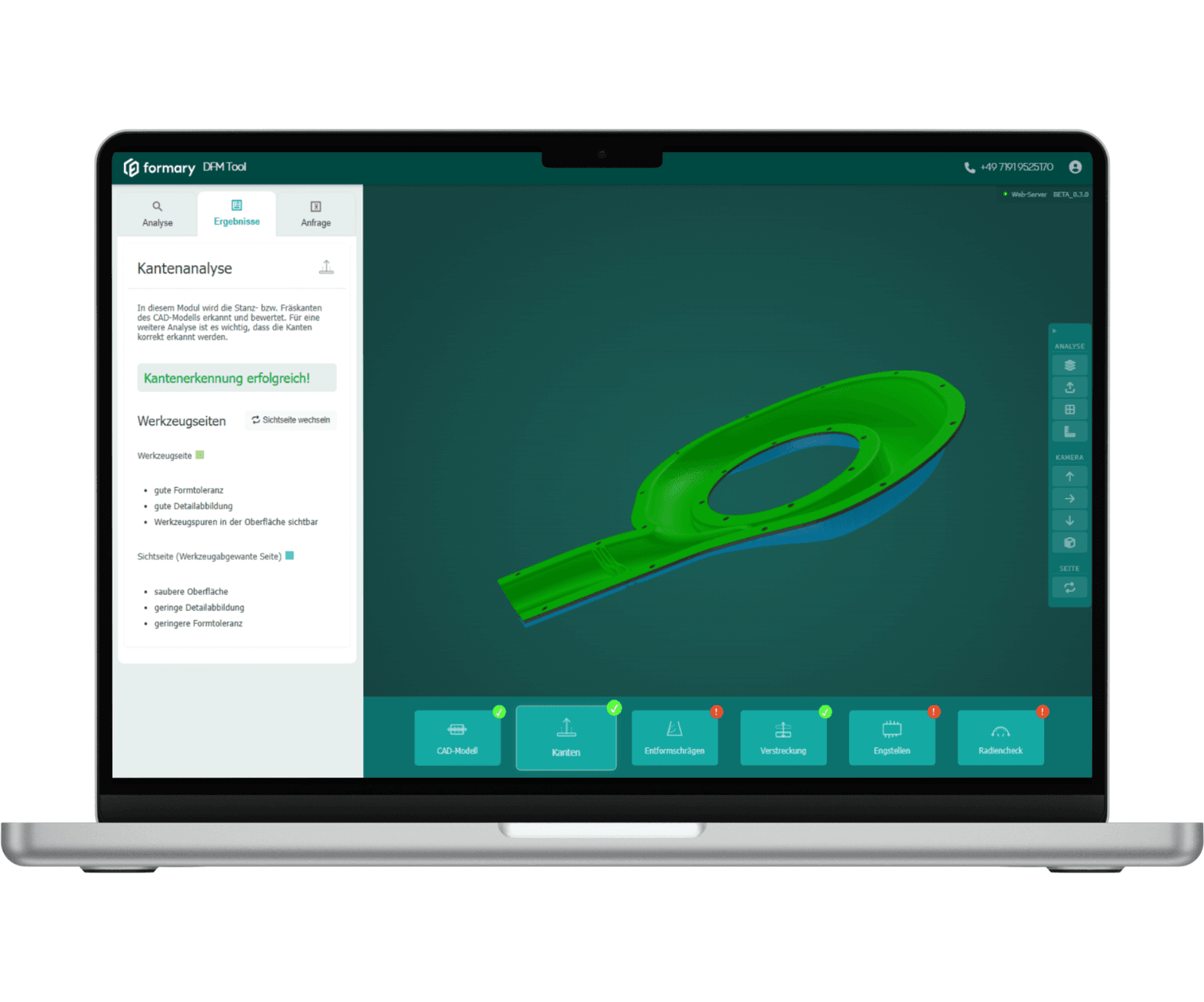

Evaluate Edges

Punching and milling edges are detected and evaluated. This ensures that all functionally or production-critical edges can be accurately reproduced in the subsequent process. This is an important basis for post-processing.

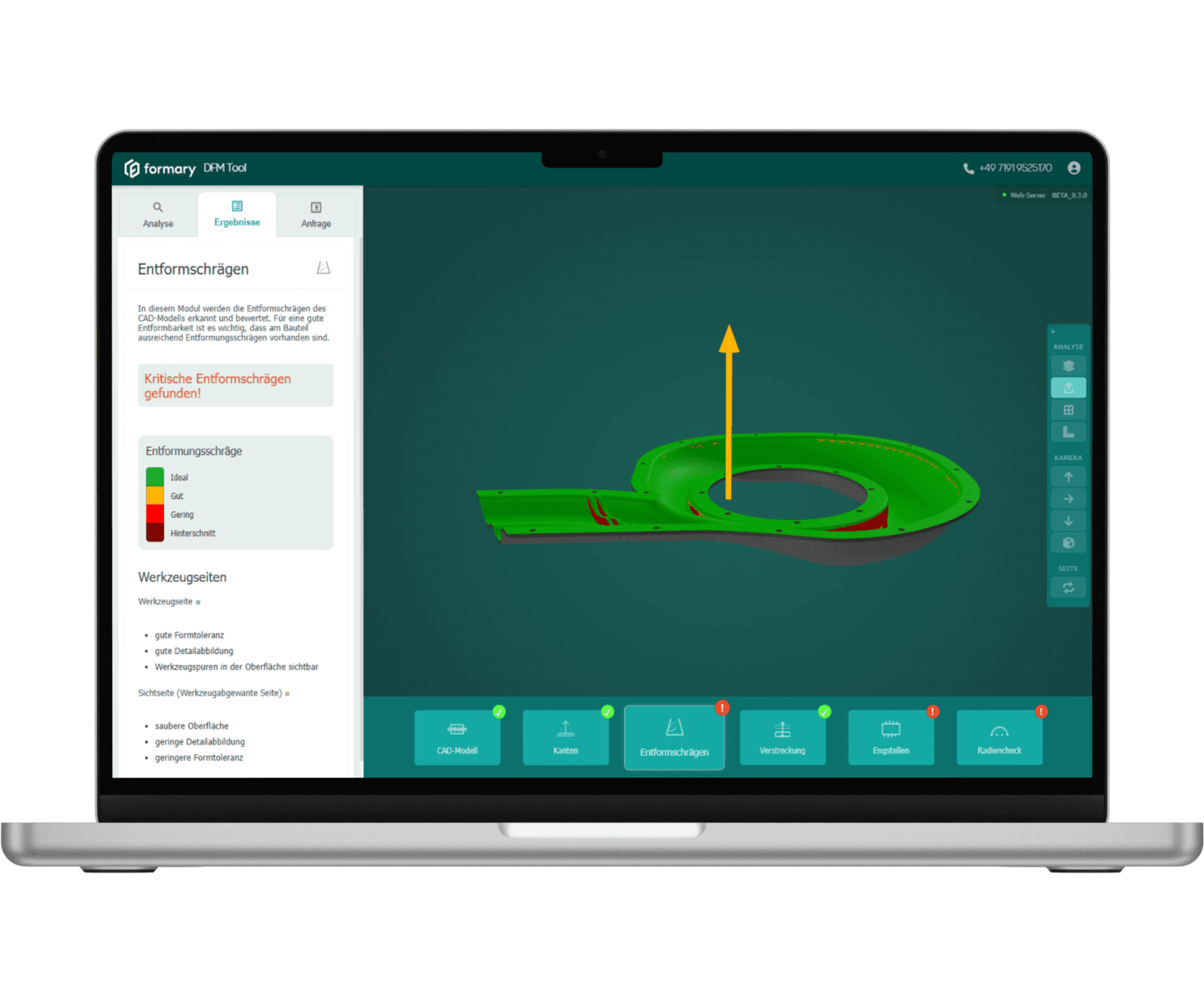

Check Draft Angles

The demoldability of the thermoformed part after the thermoforming process is checked: Critical areas without sufficient draft are highlighted. This allows you to see immediately where improvements need to be made to ensure smooth removal from the mold.

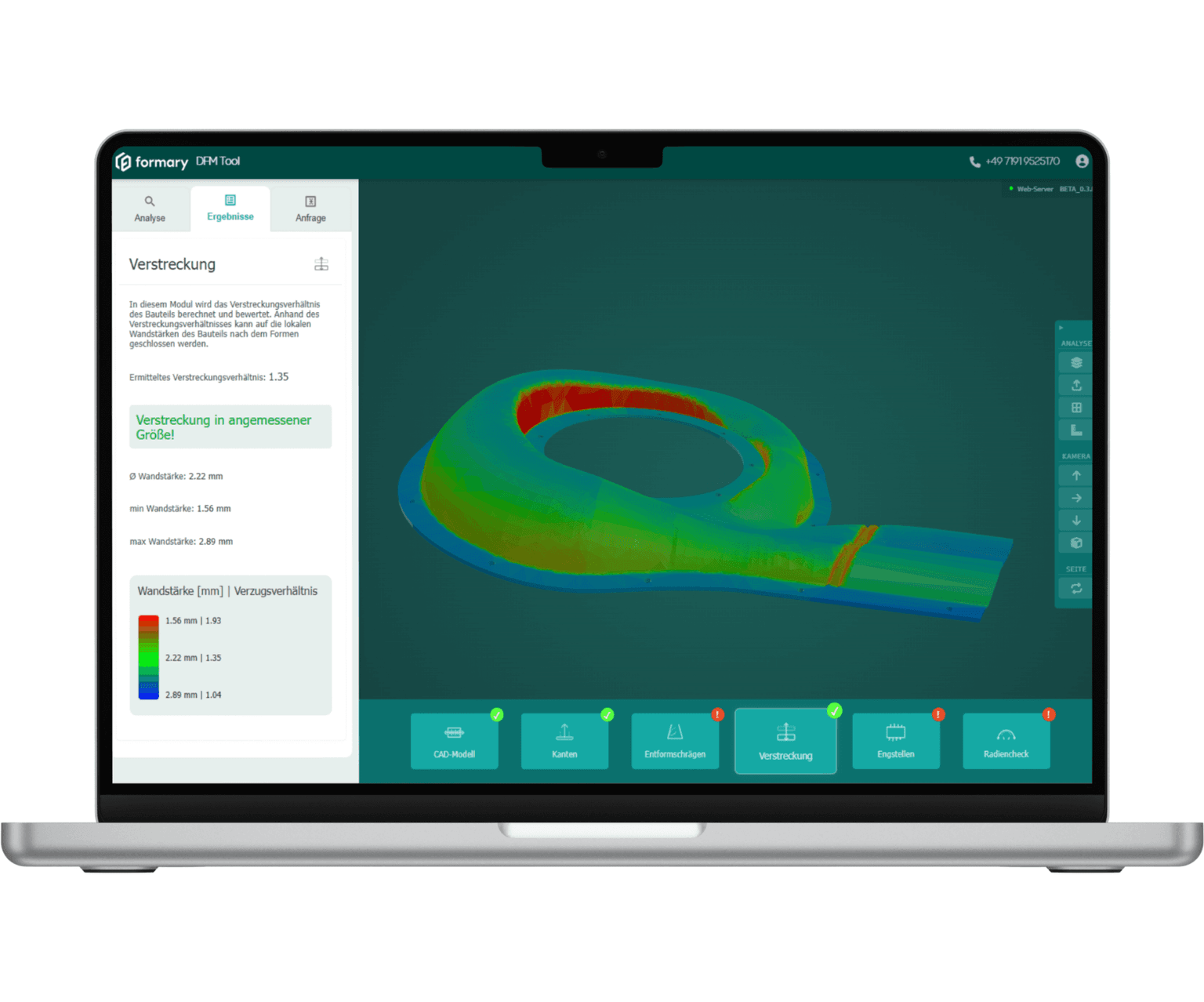

Validate Stretching Ratio

This module calculates the local strain ratio and shows how much the material is stretched at different points on the component. The DfM analysis enables a realistic assessment of the resulting wall thickness distribution after the deep drawing process—for evaluating component quality and functionality.

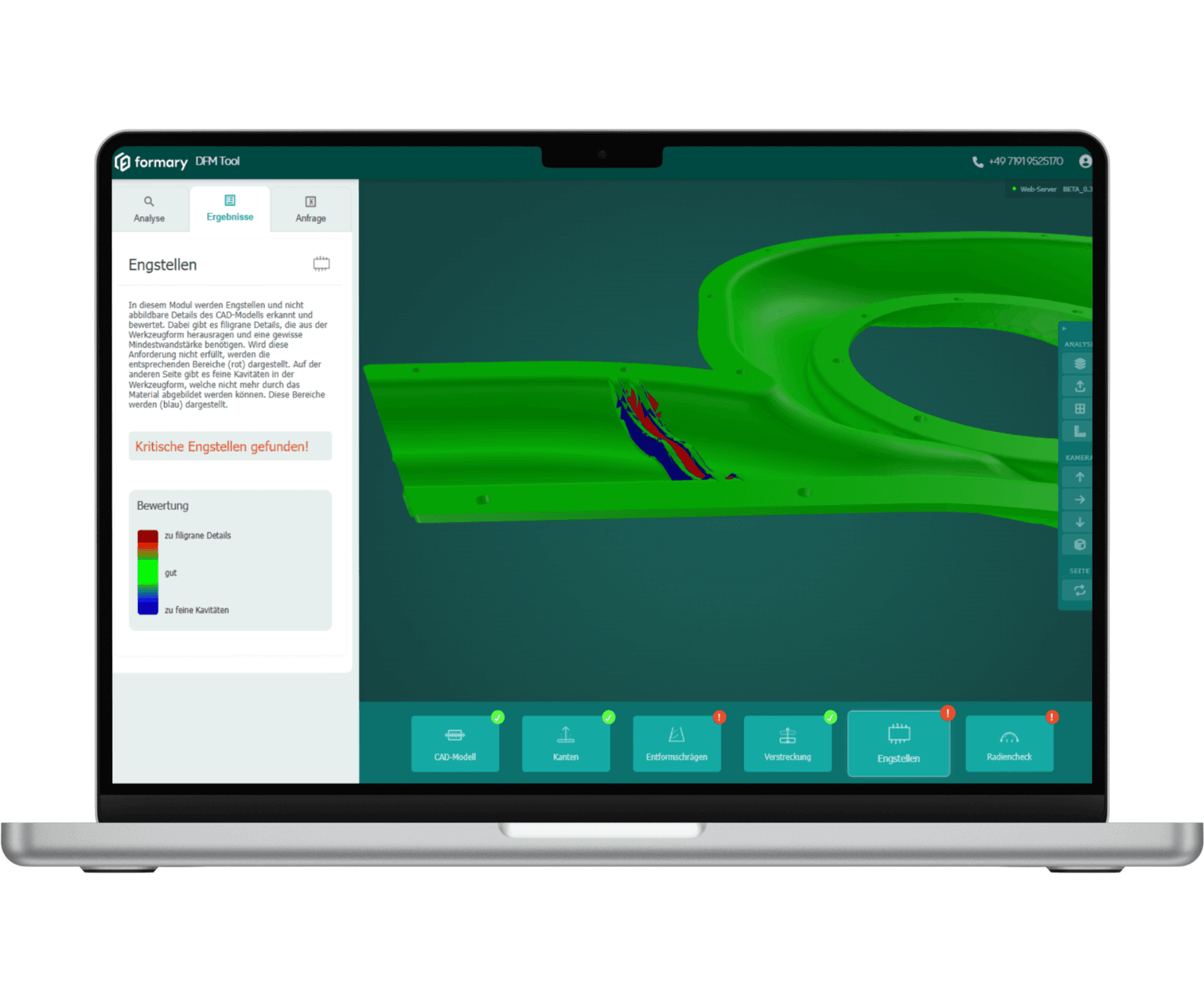

Evaluate Bottlenecks and Details

Delicate areas with insufficient wall thickness are shown in red, while fine cavities that cannot be reproduced by the material appear in blue. This allows you to identify problematic geometries at a glance that could cause difficulties in toolmaking or series production.

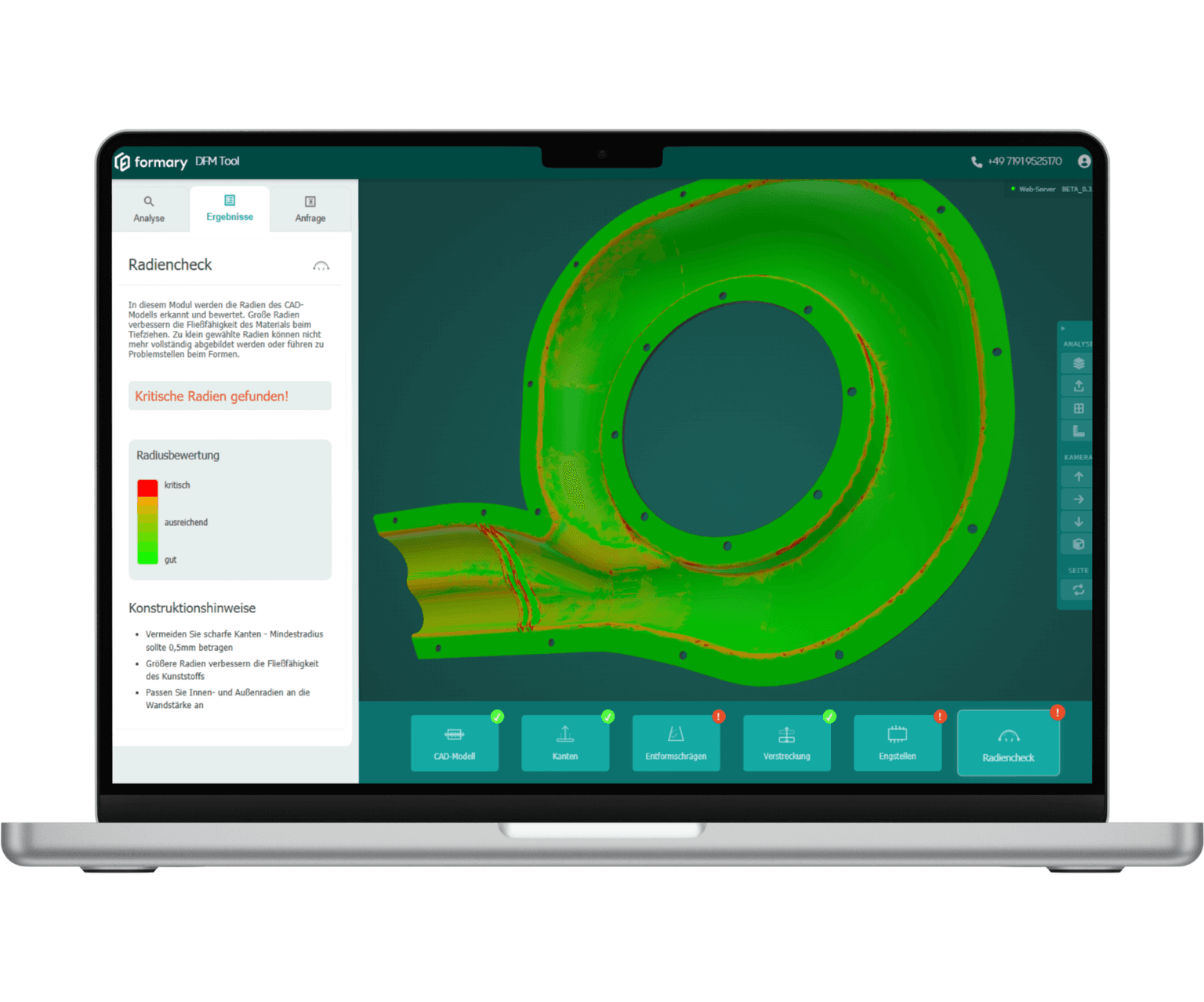

Analyze Radii

All geometric radii of the model are detected and checked for deep-drawing suitability. Radii that are too small can make forming difficult or impossible – here, the Design for Manufacturing software clearly shows where there is potential for optimization.

Your Advantages with the DfM Tool

Design engineers make complex decisions every day – the DfM tool provides them with targeted support in the area of thermoformability. The Design for Manufacturing software automatically analyzes CAD models and highlights manufacturing-critical aspects at an early stage. This significantly improves quality, speed, and safety in the development process.

Knowing early on what will cause problems later

Critical areas are identified in the CAD model before they become costly in production.

Better exploitation of technical potential

The DfM analysis provides clarity on manufacturing-related details—quickly, comprehensively, and objectively.

More efficient processes

Automated testing eliminates the need for consultation and waiting times, resulting in faster, more targeted product development.

Optimal Use – When and Why the Thermoforming Check is Useful

Thanks to its ease of use, visual feedback, and immediately available results, DfM analysis becomes an integral part of an efficient, low-error development process—whether in series production, prototyping, or component optimization.

Early Design Phase

Initial assessment of thermoformability during the design phase.

Feasibility Study

Technical validation prior to internal or external approvals.

Component Optimization

Targeted adjustment of wall thicknesses, radii, or draft angles.

Communication with the Tool Manufacturer

Objective basis for coordination without room for interpretation.

Cost Reduction

Avoidance of subsequent changes through early error detection.

Knowledge Building within the Team

Support for designers without specialized knowledge of deep drawing technology or extensive prior experience.

Example Applications for the DfM Software

Frequently Asked Questions about the DfM Analysis Tool

The Design for Manufacturing software currently only accepts the .STEP 3D CAD format.

Have your Thermoformed Component Analyzed Now

Book a demo and experience DfM analysis in action. We will analyze your thermoformed part in just a few seconds—live and clearly.