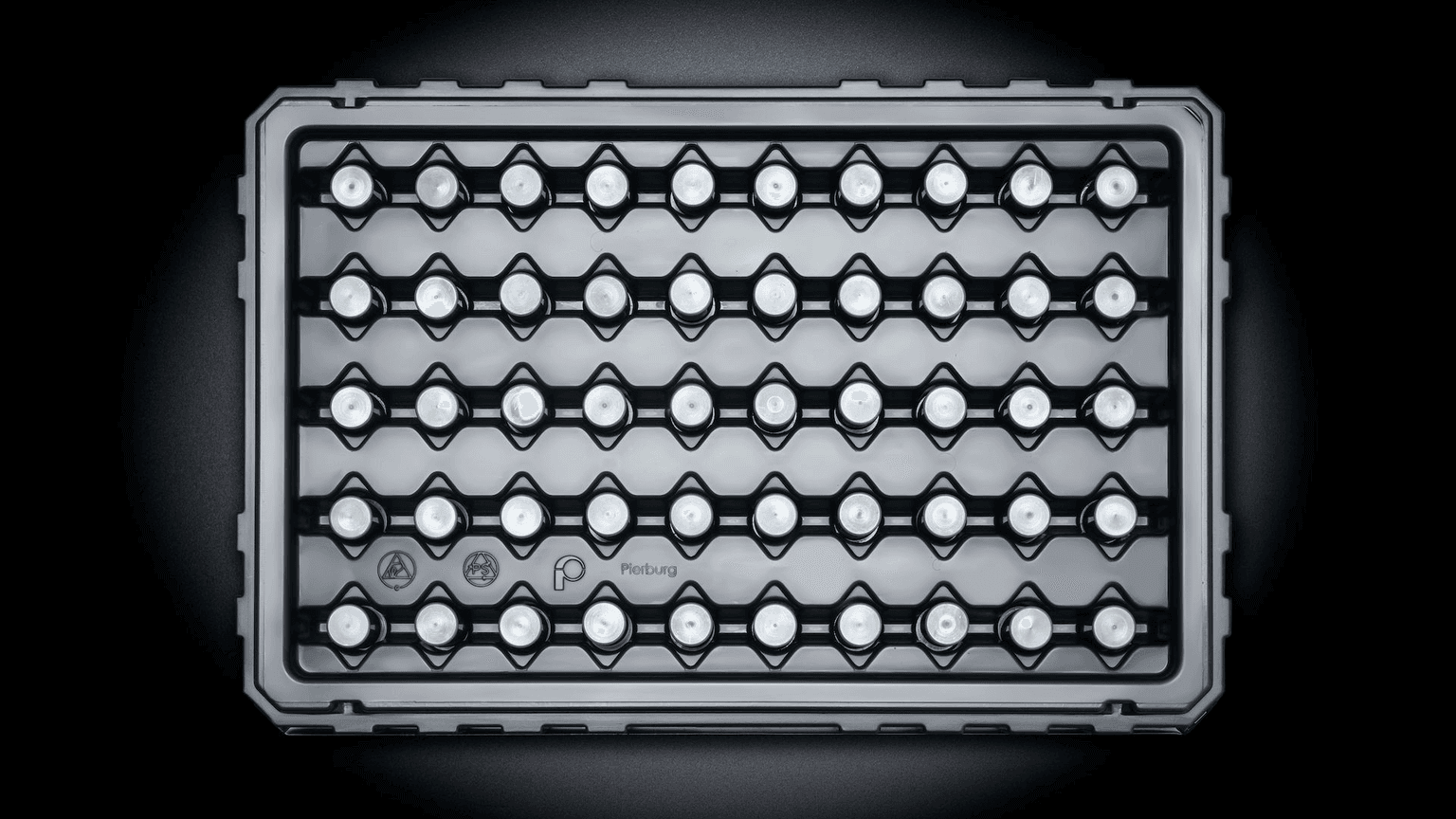

Plastic ESD containers

Deep-drawn plastic ESD containers for reliable component protection in electronics manufacturing. Ideal for transport, storage and automated handling.

What is an ESD container?

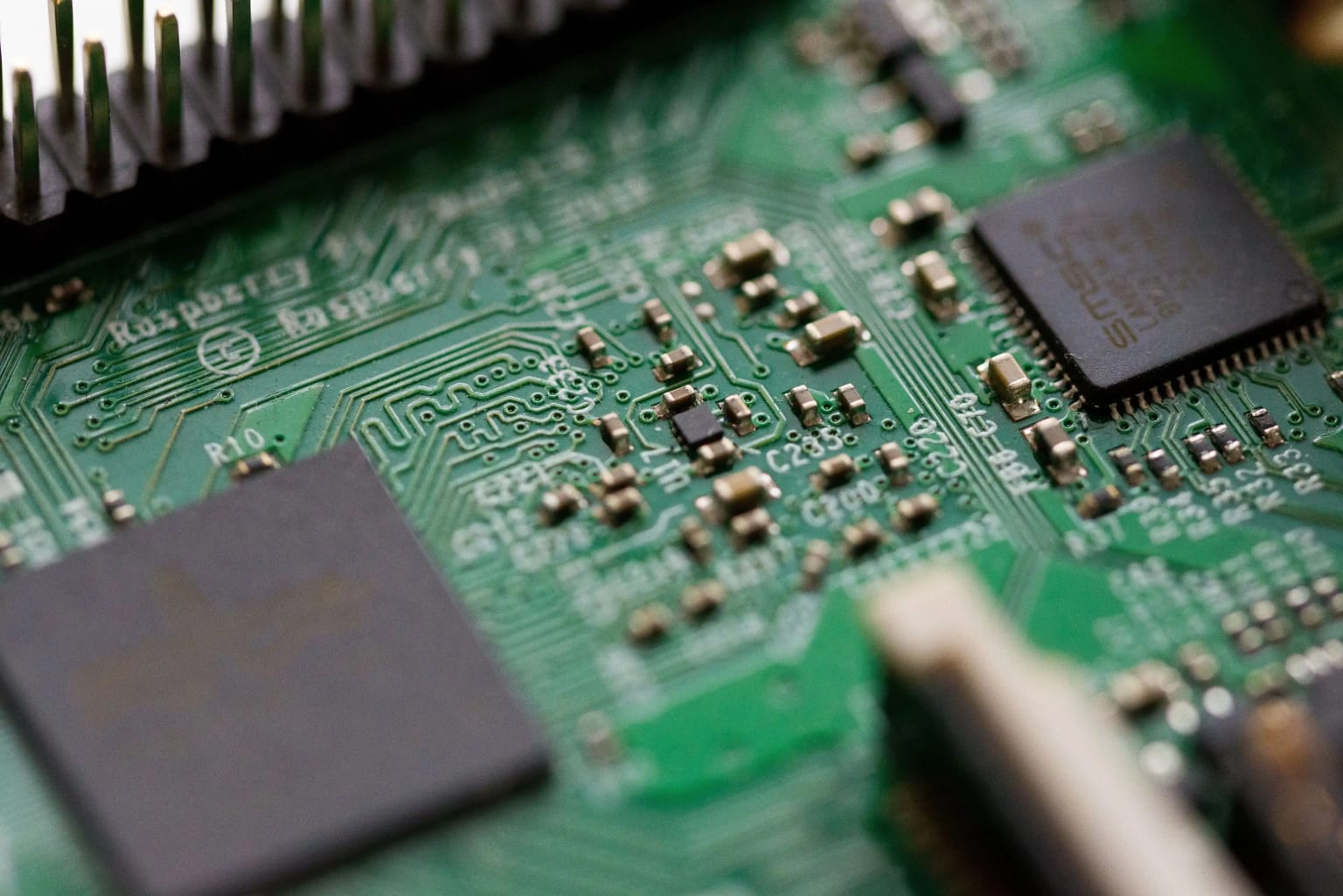

An ESD container is a special plastic container designed to protect sensitive electronic components from electrostatic discharge (ESD). This prevents electronic components such as circuit boards, chips or sensors from being damaged by static discharge.

What types of ESD containers are available?

Depending on the area of application, various types of ESD containers are available: from compact KLT containers to large-volume transport containers.

The most common variants include:

- ESD Euro containers: Standardised dimensions according to Euro standards, ideal for warehouses and logistics systems.

- ESD KLT containers: Stackable small load carriers for automated manufacturing and conveyor systems.

- ESD stacking boxes: Space-saving and robust, can be flexibly combined in different sizes.

- ESD transport containers: Offer maximum protection when shipping sensitive electronic components.

Typical areas of application are electronics manufacturing, the automotive industry, medical technology and laboratory environments, i.e. wherever electrostatically sensitive components need to be safely processed, stored or transported.

Functions & properties of ESD containers

Durable materials

Plastic ESD containers are impact-resistant, abrasion-resistant and designed for multiple use. This ensures long-lasting use with minimal wear and tear.

Customised design

Each ESD container is precisely tailored to your production processes. This ensures safety and guarantees maximum process reliability.

ESD protection

Stackable containers and transport containers with ESD protection prevent electrostatic discharges and thus protect sensitive components.

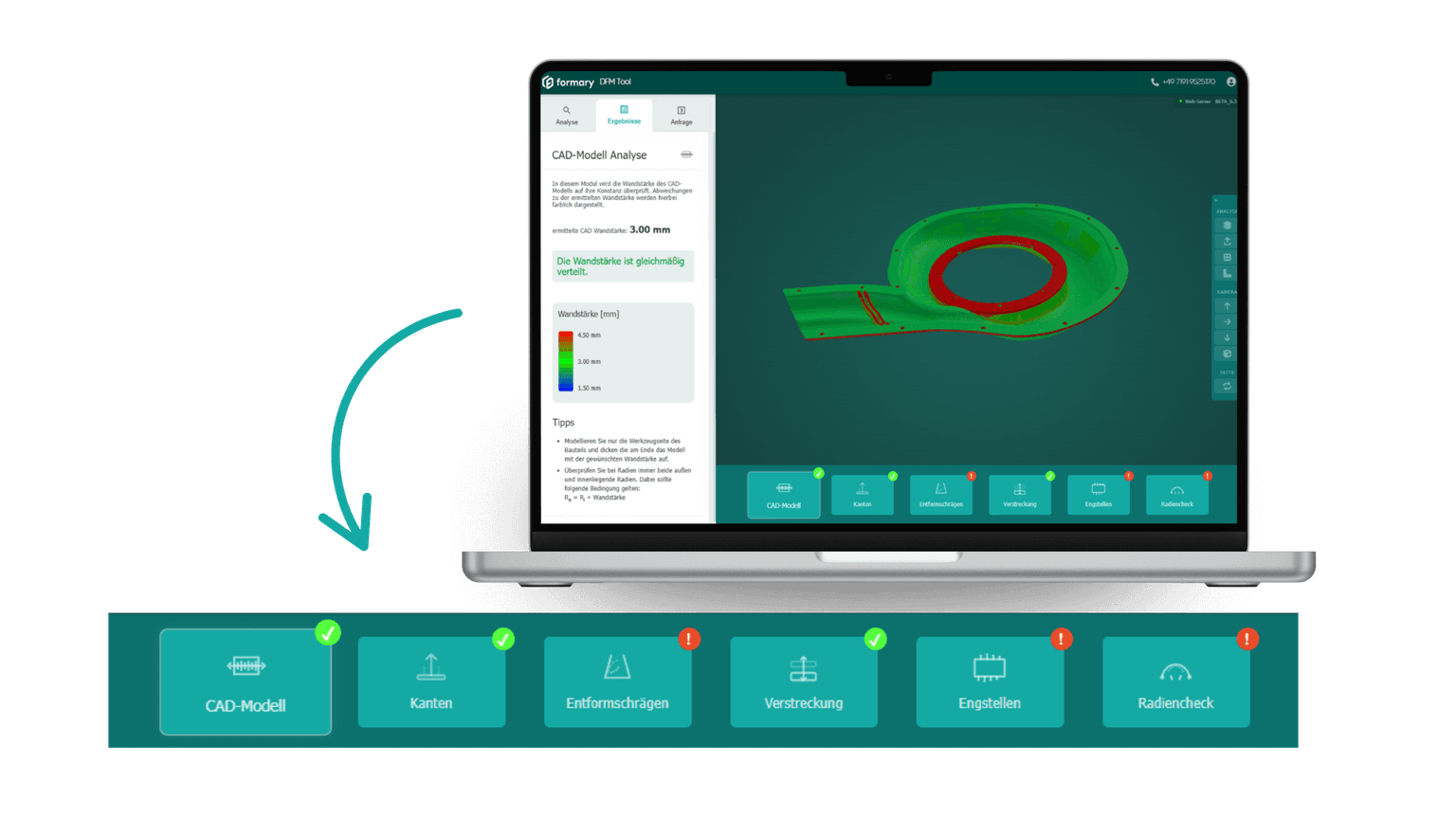

Thermoforming check for your ESD container in 60 seconds

Use our DfM analysis to check your ESD plastic container for thermoformability.

In our demo, we show you how to use our DfM analysis to check your CAD file for all relevant thermoforming criteria in just a few seconds.

Areas of application for plastic ESD containers

Electronics

- ESD containers for printed circuit boards (PCBs)

- ESD containers for microchips

- Antistatic containers for sensors

- ESD containers for connectors

- ESD containers for automotive components

- ESD containers for measurement and testing technology

- ESD containers for circuit board stacks

- ESD containers for robotics components

- ESD containers for electronic modules

- ESD containers for solar cells and photovoltaic elements

- ESD containers for sensitive electronic components in shipping

- Reusable ESD containers for production cycles

- Deep-drawn ESD containers for assembly and production lines

- ESD containers for precise handling in SMT and THT production

Advantages of plastic ESD containers

Space-saving

Thanks to their clever design, the ESD containers can be stacked efficiently and nested inside one another. This makes optimum use of the available storage and transport space.

Stackable

Sturdy ESD stackable containers enable safe and easy stacking, reducing the risk of damage to sensitive components.

Light

Made from high-quality plastic, ESD boxes are particularly light yet robust. Their low weight reduces transport costs and enables ergonomic handling in daily use.

Stable

ESD transport containers are durable and offer high dimensional stability and impact resistance. Even with intensive use, they provide reliable protection for sensitive electronic components.

Temperature resistant

ESD containers retain their shape and remain usable at both high and low temperatures. This makes them ideal for production and storage environments with changing climatic conditions.

Chemical resistant

The plastics used are resistant to many oils, greases and chemicals. This means that antistatic plastic containers remain durable and easy to clean even in demanding industrial environments.

Overview of ESD-compatible materials

Fields of application for plastic ESD containers

ESD containers in the automotive industry

Electronic systems are increasingly being used in vehicle production, for example in control units, sensor technology and driver assistance systems. ESD containers ensure the safe transport of sensitive components between suppliers, assembly lines and testing stations. They are an integral part of the material flow, particularly in the just-in-time logistics of the automotive industry.

ESD containers in aerospace

The aerospace industry uses ESD containers for high-precision electronic components, sensors and control systems. Absolute reliability is therefore crucial, as even the smallest electrostatic discharges can have serious consequences. ESD boxes ensure controlled handling in all process steps, from production to final assembly.

ESD containers in the electronics industry

In the electronics industry, ESD storage containers protect printed circuit boards, microchips, sensors and other electronic components during production. ESD protection prevents failures and quality defects, which is a particularly important factor in the series production of electrical devices.

Other ESD thermoformed parts that may be of interest to you

Industries that use plastic ESD containers

FAQ – Frequently asked questions about ESD containers

ESD stands for electrostatic discharge. During the manufacture, storage or transport of electronic components, static electricity can build up and damage sensitive components. Plastic ESD containers prevent these discharges by dissipating electrical charges in a controlled manner. This means they offer optimum protection for electronic components.