Plastic Extrusion: How Plastic Film is Made

Plastic extrusion is a highly efficient manufacturing process that transforms plastic granules into continuous film. This versatile material is used across various industries, tailored to specific applications and performance requirements.

Sarah Guaglianone

13. Januar 2026

Contents

What is Plastic Extrusion?

Meaning of Extrusion: Plastic extrusion is a molding process used to create plastic products. The extrusion of plastic is achieved by shaping and melting plastic granules. Plastic granules, also known as plastic pellets or plastic flakes, are a common starting form of plastics.

These are small, granular particles made from various types of thermoplastic materials. These particles typically have a consistent size and shape, making them ideal for use in industrial manufacturing processes. During plastic extrusion, the granules or powder are forced through a shaping nozzle to achieve the desired form.

What is an Extruder?

The extruder ensures that the molten plastic flows into an elongated, thin form known as melt strands. After cooling and hardening, the strand is cut into small granular pieces – the finished granules – which are then collected and stored in bags, big packs, or containers.

These granules are then either processed in injection molding machines or again in the extruder. The latter applies to plastic sheets and films.

Which Materials are Suitable for Plastic Extrusion?

Manufacturers of plastic films or sheets first purchase the necessary granules. The material depends on the type of plastic film being processed. For PET films, PET granules are required. Additionally, a distinction is made between using "virgin" (new) material or recycled material (regranulate). When manufacturing regranulate films, flakes are fed into the extruder.

These plastic flakes are thinner, flat pieces of plastic. Unlike granules, flakes do not have a regular shape or size. They are often produced by recycling used plastic items such as plastic bottles that are crushed and cleaned or die-cut grids, or edge strips that are further ground in the machine.

What Plastics Can Be Extruded?

Various types of plastics can be used in plastic extrusion, such as:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Polycarbonate (PC)

- Acrylonitrile-Butadiene-Styrene Copolymer (ABS)

- Bioplastics.

The choice of material depends on the desired properties of the plastic film, such as transparency, flexibility or rigidity, or resistance to external factors like heat, cold, UV resistance, etc.

For more details on the properties of different plastics, please visit the "Materials" section.

How Does Plastic Extrusion Work? Manufacturing Plastic Films

In plastic extrusion, thermoplastic plastics are transformed from granules into semi-finished products like films or thicker sheets. Semi-finished products refer to materials in their simplest form. In the following sections, the plastic extrusion process and its functionality are explained in detail.

Feeding the Raw Material

The raw material, in the form of granules or flakes, is fed into the plastic extruder through a hopper.

Depending on the desired properties of the plastic film, additives like colorants, stabilizers, or additives (e.g., for ESD or flame retardance) can be added.

Schmelzen und Homogenisieren des Kunststoffs

- The granules are melted and homogenized in the electrically heated cylinder of the extruder.

- A screw inside the extruder ensures the flow of the molten material and mixes the materials.

Extruder Setup

The setup of the extruder varies depending on the material being processed:

- Horizontal nozzles (with or without dust bars) are used for viscous melts.

- Vertical nozzles are used for thin liquids like PET.

- Plate systems have a completely different setup with varying cooling paths.

Shaping the Plastic Film

- The molten plastic exits the extruder as a strand-like melt and is pressed into the die using a melt pump.

- The die forms the melt into a thin layer, which is the precursor to the plastic film.

Smoothing and Finalizing the Film

The formed layer is guided through a smoothing station with heated rollers to ensure a consistent material thickness.

The material strip is then trimmed to the desired width using a single or multi-cut system.

What Happens to the Plastic Film After Plastic Extrusion?

After the cooling section, the plastic film undergoes further processing. This may include printing specific information or designs on the plastic film. Additional processing steps may also involve laminating with other materials or applying coatings.

The final product is then wound into rolls, or for thicker sheets, it is cut to the desired width and length using a separator saw or shear.

he extruded plastic rolls or sheets serve as raw materials for producing thermoformed parts, among other things. For thermoforming, semi-finished products are heated and drawn into a mold. The semi-finished products are either unwound from a plastic roll or placed in the machine as a plastic sheet.

For plastic rolls, the maximum starting thickness is 3mm, though many manufacturers limit it to 2.5mm due to the difficulty of winding the film to this thickness. Beyond this, the semi-finished product becomes too rigid for processing and is instead cut into sheets.

Applications of Plastic Film

Plastic film is a highly versatile product with a wide range of applications. We focus on plastic film as a thermoformed part, where it is used across various industries:

- Automotive

- Medical and Pharmaceutical

- Mechanical Engineering

- Industry

- Electronics and Semiconductor Technology

- Consumer Goods

- Food

- Cosmetics

The applications are described in more detail below. You can find more information on the application of plastic film and its processing options in the following video.

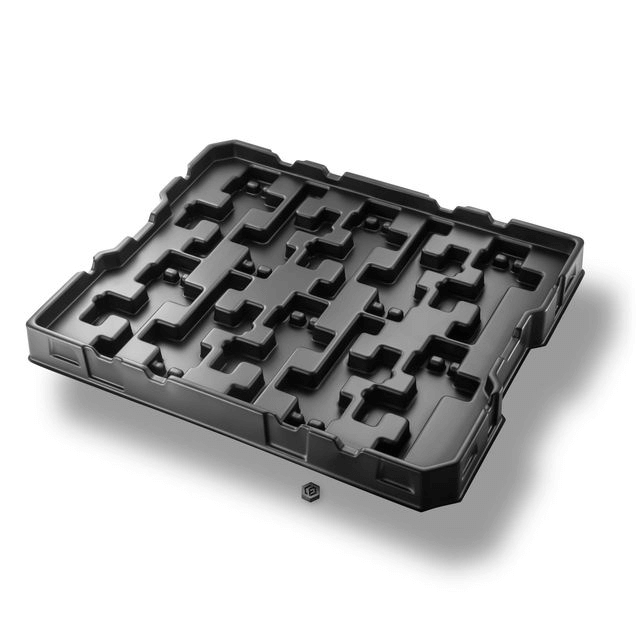

Automotive Industry

In the automotive industry, plastic films are used in transportation and storage logistics as thermoformed packaging solutions and reusable trays. The film thickness in such applications ranges from 0.2 to 0.8 mm.

Medical and Pharmaceutical

High hygiene standards are crucial in the medical field. Sterilizable and biocompatible materials are essential. Thermoformed parts, such as trays, inserts, and medical blisters, are used for packaging small medical items like syringes and needles.

Mechanical Engineering

Plastic films with ESD protection and electrical insulating properties are used as thermoformed machine covers for sensitive machine parts.

Industry

In industry, plastic films are used as thermoformed containers for chemicals and liquids, as well as for casting molds or covers.

Electronics and Semiconductor Technology

To ensure the safe transport of electrostatically sensitive components like semiconductors, circuits, or diodes, plastic films are used as thermoformed ESD workpiece carriers and ESD transport packaging. These specialized packaging solutions are designed to prevent electrostatic discharges and protect the components during shipping.

Consumer Goods

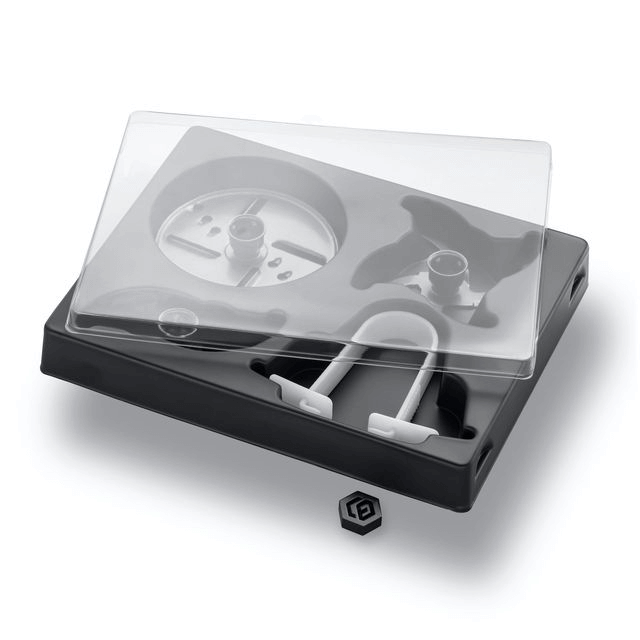

In the consumer goods sector, transparent plastic films are used as thermoformed packaging for retail and e-commerce. These clear packaging solutions allow for a visible display of the product while providing protection and security.

Food

Plastic films are used as primary packaging in the food industry, ensuring freshness and hygiene for perishable food items. They are often sealed with a protective film to preserve food quality and protect it from external influences. Thermoformed plastic trays are used for the safe transport of delicate food items.

Cosmetics

In the beauty industry, thermoformed parts are frequently used as secondary packaging in retail. Transparent materials and optimal product fit are essential for creating attractive packaging designs, while ensuring product protection during transport.

Plastic Extrusion with the formary Supplier Network

In most cases, thermoformers buy the required plastic film. However, some suppliers in the formary network extrude their own thermoforming film in-house. This in-house extrusion offers several benefits:

- Tailored solutions to meet customer needs (material properties, additives, colors).

- Better control over product quality, ensuring the film has the desired properties.

- Optimized production processes and increased efficiency due to deeper value creation.

Conclusion

Plastic extrusion is an essential process for the production of plastic films. Thanks to their diverse properties and areas of application, thermoformed parts made from plastic films are indispensable in numerous industries. Does your industry require thermoforming films in order to benefit from the above-mentioned properties? Then configure your thermoforming product now.