B2B Platforms in Plastics Processing: Functions, Processes & Decision Criteria 2026

In 2026, B2B platforms are evolving from pure procurement tools into central control elements of industrial value creation. This shift is especially pronounced in plastics processing, a field characterized by complex materials, highly variant components, and demanding quality requirements.

Sarah Guaglianone

26. Januar 2026

Contents

B2B Platforms in Plastics Processing 2026 – Key Takeaways

- By 2026, B2B platforms will prevail that seamlessly connect RFQ (Request for Quotation), engineering, quality, and delivery capability into one end-to-end process.

- Successful B2B platforms in Germany do not position themselves as pure marketplaces but as 100% responsible partners.

- Manufacturing platforms become the operational backbone between purchasing, engineering, and production.

- For plastic components in Germany, what counts is: clear responsibility, reproducible quality, and reliable delivery schedules.

What Are Digital B2B Platforms in an Industrial Context?

In an industrial context, a B2B platform is not a “portal with a list of suppliers,” but rather a process system that standardizes interaction and transactions between multiple parties: inquiry, technical clarification, quotation, order placement, quality assurance, logistics, and documentation.

Types of B2B Platforms

- Marketplace platforms: connect suppliers and buyers, with responsibility usually remaining with the two parties.

- Intermediary platforms: coordinate processes; responsibility and liability are deliberately limited.

- Managed manufacturing platforms: projects, quality, and schedules are centrally managed digitally. Production takes place within a partner network — responsibility lies with the platform operator.

Especially for thermoformed plastic parts, functional trays, housings, or serial components, model 3 is decisive. formary deliberately positions itself as the responsible contractual partner for both customer and manufacturer, not as a pure order broker.

Overview: Comparison of Three Platform Models

| Model | Characteristics | Risk |

|---|---|---|

| Marketplace | Contact brokerage, minimal process governance | High variance, unclear quality |

| Intermediary | Process coordination, limited liability | Responsibility remains fragmented |

| Managed manufacturing platform | Central project, quality, and schedule ownership | Higher demands on the platform |

Smart Manufacturing: What Do B2B Platforms Actually Deliver in 2026?

Data-driven platforms act as the operational backbone for:

- higher production utilization

- better planning reliability

- faster responsiveness

- fewer media discontinuities

Digital platforms consolidate these effects from inquiry and design through to production.

1) Process APIs Between Purchasing, Engineering & Manufacturing

B2B buyers still work across countless channels (email, phone calls, approval PDFs, Excel bills of materials, etc.), resulting in a poor purchasing experience. This is precisely why platforms in 2026 become the connective process interface between purchasing, engineering, and production. Digital configurators, structured RFQs, and consistent documentation replace fragmented email, Excel, and PDF processes, enabling an end-to-end, media-break-free flow from inquiry to implementation.

2) Decision Capability Instead of Price Comparison

Competition is increasingly no longer decided by the lowest price, but by the best data-based decision foundation. Platforms do not merely provide supplier prices; they make technical and economic implications transparent, for example through DfM analyses or alternative materials and processes. This makes it clear early on which option best balances cost, risk, and feasibility.

3) Standardized Quality Management

In 2026, quality is systematically embedded in the process. B2B platforms establish defined approval steps, versioned data states, and traceable decision paths. Supplier audits are standardized and centrally handled by the platform provider.

4) Traceability as the Default

Traceability evolves from an optional feature to a standard. Manufacturing platforms ensure that CAD versions, approvals, tool status, and relevant quality information are clearly linked. Transparency across the entire lifecycle becomes the norm.

5) Central Customer Portal

Instead of scattered communication, the customer portal becomes the central workspace. Project status, changes, approvals, and communication are bundled in one place.

6) Digital Engineering Tools

Early concepts, layouts, and technical evaluations accelerate decisions and reduce costly and time-intensive iteration loops.

7) Responsibility Instead of Mediation

By 2026, platform performance is increasingly judged by responsibility. Rather than simple mediation, platforms assume the role of a digital manufacturer across the entire lifecycle — from technical clarification and quality assurance to scheduling and serial production.

How Does formary Implement These Requirements as a B2B Manufacturing Platform?

formary implements these general requirements specifically for plastics processing and positions itself not as a marketplace, but as the responsible single point of contact between purchasing, engineering, and manufacturing.

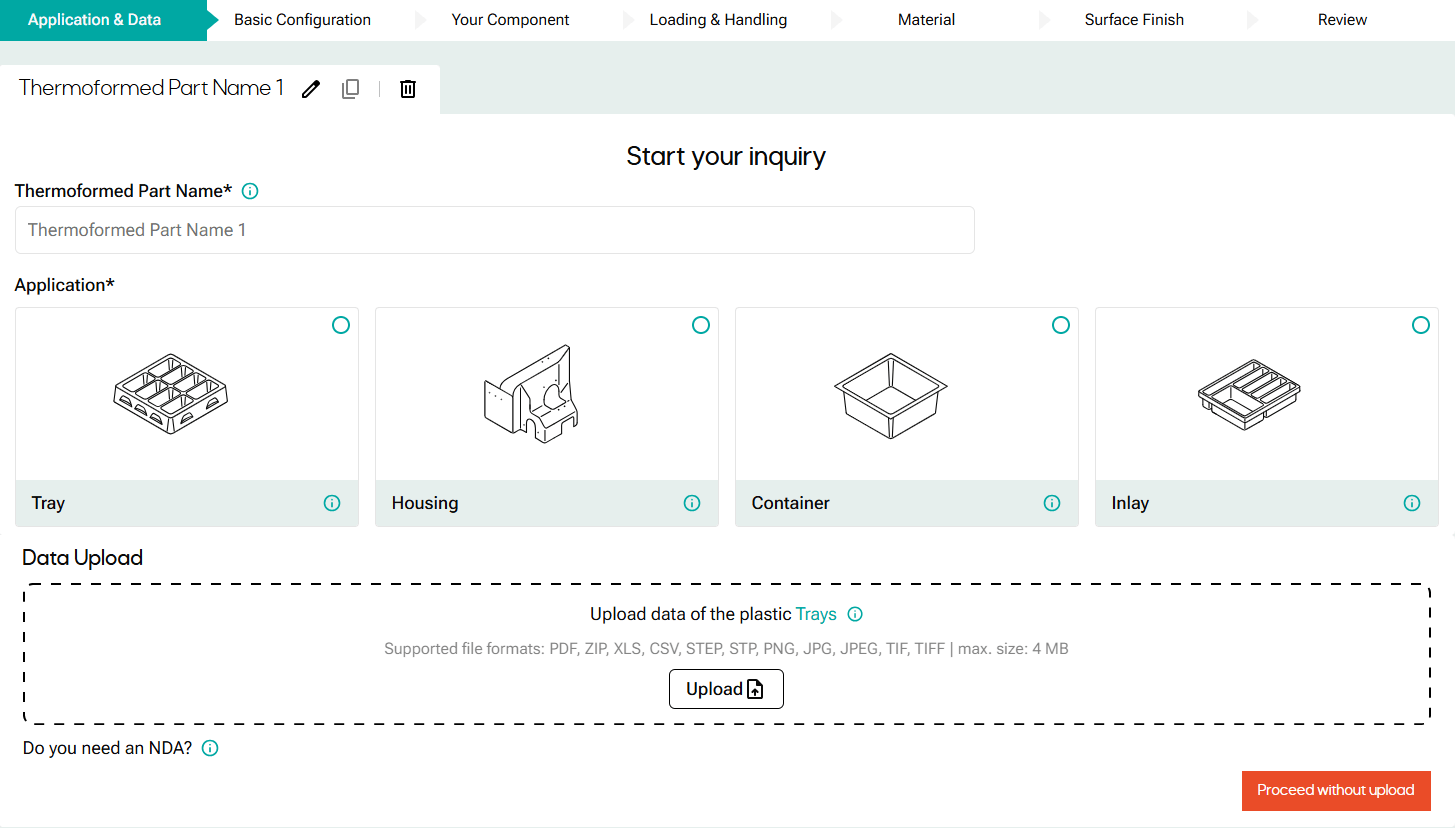

At formary, projects start with a structured inquiry using the configurator, which is specifically designed for thermoformed plastic parts, trays, housings, inlays, and containers. Among other things, the following are captured:

- 3D and 2D data

- dimensions

- planned quantities and annual volumes

- functional requirements

- aesthetic requirements

- specific plastic requirements (fire resistance, chemical resistance, etc.)

- material selection (e.g., ABS, PS, PET-G, etc.)

- and additional factors

The goal is a robust technical and economic decision basis.

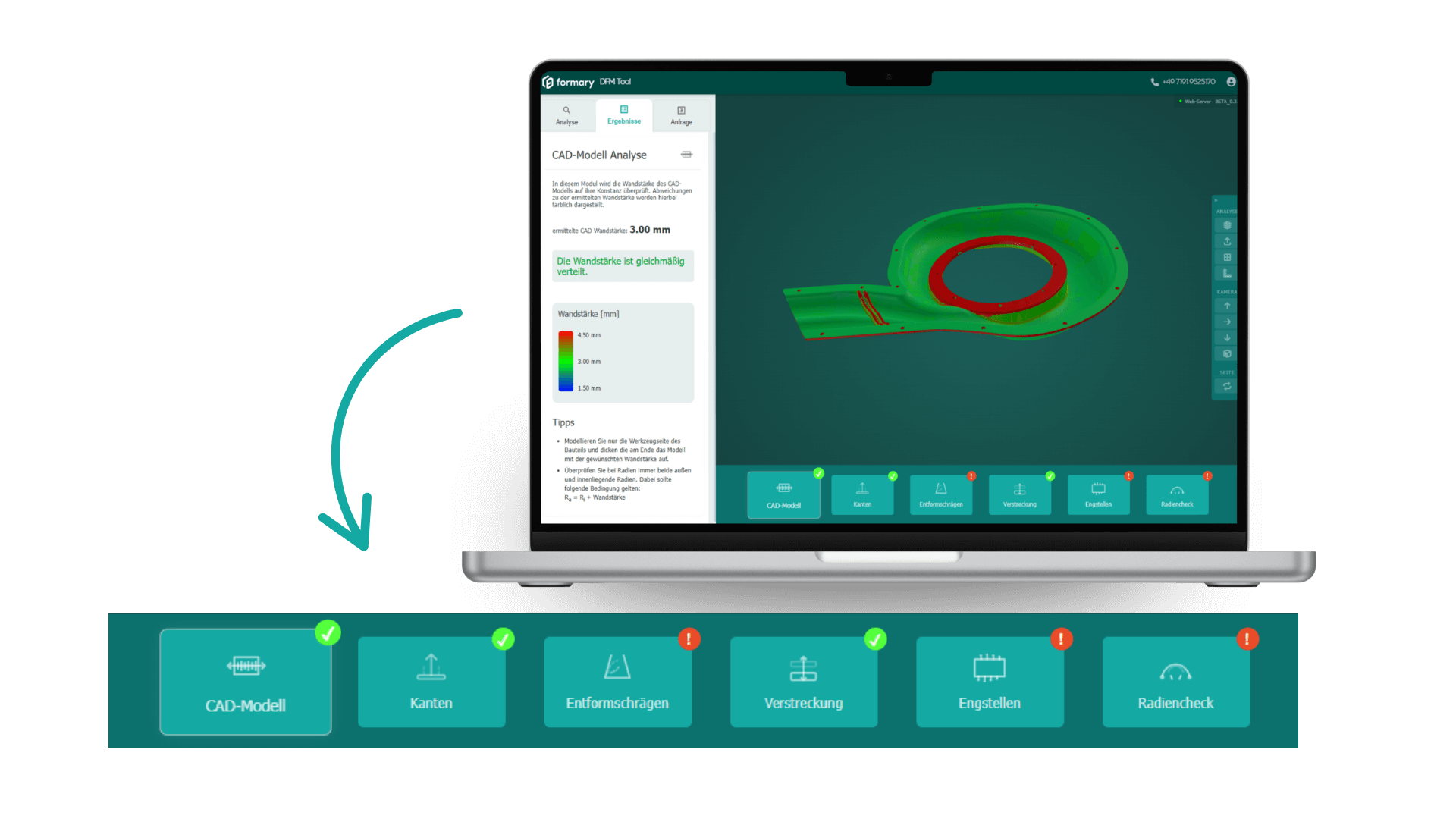

DfM & Engineering as an Integrated Process

formary integrates manufacturing-oriented design early on through a DfM analysis. This technical clarification takes place before quotation and is documented so that decisions remain traceable.

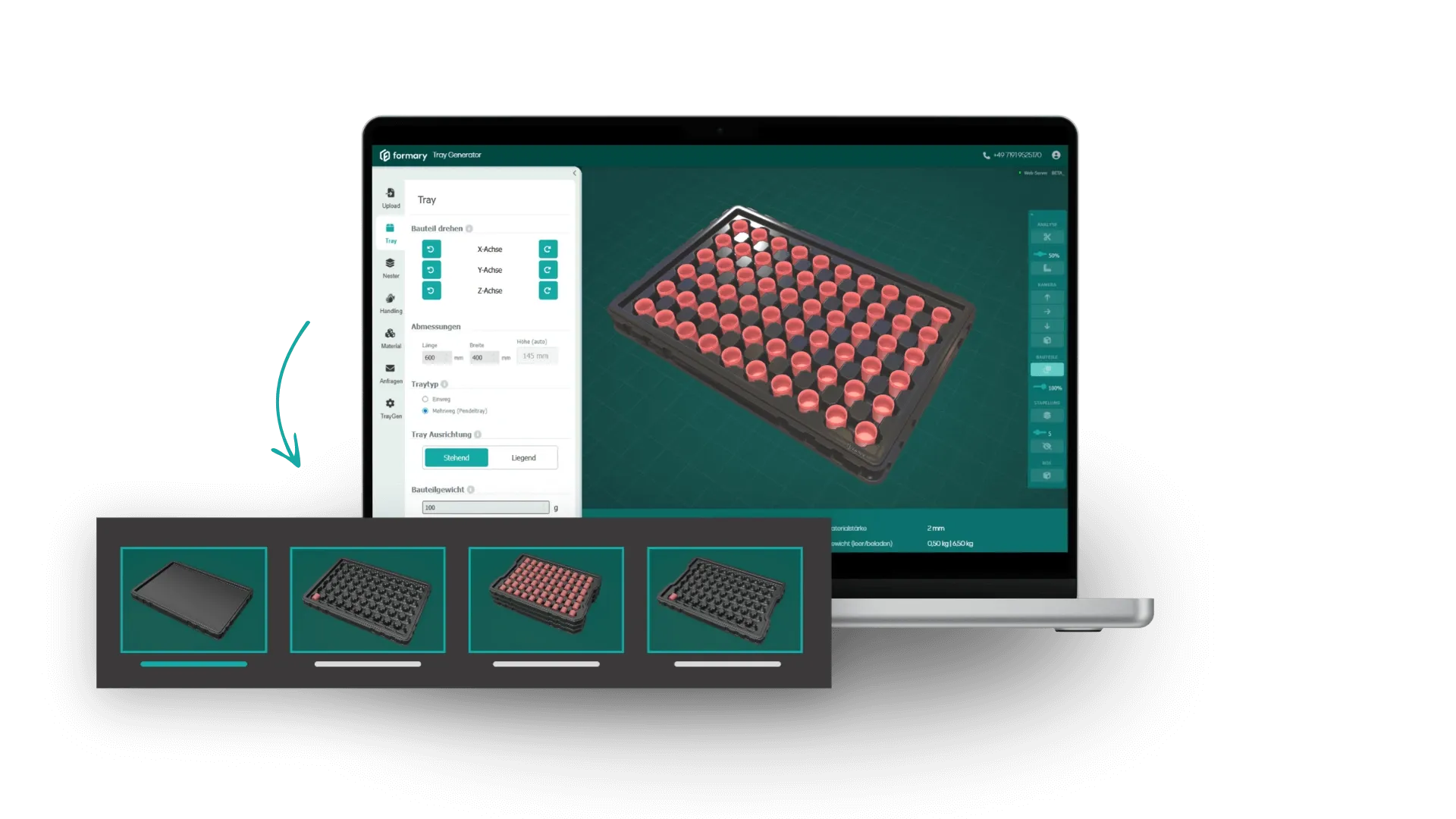

With the 3D Tray Generator, tray concepts can be created by uploading component data, enabling companies to start internal planning at an early stage.

Quotation Logic with Technical Safeguards

Quotations at formary are based on structured costing models that consider, among other factors:

- material usage

- tooling concept and design

- machine selection

- setup and cycle times

- post-processing and quality assurance

Serial Approval & Traceability

After order placement, all relevant data states are centrally consolidated in the formary customer portal. The customer portal provides full transparency regarding:

- status tracking

- specification changes

- direct communication with the project manager

- fast approvals

This establishes the foundation for traceability, reproducible quality, and long-term serial production.

End-to-End Responsibility in Project Planning

Within project planning, formary assumes full responsibility for:

- technical clarification

- quality assurance

- schedule and capacity planning

Manufacturing partners are integrated into the network, but overall project responsibility remains centrally managed.

Opportunities and Risks of Online Manufacturing Platforms

Opportunities

- reduced time-to-market

- improved planning reliability

- greater transparency

- lower coordination costs

Risks

- unclear responsibility

- missing DfM validation

- quality responsibility shifted to partners without a system

- lack of traceability

The decisive factor is not platform size, but process quality.

Decision Support: Platform Checklist 2026

| Criterion | Good Answer in 2026 | Warning Sign |

|---|---|---|

| Technical clarification | DfM review, clear specification logic | “Just send a drawing” |

| Quotation quality | Transparent pricing logic, documented assumptions | Price without parameters or assumptions |

| Quality | Defined inspection and approval processes, traceable documentation | Quality “handled by partner” without a system |

| Delivery capability | Reliable capacity and schedule commitments | Non-binding lead times |

| Data & evidence | Exportable documentation bundles, traceability | PDFs via email, no versioning |

| Responsibility | Single point of contact | “We only mediate” |

FAQ – Frequently Asked Questions About B2B Platforms

What Is a B2B Platform?

A B2B platform is a digital system for the standardized execution of business and manufacturing processes between companies.

What Is an RFQ?

RFQ stands for Request for Quotation. It is a standardized inquiry that invites suppliers to submit a concrete quotation for a clearly defined product or service.

What Is the Difference Between a Marketplace and a Manufacturing Platform?

Marketplaces broker contacts; manufacturing platforms manage processes, quality, and execution.

How Can I Tell Whether a Platform Only Brokers or Actually Delivers?

Look at project governance: Is there a clear single point of contact, defined approvals, documented DfM decisions, and a standardized complaint process? If quotations and quality lie entirely with partners and the platform cannot demonstrate its own processes, it is usually pure mediation.

Which Platform Functions Save the Most Time in 2026?

The biggest time savings come from structured RFQs, fast technical clarification (DfM), and rapid concept development. These reduce follow-up questions, iteration loops, and friction between engineering and purchasing — exactly where days are often lost in practice.

What Is the Biggest Risk in Platform Projects in 2026?

The biggest risk is not price, but unclear responsibility. If no one owns technical corrections, partner coordination, and communication when deviations occur, costs and lead times escalate quickly. Clarify before starting: Who decides in DfM conflicts? Who bears schedule risk? Who is responsible for quality?

Platform Economy in Germany 2026 – Conclusion

In 2026, B2B platforms in plastics processing will primarily do one thing: standardize execution — technically, operationally, qualitatively, and data-driven. Platforms like formary already demonstrate what this future looks like today:

- one system instead of many isolated solutions

- smart manufacturing instead of fragmented processes

- decision capability instead of pure quotation handling

formary is not a marketplace, but a managed digital manufacturing platform — with a clear focus on manufacturing-oriented design, reliable quotations, and reproducible quality for thermoformed plastic components.