Construction Data in Thermoforming: These Factors Must Be Considered for Plastic Deep Drawn Parts

Deep drawn parts are custom-made and designed individually in a CAD format. Before a deep drawing tool is manufactured, a customer approval process of the CAD data or the derived, dimensioned PDF drawing takes place.

Sarah Guaglianone

13. Januar 2026

Contents

This post explains the creation and approval process for the construction data of a plastic deep drawn part and highlights the key factors that are important for customer approval.

Creation of Construction Data in Thermoforming

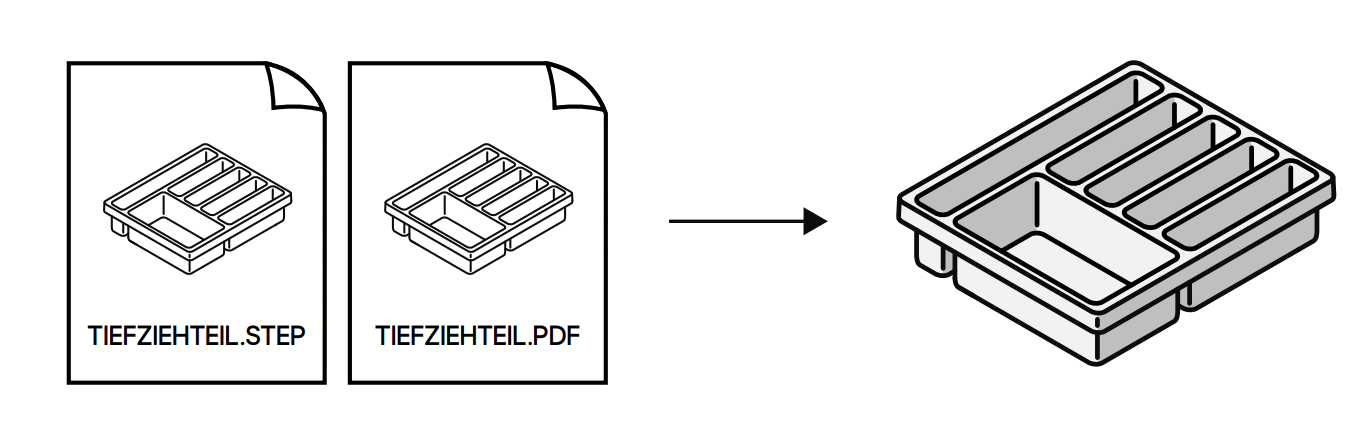

When talking about construction data in plastic thermoforming, we refer to the CAD (Computer-Aided Design) file or the derived, dimensioned drawing (often in PDF format) of the finished end product, which is the deep drawn part in this case. The creation of the data incorporates both customer requirements and Design for Manufacturing (DfM) recommendations from the thermoformer or tool manufacturer.

These include everything from length dimensions to component-specific nesting geometries, material thicknesses, the assembly situation, and cutouts that will later be milled. These parameters are integrated into a deep-drawable design, with particular attention paid to radii and wall slopes. The design of the plastic deep drawn part serves as the foundation for creating the deep drawing tool from aluminum. Once the tool is created, the next step is the prototype approval.

Customer Requirements for Construction Data

Usually, formary develops the product and, consequently, the construction data completely from scratch based on customer requirements. However, sometimes customers also provide ready-made CAD data of the deep drawn part. This happens either when the plastic deep drawn part already exists within the company and is being re-requested, or when the internal design department has created a proposal. In this case, we check the CAD data for Design for Manufacturability (DfM) and adjust them for deep drawability. The customer then reviews the data for correctness regarding the agreed requirements.

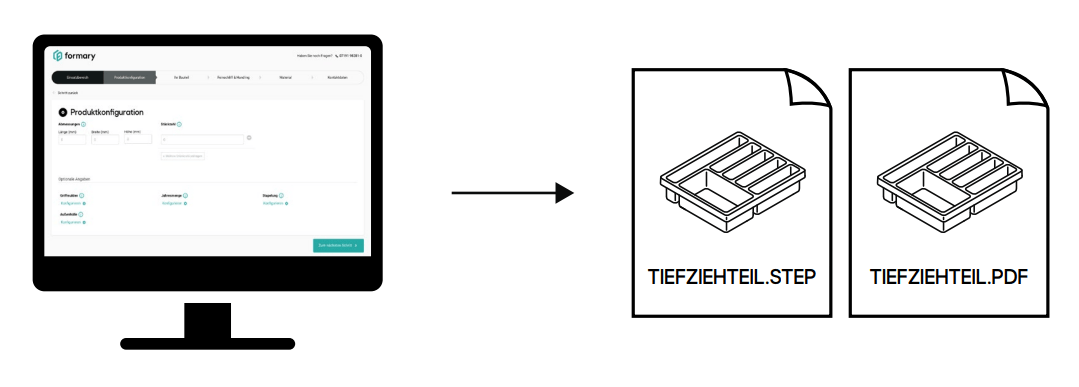

What Format Should Your Construction Data Have?

At formary, construction data is always provided to customers in the form of 2D drawings in PDF format and 3D data in STEP format (Standard for the Exchange of Product model data). The STEP format is a file type that enables the exchange of 3D models between CAD systems, regardless of which system the model was created on. The technical drawing includes detailed information about:

- Textures

- Tolerances

- Material properties

A precise and careful review of the construction data is crucial to ensure that the thermoformed parts meet the desired requirements in terms of functionality, quality, and design.

The Key Factors in Reviewing Construction Data for Approval

To ensure that the created deep draw design meets the requirements and guarantees functionality, the following factors must be carefully considered:

Dimensions

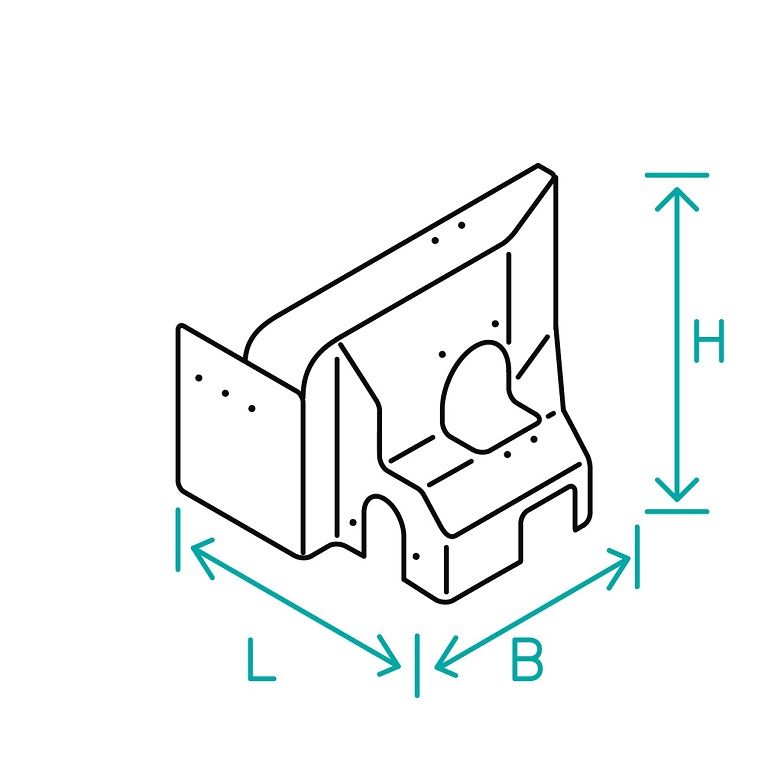

The tolerance-compliant adherence to length dimensions (e.g., length x width x height) is always relevant to ensure that the final product meets the desired specifications. It should be checked whether the construction data were created with dimensional accuracy according to the agreed DIN ISO 2768 length measurement standard. A careful review of the data is significant to ensure successful prototyping through the manufactured tool.

Nesting Geometry

Nesting geometry is particularly crucial for transport solutions. The following questions must be addressed:

- Are the components placed in the agreed orientation?

- Are the components picked up by the desired geometry to ensure safe transport along the planned route (factory, road, or rail)?

- Are handle recesses included for easy removal?

- Is the packing density as discussed?

The construction data should therefore provide clear information on the conditions and tolerances that apply to the nesting geometry of the plastic deep drawn parts. This means the parts should be designed to make optimal use of the available space while ensuring smooth production flow.

Assembly Situation

Covers require concrete data regarding the assembly situation. The assembly situation refers to the integration of the thermoformed part into the customer's overall product or assembly. When reviewing the construction data, it is important to consider the assembly situation to ensure that the part fits seamlessly into the intended environment and meets all assembly requirements. Therefore, questions like these are relevant:

- Do the dimensions match the geometries where the cover will be fixed/assembled?

- Aspects such as the positioning of fasteners, tolerances for assembly, and ensuring compatibility with other components must be considered when reviewing the construction data in plastic thermoforming.

Material and Material Starting Thickness

Different plastics have different properties and are suitable for various applications, such as temperature resistance, hardness, UV protection, ESD protection, and chemical resistance. More information about different plastics can be found in the materials section.

The material specified on the drawing should be checked for accuracy.

The material starting thickness is also essential when reviewing the construction data. This refers to the thickness of the plastic sheet or roll used in thermoforming. The material starting thickness was determined during the quoting process based on technical criteria and can be compared with it.

If multiple starting thicknesses are sampled to achieve the optimal stability and geometry result, the final construction drawing will be updated according to the chosen solution.

The Process Flow for Creating and Reviewing Construction Data at formary

The process for creating and reviewing construction data is as follows: Requirements - Design - Data Approval - Sample - Sample Approval - Production.

In detail, the project planning for thermoforming is roughly divided into the following steps:

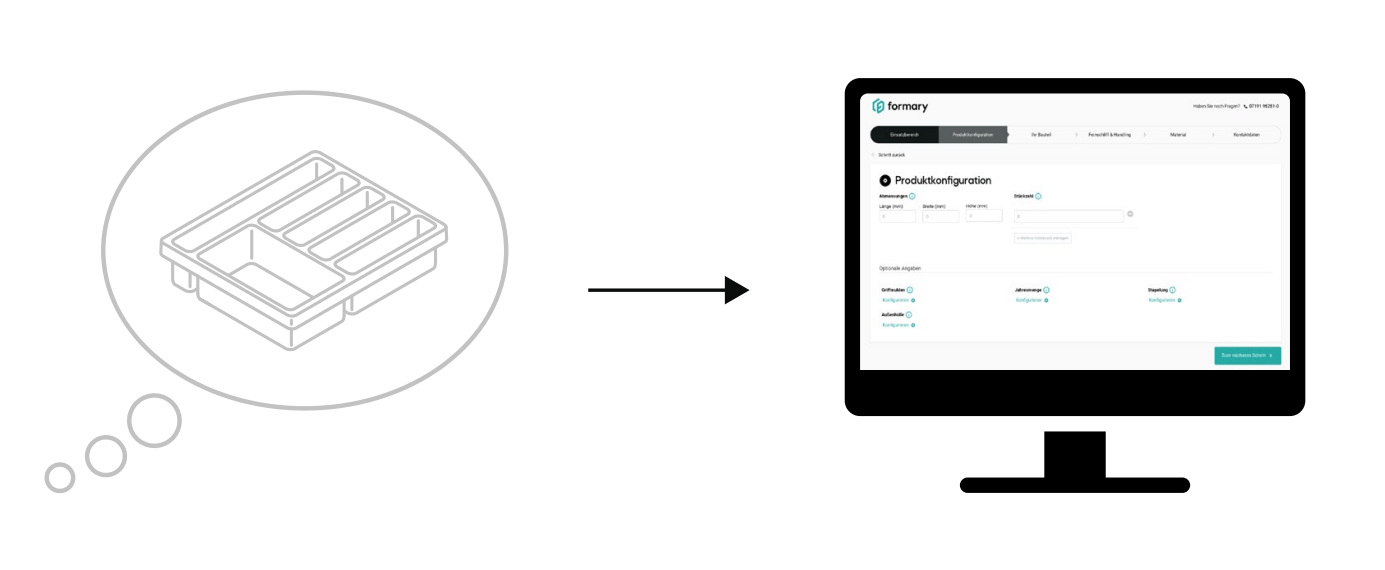

Request Your Project

Enter your requirements in the configurator and send your inquiry to formary. You will receive an offer within 24 hours.

Lassen Sie uns Ihre Daten erstellen

In the second step, you have two options:

- Do you have a design department? Then feel free to create your plastic deep drawn part yourself. You can consult our guide for the relevant parts of deep-drawable design. We will then review the drawing and adjust it for deep drawability.

- Would you like to have your plastic deep drawn part designed by experienced designers from the start? formary will create your data and design optimal geometries for thermoforming according to your requirements.

formary creates your data and designs optimal geometries for thermoforming according to your requirements.

Receive Your Sample Quickly

- Depending on your schedule, you will receive samples from the corresponding suitable option. There are 4 options, depending on the purpose of the samples:

- Samples from 3D printed tool

- Samples from Ureol tool

- Samples from partial segment series tool

- Samples from series tool

We Start Your Series Production

After successful sampling, we will start series production. Depending on your material, the chosen tool design, the type of machine used for manufacturing, and the quantity, the lead time is approximately 3-5 weeks from approval/order receipt to delivery of your series.

Conclusion: Quality Assurance in Thermoforming Through Thorough Review of Construction Data

Construction data for the thermoformed part is not only created for tool manufacturing but also primarily for customer approval of the end product. At this stage, any additional or previously overlooked requirements can be easily identified and incorporated into the design. This ensures an efficient prototyping and project process. formary ensures that a competent contact person is available throughout the project to clarify any questions. Try it yourself and request your plastic deep drawn part digitally.