ESD Packaging Made of Plastic

ESD packaging for safe transport, aesthetic product presentation, and ESD protection.

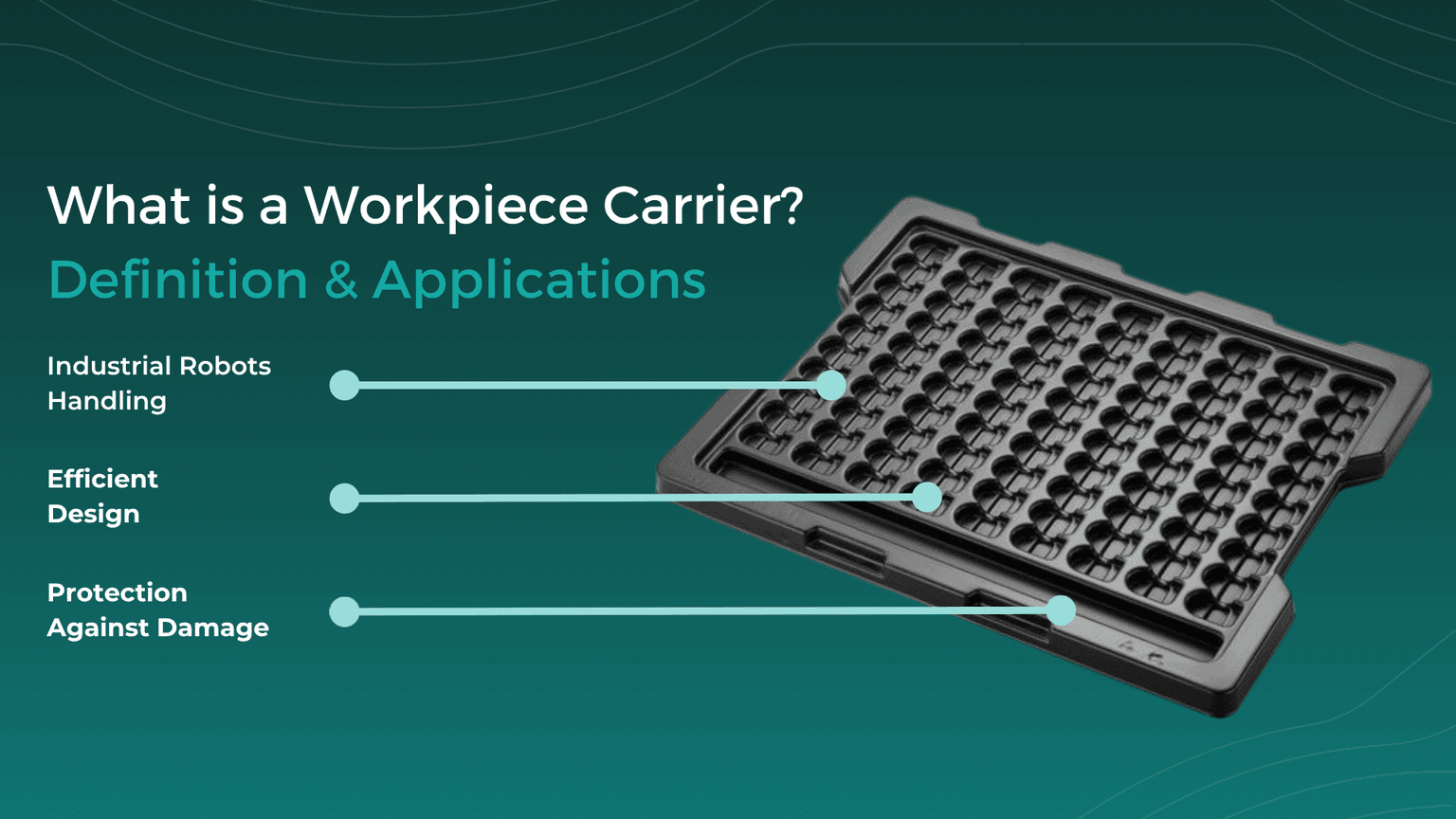

Optimal ESD Protection for Electronics: Custom-Made ESD Packaging for Safe Transport

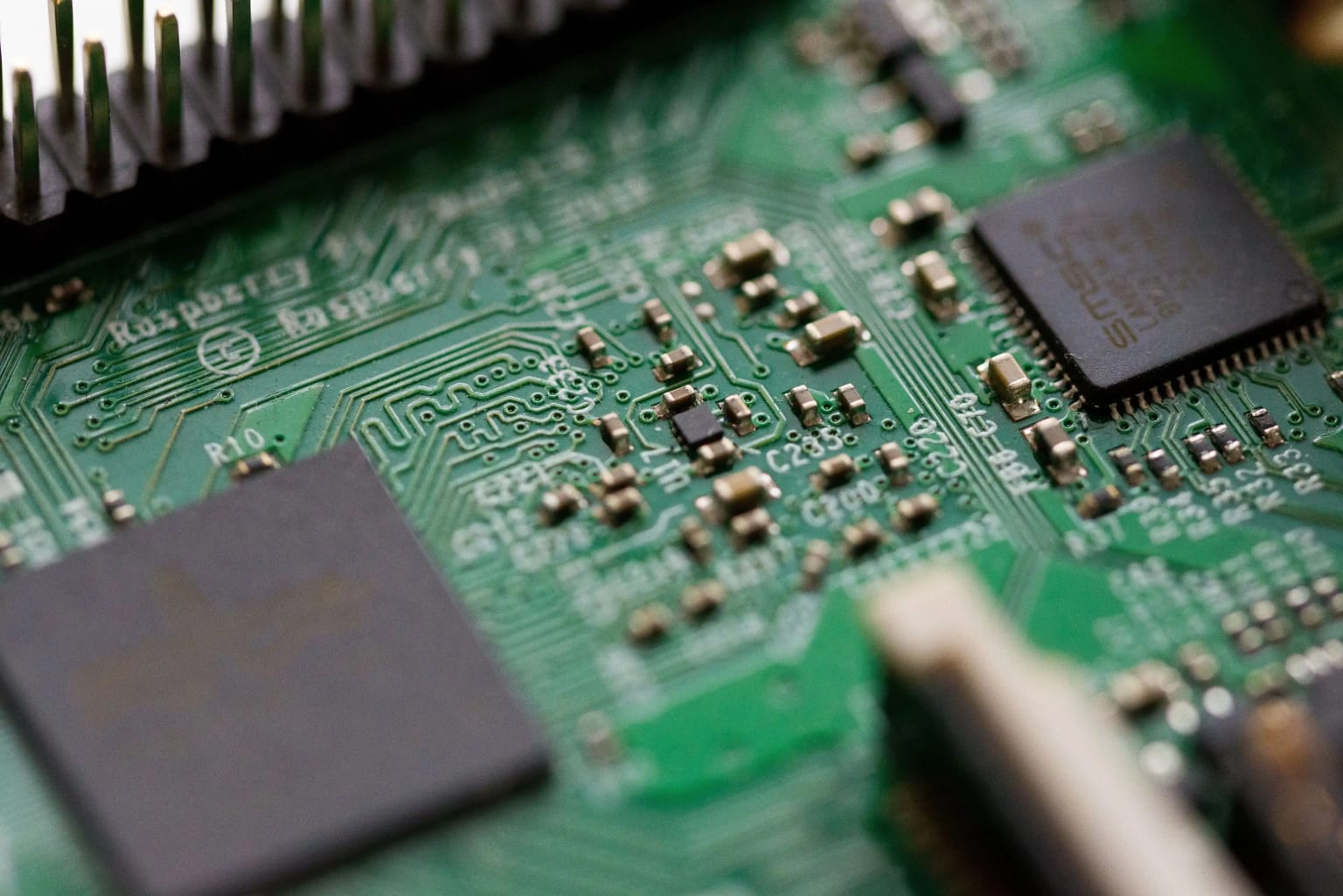

Sensitive electronics require the highest level of protection. By using electrically conductive materials in our custom-made ESD packaging, we effectively prevent electronic charging and discharging from occurring on the transport packaging. This ensures optimal ESD protection for electronic components. Our ESD packaging, specially designed as transport trays, is not only highly stackable but also ideal for the safe transport of loose goods. The electrical conductivity of the ESD packaging ensures reliable protection during transport. Furthermore, ESD-safe packaging is excellent for showcasing and presenting new products, underscoring its versatility in various applications.

How does plastic ESD packaging work?

ESD packaging consists of electrically conductive materials or plastic compounds with antistatic additives.

The electrically conductive surface of the antistatic packaging dissipates charge in a controlled manner, providing reliable protection for electrosensitive components such as circuit boards, sensors and chips. formary develops customised ESD packaging, e.g. as thermoformed trays, workpiece carriers or shuttle packaging – precisely tailored to your components and application process.

ESD Packaging: Requirements & Applications

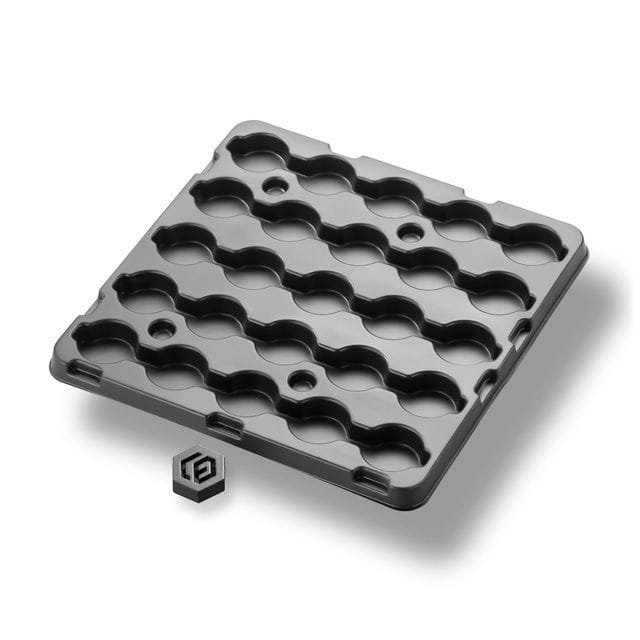

ESD Packaging Provides a Tailored Fit and Protection

The conductive materials used in ESD packaging prevent the formation of electrostatic charges and safely dissipate existing charges. This not only protects the components but also ensures the reliability of the electronic devices.

ESD Packaging for Transport is Robust and Resistant

Plastic ESD packaging is characterized by its stackability, reusability, abrasion resistance, impact resistance, and chemical and water-resistant properties. Depending on the application, transport packaging in ESD design is made according to your specific requirements.

ESD Packaging Ensures Optimized Logistics

Custom-form cavities and side handle recesses help support optimal ESD-safe packaging in your industrial operation. Efficient packing, stacking, transporting, storing, and shipping make ESD packaging ideal for efficient processes.

Smart tray development with the 3D Tray Generator

Do you already have a component – for example, a circuit board or chip carrier – and want to know what customised ESD packaging for it might look like?

With formary's 3D Tray Generator, you can upload your CAD model directly and automatically create a customised tray as a 3D model. This saves development time, avoids design errors and gives you a quick visual impression of your future ESD packaging.

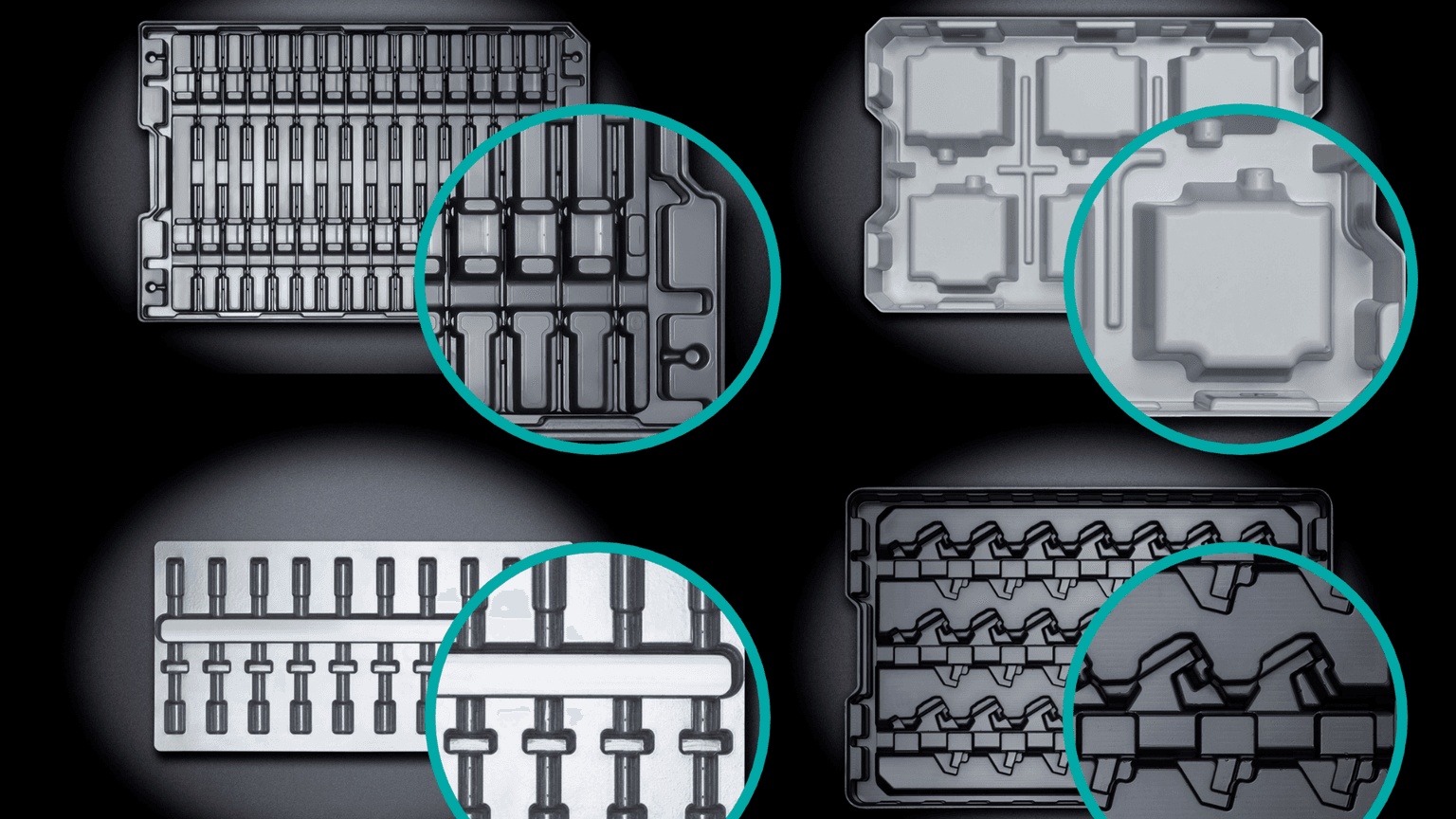

Areas of Use for ESD Packaging Made of Plastic

Electronics

- Trays for acoustic filters

- Trays for electronic parts

- Blisters for sensor elements

- Trays for IGBT chip frames

- Trays for PCBs

- ESD packaging for circuit boards

Mechanical Engineering

- Antistatic trays for control units

- ESD packaging for relays

- ESD-safe packaging for measuring instruments

- Antistatic trays for electronic subcomponents

Advantages of ESD Packaging

Reduce Storage Volume

ESD packaging ensures no empty spaces due to its increased packing density, optimizing space usage.

Reusability

ESD packaging establishes an industrial cycle with your customers and suppliers, as there is an option for reuse.

Specific Material Properties

Plastic ESD packaging offers high conductivity through selected materials, ensuring the safety of electrical components.

Optimized Logistics

Plastic ESD packaging comes with handle recesses, enabling efficient packing, stacking, transporting, storing, and shipping.

Easy Identification

Transparent ESD packaging provides clear visibility of the packaged components, making identification and organization easier.

Abrasion Resistance

The robust properties of ESD packaging materials ensure high resistance to abrasion and wear during transport and handling.

Which materials are suitable for ESD packaging?

Applications of ESD Packaging Made of Plastic

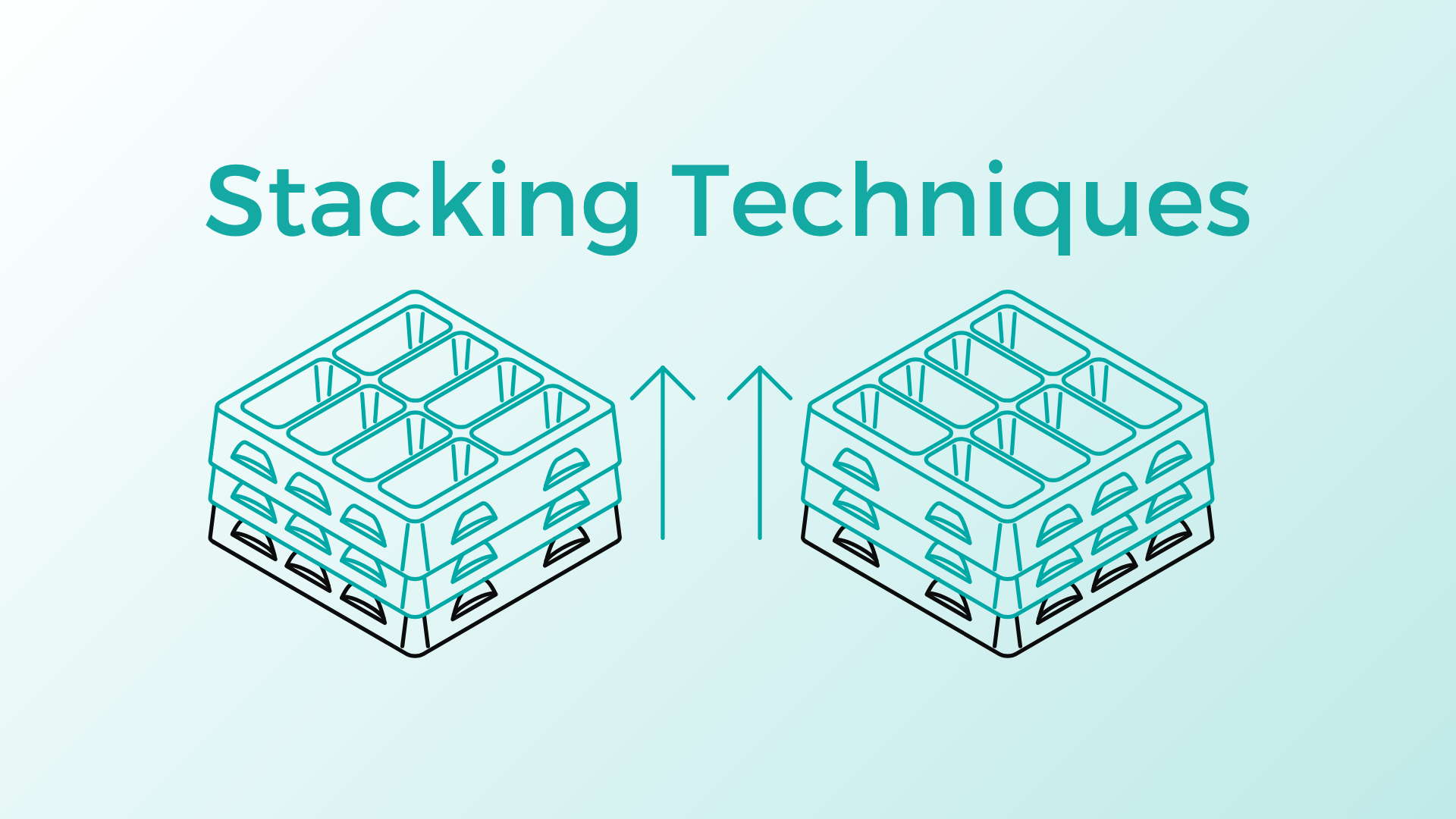

ESD Packaging for Transport and Storage Logistics

For stable storage, ESD packaging is often combined with various stacking techniques. The precise fit of the cavities for sensitive electronic components is crucial. To prevent components from falling out or touching the electronics, restraining elements are incorporated into the ESD packaging to securely hold the components.

ESD Packaging in the Form of Shuttle Packaging and Reusable Trays

For the safe transport of electrostatically sensitive components like semiconductors, circuits, or diodes, ESD packaging and trays are used. Often, plastic ESD trays are used as shuttle packaging for shipping to and from suppliers and customers. Here, robust plastics and suitable material thicknesses are chosen to ensure long-lasting use of the reusable tray.

As shuttle packaging, ESD packaging can also be adapted to common loading aids like KLTs or cartons or designed to be stacked freestanding.