Plastic Inlay Packaging

Plastic inlay packaging for optimal placement and fixation of your products.

Inlay Packaging: Protective Product Presentation

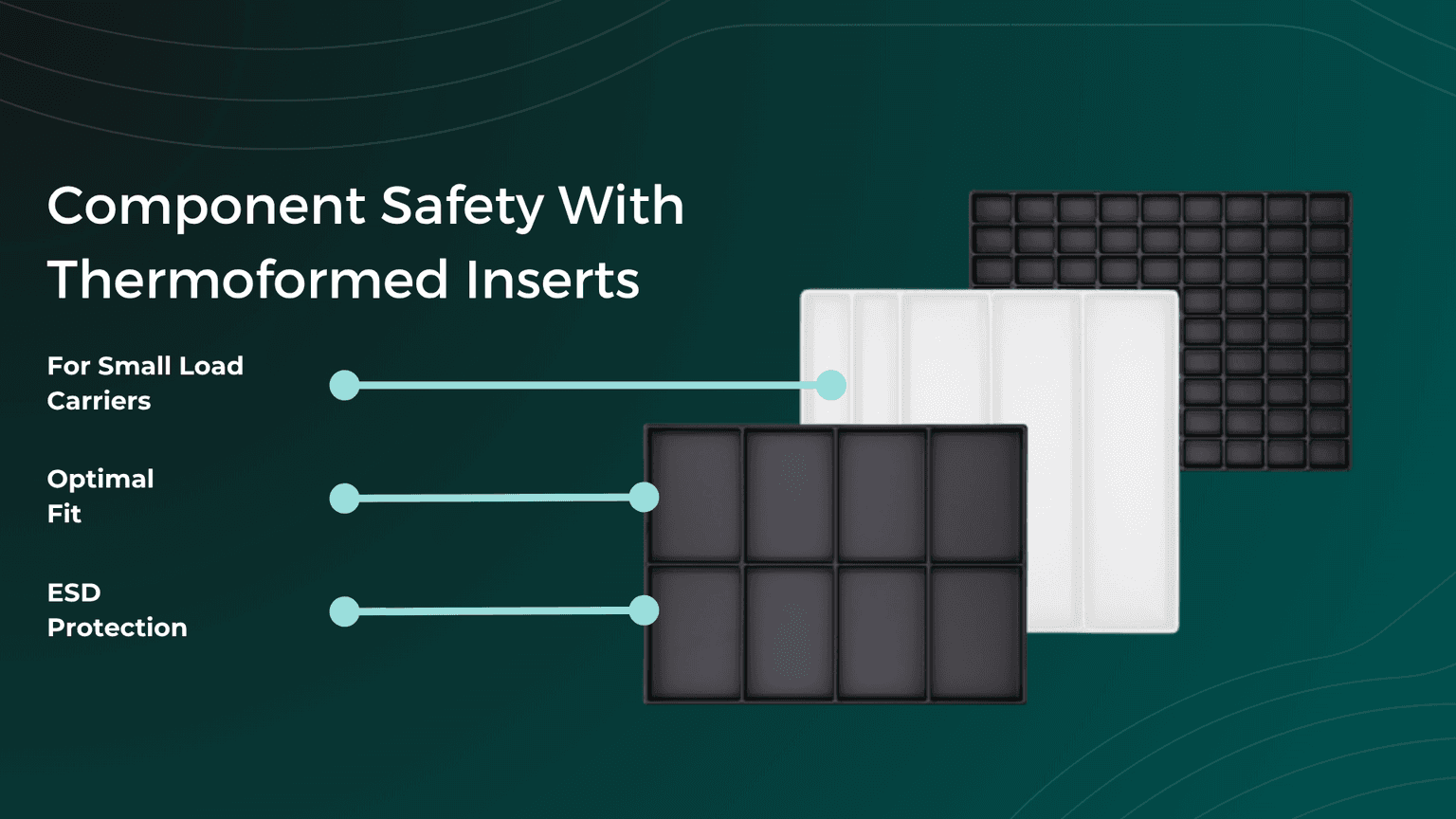

An inlay packaging is a custom insert for product packaging. Inlay packaging serves to optimally position and secure products within the packaging. Packaging with inlays also provides additional protection during transport. Especially for products with various components, inlay packaging offers a smart solution. It divides the inlay packaging into different sections, which not only enables an organized arrangement but also enhances the aesthetic quality of the presentation. The applications for plastic inlay packaging are vast, ranging from the electronics and medical industries to food packaging. Through customized manufacturing, plastic inlays offer a secure and aesthetic framework for a variety of products.

Features & Properties of Inlay Packaging

Protection & Fixation

Plastic inlays prevent your products from slipping and being damaged during transport or in warehouse logistics. Custom-made molded cavities secure each part optimally.

Presentation at the Point of Sale

The precise fit of the plastic inlays not only protects products, but also presents them attractively at the point of sale.

Overview & Structure

Inlays divide the packaging into individual segments. This allows sets, multi-part products, or sensitive components to be arranged clearly and securely.

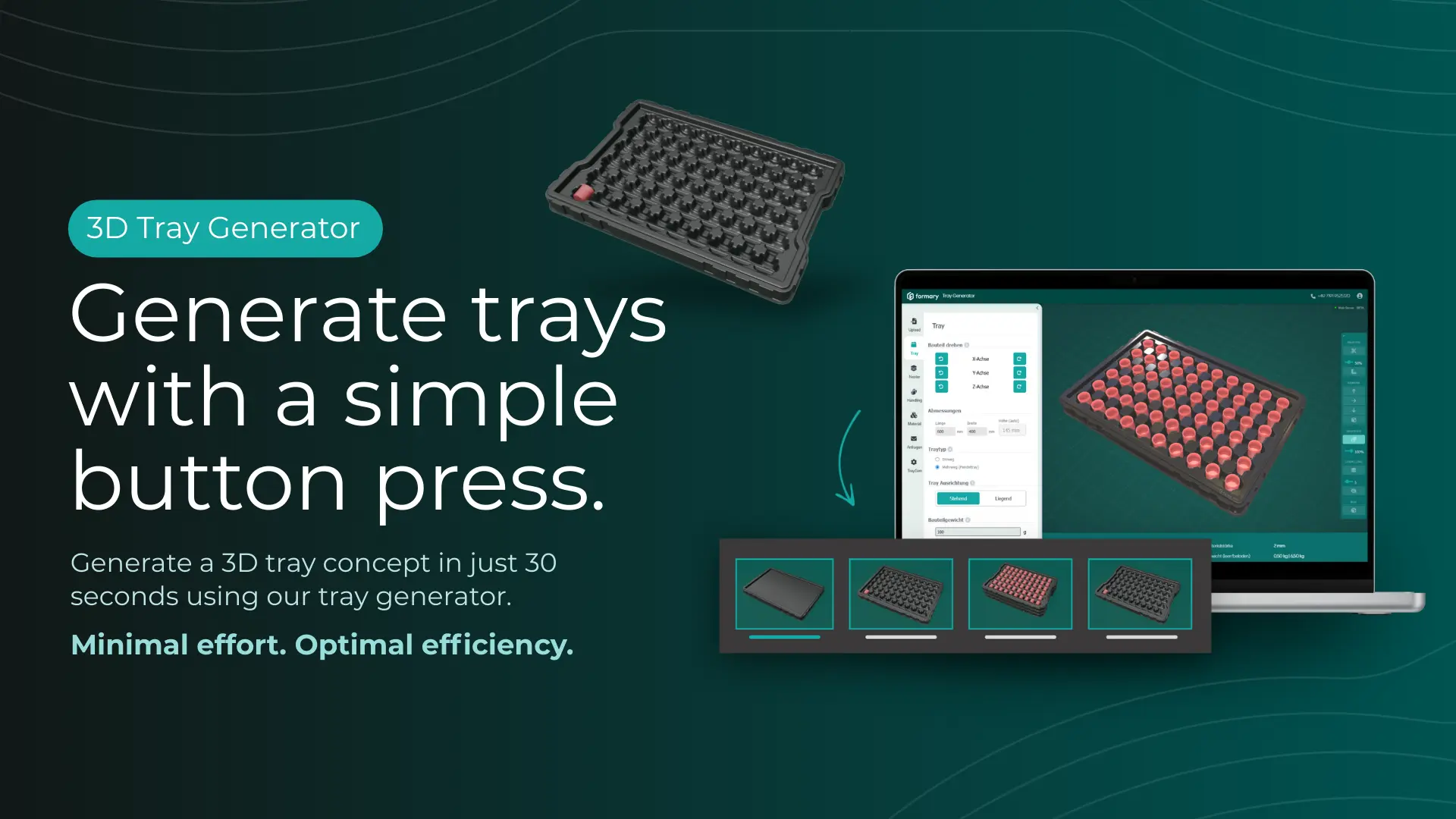

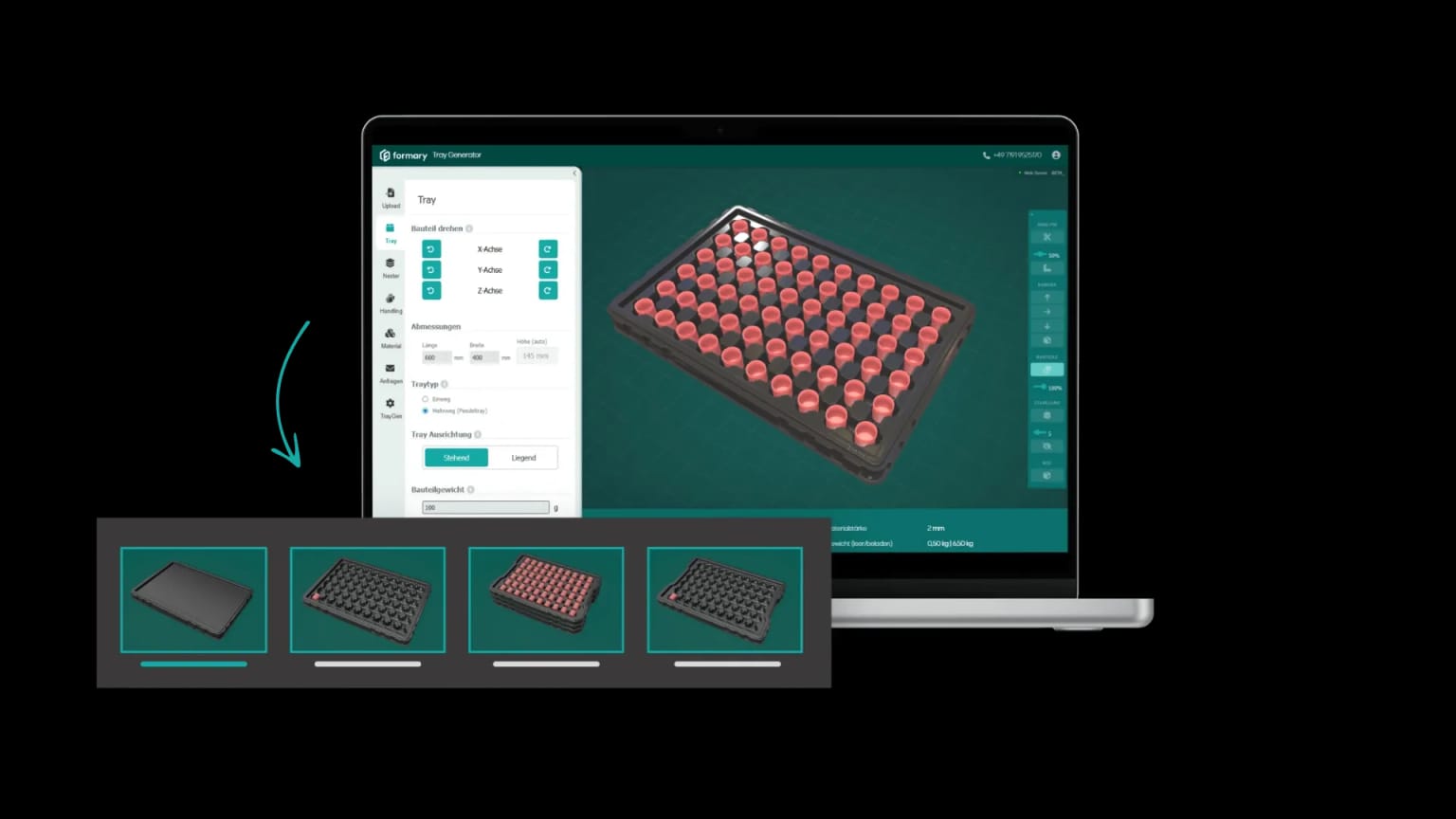

Smart Inlay Development with our Tray Generator

Do you have a Component for which you require Inlay Packaging? Create your Inlay Concept now.

With our 3D Tray Generator, you can simply upload the component for which you need your inlay packaging and create an inlay concept in 30 seconds. This gives you an idea of what your end product will look like.

Areas of Application for Inlay Packaging

Medical Technology

- Medical Blisters

- Medical Packaging

- Display Packaging

- Hygiene Product Packaging

- Inlay Packaging for Medical Instruments

- Packaging for Scalpels

- Tweezers Inlay

- Syringe Blisters

- Blister Inserts for Needles

- Surgical Instrument Sets Inlay

Consumer Goods

- Clamshell Packaging

- Board Game Inlays

- Advent Calendar Packaging

- Presentation Packaging

- Chocolate Packaging

- Inlays for Jewelry

- Inserts for Rings, Earrings, Necklaces and Bracelets

- Inlay Packaging for Watches

- Eyewear Inlays

- Stationery Packaging Inserts

- Inlays for Pens, Pencils, Ballpoint Pens

- Inlays for Markers and Felt Pens

- Packaging Inserts for Game Figures

- Blisters for Miniature Vehicles

Industrial Solutions

- Packaging for Small Tools

- Drill Inlays

- Inlays for Screwdrivers

- Socket Set Blisters

- Inlay Packaging for Cutting Tools

Food

- Inlay Packaging for Chocolates

- Chocolate Inlays, Blisters for Pastries

- Chocolate Advent Calendar Inlay

- Cookie Packaging

Cosmetics

- Secondary sales packaging

- Inlay packaging for cardboard folding boxes

- Transparent packaging

Advantages of Plastic Inlay Packaging

Visual Variety

To meet aesthetic demands, plastics are used in different colors, transparent versions, and various surface textures in inlay packaging.

Functionality

Ribs ensure the functionality of inlay packaging, while food-safe plastics and scratch-resistant surfaces provide a mechanically durable structure.

Long Durability

With stabilizing features such as ribs and braces, the stability and durability of packaging with inlays can be increased, especially for high-load items.

Variable Nest Contours

You can also accommodate products with complex contours, heavy weight, or replacement parts in the plastic inlay packaging.

Resistance to Cleaning Agents

Plastic inlay packaging is highly resistant to aggressive substances such as alkalis, acids, or alcohols, which are often found in cleaning agents.

Easy Handling

The plastic inlay forms the content of your packaging. Depressions on the sides of the inlay, which serve as finger grips, make handling easier.

Suitable plastics for Inlay Packaging

Sustainable Alternatives to Plastic Inlays

In addition to our plastic inlays, formary also offers sustainable packaging solutions such as fibre casting and paper injection moulding. These paper-based processes use recycled paper or cellulose fibres, which are moulded into stable, custom-made inlays – without the use of plastic.

FAQ – Frequently asked questions about plastic inlay packaging

Inlays are custom-fit plastic inserts that secure, organise and protect products inside Packaging. They ensure safe storage during transport and warehousing while also improving product presentation.