Thermoforming vs 3D Printing – Advantages, Disadvantages, Differences, and Similarities

Plastic parts are manufactured using various processing methods. In this article, we focus on comparing the processes of plastic thermoforming and 3D printing.

Amin Lakhal

13. Januar 2026

Contents

Both 3D printing and thermoforming have different applications, advantages, and challenges. In this blog post, we take a closer look at these two plastic processing technologies to help you decide which is best for your use case.

How Does Thermoforming Work?

Thermoforming, also known as plastic deep drawing, involves heating thermoplastic sheets and shaping them using vacuum or pressure in deep-drawing machines. Once cooled, the material is cut into the desired shape through punching or milling. One key advantage of thermoforming is the ability to produce large parts in various forms.

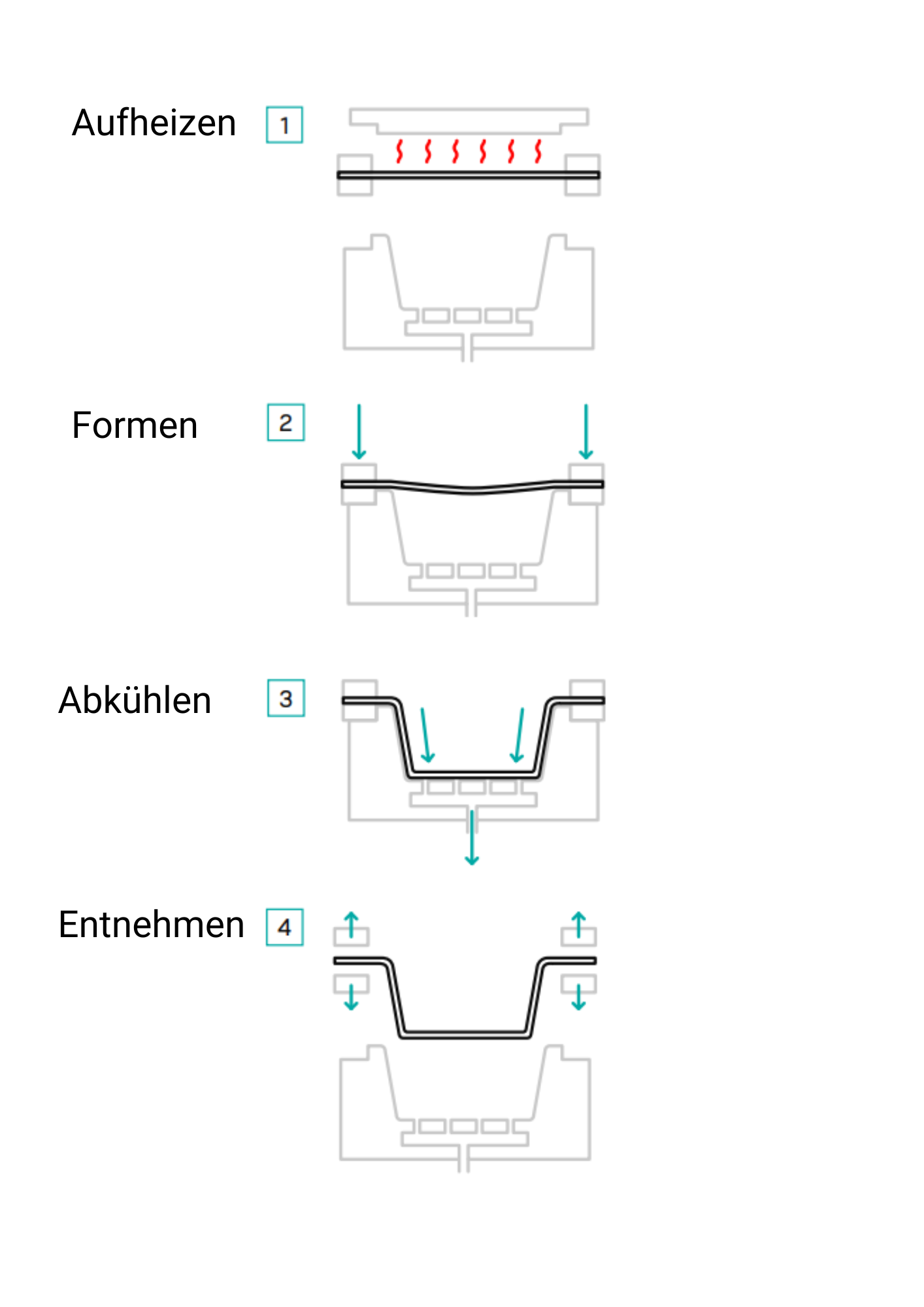

The Thermoforming Process

The thermoforming process follows these steps:

- Heating: The thermoplastic is heated to the forming temperature, making it soft and elastic.

- Forming: The plastic sheet is stretched into the desired shape by positioning it over a mold and applying vacuum or pressure. This process typically takes only a few seconds.

- Cooling: Once shaped, the plastic cools and solidifies, with the cooling process aided by contact with an aluminum mold.

- Trimming: The formed part is separated from excess material using punching or milling techniques.

What is 3D Printing?

3D printing, also known as additive manufacturing (AM), starts with creating a digital 3D model, which is then sliced into thin horizontal layers. The 3D printer builds the object layer by layer by depositing material, typically plastic.

Invented in the early 1980s, 3D printing was initially slow and expensive. However, with significant technological advancements, it has become a widely used manufacturing method across various industries.

What Are the Different Types of 3D Printing?

There are several types of 3D printing processes. The three most common are:

- SLS (Selective Laser Sintering): A laser fuses plastic powder particles to build a 3D part layer by layer. The unused powder can be reused, making this process material-efficient.

- SLA (Stereolithography): A laser cures liquid resin to form the desired shape. This method offers high precision but has limited material options.

- FDM (Fused Deposition Modeling): A plastic filament is melted and extruded layer by layer to form the object. After printing, support structures may need to be removed.

How Does 3D Printing Work?

Here is a simplified breakdown of the FDM 3D printing process:

- Material Preparation: The 3D printer is loaded with filament, and print settings such as temperature and speed are configured. The print bed is also prepared for proper adhesion.

- Heating: The 3D printer heats the material to a molten state.

- Layer Deposition: The printer deposits material layer by layer to build the object.

- Cooling & Hardening: The finished part cools and solidifies. Post-processing, such as removing supports or smoothing surfaces, may be required.

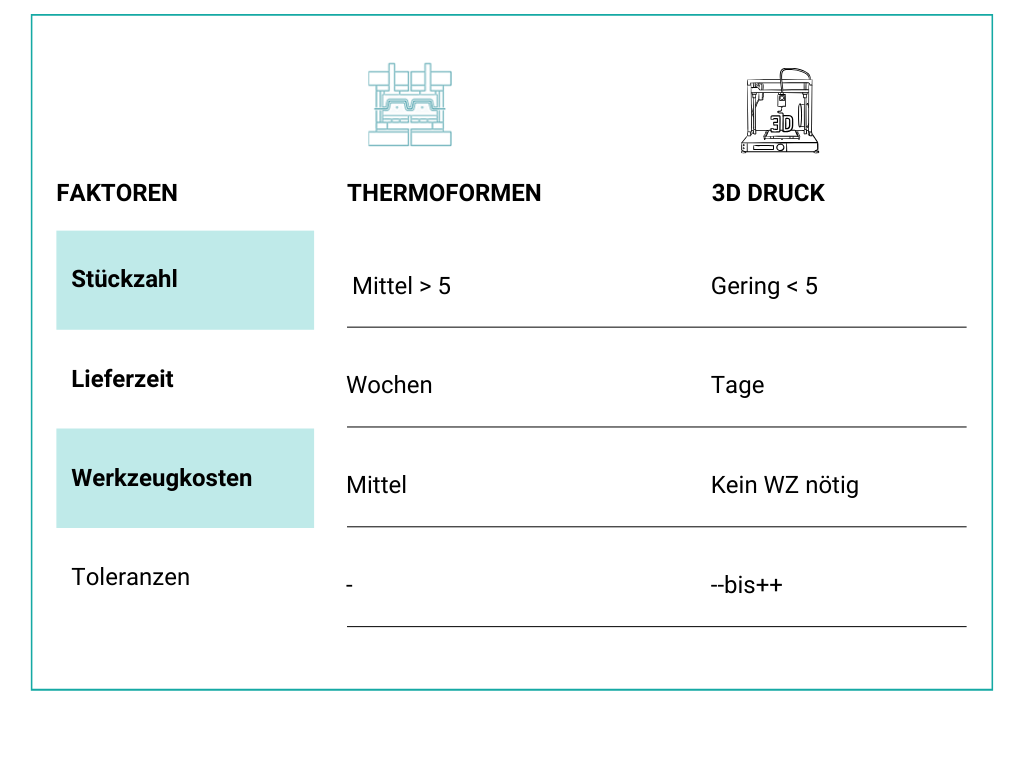

Key Differences Between Thermoforming and 3D Printing

The most striking differences between thermoforming and 3D printing are highlighted in this comparison of the two processes.

Quantities in 3D printing and deep drawing

The usual quantities for 3D printing are in the prototype range, which is significantly lower than for thermoforming. 3D printing does not require any tools for the production of plastic parts. The production of 3D-printed parts therefore requires no lead times if the material is in stock, and delivery times of just a few days are possible.

This makes the process particularly popular for sampling and prototyping. However, the application of 3D printing for larger series production is limited by factors such as slower production speeds, poor scalability, and higher material costs.

In comparison, deep-drawn parts can be produced at high cycle speeds and production can be scaled using appropriate tool designs. The thermoforming process can therefore be flexibly adapted to quantities ranging from 5 pieces to millions. This requires the tool mentioned above, which will be discussed in the next section.

3D printing and thermoforming tool costs

Depending on the design, material, number of uses, size, and structure, thermoforming tools cost between €500 and €10,000, but can be significantly higher for large parts or multi-use tools. With 3D printing, the costs are normally €0, as no tools are required.

Production time for deep-drawing tools

Additive processes such as 3D printing technology can produce the finished parts virtually overnight once the design has been created and approved. This is not possible with thermoforming in this form.

However, in the best case scenario, thermoforming tools can be milled by the toolmaker in just 1-2 weeks. Normally, several weeks are required for production up to sampling. This has a significant impact on the delivery times for initial series in deep drawing.

Tolerances in deep drawing and 3D printing

Deep-drawn components are designed with a tolerance of approximately +/- 1 mm in most industrial and packaging applications. This tolerance corresponds to the range specified in ISO 2768-c for the common length dimension of 120 to 400 mm in this product segment.

In 3D printing, tolerances vary depending on the printing process, ranging from ±0.2% for SLA to ±0.5% for FDM.

More information about thermoforming quantities, delivery times, and more can be found in the Design Guide. If you want to know how other plastic processing methods differ from plastic thermoforming, read our blog post “Injection Molding vs. Thermoforming.”

Possibilities and limitations of thermoforming

Thermoforming is proving to be an extremely cost-effective option, even for large quantities. This is due to a number of advantages of plastic deep drawing, including fast and inexpensive production, low tooling costs compared to processes such as injection molding, and high material efficiency.

Further advantages include flexibility in mold design and the ability to reproduce complex geometries with precision. The wide range of materials, additives, and surface finishes available for semi-finished products also make thermoforming an extremely attractive solution in various industries.

The disadvantage, depending on the production run size, is the necessary investment in a mold.

Overview of the advantages and disadvantages of thermoforming

| Advantages of thermoforming Disadvantages of thermoforming | Disadvantages of thermoforming |

|---|---|

| Low investment costs for tools | Tool adjustments can be expensive |

| Cost-effective production | Potential sources of error in semi-finished product manufacturing due to frozen stresses in the material during extrusion |

| Worthwhile even for small quantities | Complex shapes with very thin walls are limited |

| Optimal options for post-processing | Potential difficulty in achieving uniform material thicknesses in complex shapes |

| Post-industrial recycling possible for simple cycles | One-sided material contact |

| Unrivaled for thin-walled parts | More complex geometries cannot be produced using 3D printing |

| Short lead times | Semi-finished products more expensive than with 3D printing |

| Large selection of materials | Cutting and punching costs |

| All sizes and shapes possible (large parts) | Complex geometries that cannot be produced using 3D printing |

What are the advantages and disadvantages of 3D printing?

3D printing offers several advantages, but also has some limitations compared to thermoforming.

Advantages of 3D printing

3D printing enables the production of complex, customized parts with high precision and minimal material waste. This leads to material and cost savings for smaller quantities or prototype development. In addition, there is no need for costly molds or tools for production, which reduces the initial investment.

3D printing disadvantages

3D printing is generally slower and less cost-efficient for large production runs. The limited choice of materials and their strength may also mean that 3D printing is not suitable for all applications. In addition, the layered structure of the parts may require time-consuming post-processing, which takes up time and resources.

In comparison, a deep-drawn part can often be used without additional grinding, polishing, or painting. The desired finish can be achieved directly with the material or by incorporating an impression of the desired surface structure into the tool.

Overview of the advantages and disadvantages of 3D printing

| Advantages of 3D Printing | Disadvantages of 3D Printing |

|---|---|

| No tooling costs | Low quantities |

| Short delivery times | Slow manufacturing process |

| Complex shapes possible | Limited material selection |

| No long setup times & tool changes | Surface may require post-processing |

| No tool adjustments | Component size limited |

| Constant price per part | Manufacturing process is more prone to errors, especially with complex components |

| Shortened production time for prototypes | Slightly larger manufacturing tolerances |

| / | Low material efficiency → necessary support structures |

3D printing possibilities and areas of application

The 3D printing process offers a wide range of applications, from prototype development to the manufacture of customized medical implants. 3D printing not only enables cost-efficient solutions, but also contributes to improving patient care and the economical production of small series.

Samples/small series and prototypes

3D printing is particularly suitable for the cost-effective production of small series, as no expensive tools are required. This is particularly advantageous for companies that require flexible and demand-driven production of construction or replacement parts. In addition, 3D printing technology is ideal for producing detailed samples and models, especially in industries such as design and architecture, where realistic models are essential for planning and visualization.

Healthcare

In healthcare, 3D printing enables the production of customized medical components that can be tailored precisely to the individual characteristics of a patient. This increases the chances of successful implantation and minimizes the risk of complications.

Industry

3D printing is used in various industries, such as mechanical engineering and automotive, to manufacture customized spare parts. This enables efficient production of components, especially for models where conventional manufacturing methods may no longer be economical.

Deep drawing Application areas

The deep drawing process opens up a wide range of applications, from transport packaging and automation trays to housings and covers to blister packaging.

Automotive

In the automotive industry, deep drawing has established itself as the preferred method for manufacturing automation trays and transport trays. Choosing the right transport system is crucial for the safe transport of car body parts, electronic components, and other vehicle components.

Thanks to the high formability of plastics, deep drawing enables the production of complex and efficient component carriers that optimally support your manufacturing process. These carrier systems not only ensure safe transport, but also help to support the efficiency of the entire manufacturing process.

Industry & mechanical engineering

Deep drawing enables cost-effective production in industry and mechanical engineering of

- Housings

- Covers

- Screen frames

- and machine parts

which are installed in machines. Automation and workpiece carriers are used in machines, automated production lines, and industrial robots. In production, deep-drawn plastic parts are mainly used as workpiece trays, which enable simple and optimized handling along the production or assembly line.

Deep-drawn plastic trays and deep-drawn containers are used for chemicals and liquids, as molding forms or covers. When cleaning dirty or oily components, plastic trays are used as workpiece carriers, which transport the components safely through professional washing lines.

Electrical industry

Deep-drawn parts with ESD protection protect delicate electronic components from electrostatic charging and discharge. ESD protection parts can be used in transport and warehouse logistics as well as in housings and trim parts. ESD protection prevents charge exchange that could damage your components. This is achieved through specific surface resistance and the right choice of materials. You can find out which materials are suitable for this purpose here.

Thermoforming and 3D printing – a conclusion

In conclusion, the comparison of thermoforming and 3D printing shows that both technologies have specific strengths and weaknesses that should be considered depending on the requirements of a project or product.

3D printing is particularly suitable for creating short-term prototypes and small quantities. Thermoforming is a cost-effective option for medium to large quantities. In addition, thermoforming offers fast production costs, comparatively low tooling costs, and material efficiency, as well as broad material requirements.

Do you have any questions about thermoforming? We are happy to help. Simply contact us or subscribe to our newsletter for the latest information from the world of thermoformed parts!

Save this post

Want to continue reading this blog post later or use it on your computer? Download and save it now.