What is Plastic Vacuum Forming? A Brief Explanation of Vacuum Thermoforming

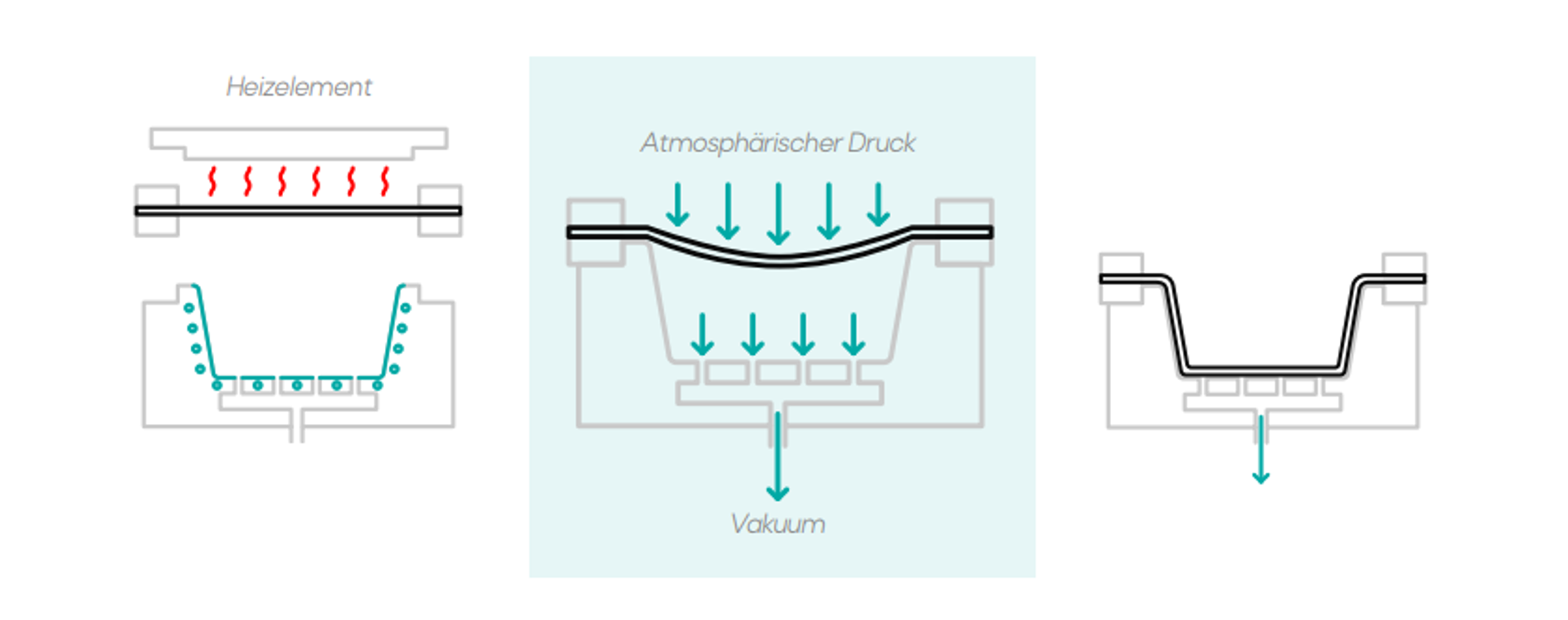

Vacuum forming is a method that uses vacuum and compressed air to shape plastic parts from rolls or sheets. In this process, also known as vacuum thermoforming, the vacuum pump plays a crucial role. In this article, we explain the key aspects of the vacuum forming process.

Sarah Guaglianone

13. Januar 2026

Contents

How Does Plastic Vacuum Forming Work?

Vacuum and compressed air are used in plastic thermoforming and twin-sheet processes to shape thermoformed parts from rolls or sheets. While vacuum forming creates a vacuum to shape the material, pressure forming additionally uses compressed air to apply greater force during the forming process. This blog post focuses on the former. Vacuum thermoforming is the oldest plastic forming method and is still widely used today. Many machine manufacturers and processors specialize in vacuum forming.

How Are Molds for Vacuum Forming Made?

A vacuum pump creates negative pressure to pull the semi-finished plastic onto the mold. The required vacuum for the forming process is generated by the vacuum pump, typically at around one bar. This process removes air between the material and the mold surface.

A common issue in plastic vacuum forming is that the vacuum pressure decreases when the heated material is applied to the mold. However, this phase requires the highest forming pressure. A two-stage vacuum system can optimize this process, requiring a high-capacity vacuum pump. In this method, a second vacuum is generated before the material cools, allowing better distribution of the material into the mold’s corners and achieving sharper contours.

Even small radii can be achieved. While vacuum forming has disadvantages compared to pressure forming when producing large series and complex geometries, it is sufficient for simpler parts and small production runs. Due to the low forming pressure, vacuum forming is particularly suitable for relatively simple parts, such as plastic inlays for packaging or plastic trays for food.

Possibilities and Limitations of Plastic Vacuum Forming

Plastic vacuum forming is highly advantageous for producing plastic parts, especially for simple parts and small quantities. Tooling costs remain affordable due to the simpler mold design compared to pressure forming tools. Additionally, vacuum forming has lower energy costs, as vacuum usage consumes less energy than compressed air forming. These advantages make vacuum forming a well-established method used successfully in various industries for a wide range of applications.

Vacuum Forming: Pros and Cons

| Advantages of Plastic Vacuum Forming | Disadvantages of Plastic Vacuum Forming |

|---|---|

| Suitable for simple parts | Lower form sharpness compared to pressure forming |

| Low tooling costs | Higher risk of blemishes compared to pressure forming |

| Lower energy consumption than pressure forming | Lower temperature resistance than pressure forming |

| Cost-effective for small production runs | Longer cycle times than pressure forming |

It is essential to consider the overall cost calculation. This means that when choosing plastic vacuum forming, both tooling and part costs should be carefully evaluated.

Plastic Vacuum Forming – A Conclusion

Plastic vacuum forming is a cost-effective and efficient solution for manufacturing plastic parts. It is particularly well-suited for simple parts, small production runs, and applications such as packaging inlays or food trays. Its advantages, including cost-efficient tooling, energy efficiency, and versatile usability, make vacuum forming a popular choice across various industries.

Do you have questions or want to produce your thermoformed product using vacuum forming? Contact us or submit an inquiry via our configurator.

Save this post

Would you like to continue reading the blog post later or use it on your computer? Download and save now.