What is Pneumatic Forming? A Quick Guide to Shaping Plastic with Compressed Air

Pneumatic forming is a widely used technique for shaping thermoformed parts from rolls or sheets. This process utilizes compressed air to apply greater force during the forming stage, ensuring precise shaping and efficient production. Find out how pneumatic forming works and the key advantages it offers in this article.

Sarah Guaglianone

13. Januar 2026

Contents

How does compressed air moulding work?

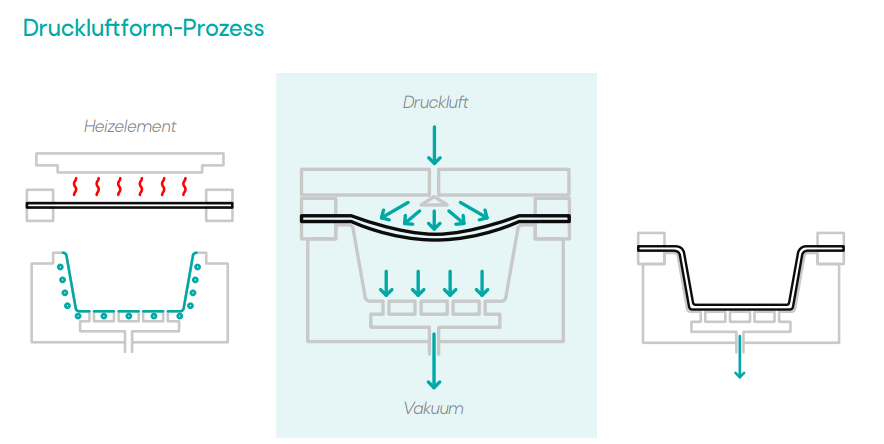

Compressed air moulding is used in the plastic thermoforming and twin-sheet processes. In compressed air moulding, the heated material is pressed precisely against the tool using additional compressed air. Due to the more intensive forces involved, a robust tool design is important in order to withstand the pressure. In most cases, an aluminium tool is essential for air forming, as plastics, ureol or alternative pattern tool materials could collapse under the forming pressure or even damage the machine under certain circumstances. Vacuum moulding is an alternative.

A bottom-up approach is important for the optimum moulding pressure for hot forming with compressed air, starting with low pressure and gradually increasing it as required. The pressure should only be as high as necessary for the sharp shaping of the moulded part. An excessive increase in pressure leads to a waste of energy and also increases the risk of mould damage during production.

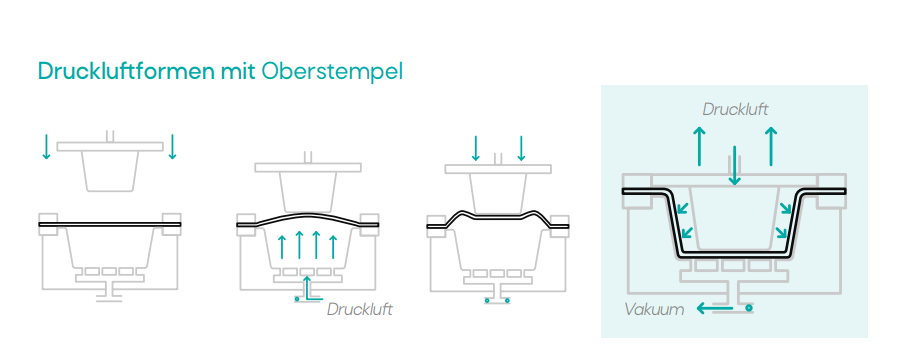

Compressed air moulding enables the use of specific moulding techniques for the targeted control of wall thickness distribution and geometries. For example, a bubble can be formed before the vacuum and upper punch are applied in order to pre-stretch the heated material.

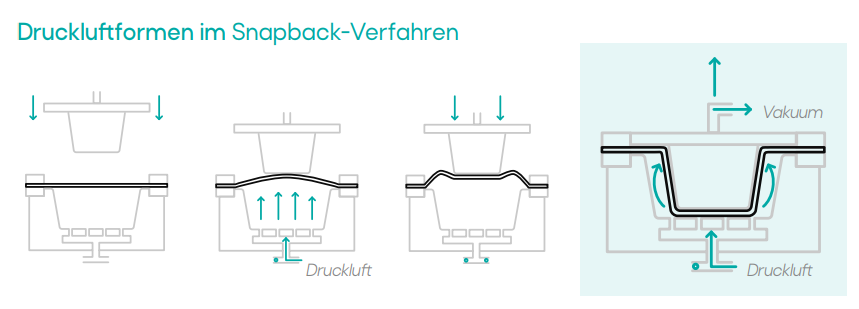

The snapback process, which works with additional compressed air from the lower table, is another example.

Advantages and limitations of compressed air moulds

Although compressed air machines are more cost-intensive, they offer several advantages due to their manufacturing method:

- Shorter heating and cooling times enable shorter cycle times, which reduces the unit price.

- The lower forming temperature counteracts the risk of material sagging, supported by the higher forming pressure.

- Optimisation of moulding sharpness and material distribution, while at the same time preventing chill marks.

Plastic forming with compressed air is particularly suitable for higher quantities, where the investment in more expensive tools is quickly amortised. In addition to high quantities, compressed air moulding is also suitable for high mechanical and optical requirements, such as clarity and precise material distribution for technical plastics such as PC (polycarbonate). Even pre-printed parts can be moulded much better with compressed air than with vacuum forming.

Find out more in our formary x Illig webinar on the topic of "What is the right process for my thermoformed product?"

Compressed air moulding advantages and disadvantages

| Advantages of compressed air moulds | Disadvantages of compressed air moulding |

|---|---|

| Mould sharpness is sharper than with vacuum forming | Higher mould costs than with vacuum forming |

| Lower risk of chill marks | Higher energy costs than with vacuum forming |

| High temperature resistance | / |

| Shorter cycle times | / |

| Suitable for large quantities | / |

Compressed air moulds - A summary

Compressed air moulding is an effective method for precise and economical thermoforming of plastics. The combination of targeted compressed air application and robust tools enables sharp moulding. Despite higher initial investments, compressed air machines offer an advantage over vacuum moulding machines thanks to shorter cycle times and higher temperature resistance.

Compressed air moulding is particularly suitable for projects with high quantities and demanding requirements, such as technical plastics with clear view or pre-printed parts. Compressed air moulding is therefore a cost-effective and high-quality solution.

Do you want to get started with your thermoforming project? Then enquire now using our configurator!