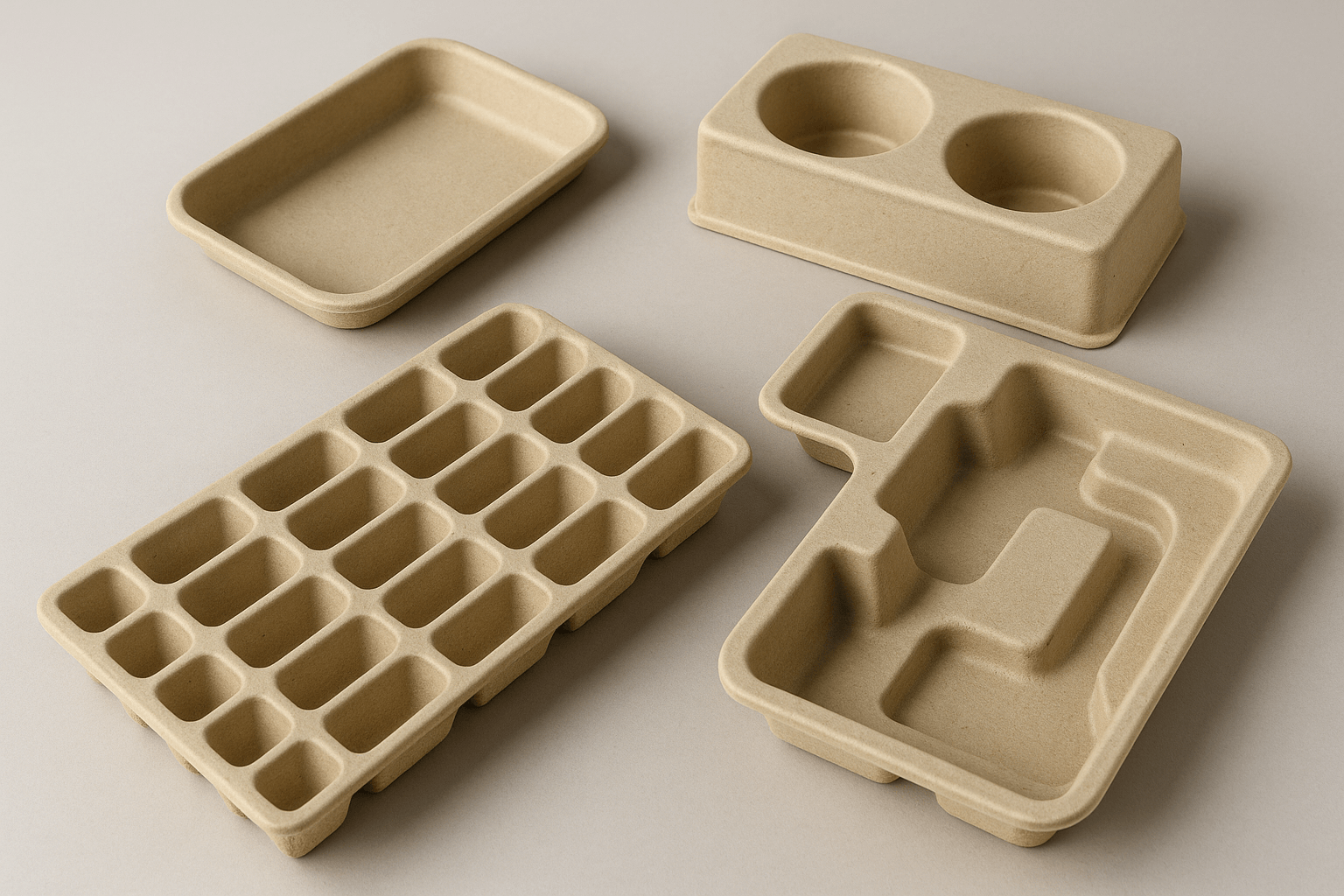

Fiber Molded Parts for Every Need

Molded Fiber Packaging – Individually Tailored to Your Requirements

Individually shaped molded fiber packaging - ideal for sensitive products from the electronics, cosmetics, food, or mail order industries.

What is Fiber Casting or Fiber Pulp?

Molded fiber is a material based on paper or cellulose fibers.

Fiber casting—also known as “molded pulp”—is a sustainable material produced using a wet pressing process. In this process, an aqueous fiber pulp made from recycled paper or cellulose is sucked into a mold and then dried.

The result is robust, recyclable, and biodegradable molded fiber parts that are used as individual fiber molds in a wide variety of molded fiber packaging – for example, as shock-absorbing, eco-friendly packaging solutions for electronics, cosmetics, food, or shipping products.

Fun fact: Egg packaging is one of the oldest applications for molded fiber packaging. Classic egg carton production uses the wet pressing process, as is common in fiber molding.

Advantages & Properties of Fiber Molded Packaging

Fiber-reinforced packaging offers a number of advantages:

Sturdiness

Fiber-reinforced inlays provide cushioning and shock absorption – ideal for sensitive products.

Sustainability

Fiber moulded trays are made from recycled paper or natural fibres, they are biodegradable and recyclable.

Individually Moldable

Fiber-molded packaging adapts precisely to the product (e.g., as a tray or inlay).

Suitable for the Food Industry

Fiber molded parts are also suitable for fresh or moist contents.

Areas of Application for Fiber Molded Packaging

Food

- To-go trays

- Meal boxes

- Egg cartons

- Food packaging

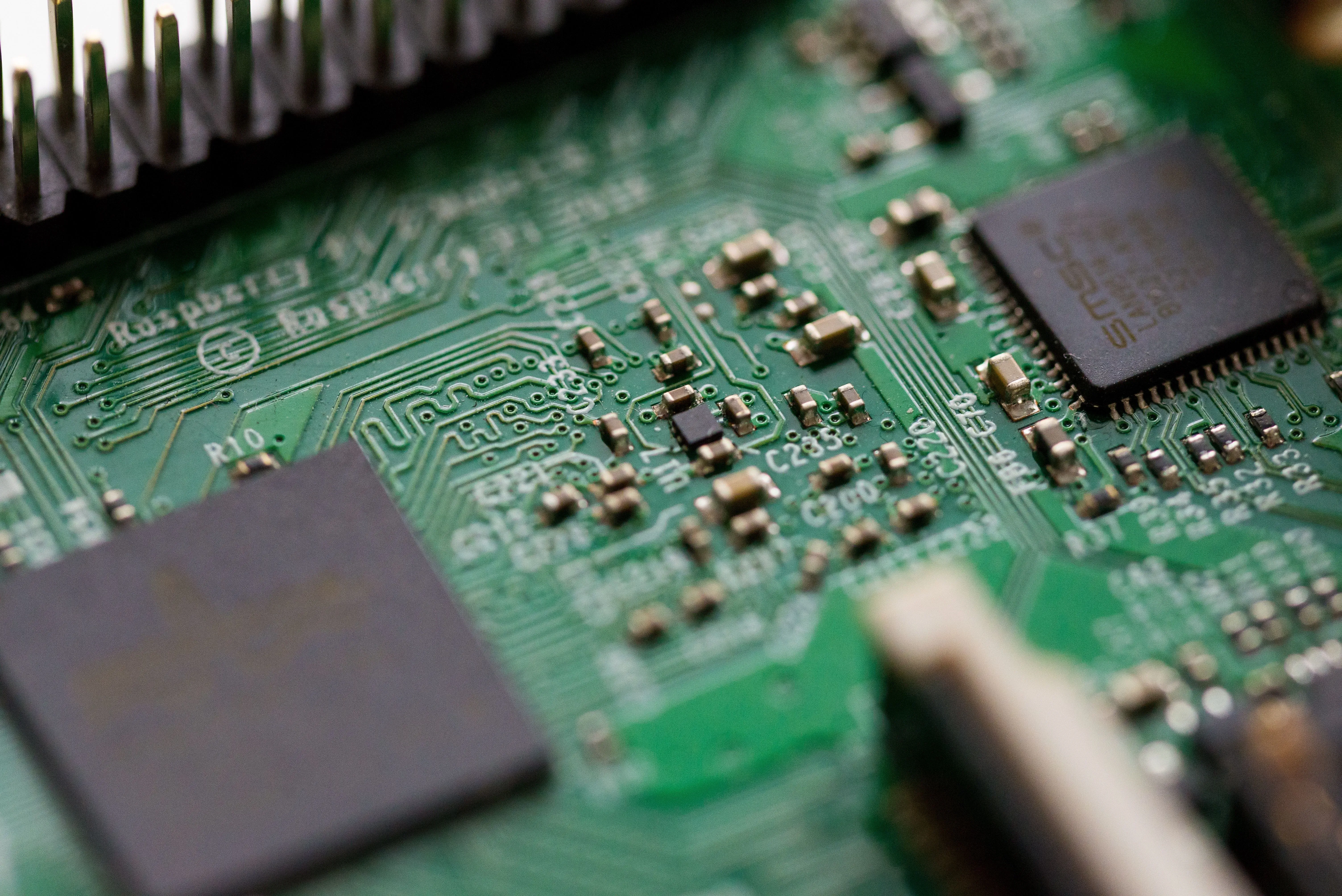

Electronics

- Fiber-reinforced inlays for tablets

Cosmetics

- High-quality fiber molding packaging

- Inserts for product packaging

Consumer Goods

- Fiber-cast Advent calendar

- Waterproof cardboard boxes

What are Fiber-reinforced Inlays and Trays Used for?

Fiber-reinforced trays for transport and logistics

A typical application for fiber-molded packaging is trays for transport and logistics processes—for example, for the secure storage and fixation of parts, electronic components, or medical samples. Fiber-molded trays are stackable, shock-absorbing, and can be used in both manual and automated processes.

Fiber-reinforced packaging for medical products

Fiber-molded packaging is also used in the medical sector, for example as disposable trays for surgical instruments, dental products, or diagnostic kits. Depending on the manufacturing process, these can even be sterilized, thus meeting the highest hygiene requirements—while at the same time being easily disposed of via the paper recycling system.

Fiber-reinforced molded parts as shipping packaging

Fiber castings are used in shipping packaging—for example, as protective inlays for machine parts, automotive components, or sensitive industrial electronics.

Fiber-reinforced inlays for high-quality consumer goods packaging

Another important area of application is fiber-molded inlays for packaging high-quality consumer goods. In electronics, cosmetics, and household appliance industries, attractive fiber-molded inlays are increasingly replacing conventional plastic parts. Fiber-molded packaging not only reliably protects the product, but also emphasizes the brand's commitment to sustainability.

Project Process for Fiber Molded Packaging

We explain how your fiber casting project works, from inquiry to order.

Inquiry

Request your fiber-cast tray and you will receive a quote within 24 hours.

Data Creation

We will provide you with suggestions for creating data for your fiber molded part as well as useful sampling options.

Tools & Sampling

We manufacture your fiber casting tool and send you series samples for approval.

Series Production & Shipping

After reviewing and approving the samples, we will manufacture your series and deliver it to you.

Frequently Asked Questions about Fiber Casting & Fiber Molded Parts

Fiber casting is an environmentally friendly packaging solution made from paper fibers that are shaped and dried using a special pressing process. Fiber materials are ideal for sustainable packaging solutions.

Do you have any questions about fiber molded packaging?

We will answer all your questions about the process and how fiber molded parts are suitable for your products.