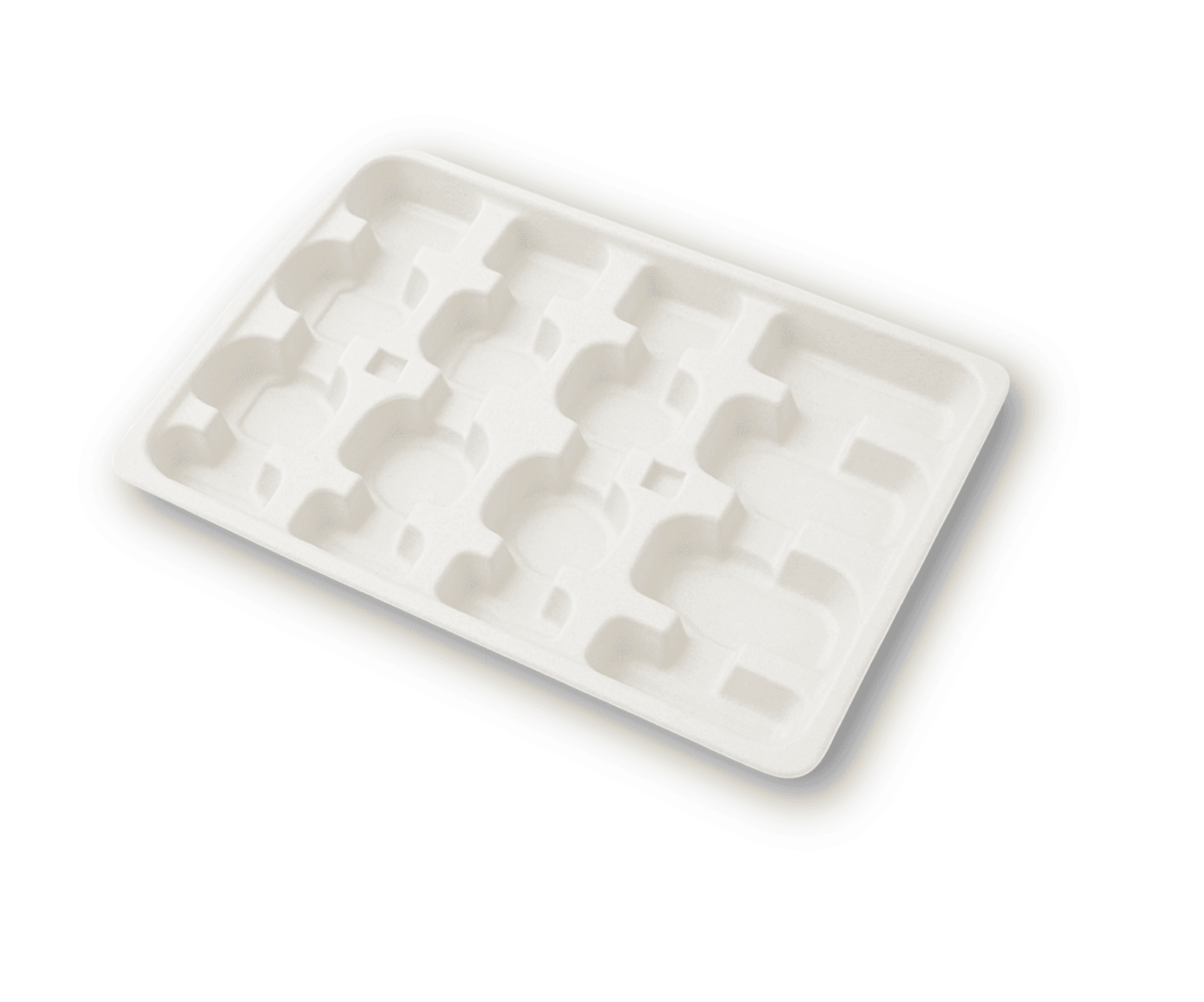

Inlay Packaging Made from Paper Pulp – For any Application

What is Paper Pulp Injection Molding

Paper injection molding is a packaging technology that integrates renewable raw materials into existing injection moulding processes. Cellulose fibres and starch are used instead of plastic. The result: dimensionally stable, recyclable paper packaging with a significantly lower carbon footprint.

How does Paper Pulp Injection Molding work?

In paper injection molding, cellulose fibres and vegetable starch are formed into stable, biodegradable packaging components.

Step-by-step manufacturing process:

- Material preparation: Cellulose fibres and vegetable starch are mixed to form a granulate that can be processed.

- Shaping: The granulate is injected into a paper injection moulding machine, similar to plastic injection molding.

- Temperature treatment: The mold is subjected to a specific temperature, which "bakes" and solidifies the component.

- Fibre alignment: Controlled fibre orientation allows the strength and surface structure to be specifically controlled.

- Finishing: Depending on the application, the result is either fine, filigree structures or robust, load-bearing packaging components, completely without plastic.

Advantages & Features of Paper Pulp Injection Molded Packaging

Inlay packaging made from paper pulp offers many advantages:

Surface Finishing

Smooth or textured surfaces are possible with paper injection molded packaging.

Sustainability

Made from natural materials and fully biodegradable.

Low Carbon Footprint

Emits significantly less CO₂ compared to conventional plastic packaging.

Design Flexibility

Almost any shape can be realized with the paper pulp injection molding process.

Machine Compatibility

Can be processed on standard injection molding machines – ideal for an easy transition.

Protection & Stability

Highly stable and protective, even for complex product geometries.

What is Paper Pulp Injection Molding Packaging used for?

Transport & Logistics Trays

Perfect for repeated logistics processes requiring precision and protection. Stackable and stable, ideal for electronics, automotive parts, and assemblies. Their precision makes them suitable for automation.

Shipping Packaging with Paper Inlays

Provides cushioning and protection during transport – a sustainable alternative to foam or thermoformed plastic. Custom-fit shapes ensure secure placement in boxes.

Sales Displays & POS Solutions

Custom-molded and brandable for retail applications. Perfect for point-of-sale displays or product carriers.

Premium Consumer Goods

Used in cosmetics, lifestyle, and electronics industries – for example, in advent calendars. Stylish, eco-friendly, and optionally finished with embossing or colored surfaces.

Industries Using Paper Pulp Injection Molding

Food

- Compostable takeaway containers

- Inserts for fruit & vegetable trays

- Paper pulp cups

- Lids and trays for reusable systems

- Portion control aids

- Barrier packaging

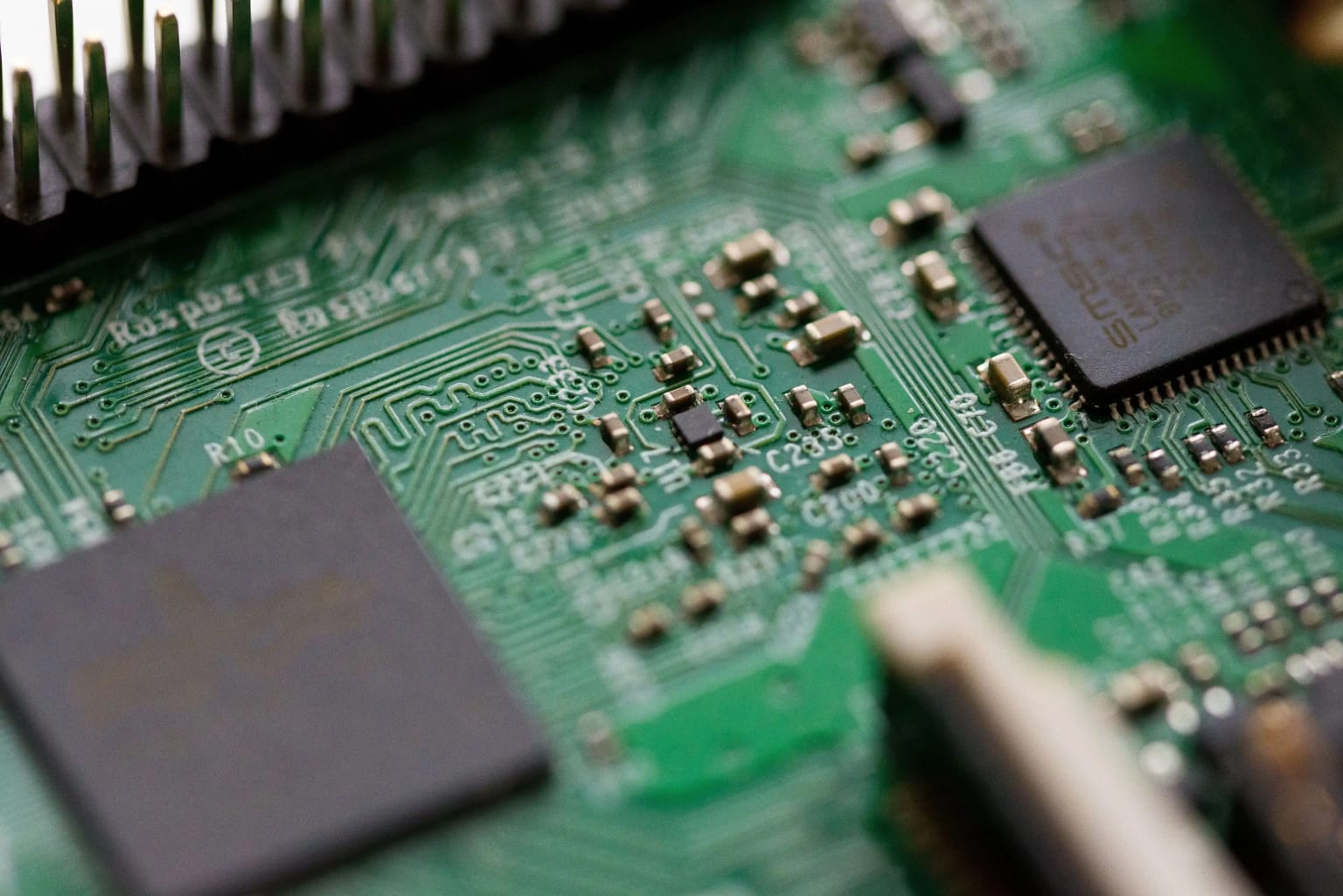

Electronics

- Shock-absorbing inserts

- Laptop and smartphone protection

- Component carriers

- Inserts for small devices

Cosmetics

- Inlays for makeup and skincare sets

- Refill modules for reusable packaging

- Gift set trays

- Colored & embossed packaging

Consumer Goods

- POS trays

- Displays

- Primary packaging for caps & jars

- Advent calendar inlays

- Inlays for appliances or design products

- Packaging for reusable items

- Refill trays for shower gel or soap systems

- Carriers for refillable cleaning products

- Paper capsules (e.g., dishwasher tablets)

- Luxury packaging

- Inlays for toys or kits

- DIY kits with molded paper parts

- Packaging for experiments or creative sets

- Giveaways, trade fair kits, or samples

- Packaging for Bluetooth speakers, headphones, smartwatches

Automotive

- Trays for small parts

- Transport carriers for sensitive components

- Tailored packaging for parts

- Aftermarket spare parts trays

- Component trays for production

- Carriers for automated assembly lines

Project Workflow for Paper Pulp Injection Molded Packaging

We explain how your paper packaging order is processed, from inquiry to order.

Inquiry

Request your paper packaging and receive a quote within 24 hours.

Data Preparation

We support you with CAD creation and sampling strategies.

Tooling & Sampling

We produce custom tools and send you pre-series samples.

Serial Production & Delivery

After approval, your series goes into production and is delivered.

Frequently Asked Questions About Paper Pulp Injection Molding

Paper pulp injection molded products are created using an environmentally friendly injection molding process based on paper fibers and vegetable starch.

Got questions about paper pulp packaging?

We will answer all your questions about the paper injection molding process and how paper inlays are suitable for your products.