Rapid Prototyping in Thermoforming – Definition, Benefits & Processes

Rapid prototyping is used in product development to quickly create preliminary models. In thermoforming, rapid prototyping offers numerous advantages for producing high-quality prototypes efficiently and cost-effectively.

Sarah Guaglianone

13. Januar 2026

Contents

What is Rapid Prototyping?

Rapid Prototyping, also known as Fast Prototyping, refers to the process of quickly and efficiently creating physical models or prototypes of a component or assembly based on three-dimensional CAD/construction data. The prototype serves as the first version of the product, which is thoroughly tested and revised if necessary before mass production.

What is the Purpose of Rapid Prototyping?

- Speed: Rapid Prototyping enables the production of prototypes in the shortest possible time, significantly accelerating the development process.

- Flexibility: The process allows for quick modifications and corrections to prototypes, improving the final product.

- Shorter Time-to-Market: The production and delivery of prototypes are significantly shortened, allowing products to be launched faster.

Benefits of Rapid Prototyping

- Early detection of design improvements

- Cost efficiency

- High precision through computer-aided design

- Reduced risk of costly errors

- Ability to present physical prototypes and gather feedback

- Cost-effective integration of customer requirements

What Types of Rapid Prototyping Methods Exist in Thermoforming?

There are four primary Rapid Prototyping methods in thermoforming, depending on the purpose of the sample. The following sections provide an overview of these methods.

Rapid Prototyping with 3D-Printed Molds

Using 3D-printed thermoforming molds is common for testing critical segments of thermoforming processes. However, due to the high temperatures and mechanical stresses involved in thermoforming, only a small number of samples can be produced from a 3D-printed mold.

- Maximum number of samples: 1-3 pieces

- Production time (best case): 3-5 working days

- Cost: €€€€€

Application Areas:

- Testing form-fit accuracy of tray cavities

- Rapid production of prototypes within a few days

- Small batch production in standard material

Advantages vs. Disadvantages of 3D-Printed Molds

| Advantages | Disadvantages |

| Often cost-effective | Layer-based printing (e.g., FDM) results in surface imperfections that may affect aesthetics |

| Quick fit testing for tray cavities | Some materials (e.g., PP) require heated molds for optimal forming |

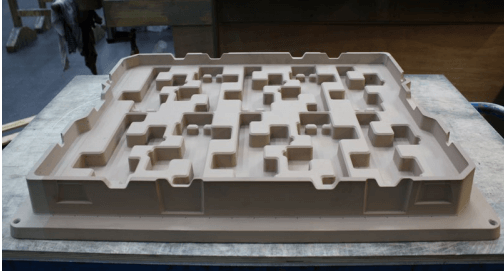

Rapid Prototyping with Ureol Sample Molds

Ureol is a block material used in model making. It can replicate either specific segments or the entire final product, offering a prototype that closely resembles thermoformed parts from aluminum molds. However, due to its lower heat and pressure resistance, only a limited number of samples can be produced.

Specifications:

- Maximum number of samples: 5-10 pieces

- Production time (best case): 1-2 weeks

- Cost: €€€€€

Application Areas:

The result is a pattern optimized for 3D printing that takes only slightly longer and costs only slightly more.

Advantages vs. Disadvantages of Ureol Sample Molds

| Advantages of rapid prototyping with sample tools made from Ureol | Disadvantages of rapid prototyping with sample tools made of ureol |

| The samples produced are almost ready for series production, but show slight differences in quality compared to aluminum tools. | Additional costs: The Ureol tool only serves as an intermediate step prior to the production of the series tool. |

| The price is only about 20-30% of the price of a production tool, depending on the contour and complexity of the milling work. | The series tool is only manufactured after approval, which extends the project schedule by another 2-3 weeks. |

Rapid prototyping with partial segment series tools

A partial segment aluminum tool optimally reproduces your deep-drawn part and enables cost savings compared to series production. This can be achieved, for example, by using a simple tool instead of a multi-cavity tool.

Please note: The sample tool is an intermediate step to the aluminum series tool, and the additional time required for its production must be taken into account in the project planning.

- Maximum number of samples: unlimited

- Production period (best case): 2-3 weeks

- Price: €€€€€

Areas of application

Testing a sub-segment using series production tools provides the most realistic result for series production. It should be possible to abstract the lessons learned from the sub-segment to the entire tray.

Overview of the advantages and disadvantages of rapid prototyping with sub-segment series production tools

| Advantages | Disadvantages |

| Closely replicates serial production quality | Additional production step delays final mold approval by 2-3 weeks |

| More affordable than a full-scale production mold | / |

| Can be adjusted for final production after approval | / |

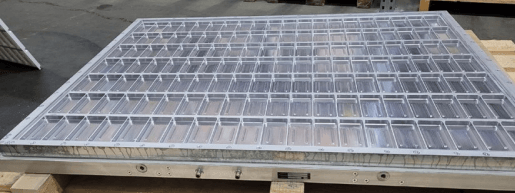

Rapid prototyping with series production tools

The aluminum series production tool is also used to manufacture release samples. The deep-drawn parts produced using this tool are manufactured under optimal conditions in terms of elongation, heat, and cooling behavior.

The production rate per unit of time is a decisive factor in terms of price, particularly for medium to high production volumes, which is why large multi-purpose tools are often used.

- Maximum number of samples: unlimited

- Production time (best case): 2-6 weeks (depending on size, design, and number of functions, as well as any special components required; up to 10 weeks possible)

- Price: €€€€€

Area of application

Series tools are naturally the prototyping method that takes the longest to produce. They are therefore primarily used for the approval of the series product before series production starts – not necessarily for the empirical determination of test-relevant points, such as sample variants 1-3.

Overview of the advantages and disadvantages of rapid prototyping with series production tools

| Advantages of rapid prototyping with production tools | Disadvantages of rapid prototyping with production tools |

| High-quality production of deep-drawn parts | Possible effort for reworking on the production tool |

| No additional tool costs before the start of series production | Production tools have the longest manufacturing time, so it is advisable to opt for a simplified version for urgently needed samples |

| Samples are usually included in the price of the series tool | / |

| Time savings, as no additional approval steps are required | / |

Rapid prototyping applications

Rapid prototyping in deep drawing is used in a wide range of industries, including:

- Automotive: Prototypes of vehicle parts such as dashboards, door panels, and bumpers can be produced quickly and cost-effectively.

- Medical and pharmaceutical: The production of prototypes for medical devices and housing enables manufacturers to develop and test new products quickly.

- Packaging industry: Prototypes of packaging and plastic containers can be created to test their functionality and aesthetics before they go into mass production.

Rapid prototyping in deep drawing – a summary

Rapid prototyping in deep drawing offers a wide range of options for creating high-quality prototypes of parts and components quickly and cost-effectively. By combining speed and flexibility, the fast prototyping process simplifies product development and enables formary to bring innovative products to market faster.

Get in touch with us now!