Project Planning in Thermoforming – From Concept to Mass Production

From the initial idea to mass production, various factors must be considered in thermoforming project planning, including material selection, tool manufacturing, and quality control. This article provides a detailed look at how a thermoforming project with formary is executed.

Sarah Guaglianone

13. Januar 2026

Contents

Thermoforming Projects with formary – How the Process Works

With formary, you have a reliable partner by your side who optimizes the entire process and finds the best possible solution for your specific requirements. We will show you how a thermoforming project at formary is structured and what steps are necessary to successfully produce your custom plastic parts.

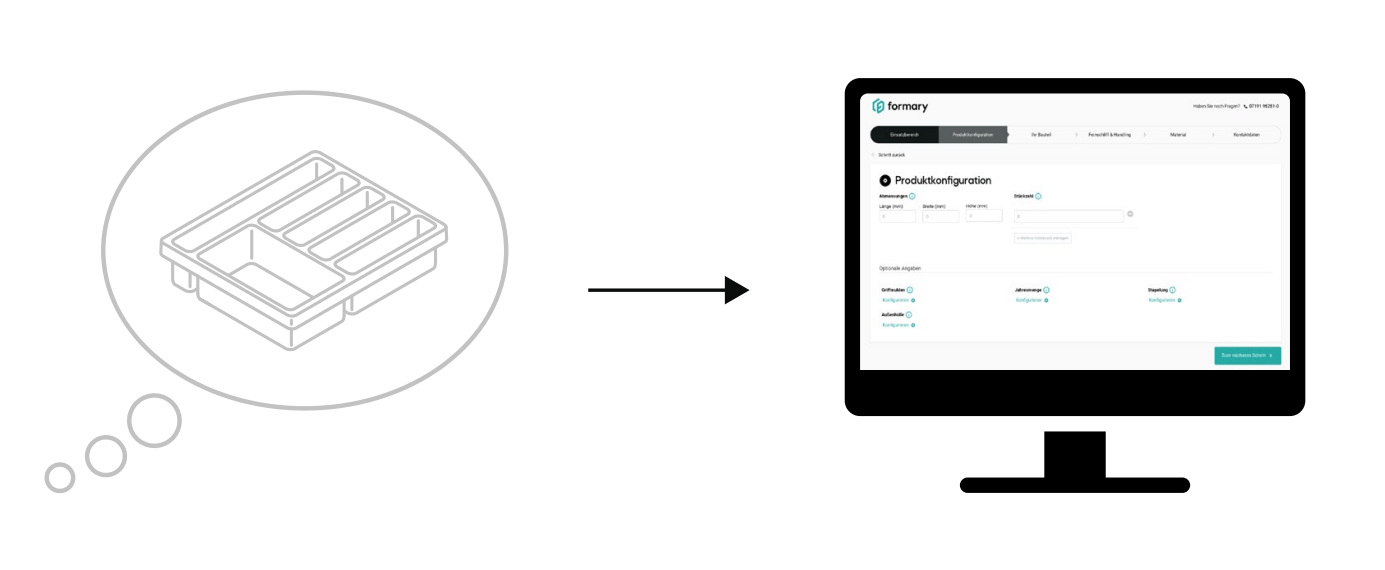

1. Request a Thermoformed Part

Do you have a specific product in mind or already know exactly what you need? Enter your requirements into our configurator and submit your request."

2. Review and Quotation

We assess your data for feasibility and implementation, providing you with a quotation within 24 hours. At the same time, we suggest suitable sampling options and prototype production.

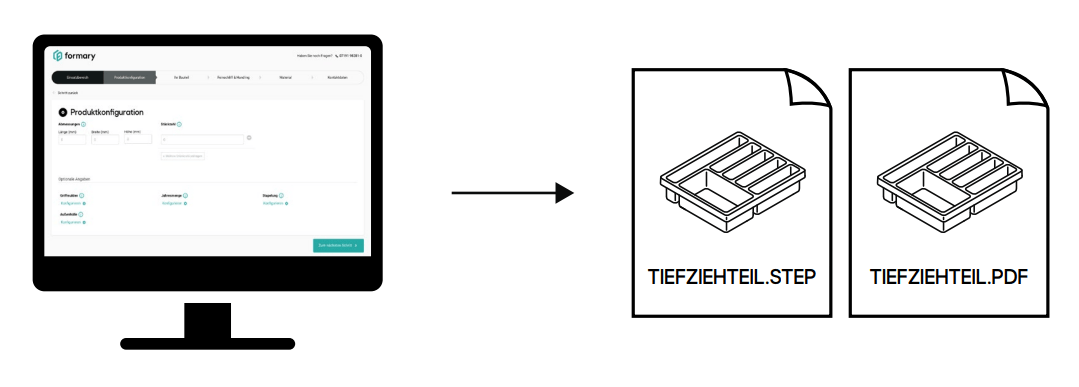

3. Datenfreigabe

Bei Bestellung erstellen wir auf Basis Ihrer spezifischen Bedarfe die Konstruktion des Tiefziehteils. Wir achten darauf, dass wir alle Ihre Anforderungen verstanden haben, um das beste Kosten-Nutzen optimierte Tiefziehteil zu konstruieren. So selektieren wir bei Bedarf die optimale Kombination aus Werkstoff, Stabilität und Werkzeugausführung. Sie geben uns das Design frei, und wir können in die Bemusterung Ihres individuellen Prototypen starten.

4. Tooling and Sampling

Depending on your deadline, you will receive samples for the most suitable option. There are four sampling methods, each chosen based on the purpose of the sample.

3D-Printed Thermoforming Tools

Ideal for fast sampling of small part segments. However, due to high temperatures and stress, only a few samples (1-3 pieces) can be produced.

- Max. number of samples: 1-3 pieces

- Production time: 3-5 business days

- Cost: €€€€€

- Best for: Form-fit tests, short-term prototypes, and small series in standard materials.

Samples from Ureol Tooling

Ureol prototype tools allow for near-series thermoformed parts comparable to aluminum tooling. However, Ureol is less heat- and pressure-resistant, limiting production to 5-10 samples.

- Max. number of samples: 5-10 pieces

- Production time: 1-2 weeks

- Cost: €€€€€

- Best for: Near-series prototypes with higher durability than 3D-printed tools.

Samples from Partial-Series Tooling

A partial-segment aluminum tool enables realistic testing while reducing costs compared to full series production. It serves as an intermediate step toward the final series tool, requiring additional manufacturing time.

- Max. Musteranzahl: Unbegrenzt

- Fertigungszeit: 2-3 Wochen

- Kosten: €€€€€

Muster aus Teilsegment-Werkzeugen liefern optimale Seriennähe.

Samples from Full-Series Tooling

Aluminum series tools enable the production of approval samples under optimal conditions. For high quantities, multi-cavity tools are the most cost-effective option.

- Max. number of samples: Unlimited

- Production time: 2-6 weeks (up to 10 weeks depending on size and complexity)

- Cost: €€€€€

- Best for: Final product approval before mass production, less suitable for early-stage testing.

5. We Start Your Mass Production

After successful sampling and any necessary adjustments, mass production begins. Depending on the material, tooling design, and production capacity, the lead time from approval to delivery is approximately 3-5 weeks. Production is carried out using high-quality aluminum series tools on automated production systems.

6. Shipping

After a thorough quality inspection, your series production is prepared for shipment. Our logistics team ensures that your delivery arrives on time and in perfect condition.

Thermoforming Projects with formary

The formary algorithm calculates a fast, competitive price, and you receive your quote within 24 hours after review. We then automatically select the best manufacturer from our network, giving you access to certified production facilities across the DACH region.

Are you currently planning a thermoforming project? Contact us—we support you from concept to completion.