Medical Technology Enclosures: Durable, Robust, and Resistant to External Influences

The standards for the quality of medical enclosures, whether for ventilators, defibrillators, or diagnostic and analysis devices, are demanding. Medical technology enclosures must securely protect sensitive electronics, be durable, and convey clinical purity and competence. When developing new measurement or therapy devices, it is important to use robust materials such as ABS or PC for medical covering parts. These materials are resistant to aggressive cleaning and disinfectants, ensuring a long service life for medical technology enclosures.

What are Enclosures for Medical Devices used for?

Medical technology enclosures are used in almost all areas of healthcare:

- Diagnostic devices such as ultrasound, ECG or blood analysis systems

- Therapy and treatment devices such as infusion pumps or radiotherapy equipment

- Monitoring devices for vital signs or intensive care

- Medical aids such as wheelchairs, hospital beds or surgical equipment

Each enclosure is individually tailored to the device geometry, the medical environment and regulatory requirements.

Options in Design for Medical Covers

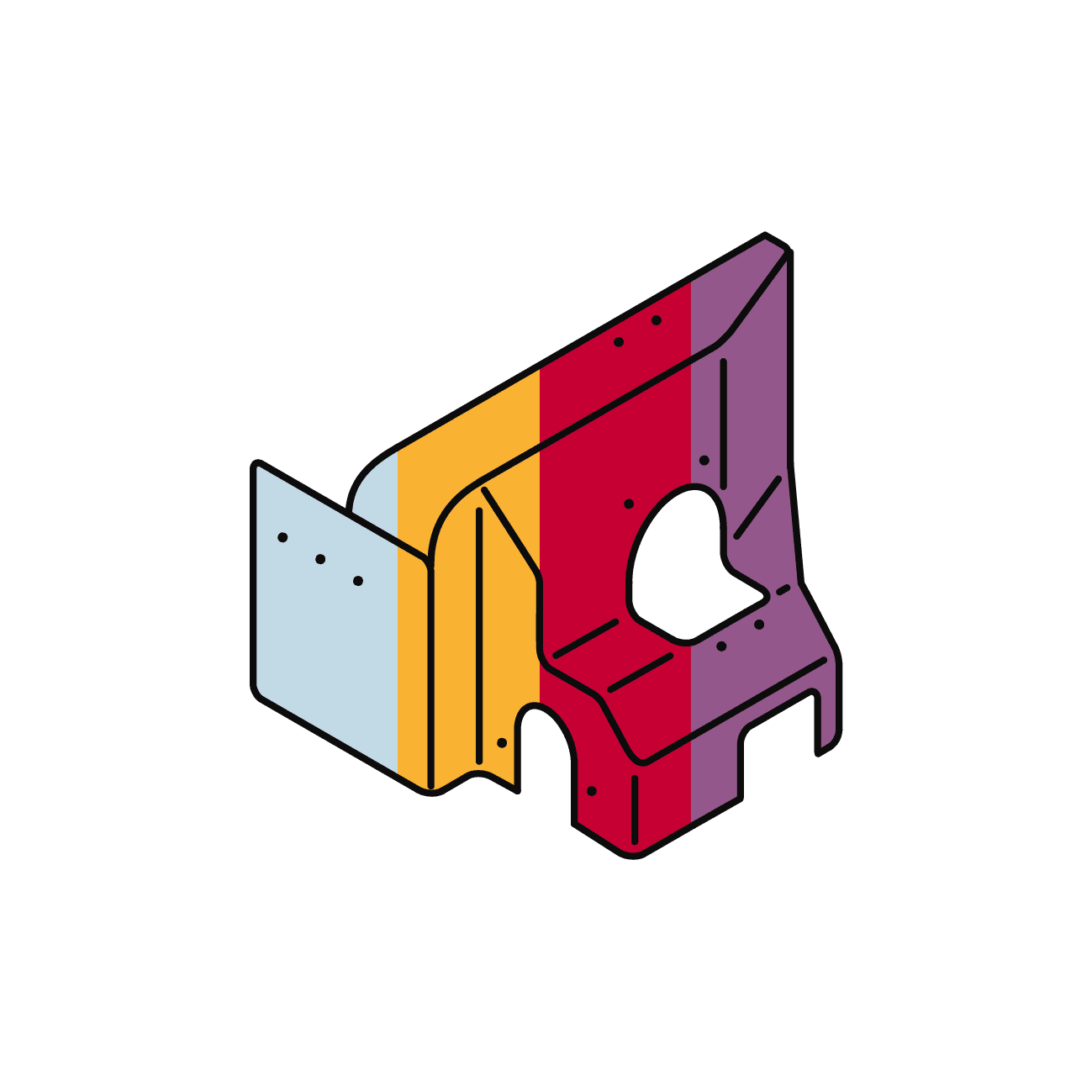

Color and Surface Structure of Medical Technology Enclosures

Colorized materials and surface structuring can be integrated directly into the material of the medical technology enclosures and thermoformed.

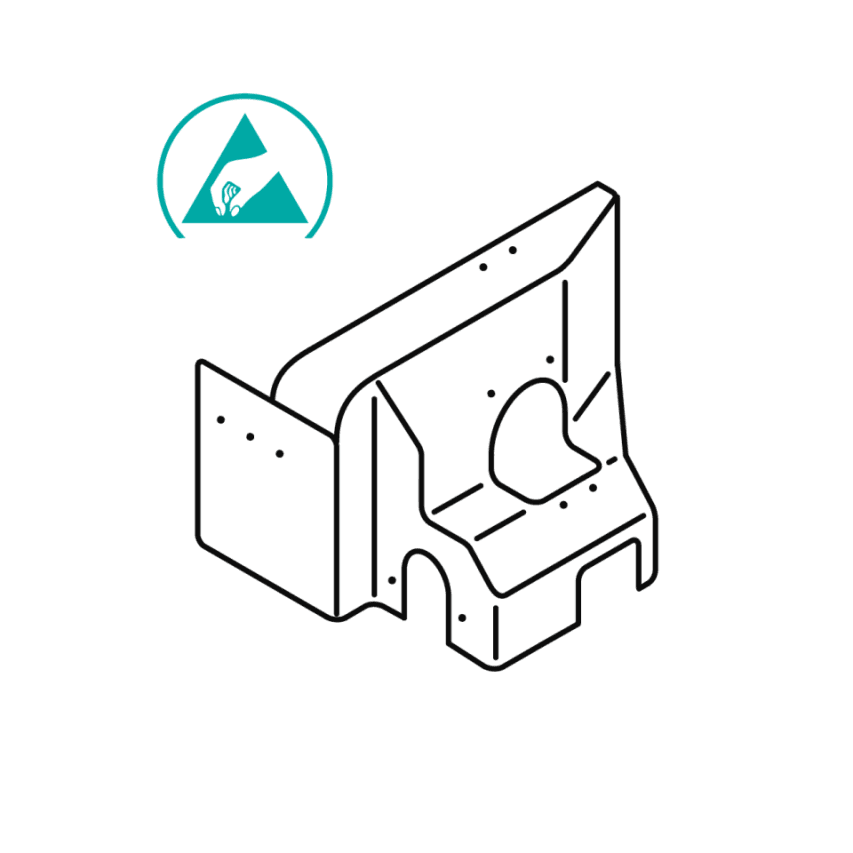

EMC Coating as Protection for Medical Covers

EMC coatings are applied to ensure the reliable operation of the electrical and electronic components in the enclosures for medical devices.

Tolerances and Undercuts in Medical Technology Enclosures

Assembly parts from >5 thermoformed parts with minimal tolerances matching each other are possible. Undercuts, 0-degree wall angles, clip-in mechanisms, bonded subassemblies for easy assembly of part sets for medical technology covers.

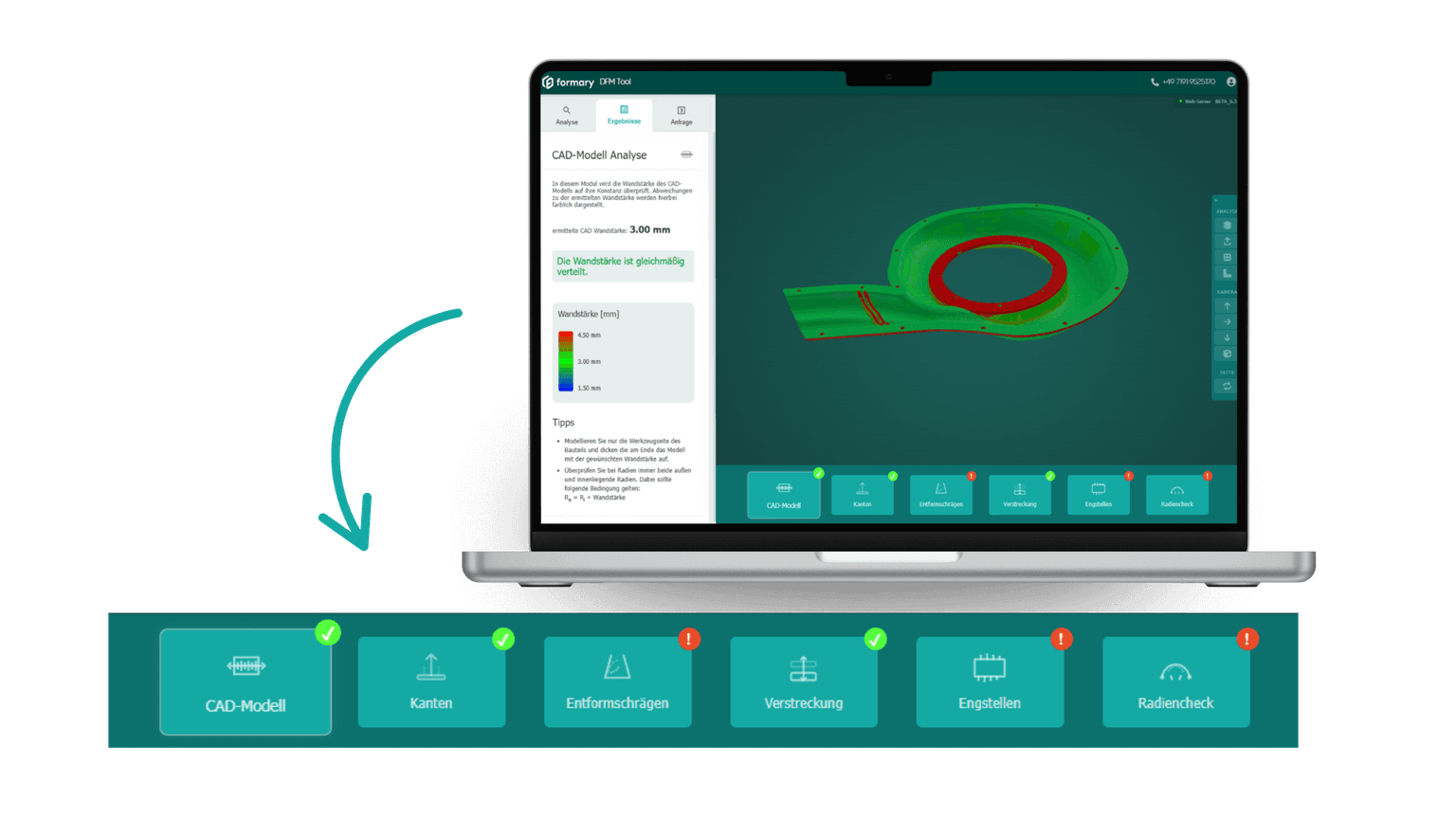

DfM analysis for Medical Enclosures

Do you already have a CAD model for your medical technology housing? Check it now for thermoformability.

With our free Design for Manufacturability (DfM) analysis, we check whether your enclosure design is suitable for deep drawing and meets all requirements. This helps you avoid costly corrections and gives you planning security.

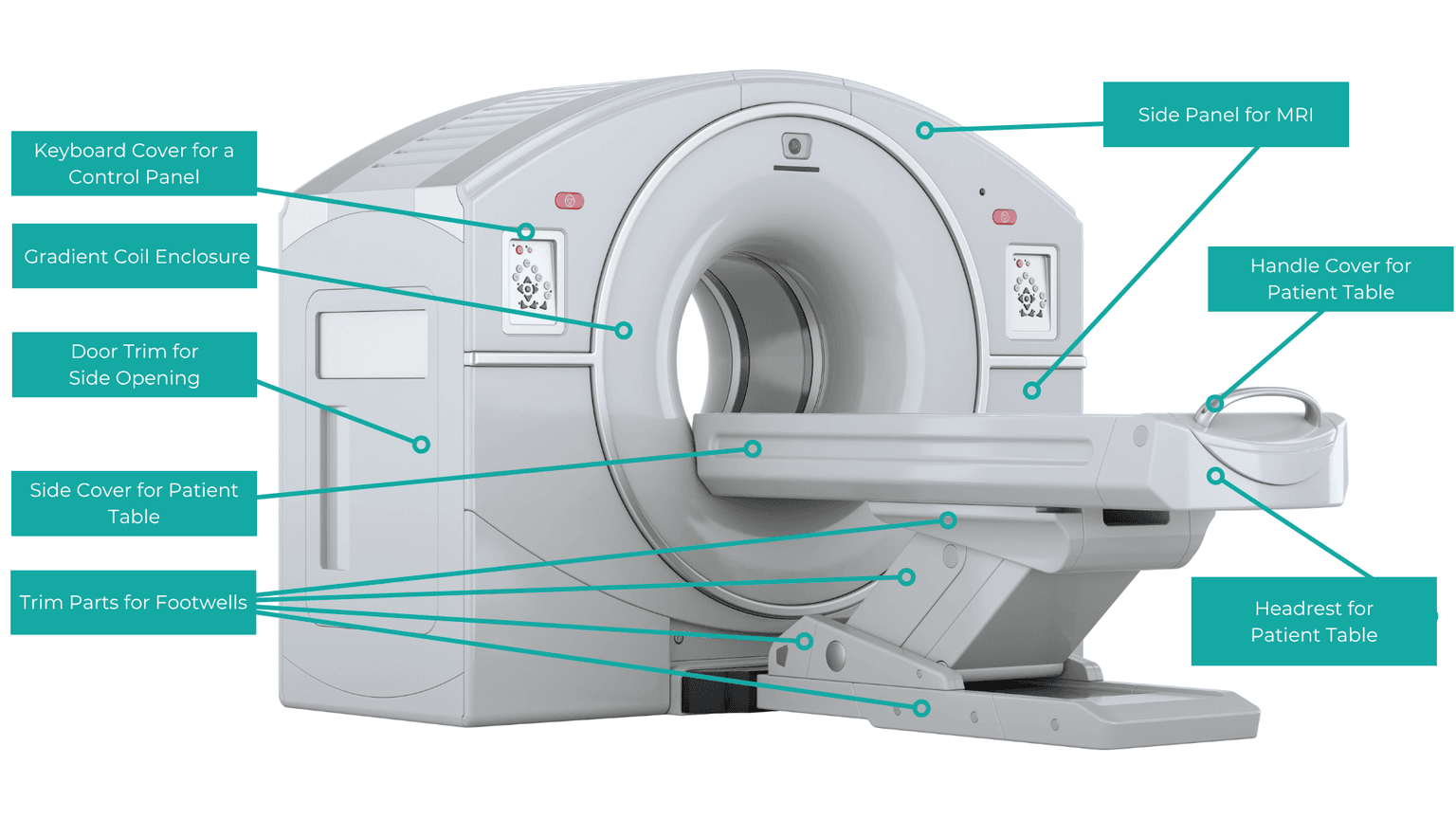

Areas of application for Medical Technology Enclosures

Medical Technology

- Keyboard covers for control panels

- Gradient coil enclosures

- Door panels for side openings

- Side covers for patient tables

- Cover parts for foot columns

- Side panels for MRIs

- Handle covers for patient tables

- Head covers for patient tables

Advantages of Plastic Medical Covers

Low Part Costs

High automation level, short setup times, quick cycle times, CNC milling trimming of medical technology enclosures directly connected to thermoforming.

Protection

UV and heat protection, flame retardants, talc to improve the modulus of elasticity and bending strength, as well as reinforcement fibers are used in plastics for medical technology.

Easy Cleaning

Plastic covers in medicine provide smooth surfaces for easy cleaning, which do not wear out or become dull even after years of cleaning.

Hygiene

Antibacterial surfaces, antimicrobial coatings, easy-to-clean materials and surfaces, and easy-to-clean designs of covers for medical devices.

Surface Quality

Aesthetics, design, color, surface structures, plastic or metal look, and texturing are possible in medical technology covers.

Pre-Fabricated Modules

Assembly of subassemblies and clip-in mechanisms, colorized materials, EMC coating, screen printing, pad printing, undercuts, 0-degree draft angles, and logos can be implemented in medical technology enclosures.

Suitable plastics for Medical Technology Housings

Case study: High-speed prototypes for Medical Enclosure applications

How medical technology company iThera Medical used the formary supplier network to reduce costs and successfully meet tight deadlines.

See our Case Study with iThera Medical to find out how we developed and produced customised housing components for a complex diagnostic device in record time, including:

- Material consulting (ABS/PC blend, UL94 V0)

- EMC & flame retardancy

- CNC milling & surface finishing

- Coordination of a multi-stage supplier network

- On-time production despite early EMC testing

Application Areas for Medical Technology Enclosures

Medical Technology Covers for Diagnostic Devices

Medical technology enclosures are used for a variety of diagnostic devices. Examples of such medical devices include ultrasound imaging devices, blood pressure monitors, EKG monitors, digital thermometers, blood glucose meters, and many more.

Medical technology enclosures are specifically designed to protect sensitive electronic components while meeting the requirements for hygiene, ergonomics, and user-friendliness.

Medical Technology Enclosures for Therapy Devices

Enclosures for medical devices serve multiple important functions that are critical to their effectiveness and safety in medical therapy. The enclosures for medical technology must be designed to support the precise functionality of medical devices. This means they must allow proper placement of controls, displays, and connections, and offer clear visibility of relevant information.

Particularly for radiation therapy devices, medical technology enclosures must be designed to protect patients and medical staff from excessive radiation exposure without impairing the effectiveness of the treatment.

Medical Covers for Monitoring Devices

Medical technology enclosures are used for a variety of monitoring devices used in medical environments. These devices can monitor vital parameters such as heart rate, blood pressure, oxygen saturation, or temperature. They can also be monitoring devices for more specific applications, such as monitoring patients in intensive care units or during surgical procedures.

Medical technology enclosures are designed to securely protect electronics and ensure a hygienic environment. They often need to withstand the requirements for cleaning and disinfection in clinical settings.

Medical Enclosures for Medical Aids

Medical technology enclosures contribute to safety and hygiene by protecting the sensitive internal mechanisms of wheelchairs, walking aids, and hospital beds from external influences such as impacts, moisture, or dirt.

Other thermoformed products in Medical Technology

More About the Industries

FAQ – Frequently asked questions about medical technology enclosures

Medical technology housings are protective plastic covers for medical devices. They are adapted to the shape, function and hygiene requirements.

Further information on Medical Technology Enclosures

Find out what you need to know as a manufacturer of medical devices about deep-drawn medical technology enclosures in our webinars and white papers.