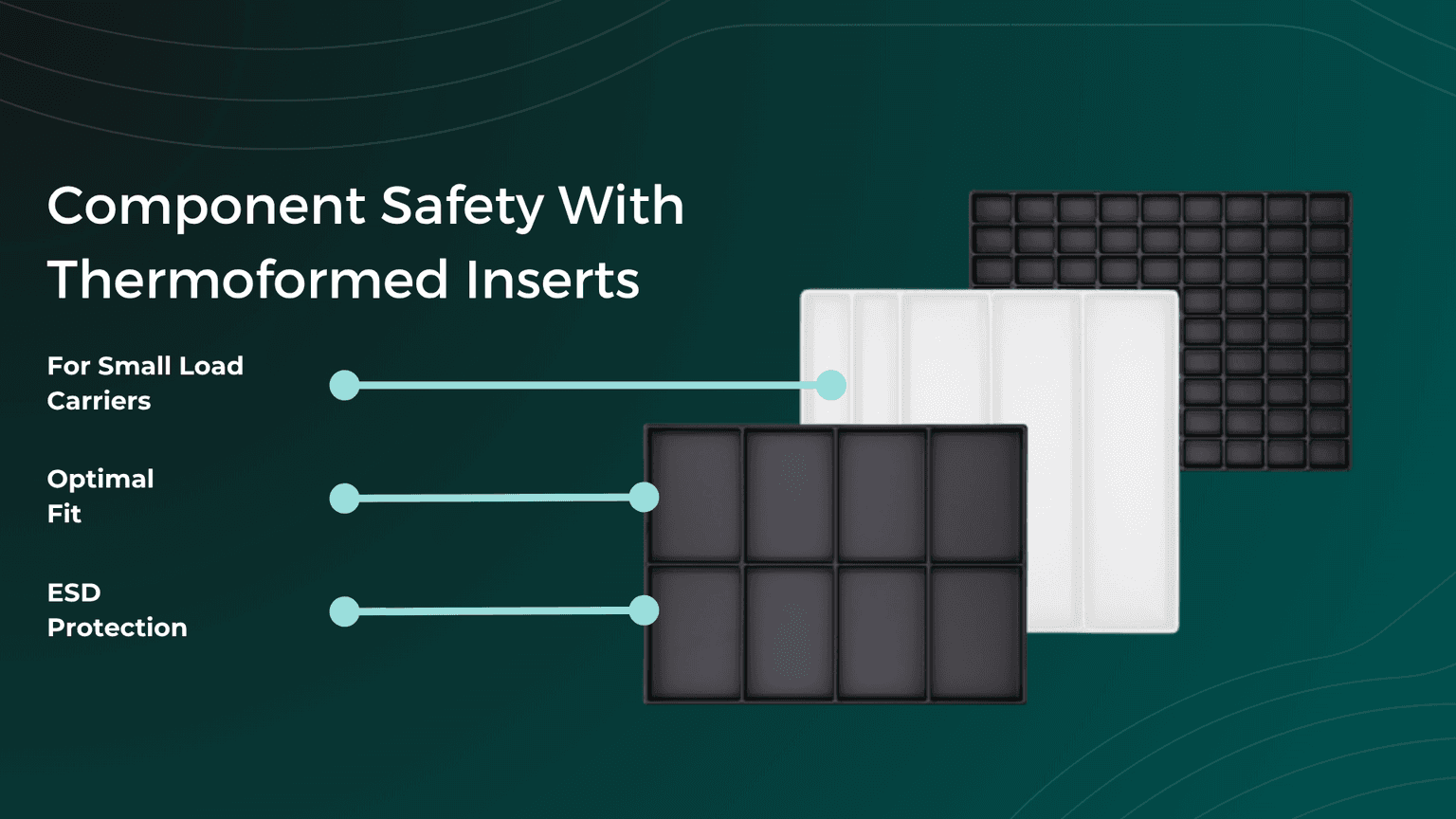

Component Safety for Your Small Parts: How Thermoformed Plastic Inserts Ensure Secure Transport

Delicate components require protection against damage to prevent costs and downtime. Thermoformed plastic inserts provide an efficient solution for safe transport and storage. In this article, you will learn how thermoformed inserts optimize component safety.

Sarah Guaglianone

13. Januar 2026

Contents

What Is Component Safety?

Definition: Component safety includes all measures designed to protect sensitive or valuable components from damage. This involves specialized packaging solutions and transport aids that ensure secure handling. Protection can include the following aspects:

- Mechanical Protection – Prevents scratches, impacts, dents, or other damage from external forces.

- Chemical Protection – Shields components from corrosion, moisture, or harmful chemicals.

- ESD Protection – Prevents damage from electrostatic discharge (ESD), which is especially crucial in the electronics industry.

How Thermoformed Plastic Inserts Protect Your Components

Thermoformed inserts, also known as inlays, are produced using the plastic thermoforming process. Through sheet or roll production, plastic films are heated and shaped into a mold. The result includes not only inserts but also plastic trays, covers, and containers.

These inserts securely hold products or bulk materials in a custom-fit blister within a container or box. Their precise shape prevents movement, ensuring that sensitive components remain in place. This is especially crucial for delicate parts or products that require a specific orientation during assembly. By securing components, thermoformed inserts prevent transport damage and ensure component safety.

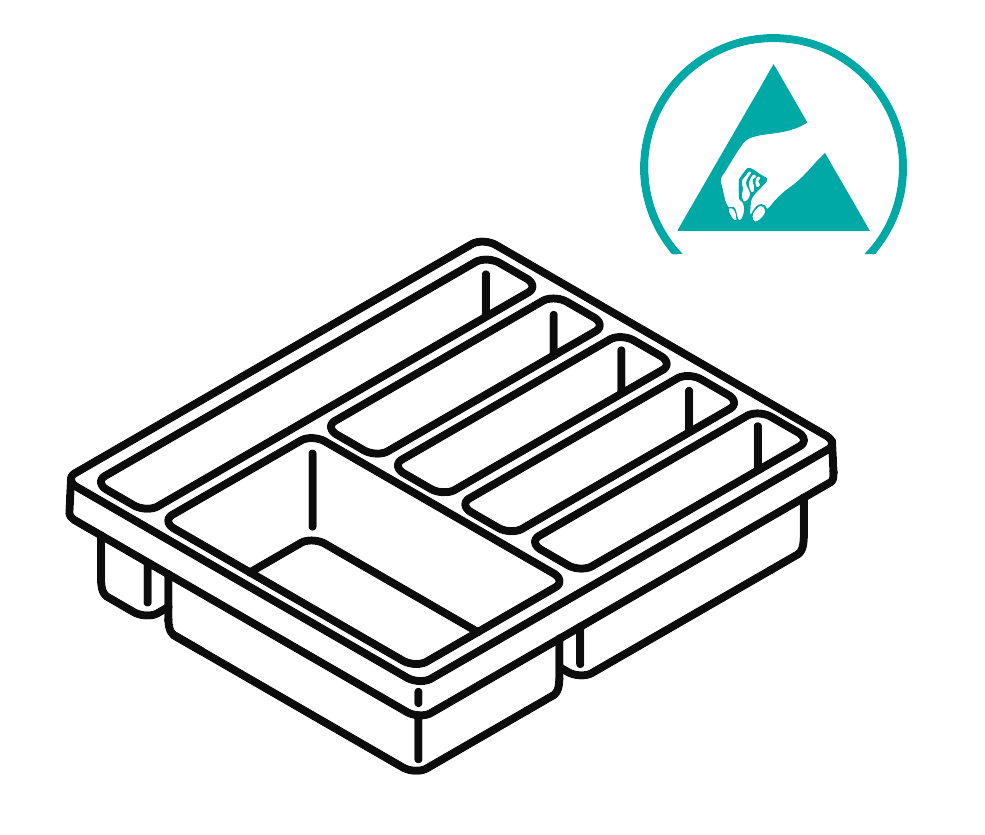

Component Safety for ESD-Sensitive Parts

In the electronics industry, protecting delicate components from electrostatic discharge (ESD) is crucial. This electrical discharge can irreparably damage electronic parts, leading to production failures or quality defects.

To prevent this, ESD inserts and trays are specially designed to securely store and transport electronic components, ensuring safe handling throughout the logistics chain.

Industries That Rely on Thermoformed Inserts for Component Safety

Thermoformed plastic inserts serve as protective transport solutions across various industries. Here are some examples:

Industry | Use Case for Thermoformed Inserts |

|---|---|

Automotive | Protection for body parts, electronic modules, and engine components |

Electronics | Safe transport of sensitive circuit boards and semiconductor components |

Medical Technology | Secure storage of precision instruments and implants |

Logistics & Packaging | Interlayers for stackable containers and pallets |

Why Are Thermoformed Plastic Inserts Ideal for Component Safety?

Thermoformed plastic inserts are widely used as durable inlays in small load carriers (KLTs) and Euro containers, which often endure intensive use. For heavy-duty applications, such as protecting tools, the material must be particularly robust.

Plastic is the preferred material for thermoformed inserts due to its versatility and durability. Key benefits include:

- Lightweight & Long-Lasting – Reduces overall weight while withstanding heavy use.

- Flexible & Malleable – Easily heated and shaped into precise, custom designs.

- Shock-Absorbing – Thermoplastics provide impact resistance, protecting fragile components.

- Chemical & Corrosion Resistant – Most plastics do not react with water, acids, or bases, making them ideal for humid or chemically demanding environments.

Commonly Used Plastics in Thermoforming:

- PS (Polystyrene) – The standard reference material for thermoforming, known for its hardness and chemical resistance, making it ideal for transport applications.

- ABS (Acrylonitrile Butadiene Styrene) – Offers high impact resistance and is widely used in automotive and industrial applications.

- PP (Polypropylene) – Known for its flexibility and heat resistance, often used in food and medical industries.

When designing the insert, it is important to consider the requirements that the plastic used must meet in order to ensure smooth transport protection for the components.

Component Safety for Your Parts – With formary Standard Thermoformed Inserts

Effective component protection is essential to ensure products arrive safely and undamaged. Our high-quality thermoformed inserts provide secure storage and transport for your parts.

Do you have questions or need personalized advice? Contact us today – we’ll help you find the perfect protective solution for your components!