Twin-Sheet Process: Definition, Advantages, and Applications

The Twin-Sheet process is a thermoforming technique that differs from the Single-Sheet process. In this method, two plastic sheets are heated and shaped simultaneously, enabling the production of hollow and stable components with complex geometries.

Sarah Guaglianone

13. Januar 2026

Contents

In this article, we look at how the twin-sheet process works, its advantages, and its diverse applications in various industries.

What is the twin-sheet process?

The twin-sheet process, also known as twin-sheet thermoforming, is a further development of plastic deep drawing, which is also known as the single- or mono-sheet process. While conventional thermoforming involves forming a single plastic sheet or roll, the twin-sheet process involves processing two plastic sheets simultaneously to produce a hollow component.

There are differences between the European and American versions: in the European version, the sheets are formed simultaneously, while in the American version they are formed one after the other.

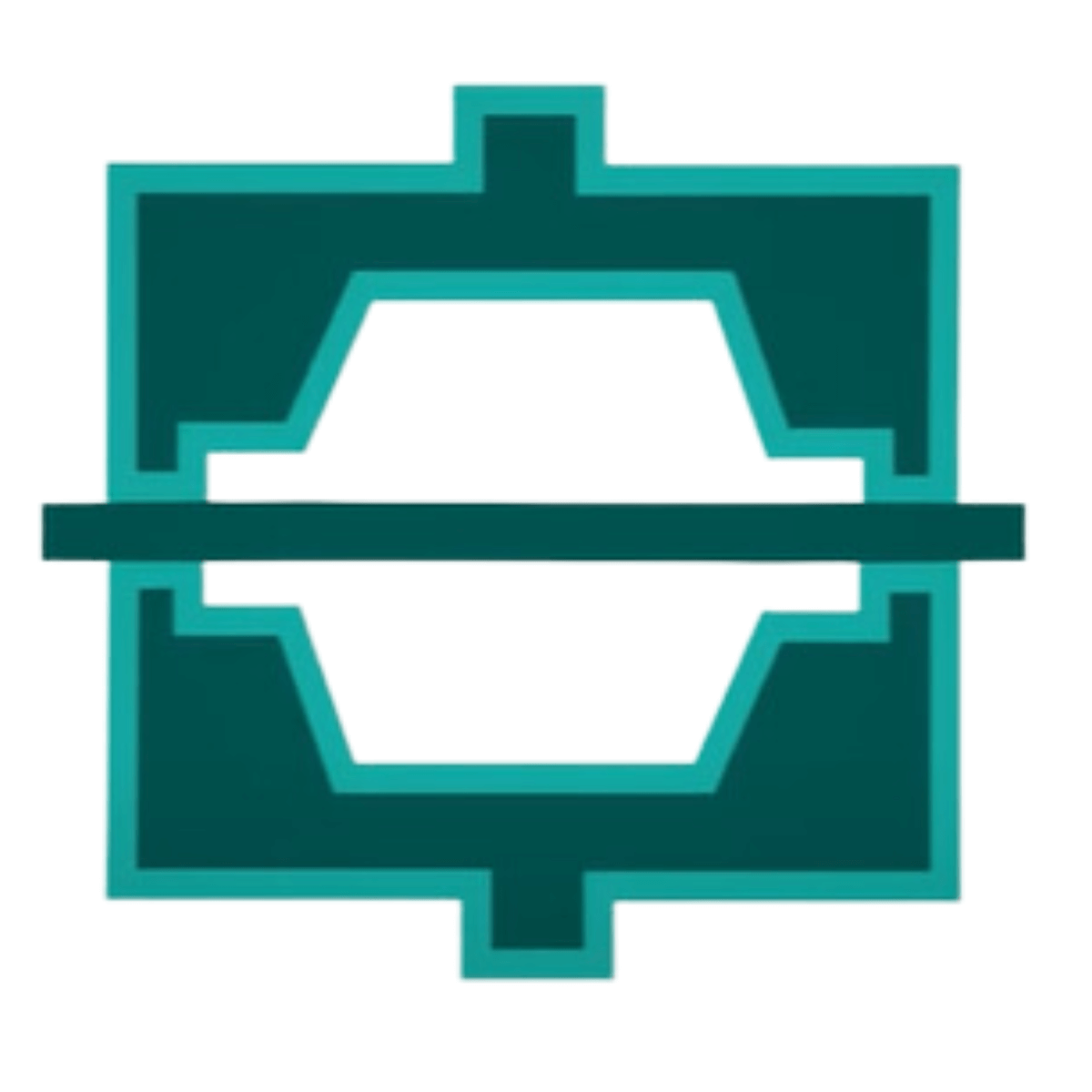

A crucial process step in twin-sheet technology is negative thermoforming, in which both plastic films are heated simultaneously to the thermoplastic range and then formed into a profiled component and welded together in a single operation.

The high-strength bond between the sheets is created solely by the forming temperature and pressure, resulting in a particularly stable, stress-free bond. Twin-sheet thermoforming thus offers high strength and flexible design options.

ℹ️ You can find out more about the differences between single-sheet thermoforming and twin-sheet thermoforming in this video:

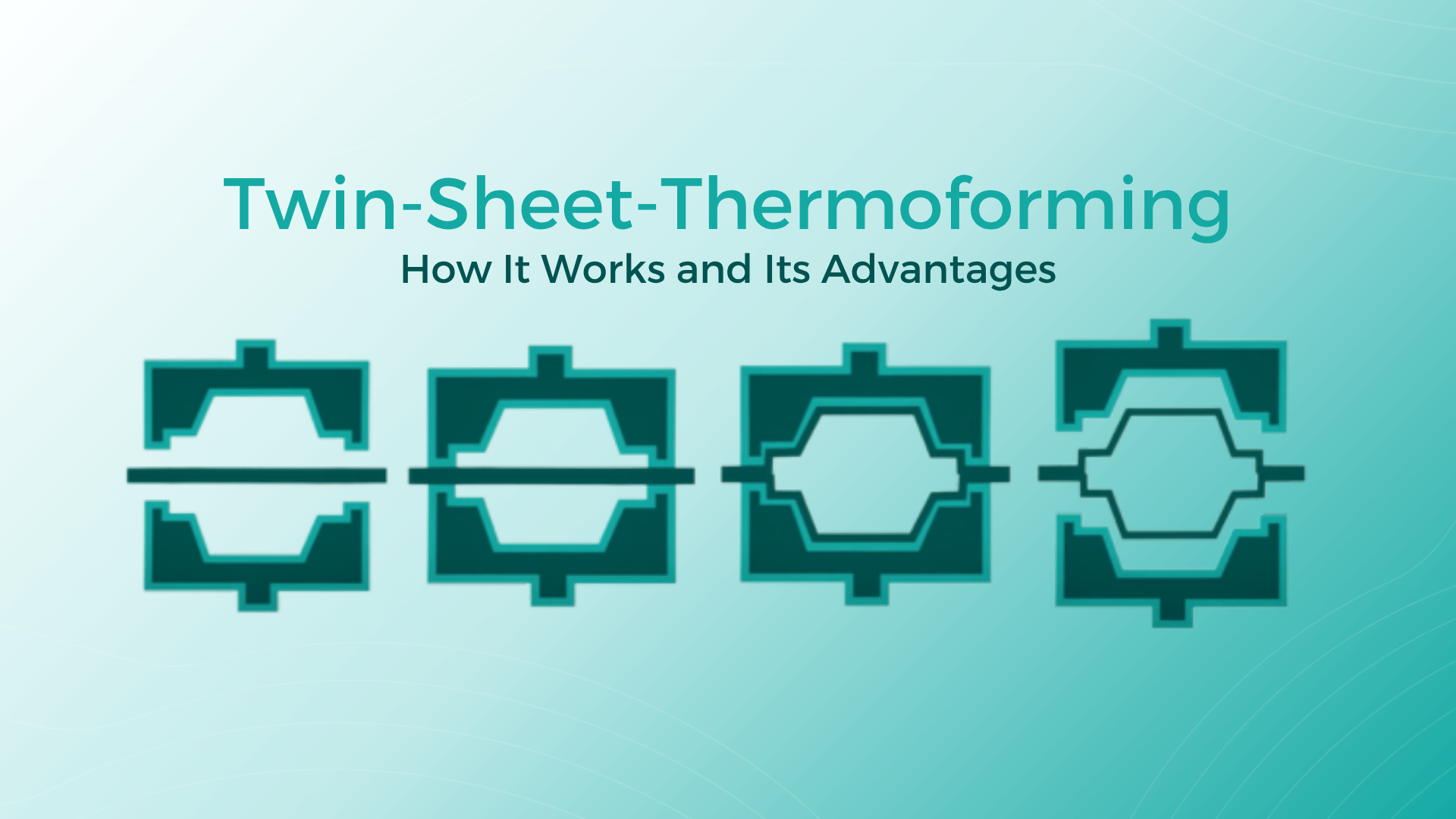

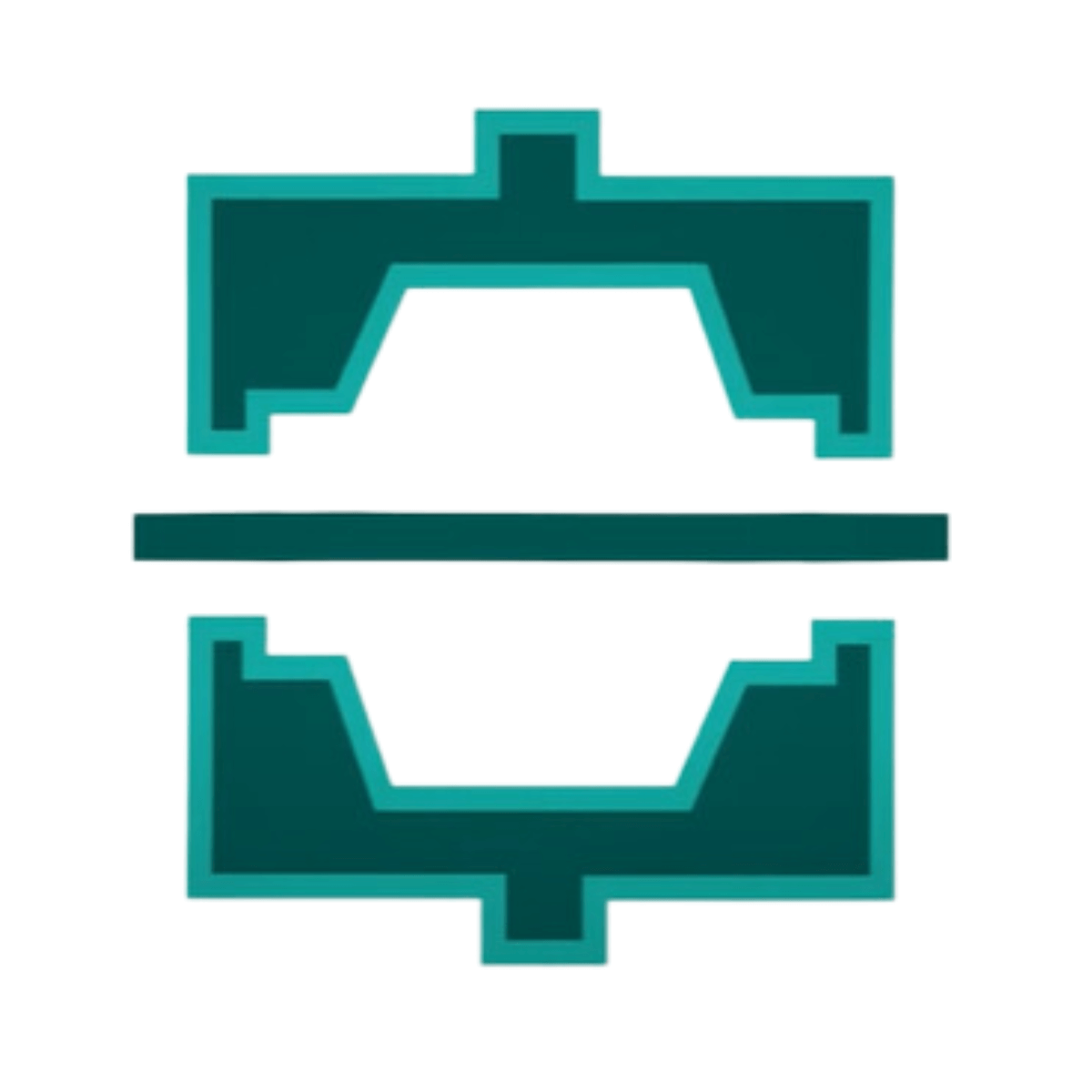

How does the twin-sheet process work?

The twin-sheet process consists of several steps and can be divided into the following process:

1. Material selection

Two plastic sheets are clamped into the thermoforming machine. The sheets can be made of identical or different materials, depending on the desired properties of the end product, such as strength, UV resistance, or ESD protection. This allows for a high degree of flexibility in the design of the thermoformed parts.

2. Heating

In the twin-sheet process, both plastic sheets are heated simultaneously until they reach the so-called thermoelastic state, in which they are soft and malleable. It is important that the heating is uniform in order to avoid material stresses and guarantee high-quality shaping. This step is typically carried out in special ovens that are integrated into the thermoforming machine.

3. Shaping

Once the plastic rolls or sheets have reached the right temperature, they are placed in two separate halves of a mold. Each sheet is pressed into its own cavity, where it is drawn into the desired shape using vacuum or compressed air. This process enables precise shaping and ensures that even complex geometries can be reliably produced.

4. Welding

While the sheets are still warm and malleable, the two mold halves are pressed together so that the plastic sheets fuse together at the points of contact. This results in a permanent and stable bond that forms a hollow structure. The double wall thickness creates a component with particularly high strength that meets the requirements for structural load-bearing capacity.

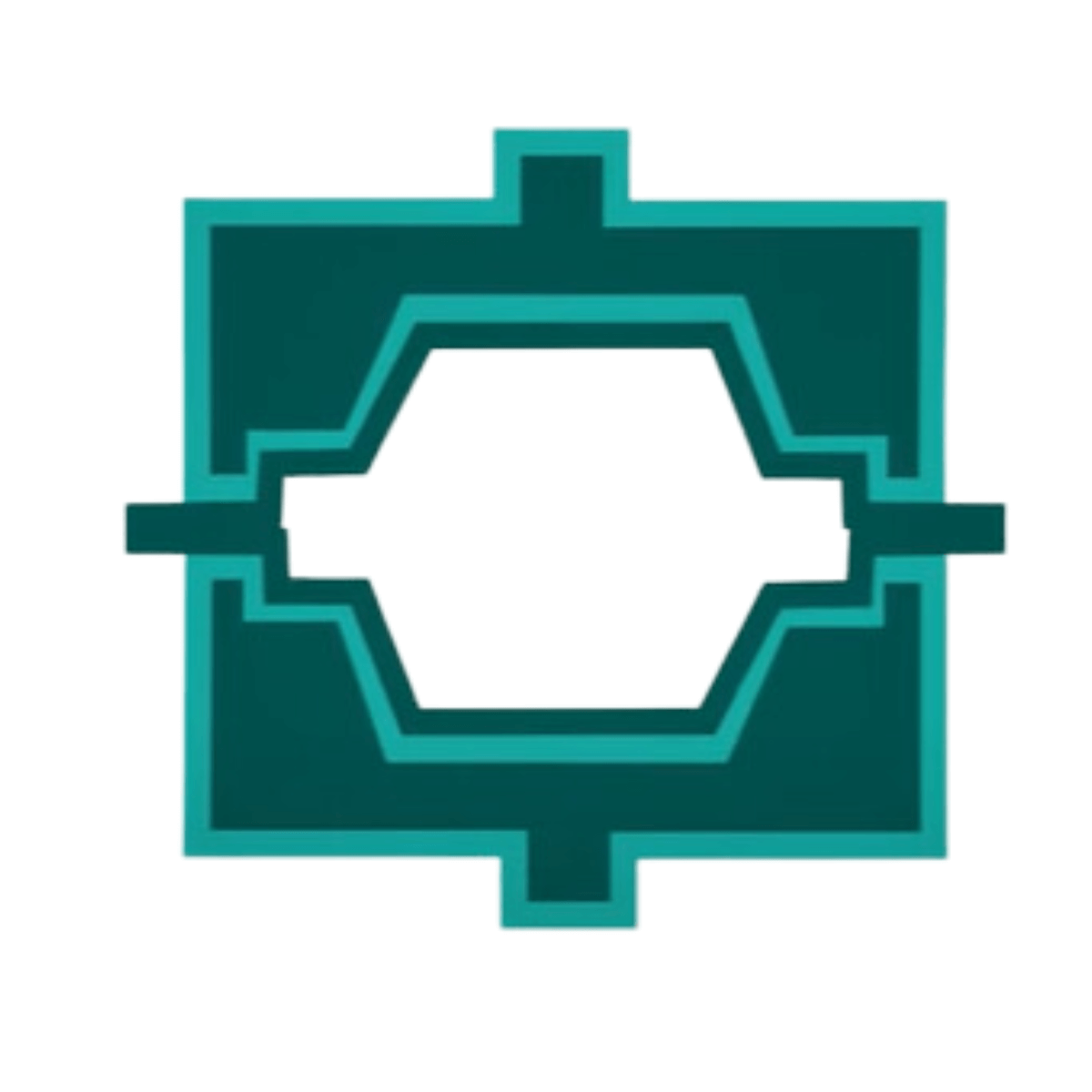

5. Cooling and removal of the component

Once the molded component has cooled, it is removed from the mold and can be used for further processing or direct use.

What are the advantages of the twin-sheet process?

The twin-sheet process offers several significant advantages over other plastic processing methods:

- Increased stability: Twin-sheet thermoforming is characterized by high structural strength, which is achieved by the double wall structure of the components. This not only ensures high stability, but also enables weight reduction, as stable and rigid parts can be produced with less material.

- High accuracy: Both sides of the molded parts benefit from double-sided mold contact, which increases accuracy. This is reflected in the visually appealing quality of both sides of the component.

- Cost-effectiveness: Compared to conventional processes such as blow molding or injection molding, the cost of the deep-drawing tool is often more cost-effective with the twin-sheet process. This is because two sheets are processed simultaneously, which reduces the need for additional processing steps and tools.

- Large part dimensions: The process enables the production of very large parts at relatively low tool and part prices, which further increases cost-effectiveness.

- Inserts and insert parts: The twin-sheet process allows inserts to be inserted directly into the cavity of the component. This means that complex shapes and integrated functional elements such as reinforcements or mounting points can be easily integrated into the component.

- Material diversity: It is possible to combine different materials and colors on the inside and outside of the parts. A mix of new and recycled materials is also possible.

- Fast implementation times: Even larger components can be produced quickly, which shortens production times.

In which industries is the twin-sheet process used?

The twin-sheet process is characterized by its versatility and is of great interest in numerous industries.

Automotive

In the automotive sector, twin-sheet thermoforming is often used to manufacture air ducts, door panels, covers for luggage compartments, and other interior trim. These applications benefit from the high strength and ability to efficiently produce complex geometries.

Packaging

Another important area is the packaging industry, where the twin-sheet process is used to produce stable and reusable thermoformed containers and pallets.

Medical technology

In medicine, the process is used in the manufacture of medical technology housings, which must be both lightweight and robust.

Consumer goods

The process also plays a central role in the manufacture of consumer goods such as leisure and sports equipment. For example, caravan covers, kayaks, and other leisure equipment are produced using the twin-sheet process, enabling manufacturers to create high-performance yet lightweight products.

Twin-sheet thermoforming – a summary

The twin-sheet process is a powerful and flexible technology that offers numerous advantages in both mass production and special applications. Thanks to its ability to combine complex geometries with high structural strength and low weight, twin-sheet thermoforming is used in a wide range of industries.

Would you like to know whether single-sheet thermoforming or the twin-sheet process is more suitable for your application? Then contact us and we will be happy to help you.