Timely Prototype Manufacturing for Medical Covers

iThera Medical: How the medical technology company was able to reduce costs and meet accelerated deadlines successfully with the formary supplier network.

About iThera Medical

iThera Medical is a leading medical technology company specializing in high-resolution photoacoustic, non-invasive imaging technologies. With its innovative multispectral optoacoustic tomography (MSOT), iThera Medical enables real-time visualization and quantification of biomarkers such as hemoglobin in blood or collagen in muscle, which vary in certain medical conditions. This technology significantly contributes to improving patient care in the field of medical research.

Watch the case study video and find out how iThera Medical was able to benefit from the B2B platform formary.

By playing the video, you agree that your data will be transmitted to YouTube and that you have read the Privacy Policy.

💡The deep-drawing project with iThera illustrates how formary takes on projects with demanding requirements, including tight schedules, small-volume material procurement, and complex post-processing steps. The result: The client can relax knowing that formary handles all requirements, ensuring that all specifications are met through its powerful supplier network.

Project Overview

- Project goal: 50% reduction in costs and volume for the new device generation

- Challenge: Tight deadlines, material shortages, and stringent medical requirements

- Solution: Coordination of multiple specialist manufacturers within the formary network

- Result: On-time production of visually and qualitatively high-end housing components

New Generation of Medical Devices with Complex Requirements

iThera set itself the goal of achieving a 50% reduction in both cost and volume for the new generation of the MSOT Frontier platform—without compromising on quality or design. The requirements for plastic housing components in medical technology are demanding:

The material requirements include fire protection, scratch-resistant surfaces, resistance to cleaning agents, protection against electromagnetic radiation, UV protection, and reliable ventilation of the electronic components. In addition, a clean, flawless, and high-quality appearance is essential for medical parts used in practices and hospitals. Seamless integration into the device and pressure equalization for ventilation require complex milling operations within the manufacturing process.

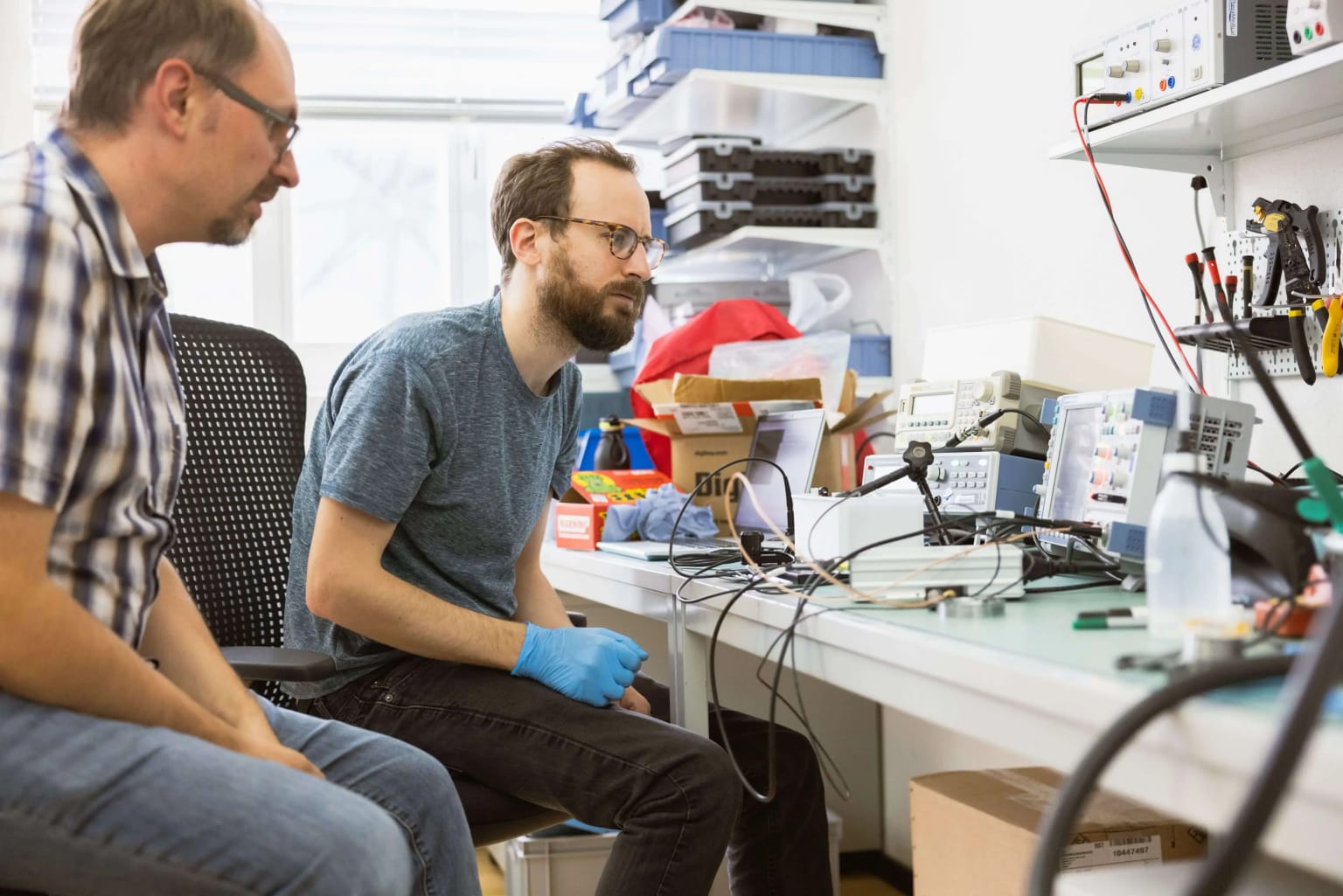

“When we approached formary, the initial focus was on prototype manufacturing, which was to be transferred into series production after various approval processes. Since the process wasn't finalized, we first submitted several designs for feasibility testing in thermoforming with formary.”

— Torsten Parth, iThera Medical

Challenge

Enclosure part for medical device with complex requirements and a goal of 50% cost reduction. Very tight deadlines due to accelerated external verification tests. Scarcity of special material availability.

Solution

Achieving the goal through the design of cost-benefit optimized enclosures while meeting all medical requirements. Timely production with thermoforming and post-processing carried out by multiple suppliers, ensuring the right allocation of available materials at the correct locations within the network.

Optimal Design with Achievement of Cost Reduction Goals

Based on the initial design drafts, formary developed a series of further proposals aimed at a more efficient and cost-effective implementation of the prototype enclosure parts. All key aspects of a cost-benefit evaluation were considered:

- Material selection and procurement costs

- Design of the thermoformed parts with regard to necessary milling, trimming, and assembly elements

- Tooling design using aluminum or an alternative material

- Material thicknesses considered from a tooling perspective

- Impact of these factors on the delivery schedule and its manageability

The consulting process provided detailed recommendations regarding the optimal material selection, including specific material thicknesses, chosen with consideration of mechanical requirements and cost. The result was the design of three optimized, aesthetically high-quality enclosure parts that provided EMC shielding through coating, ensured UV protection and flame resistance (UL94 V0), and allowed for ventilation of electronic components and the CPU—achieved with a small batch and sample production.

“For us, it was crucial to receive the fully manufactured parts on time and be able to integrate them directly into the prototypes. In the end, thanks to the sophisticated quality management, we received flawless enclosure parts with precise tolerances and excellent optics.”

— Torsten Parth, iThera Medical

Critical Hurdle: Accelerated External Testing

However, an unexpected challenge arose during the project.

"Due to an accelerated external verification test – specifically an EMC (Electromagnetic Compatibility) test – we urgently needed approval-ready enclosure components," says Torsten Parth.

Due to the tight schedule, the specialized manufacturer initially selected by formary could not procure the required specialty material in time. The delivery of the fully produced and post-processed parts, including milling and external coating, seemed impossible.

Flexible Supplier Network Ensures Timely Completion

In this critical situation, formary leveraged its extensive supplier network. Thanks to its deeply integrated network and thorough knowledge of supplier capacities and capabilities, formary quickly identified an alternative operation that had the required specialty material in stock. This facility not only provided the material on short notice but was also able to thermoform one of the three parts, which was less complex. However, complex post-processing could not be done at this facility, so the parts were sent to the originally specialized manufacturer, along with the necessary materials to complete the remaining enclosures.

The manufacturer took over the remaining production, focusing on the more complex parts that required specific manufacturing techniques and post-processing. To speed up the completion of the components and ensure the quality of the surface finishing, formary also organized the transport of the parts to a third-party post-processing service provider from the network. This provider handled the final coating of the parts. Through this coordinated collaboration of various specialists, the project was successfully and timely completed despite the initial material procurement issues.

Successful Completion of EMC Test

After quality checks, the three finished enclosure parts were sent to iThera Medical. Thanks to the continuous search for new solutions to meet the schedule, the medical company could focus on the many other challenges of product development. iThera Medical received regular status updates and was always informed about the progress of the project while formary handled the coordination and management.

"For us, it was crucial to receive the fully manufactured parts on time and be able to integrate them directly into the prototypes. In the end, thanks to the sophisticated quality management, we received flawless enclosure parts with precise tolerances and excellent optics." (Torsten Parth)

The first internal and external tests, as well as the general introduction of the prototype at iThera Medical, were successful.

FAQ – Frequently Asked Questions About Medical Housing Projects

formary supports medical technology companies from feasibility analysis and prototyping through to series production. The supplier network enables fast and efficient workflows.

Further Information on Medical Housing Components

Medical Housing Components in Theory and Practice

Webinar

We show you for which production volumes, sizes, and geometries the thermoforming process is ideally suited for medical housings—functionally, visually, and from a cost–benefit perspective.

Medical Housing Components in Plastic Thermoforming

Whitepaper

Learn why plastic thermoforming is gaining relevance in medical technology and what medical device manufacturers should know about the possibilities of thermoformed plastic housing components.