Tool Transfer in Thermoforming: A Guide for Existing Thermoformed Tools

Tool transfer in thermoforming makes it possible to continue using existing tools and to keep producing components without unnecessary costs or delays. In this article, you will learn about the benefits this offers, which information is required, and how formary efficiently supports the entire process.

Talida Eichhorn

26. Januar 2026

Contents

Tool Transfer in Plastic Thermoforming – Key Facts in Brief

- A tool transfer allows existing thermoforming tools to be reused without the need to manufacture new tooling.

- Companies save costs and time while reducing project risks and waste.

- For a smooth transfer, key technical data must be available and clarified in advance.

- formary handles the technical assessment and ensures efficient integration into the serial production process.

What Does Tool Transfer in Thermoforming Mean?

Tool transfer, often also referred to as tool relocation, describes the transfer of an existing thermoforming tool to a new manufacturer in order to continue production there without creating a new tool.

A prerequisite for a tool transfer to a new thermoforming supplier is that the tool is owned by the customer. This is typically the case if the tooling costs were listed separately in the original quotation and not allocated proportionally to part prices. In this situation, the tool belongs to the customer and can be withdrawn from the current manufacturer and relocated to another producer at any time.

The aim of tool transfer: to continue using existing tools efficiently and to maintain production without interruption.

When Does a Tool Transfer in Thermoforming Make Sense?

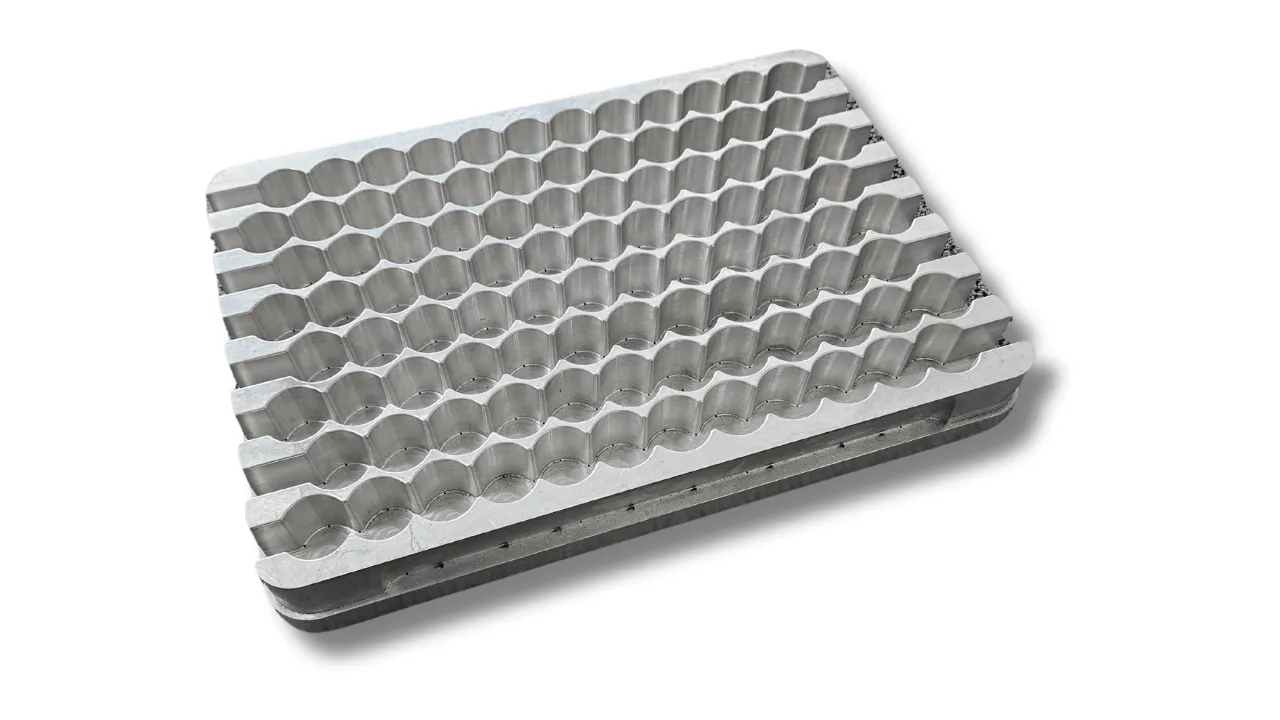

Relocating thermoforming tools is particularly beneficial when an existing thermoforming tool is still fully functional and capable of production. By continuing to use an existing tool instead of building a completely new one, companies can keep using their thermoformed tools economically, even if contract manufacturing with the current supplier is no longer desired.

Once a tool has been manufactured, it can typically be used for production over a very long service life. When aluminum tools are used and regular maintenance is carried out, production volumes of tens or even hundreds of thousands of cycles are common.

Why Are Thermoforming Tools Typically Transferred?

In industrial practice, the relocation of existing thermoforming tools can be a strategically important step. Companies sourcing plastic thermoformed parts usually relocate tools to ensure production continuity, control costs, and minimize risks.

Typical reasons for tool relocation include:

- (Impending) insolvency or business closure of the current supplier

To avoid production stoppages, tools are transferred early to an alternative manufacturer. - Quality issues within the existing supply chain

Repeated deviations in dimensional accuracy, surface quality, or material processing make a change of supplier necessary. - Increasing cost pressure

Changes in pricing structures, energy costs, or labor costs may require a more economical production setup. - Risk management and supply chain security

Tool relocations are a proven means of reducing dependencies and increasing supply reliability. - Tool damage or limited production capability

When maintenance, repairs, or modifications can no longer be carried out reliably by the current supplier. - Prevention of production downtime

Early relocation helps prevent unplanned stoppages in series products with long life cycles.

Advantages of taking over existing thermoforming tools:

- Cost efficiency: Avoiding new tool costs leads to significant cost savings.

- Fast start of series production: Since the tool already exists and has been tested, sampling, prototyping, and production can begin much earlier.

- High process reliability: Geometries and material behavior have already been validated, ensuring functionality and requiring only minimal adjustments.

- Sustainability: The service life of the tool is extended and unnecessary new construction is avoided.

Guide: How Tool Transfer Works with formary

To ensure that a thermoforming tool can be seamlessly transferred to a new manufacturer, all technical details must be clarified in advance. formary reviews this information to ensure compatibility and a fast start to serial production.

The following questions should therefore be clarified upfront:

1. CAD Data

- Are CAD data for the tool available?

- Can 2D or 3D files be provided?

2. Photos & Visual Inspection

- Are images of the tools available?

- Are the vacuum ports visible?

- What is the general condition?

Photos provide a quick indication of whether the tool, frame, and surfaces are intact.

3. Dimensions

- What is the overall size of the tool?

- What specific forming dimensions are involved?

These details affect machine compatibility and clamping options.

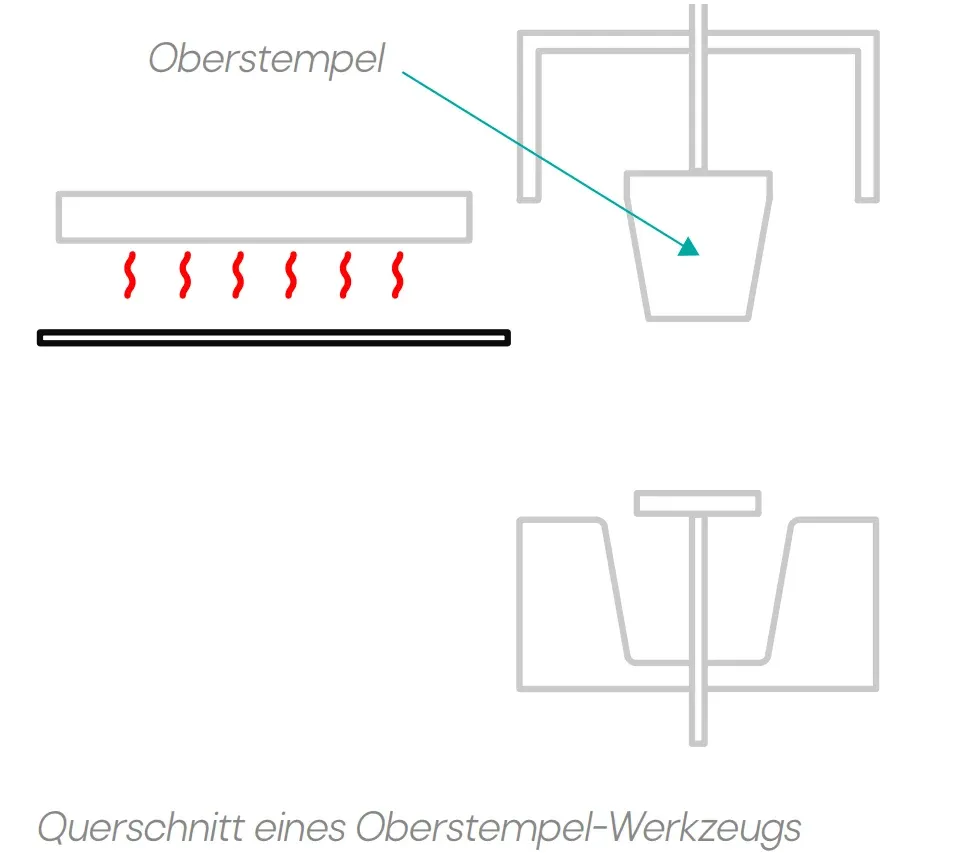

4. Substructures & Frames

- Are substructures available?

- Will these be provided?

- Is a suitable frame available?

- Is a top plug required – and if so, is it included?

All of these elements are important to ensure that the tool can be correctly installed on the target machine.

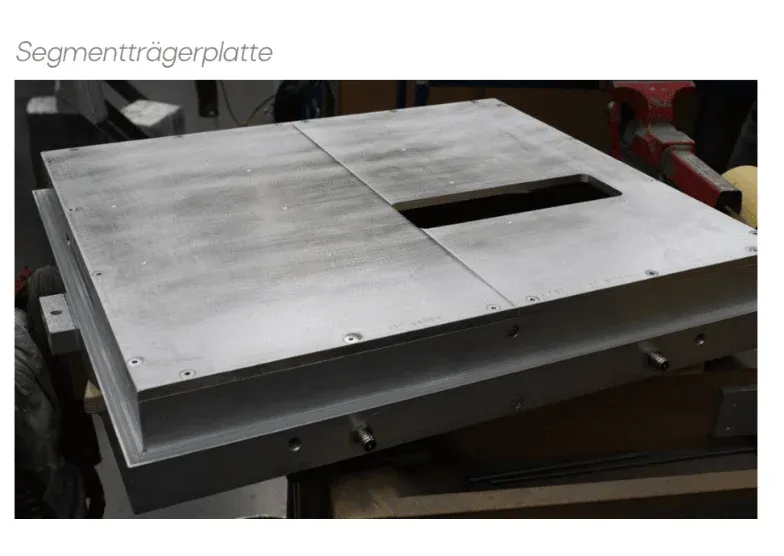

5. Base Plate

- What are the dimensions of the base plate on which thermoforming has previously been carried out?

6. Cooling

- What type of cooling does the tool have?

This is a relevant factor for cycle times and repeatability (see blog article: Thermoforming tools for plastic thermoformed parts).

7. Number of Cavities

- How many cavities does the tool have?

8. Previously Used Machine

- On which machine (manufacturer, model) has the tool been used so far?

This information helps facilitate the compatibility assessment. formary operates the following machines in its portfolio:

- Roll-Fed Machines:

- Illig RV

- Illig IC-RD

- Illig IC-RDK

- Illig IC-RDKP

- Kiefel KMD

- Kiefel KMV

- Kiefel KTR

- Hamer TFP

- Gabler Focus

- Sheet-Fed Machines:

- Geiss T10

- Geiss U8

- Illig UA

- Berg M7

9. Trimming and Post-Processing Tools

Depending on the downstream processing, the following documents or fixtures are required:

Milled Parts

- Are milling fixtures available?

- Is the milling program available?

Punched / Die-Cut Parts

- Are the required punching tools available?

10. Material Data Sheet

- Can you provide a material data sheet for the processed material?

This ensures that parts can be manufactured identically after the tool transfer.

11. Sample Parts

Are sample parts available that you can provide to us for evaluation? formary uses these samples for:

- Dimensional analyses

- Surface comparisons

- Functional testing

Tool Transfer Checklist

The following checklist summarizes which information is required for a fast and secure tool transfer:

| Category | Required Information |

|---|---|

| CAD Data | 3D/2D files, tool geometry |

| Images | Detailed photos, condition, vacuum ports |

| Dimensions | Tool dimensions, base plate |

| Additional Elements | Frame, substructure, top plug |

| Machine Information | Previously used machine type |

| Cavities | Number of forming cavities |

| Cooling | Type of tool cooling |

| Trimming Tools | Milling fixture, milling program, or punching tool |

| Material | Data sheet of the material used |

| Sample Parts | Samples for evaluation |

Frequently Asked Questions About Thermoforming Tool Transfer

What is tool transfer in thermoforming?

Tool transfer refers to the continued use of an existing thermoforming tool at a new manufacturer without the need to build a new tool.

How does the transfer of thermoforming tools work?

An existing tool is technically inspected, adapted if necessary, matched to the new machine, and then used for sampling and series production.

When does a tool transfer make sense?

Whenever the tool is still functional. Tool transfer reduces costs, enables faster production start-ups, and ensures that existing part geometries can continue to be produced unchanged.

Can every thermoforming tool be transferred?

In most cases, yes. The decisive factors are the tool’s condition, material, design, and machine compatibility.

How long does a thermoforming tool transfer take?

In many cases, a transfer is significantly faster than building a new tool. The more complete the available data, the quicker series production can begin.

For which industries is tool transfer particularly useful?

Transfers are used in any industry where series products need to be manufactured consistently over many years. Examples include medical technology, mechanical engineering, electronics, automotive, and industry.

For which products is tool transfer particularly suitable?

For housings, containers, trays, inserts, and all components with long product life cycles.

Which thermoformed parts benefit most from the reuse of existing tools?

Above all, components that are manufactured in long product life cycles, require precise fits, and are regularly reproduced.

Conclusion: Tool transfer as a fast and economical route to series production

Tool transfer in deep drawing is one of the most efficient ways to continue producing existing components without delay and without incurring new tooling costs. Companies benefit from validated product quality and fast, cost-efficient series production. With formary, you receive a technical review within a very short time and secure integration of your tool into production.

Are you currently planning your deep drawing project? Then contact us—we will support you from the initial idea to implementation.